ignition VOLVO V60 2016 Owner´s Manual

[x] Cancel search | Manufacturer: VOLVO, Model Year: 2016, Model line: V60, Model: VOLVO V60 2016Pages: 402, PDF Size: 10.3 MB

Page 316 of 402

09 Wheels and tires

09

314

Tire Pressure Monitoring System (TPMS) – activating/deactivating

Activating/deactivating TPMS

(Canadian models only)

1. Switch off the engine.

2. Put the ignition in mode I or II (see Igni-

tion modes (p. 77) for additional informa- tion).

3. Press the MY CAR key in the center con-

sole control panel and select

Settings

Car settingsTire pressure

4. Select Tire monitoring and press OK/

MENU to turn the system on or off.

Related information

•Tire Pressure Monitoring System (TPMS) – general information (p. 311)

Tire Pressure Monitoring System (TPMS) – messages

Erasing warning messagesWhen a low tire pressure warning message has been displayed and the tire pressure warning light in the instrument panell (

)

has come on:

1. Use a tire pressure gauge to check the inflation pressure of all four tires.

2. Re-inflate the tire(s) to the correct pres- sure (consult the tire pressure placard located on the driver's side B-pillar (thestructural member at the side of the vehi-cle, at the rear of the driver's door open-ing) or the inflation pressure table, seeTire inflation – pressure table (p. 305).

3. In certain cases, it may be necessary to drive the vehicle for several minutes at aspeed of 20 mph (30 km/h) or faster. Thiswill erase the warning text and the telltalewill go out.

NOTE

•Tire monitoring systems use a tem- perature compensated pressure value.This pressure value is dependent ontire temperature and ambient tempera-ture, which can differ from the recom-mended cold tire pressure in the tireinflation table and on the tire pressureplacard located on the driver's side B-pillar (the structural member at theside of the vehicle, at the rear of thedriver's door opening). This meansthat it may sometimes be necessary toinflate them slightly above the recom-mended cold pressure value(approx. 3-4 psi or 0.2-0.3 bar) in orderto reset a low tire pressure warning.

• To help avoid incorrect tire inflationpressure, if possible only inflate thetires when they are cold. The tires areconsidered to be cold when they havethe same temperature as the sur-rounding (ambient) air. This tempera-ture is normally reached after the vehi-cle has been parked for at least3 hours. After driving a distance ofapproximately 1 mile (1.6 km), the tiresare considered to be hot.

Page 318 of 402

09 Wheels and tires

09

316

Calibrating Tire Monitor

In order for Tire Monitor to work correctly, tire pressure reference values must be set. Thismust be done each time wheels or tire pres-sures are changed.

Calibration1. Switch off the engine.

2. Inflate the tires to the desired pressure(consult tire pressure placard located on the driver's side B-pillar (the structuralmember at the side of the vehicle) andput the ignition in mode II, see Ignition

modes (p. 77).

3. Press the MY CAR button on the center

console control panel and select

Settings

Car settingsTire monitoring.

4. Press OK/MENU , select

Calibrate tire

pressure and press OK/MENU again.

5. Drive away. > The calibration process will be comple-ted while driving and will be interrupted if the vehicle is parked and the engineis switched off. Calibration continuesautomatically when driving resumes.The system will not give any confirma-tion when calibration is finishedalthough it will state if calibration fails.

The new reference values will be used untilsteps 1-5 stated above are repeated.

NOTE

Always remember to calibrate Tire Monitor when the wheels have been changed orthe tire pressure has been correctedaccording to tire pressure placard or tirepressure table. If correct reference valueshave not been set, the system cannotissue low tire pressure alerts correctly.

Tire Monitor status information

The current status of the system and the tires is indicated by color-coded graphics. This status can be displayed by pressing the MY CAR button on the center console and

going to

SettingsCar settingsTire

monitoring.

The following color-coded graphics indicate:

• All green

: the system is operational and

all tire pressures are at or above the rec- ommended levels.

• One yellow wheel

: the tire indicated is

under-inflated.

• All wheels yellow

: two or more tires are

under-inflated

• All wheels gray

: the system is currently

unavailable. It might be necessary todrive at a speed of at least 20 mph(30 km/h) for several minutes for the sys-tem to become operational.

