lock VOLVO XC70 2013 Owner´s Manual

[x] Cancel search | Manufacturer: VOLVO, Model Year: 2013, Model line: XC70, Model: VOLVO XC70 2013Pages: 382, PDF Size: 6.78 MB

Page 281 of 382

07 During your trip

Loading

07

279

Fold up the hook. It will lock in place.

NOTE

There should be at least 2 in. (50 cm)

between the hooks in the rail.

WARNING

Switch off the engine, apply the parking

brake and put the gear selector in P when

loading and unloading the vehicle.

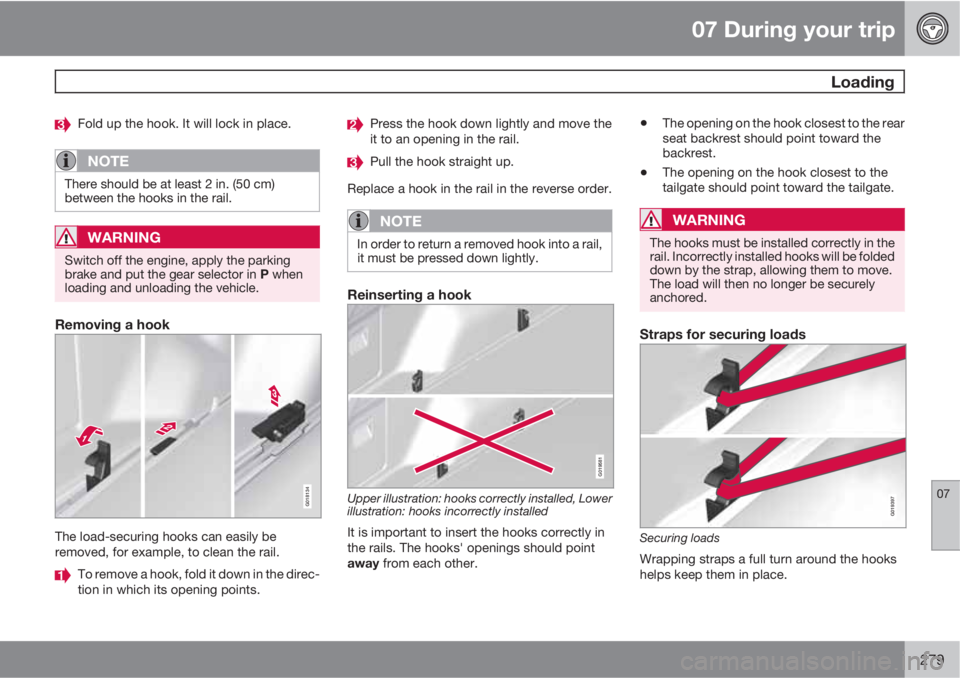

Removing a hook

G018134

The load-securing hooks can easily be

removed, for example, to clean the rail.

To remove a hook, fold it down in the direc-

tion in which its opening points.

Press the hook down lightly and move the

it to an opening in the rail.

Pull the hook straight up.

Replace a hook in the rail in the reverse order.

NOTE

In order to return a removed hook into a rail,

it must be pressed down lightly.