• All wheels gray in combination with the message

Tire press. syst Service

required and the telltale in the instru-

ment panel (

) is illuminated : the

system is not functioning correctly. Have it checked by a trained and qualifiedVolvo service technician.

• All wheels gray in combination with the message

Tire press. syst currently

unavailable and the telltale in the

instrument panel (

) is illuminated :

Page 334 of 402

10 Maintenance and servicing

10

332

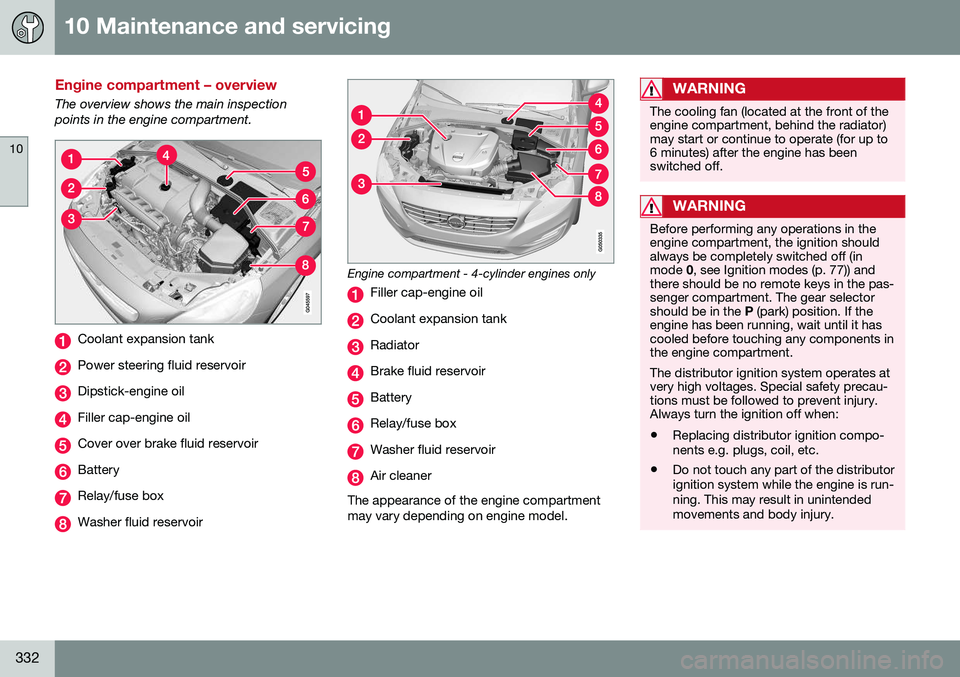

Engine compartment – overview

The overview shows the main inspection points in the engine compartment.

Coolant expansion tank

Power steering fluid reservoir

Dipstick-engine oil

Filler cap-engine oil

Cover over brake fluid reservoir

Battery

Relay/fuse box

Washer fluid reservoir

Engine compartment - 4-cylinder engines only

Filler cap-engine oil

Coolant expansion tank

Radiator

Brake fluid reservoir

Battery

Relay/fuse box

Washer fluid reservoir

Air cleaner

The appearance of the engine compartment may vary depending on engine model.

WARNING

The cooling fan (located at the front of the engine compartment, behind the radiator)may start or continue to operate (for up to6 minutes) after the engine has beenswitched off.

WARNING

Before performing any operations in the engine compartment, the ignition shouldalways be completely switched off (inmode 0, see Ignition modes (p. 77)) and

there should be no remote keys in the pas-senger compartment. The gear selectorshould be in the P (park) position. If the

engine has been running, wait until it hascooled before touching any components inthe engine compartment. The distributor ignition system operates at very high voltages. Special safety precau-tions must be followed to prevent injury.Always turn the ignition off when:

• Replacing distributor ignition compo- nents e.g. plugs, coil, etc.

• Do not touch any part of the distributorignition system while the engine is run-ning. This may result in unintendedmovements and body injury.

Page 337 of 402

10 Maintenance and servicing

10

}}

* Option/accessory, for more information, see Introduction.335

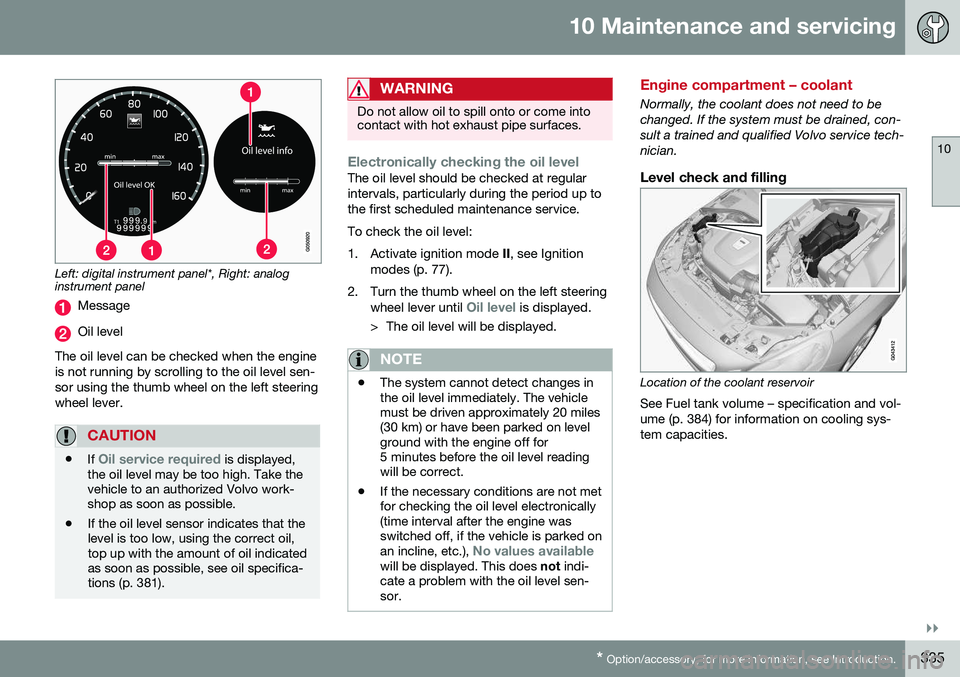

Left: digital instrument panel*, Right: analog instrument panel

Message

Oil level

The oil level can be checked when the engine is not running by scrolling to the oil level sen-sor using the thumb wheel on the left steeringwheel lever.

CAUTION

• If Oil service required is displayed,

the oil level may be too high. Take the vehicle to an authorized Volvo work-shop as soon as possible.

• If the oil level sensor indicates that thelevel is too low, using the correct oil,top up with the amount of oil indicatedas soon as possible, see oil specifica-tions (p. 381).

WARNING

Do not allow oil to spill onto or come into contact with hot exhaust pipe surfaces.

Electronically checking the oil levelThe oil level should be checked at regular intervals, particularly during the period up tothe first scheduled maintenance service. To check the oil level:

1. Activate ignition mode

II, see Ignition

modes (p. 77).

2. Turn the thumb wheel on the left steering wheel lever until

Oil level is displayed.

> The oil level will be displayed.

NOTE

• The system cannot detect changes in the oil level immediately. The vehiclemust be driven approximately 20 miles(30 km) or have been parked on levelground with the engine off for5 minutes before the oil level readingwill be correct.

• If the necessary conditions are not metfor checking the oil level electronically(time interval after the engine wasswitched off, if the vehicle is parked on an incline, etc.),

No values availablewill be displayed. This does

not indi-

cate a problem with the oil level sen- sor.

Engine compartment – coolant

Normally, the coolant does not need to be changed. If the system must be drained, con-sult a trained and qualified Volvo service tech-nician.

Level check and filling

Location of the coolant reservoir

See Fuel tank volume – specification and vol- ume (p. 384) for information on cooling sys-tem capacities.

Page 340 of 402

10 Maintenance and servicing

10

338

CAUTION

Keep the area around the power steering fluid reservoir clean when checking.

Bulbs – introduction

Certain bulbs can be replaced by the vehicle's owner. However, the bulbs on the followinglist should only be replaced by a trained andqualified Volvo service technician. All bulb specifications are listed in Bulbs – specifications (p. 345).• Active Bending Lights

• Front parking lights

• Front side marker lights

• Cornering lights

• Turn signals in the door mirrors

• Approach lighting in the door mirrors

• Interior lighting (except for the front foot- well lighting)

• Rear parking lights/side marker lights

• LED bulbsNOTE

•For information regarding any bulbs not mentioned in this section, pleasecontact your Volvo retailer or a trainedand authorized Volvo service techni-cian.