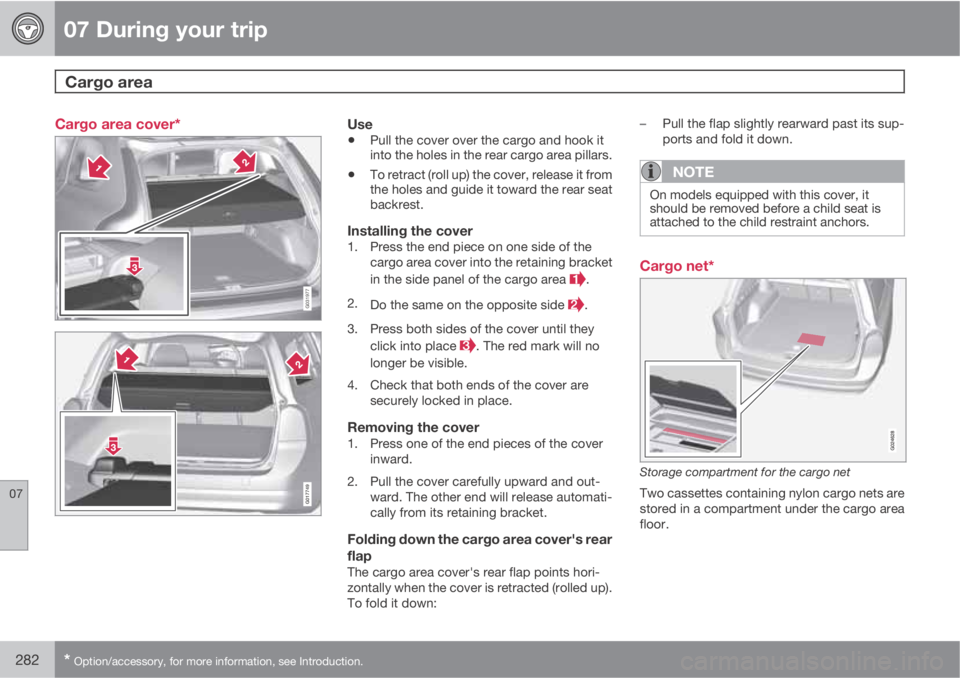

Reinserting a hook

G019581

Upper illustration: hooks correctly installed, Lower

illustration: hooks incorrectly installed

It is important to insert the hooks correctly in

the rails. The hooks' openings should point

away from each other.

•The opening on the hook closest to the rear

seat backrest should point toward the

backrest.

•The opening on the hook closest to the

tailgate should point toward the tailgate.

WARNING

The hooks must be installed correctly in the

rail. Incorrectly installed hooks will be folded

down by the strap, allowing them to move.

The load will then no longer be securely

anchored.

Straps for securing loads

G019397

Securing loads

Wrapping straps a full turn around the hooks

helps keep them in place.

Page 284 of 382

07 During your trip

Cargo area

07

282* Option/accessory, for more information, see Introduction.

Cargo area cover*

G031977

G017749

Use

•Pull the cover over the cargo and hook it

into the holes in the rear cargo area pillars.

•To retract (roll up) the cover, release it from

the holes and guide it toward the rear seat

backrest.

Installing the cover1. Press the end piece on one side of the

cargo area cover into the retaining bracket

in the side panel of the cargo area

.

2.

Do the same on the opposite side

.

3. Press both sides of the cover until they

click into place

. The red mark will no

longer be visible.

4. Check that both ends of the cover are

securely locked in place.

Removing the cover1. Press one of the end pieces of the cover

inward.

2. Pull the cover carefully upward and out-

ward. The other end will release automati-

cally from its retaining bracket.

Folding down the cargo area cover's rear

flap

The cargo area cover's rear flap points hori-

zontally when the cover is retracted (rolled up).

To fold it down:–Pull the flap slightly rearward past its sup-

ports and fold it down.

NOTE

On models equipped with this cover, it

should be removed before a child seat is

attached to the child restraint anchors.

Cargo net*

Storage compartment for the cargo net

Two cassettes containing nylon cargo nets are

stored in a compartment under the cargo area

floor.