• Always switch off the ignition beforestarting to replace a bulb.

• If an error message remains in the dis-play after a faulty bulb has beenreplaced, contact an authorized Volvoworkshop.

• Condensation may form temporarily onthe inside of the lenses of exteriorlights such as headlights, fog lights, ortaillights. This is normal and the lightsare designed to withstand moisture.Normally, condensation will dissipateafter the lights have been on for ashort time.

• The optional Active Bending Lightbulbs contain trace amounts of mer-cury. These bulbs should always bedisposed of by a trained and qualifiedVolvo service technician.

Page 341 of 402

10 Maintenance and servicing

10

}}

* Option/accessory, for more information, see Introduction.339

CAUTION

Never touch the glass of bulbs with your fingers. Grease and oils from your fingersvaporize in the heat and will leave adeposit on the reflector, which will damageit.

WARNING

• The engine should not be running when changing bulbs.

• If the engine has been running justprior to replacing bulbs in the head-light housing, please keep in mind thatcomponents in the engine compart-ment will be hot.

WARNING

•

Active Bending Lights* – due to the high voltage used by these headlights,these bulbs should only be replacedby a trained and qualified Volvo serv-ice technician.

• Turn off the lights and remove theremote key from the ignition beforechanging any bulbs.

Related information

•

Bulbs – headlight housing (p. 339)

• Bulbs – taillight housing (p. 343)

• Bulbs – vanity mirror lighting (p. 345) •

Bulbs – cargo area lighting (p. 344)

• Bulbs – license plate lighting (p. 344)

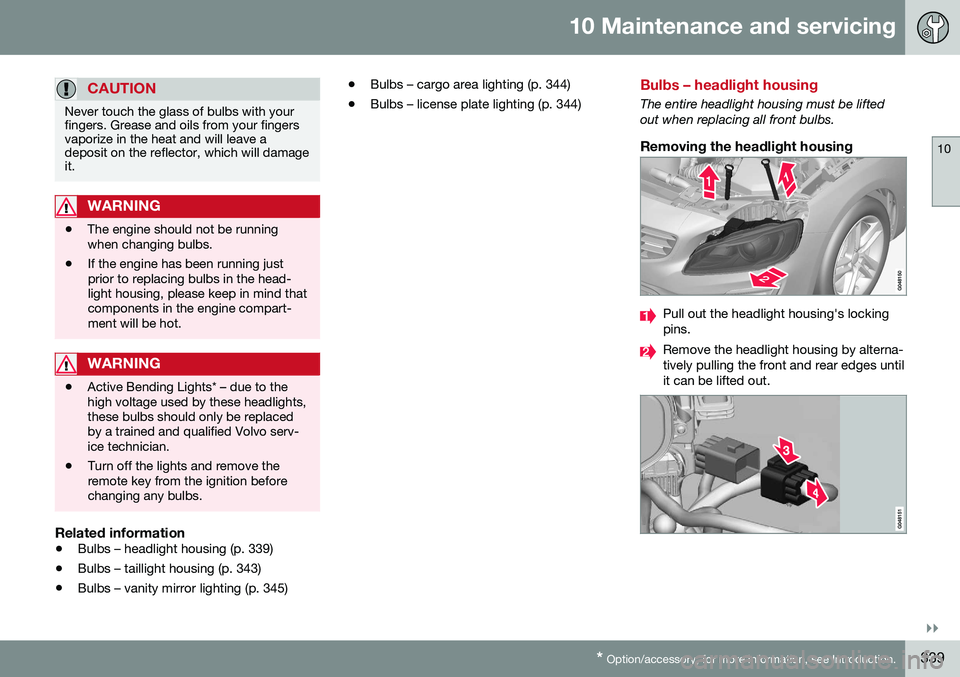

Bulbs – headlight housing

The entire headlight housing must be lifted out when replacing all front bulbs.

Removing the headlight housing

Pull out the headlight housing's locking pins.

Remove the headlight housing by alterna- tively pulling the front and rear edges untilit can be lifted out.

Page 342 of 402

||

10 Maintenance and servicing

10

340

CAUTION

When disconnecting the connector, pull on the connector itself and not on the wiring.

Unplug the wiring connector by holding down the clip with your thumb.