Page 285 of 382

07 During your trip

Cargo area

07

283

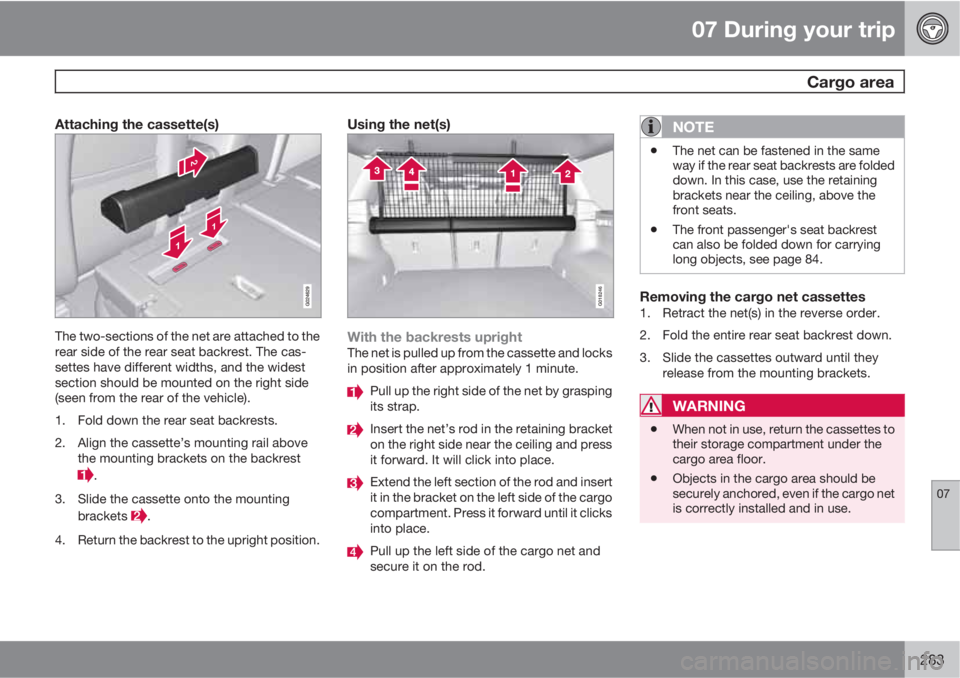

Attaching the cassette(s)

The two-sections of the net are attached to the

rear side of the rear seat backrest. The cas-

settes have different widths, and the widest

section should be mounted on the right side

(seen from the rear of the vehicle).

1. Fold down the rear seat backrests.

2. Align the cassette’s mounting rail above

the mounting brackets on the backrest

.

3. Slide the cassette onto the mounting

brackets

.

4. Return the backrest to the upright position.

Using the net(s)

G018246

With the backrests uprightThe net is pulled up from the cassette and locks

in position after approximately 1 minute.

Pull up the right side of the net by grasping

its strap.

Insert the net’s rod in the retaining bracket

on the right side near the ceiling and press

it forward. It will click into place.

Extend the left section of the rod and insert

it in the bracket on the left side of the cargo

compartment. Press it forward until it clicks

into place.

Pull up the left side of the cargo net and

secure it on the rod.

NOTE

•The net can be fastened in the same

way if the rear seat backrests are folded

down. In this case, use the retaining

brackets near the ceiling, above the

front seats.

•The front passenger's seat backrest

can also be folded down for carrying

long objects, see page 84.

Removing the cargo net cassettes1. Retract the net(s) in the reverse order.

2. Fold the entire rear seat backrest down.

3. Slide the cassettes outward until they

release from the mounting brackets.

WARNING

•When not in use, return the cassettes to

their storage compartment under the

cargo area floor.

•Objects in the cargo area should be

securely anchored, even if the cargo net

is correctly installed and in use.

Page 288 of 382

07 During your trip

Towing a trailer

07

286

NOTE

•When parking the vehicle with a trailer

on a hill, apply the parking brake before

putting the gear selector in P. Always

follow the trailer manufacturer's recom-

mendations for wheel chocking.

•When starting on a hill, put the gear

selector in D before releasing the park-

ing brake. See also page 125 for more

detailed information about starting off

on a hill while towing a trailer.

•If you use the manual (Geartronic) shift

positions while towing a trailer, make

sure the gear you select does not put

too much strain on the engine (using too

high a gear).