Pull the connector out with the other hand.

5. Lift out the headlight housing and place it on a soft surface to avoid scratching thelens.

6. Replace the defective bulb(s).

Reinserting the headlight housing

1. Plug in the connector until it clicks into place. 2. Reinstall the headlight housing and lock-

ing pins. The short locking pin should be closest to the grille. Check that they arecorrectly inserted. The headlight housing must be properly in place and the wiring connector cor-rectly reconnected before the lighting isswitched on or the remote key is insertedinto the ignition slot.

3. Check that the lights function properly.

Related information

• Bulbs – introduction (p. 338)

• Bulbs – cover (p. 340)

• Bulbs – specifications (p. 345)

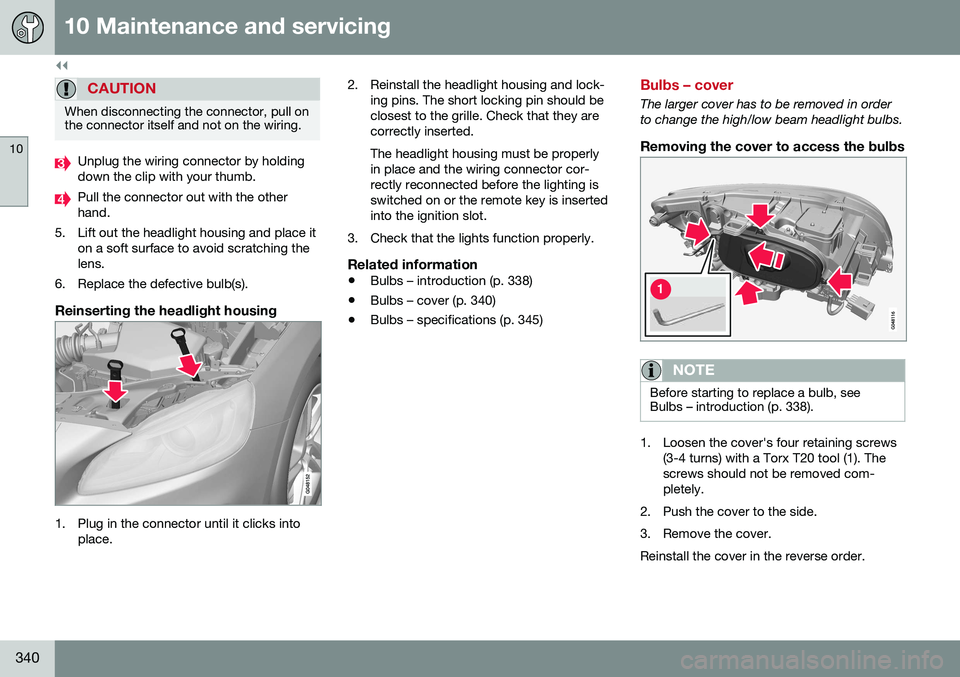

Bulbs – cover

The larger cover has to be removed in order to change the high/low beam headlight bulbs.

Removing the cover to access the bulbs

NOTE

Before starting to replace a bulb, see Bulbs – introduction (p. 338).

1. Loosen the cover's four retaining screws

(3-4 turns) with a Torx T20 tool (1). The screws should not be removed com-pletely.