•The drawbar assembly/trailer hitch may

be rated for trailers heavier than the

vehicle is designed to tow. Please

adhere to Volvo's recommended trailer

weights.

•Avoid driving with a trailer on inclines of

more than 15%.

Trailer cableAn adapter is required if the vehicle's trailer

hitch has a 13-pin connector and the trailer has

7 pins. Use an adapter cable approved by

Volvo. Make sure the cable does not drag on

the ground.

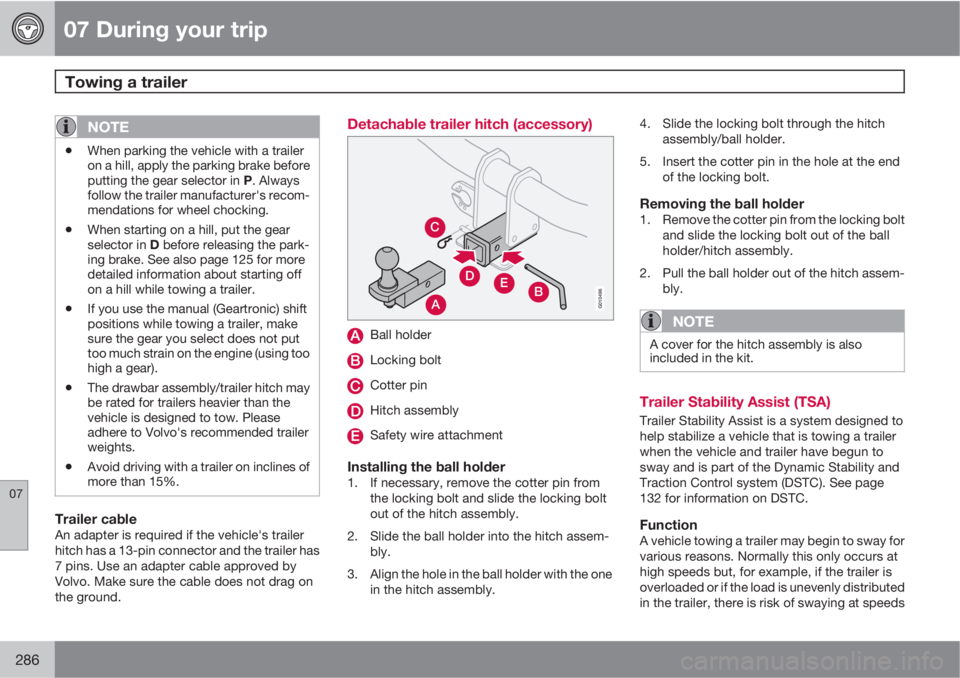

Detachable trailer hitch (accessory)

A

C

EDBG010496

Ball holder

Locking bolt

Cotter pin

Hitch assembly

Safety wire attachment

Installing the ball holder1. If necessary, remove the cotter pin from

the locking bolt and slide the locking bolt

out of the hitch assembly.

2. Slide the ball holder into the hitch assem-

bly.

3. Align the hole in the ball holder with the one

in the hitch assembly.4. Slide the locking bolt through the hitch

assembly/ball holder.

5. Insert the cotter pin in the hole at the end

of the locking bolt.

Removing the ball holder1. Remove the cotter pin from the locking bolt

and slide the locking bolt out of the ball

holder/hitch assembly.

2. Pull the ball holder out of the hitch assem-

bly.

NOTE

A cover for the hitch assembly is also

included in the kit.

Trailer Stability Assist (TSA)

Trailer Stability Assist is a system designed to

help stabilize a vehicle that is towing a trailer

when the vehicle and trailer have begun to

sway and is part of the Dynamic Stability and

Traction Control system (DSTC). See page

132 for information on DSTC.

FunctionA vehicle towing a trailer may begin to sway for

various reasons. Normally this only occurs at

high speeds but, for example, if the trailer is

overloaded or if the load is unevenly distributed

in the trailer, there is risk of swaying at speeds

Page 291 of 382

07 During your trip

Emergency towing

07

289

WARNING

•When the vehicle is being towed, the

ignition should be in mode II (in mode I,

all of the vehicle's airbags are deacti-

vated). See page 83 for more informa-

tion about ignition modes.

•Never remove the remote key from the

ignition slot when the vehicle is being

towed. For vehicles with keyless drive,

the remote key must remain inside the

vehicle.

•The power brakes and power steering

will not function when the engine is not

running. Approximately 5 times more

pressure will be required on the brake

pedal and the steering wheel will be

considerably harder to turn.

•The towing eyelets must not be used for

pulling the vehicle out of a ditch or for

any similar purpose involving severe

strain. Do not use the towing eyelets to

pull the vehicle up onto a flat bed tow

truck.

Towing the vehicle

1. With the remote key fully pressed into the

ignition slot1, press START/STOP

ENGINE for approximately 2 seconds to

activate ignition mode II.

2. The remote key must remain in the ignition

slot

2 for the entire time that the vehicle is

being towed.

3. Keep the tow rope taut when the towing

vehicle slows down by applying light pres-

sure on the brake pedal. This will help pre-

vent jarring movements of the vehicle

being towed.

4. Be prepared to apply the brakes to stop the

vehicle being towed.

CAUTION

General towing precautions:

•Please check with state and local

authorities before attempting this type

of towing, as vehicles being towed are

subject to regulations regarding maxi-

mum towing speed, length and type of

towing device, lighting, etc.

•If the vehicle's battery is dead, attach

jumper cables (see page 116) to provide

current for releasing the electric parking

brake and to move the gear selector

from the P position to N. If this is not

possible, see page 120 for information

about manually overriding the shiftlock

system to move the gear selector from

P to N.

•Maximum speed: 50 mph (80 km/h). Do

not exceed the maximum allowable

towing speed.

•Maximum distance with front wheels on

ground: 50 miles (80 km).

•The vehicle should only be towed in the

forward direction.

1Not necessary in vehicles with the optional keyless drive.2For vehicles with the the optional keyless dirive, the remote key must be in the vehicle.

Page 308 of 382

08 Wheels and tires

Snow chains, snow tires, studded tires

08

306

Winter driving conditions

Snow chainsSnow chains can be used on your Volvo with

the following restrictions:

•Snow chains should be installed on front

wheels only. Use only Volvo approved

snow chains.

•If accessory, aftermarket or "custom" tires

and wheels are installed and are of a size

different than the original tires and wheels,

chains in some cases CANNOT be used.

Sufficient clearances between chains and

brakes, suspension and body components

must be maintained.

•Some strap-on type chains will interfere

with brake components and therefore

CANNOT be used.

•All Wheel Drive models: Snow chains

should only be installed on the front

wheels.

•Certain size tires may not allow the assem-

bly of snow chains/traction devices.

Consult your Volvo retailer for additional snow

chain information.

CAUTION

•Check local regulations regarding the

use of snow chains before installing.

•Use single-sided snow chains only.

•Always follow the chain manufacturer's

installation instructions carefully. Install

chains as tightly as possible and

retighten periodically.

•Never exceed the chain manufacturer's

specified maximum speed limit. (Under

no circumstances should you exceed

31 mph (50 km/h).

•Avoid bumps, holes or sharp turns

when driving with snow chains.

•The handling of the vehicle can be

adversely affected when driving with

chains. Avoid fast or sharp turns as well

as locked wheel braking.

Snow tires, studded tires1

Tires for winter use:

•Owners who live in or regularly commute

through areas with sustained periods of

snow or icy driving conditions are strongly

advised to fit suitable winter tires to help

retain the highest degree of traction.

•It is important to install winter tires on all

four wheels to help retain traction duringcornering, braking, and accelerating. Fail-

ure to do so could reduce traction to an

unsafe level or adversely affect handling.