2. Push the cover to the side.

3. Remove the cover.Reinstall the cover in the reverse order.

Page 348 of 402

10 Maintenance and servicing

10

346

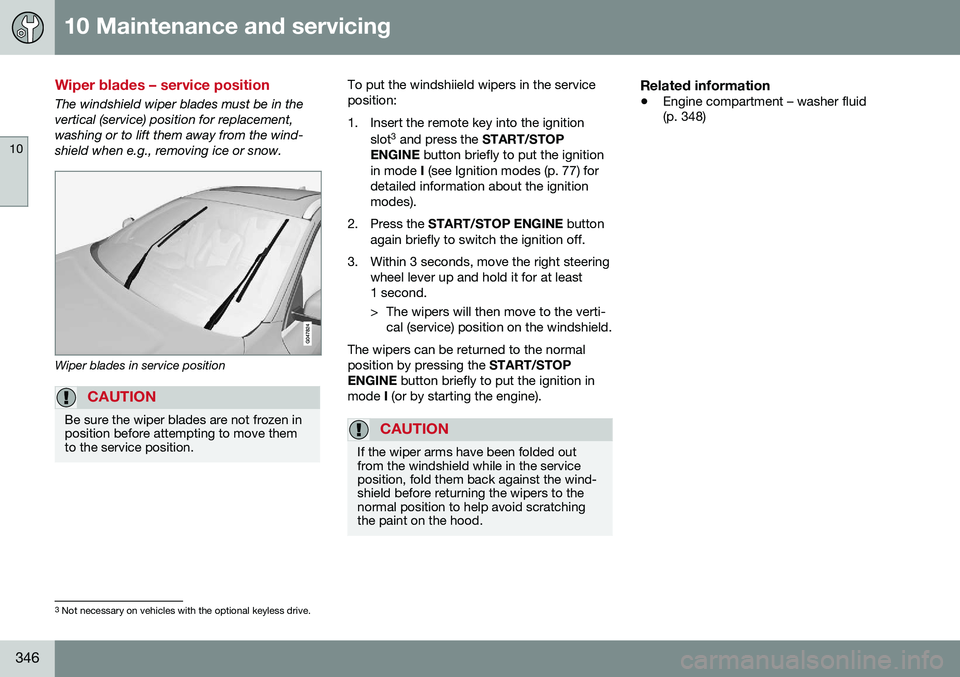

Wiper blades – service position

The windshield wiper blades must be in the vertical (service) position for replacement,washing or to lift them away from the wind-shield when e.g., removing ice or snow.

Wiper blades in service position

CAUTION

Be sure the wiper blades are not frozen in position before attempting to move themto the service position.

To put the windshiield wipers in the service position:

1. Insert the remote key into the ignitionslot3

and press the START/STOP

ENGINE button briefly to put the ignition

in mode I (see Ignition modes (p. 77) for

detailed information about the ignition modes).

2. Press the START/STOP ENGINE button

again briefly to switch the ignition off.

3. Within 3 seconds, move the right steering wheel lever up and hold it for at least1 second.

> The wipers will then move to the verti-cal (service) position on the windshield.

The wipers can be returned to the normal position by pressing the START/STOP

ENGINE button briefly to put the ignition in

mode I (or by starting the engine).

CAUTION

If the wiper arms have been folded out from the windshield while in the serviceposition, fold them back against the wind-shield before returning the wipers to thenormal position to help avoid scratchingthe paint on the hood.

Related information

• Engine compartment – washer fluid (p. 348)

3

Not necessary on vehicles with the optional keyless drive.

Page 352 of 402

||

10 Maintenance and servicing

10

350

CAUTION

The infotainment system's energy-saving feature may not function correctly or at all,and/or a message may be displayed if abattery charger or jumper cables are notconnected properly.

• The negative terminal on the battery must

never be used to connect a

jumper cable or a battery charger.Only the ground point on the chassismay be used.

See Jump starting (p. 256) for an illustra- tion and additional information.

WARNING

• Never expose the battery to open flame or electric spark.

• Do not smoke near the battery.

• Battery fluid contains sulfuric acid. Donot allow battery fluid to contact eyes,skin, fabrics or painted surfaces. Ifcontact occurs, flush the affected areaimmediately with water. Obtain medi-cal help immediately if eyes are affec-ted.

NOTE

The life of the battery is shortened if it becomes discharged repeatedly.

Related information

•

Battery – changing (p. 351)

• Battery – maintenance (p. 350)

• Battery – symbols (p. 349)

Battery – maintenance

Proper battery maintenance can help prolong its service life.

Maintenance

• Use a screw driver to open the caps or cover and a flashlight to inspect the level.

• If necessary, add distilled water. The levelshould never be above the indicator.

• The fluid level should be checked if thebattery has been recharged.

• After inspection, be sure the cap overeach battery cell or the cover is securelyin place.

• Check that the battery cables are cor-rectly connected and properly tightened.

• Never disconnect the battery when theengine is running, or when the key is inthe ignition. This could damage the vehi-cle's electrical system.

• The battery should be disconnected fromthe vehicle when a battery charger isused directly on the battery.

• To help keep the battery in good condi-tion, the vehicle should be driven for atleast 15 minutes a week or connected toa charger with an automatic chargingfunction.