•Do not mix tires of different design as this

could also negatively affect overall tire road

grip.

•Winter tires wear more quickly on dry roads

in warm weather. They should be removed

when the winter driving season has ended.

•Studded tires should be run-in

300 – 600 miles (500 – 1000 km) during

which the vehicle should be driven as

smoothly as possible to give the studs the

opportunity to seat properly in the tires.

The tires should have the same rotational

direction throughout their entire lifetime.

NOTE

Please consult state or provincial regula-

tions restricting the use of studded winter

tires before installing such tires.

1Where permitted

Page 314 of 382

08 Wheels and tires

Tire Sealing System

08

312

CAUTION

If your vehicle is equipped with the Tire

Pressure Monitoring System (TPMS), the

use of the sealing compound may lead to

incorrect tire pressure readings or in rare

cases, damage to the tire pressure sensor.

Use the tire sealing system to check and

adjust the damaged tire's inflation pressure.

NOTE

•Safely stow the tire sealing system in a

convenient place as it will soon be used

again to check the tire’s inflation pres-

sure.

•The empty bottle of sealing compound

cannot be removed from the bottle

holder. Consult a trained and qualified

Volvo service technician to have the

bottle removed and properly disposed

of.

WARNING

If heavy vibrations, unsteady steering

behavior, or noises should occur while driv-

ing, reduce speed and park the vehicle in a

safe place. Recheck the tire for bumps,

cracks, or other visible damage, and

recheck its inflation pressure. If the pressure

is below 19 psi (1.3 bar), do not continue

driving. Have the vehicle towed to a trained

and qualified Volvo service technician.

Stage 2: Checking inflation pressure1. Connect the tire sealing system as descri-

bed in stage 1.

2. Refer to the inflation pressure table in this

chapter for the correct inflation pressure. If

the tire needs to be inflated, start the tire

sealing system’s compressor. If neces-

sary, release air from the tire by turning the

air release knob counterclockwise.

CAUTION

The compressor should not be used for

more than 10 minutes at a time to avoid

overheating.

WARNING

If you interrupt your trip for more than 1

hour, check the inflation pressure in the

damaged tire again before continuing.

Replacing the sealing compound

container

The sealing compound container must be

replaced if:

•the tire sealing system has been used to

repair a tire

•the container’s expiration date has passed

(see the date on decal).

NOTE

•After use, the sealing compound bottle,

the hose, and certain other system

components must be replaced. Please

consult your Volvo retailer for replace-

ment parts.

•If the sealing compound bottle’s expi-

ration date has passed, please take it to

a Volvo retailer or a recycling station

that can properly dispose of harmful

substances.

Page 315 of 382

08 Wheels and tires

Tire Sealing System

08

313 Inflating tires

The tire sealing system can be used to inflate

the tires. To do so:

1. Park the car in a safe place.

2. The compressor should be switched off.

Ensure that the on/off switch is in position

0 (the 0 side of the switch should be

pressed down).

3. Take out the electrical wire and hose.

4. Remove the valve cap from the tire’s infla-

tion valve and screw the hose connector

onto the valve as tightly as possible by

hand.

5. Connect the electrical wire to the nearest

12-volt socket in the vehicle.

6. Start the vehicle’s engine.WARNING

•The vehicle’s engine should be running

when the tire sealing system is used to

avoid battery drain. Therefore, be sure

the vehicle is parked in a well ventilated

place, or outdoors, before using the sys-

tem. The parking brake should be

securely applied and the gear selector

should be in the P (park) position.

•Children should never be left unattended

in the vehicle when the engine is running.

7. Check the tire’s inflation pressure on the

gauge. Switch off the compressor briefly to

get a clear reading from the pressure

gauge.