• If the battery is fully discharged a numberof times, this may shorten its service life.Keeping the battery fully charged helpsprolong its service life.

Page 354 of 402

||

10 Maintenance and servicing

10

352* Option/accessory, for more information, see Introduction.

RemovalSwitch off the ignition, remove the remote key from the ignition slot and wait at least5 minutes before disconnecting the battery sothat all information in the vehicle's electricalsystem can be stored in the control modules.

Open the clips on the front cover and remove the cover.

Release the rubber molding so that the rear cover is free.

Remove the rear cover by pulling it away.

Detach the black negative cable.

Detach the red positive cable

Detach the ventilation hose from the

battery

Loosen the screw holding the battery

clamp.

Move the battery to the side and lift it up.

WARNING

PROPOSITION 65 WARNING! Battery posts, terminals, and related accessories contain lead and lead com-pounds, chemicals known to the state ofCalifornia to cause cancer and reproduc-tive harm. Wash hands after handling.

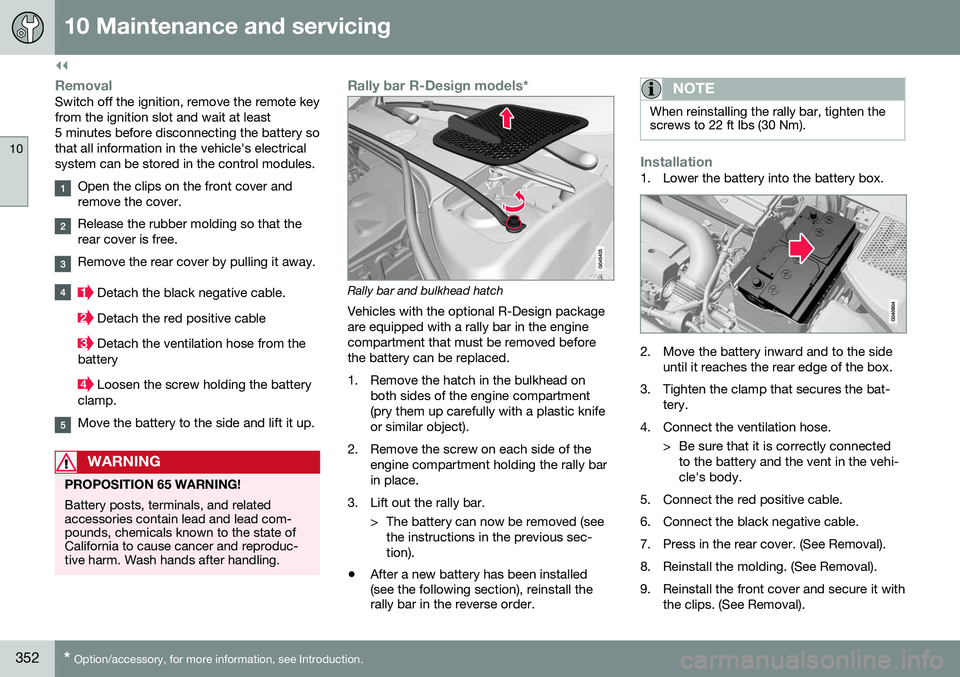

Rally bar R-Design models*

Rally bar and bulkhead hatch

Vehicles with the optional R-Design package are equipped with a rally bar in the enginecompartment that must be removed beforethe battery can be replaced.

1. Remove the hatch in the bulkhead on both sides of the engine compartment (pry them up carefully with a plastic knifeor similar object).

2. Remove the screw on each side of the engine compartment holding the rally barin place.

3. Lift out the rally bar. > The battery can now be removed (seethe instructions in the previous sec-tion).

• After a new battery has been installed (see the following section), reinstall therally bar in the reverse order.

NOTE

When reinstalling the rally bar, tighten the screws to 22 ft lbs (30 Nm).

Installation1. Lower the battery into the battery box.

2. Move the battery inward and to the side

until it reaches the rear edge of the box.

3. Tighten the clamp that secures the bat- tery.

4. Connect the ventilation hose. > Be sure that it is correctly connectedto the battery and the vent in the vehi- cle's body.

5. Connect the red positive cable.

6. Connect the black negative cable.

7. Press in the rear cover. (See Removal).

8. Reinstall the molding. (See Removal).

9. Reinstall the front cover and secure it with the clips. (See Removal).