8. Refer to the tire inflation table in this chap-

ter for the correct inflation pressure. If the

tire needs to be inflated, start the tire seal-

ing system’s compressor (press the on/off

switch to position I). If necessary, release

air from the tire by turning the air release

knob counterclockwise.

CAUTION

The compressor should not be used for

more than 10 minutes at a time to avoid

overheating.

9. Turn off the compressor (press the on/off

switch to position 0) when the correct infla-

tion pressure has been reached.

10. Unscrew the hose from the tire’s inflation

valve and reinstall the valve cap.

11. Disconnect the electrical wire from the

12-volt socket.

Page 316 of 382

08 Wheels and tires

Changing a wheel

08

314* Option/accessory, for more information, see Introduction.

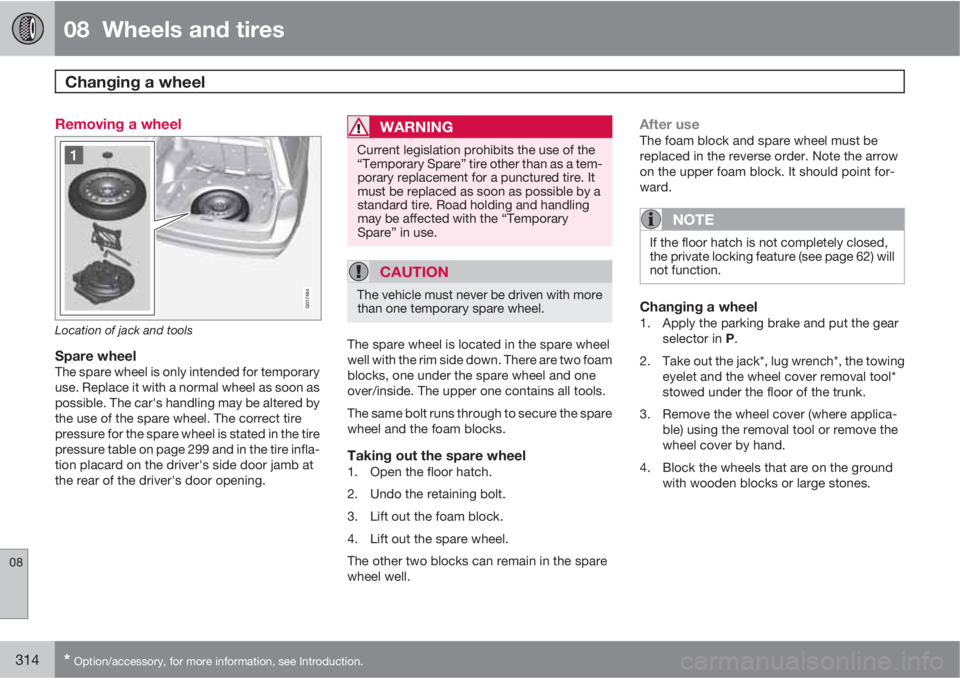

Removing a wheel

G017464

Location of jack and tools

Spare wheelThe spare wheel is only intended for temporary

use. Replace it with a normal wheel as soon as

possible. The car's handling may be altered by

the use of the spare wheel. The correct tire

pressure for the spare wheel is stated in the tire

pressure table on page 299 and in the tire infla-

tion placard on the driver's side door jamb at

the rear of the driver's door opening.

WARNING

Current legislation prohibits the use of the

“Temporary Spare” tire other than as a tem-

porary replacement for a punctured tire. It

must be replaced as soon as possible by a

standard tire. Road holding and handling

may be affected with the “Temporary

Spare” in use.

CAUTION

The vehicle must never be driven with more

than one temporary spare wheel.

The spare wheel is located in the spare wheel

well with the rim side down. There are two foam

blocks, one under the spare wheel and one

over/inside. The upper one contains all tools.

The same bolt runs through to secure the spare

wheel and the foam blocks.

Taking out the spare wheel1. Open the floor hatch.

2. Undo the retaining bolt.

3. Lift out the foam block.

4. Lift out the spare wheel.

The other two blocks can remain in the spare

wheel well.

After useThe foam block and spare wheel must be

replaced in the reverse order. Note the arrow

on the upper foam block. It should point for-

ward.

NOTE

If the floor hatch is not completely closed,

the private locking feature (see page 62) will

not function.

Changing a wheel1. Apply the parking brake and put the gear

selector in P.

2. Take out the jack*, lug wrench*, the towing

eyelet and the wheel cover removal tool*

stowed under the floor of the trunk.

3. Remove the wheel cover (where applica-

ble) using the removal tool or remove the

wheel cover by hand.

4. Block the wheels that are on the ground

with wooden blocks or large stones.

Page 317 of 382

08 Wheels and tires

Changing a wheel

08

315

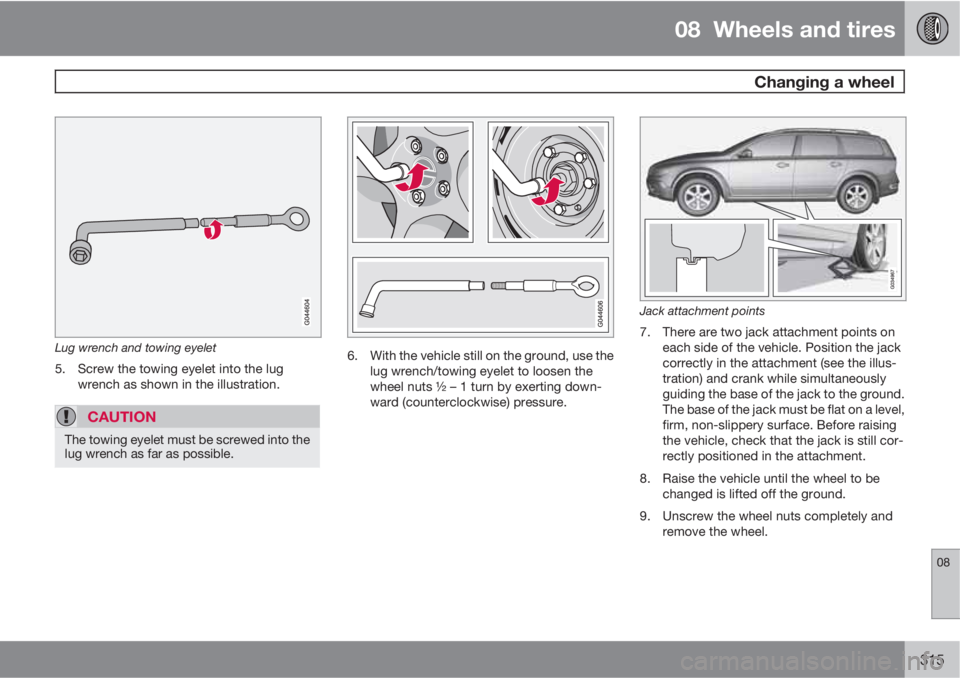

Lug wrench and towing eyelet

5. Screw the towing eyelet into the lug

wrench as shown in the illustration.

CAUTION

The towing eyelet must be screwed into the

lug wrench as far as possible.

6. With the vehicle still on the ground, use the

lug wrench/towing eyelet to loosen the

wheel nuts ½ – 1 turn by exerting down-

ward (counterclockwise) pressure.

Jack attachment points

7. There are two jack attachment points on

each side of the vehicle. Position the jack

correctly in the attachment (see the illus-

tration) and crank while simultaneously

guiding the base of the jack to the ground.

The base of the jack must be flat on a level,

firm, non-slippery surface. Before raising

the vehicle, check that the jack is still cor-

rectly positioned in the attachment.

8. Raise the vehicle until the wheel to be

changed is lifted off the ground.

9. Unscrew the wheel nuts completely and

remove the wheel.