tow bar VOLVO XC90 TWIN ENGINE 2020 User Guide

[x] Cancel search | Manufacturer: VOLVO, Model Year: 2020, Model line: XC90 TWIN ENGINE, Model: VOLVO XC90 TWIN ENGINE 2020Pages: 693, PDF Size: 13.34 MB

Page 465 of 693

STARTING AND DRIVING

}}

* Option/accessory.463

NOTE

Volvo recommends only using Volvo origi- nal accessories. Follow the instructionssupplied with the product.

CAUTION

Never use towbar adapters or towbar extenders

Only use ball mount for towing. Do notmount accessories directly on the ballmount. Use accessories designed tobe mounted in the towbar's squarebracket. Do not use accessoriesdesigned to be secured around the ballmount.

Loading the bicycle holderThe greater the distance between the load and the bicycle holder, the greater the load on thehitch and on the vehicle. Keep the following points in mind: Mount the heaviest bicycle closest to the vehicle.

If possible, mount the bicycles symmetri-cally, as close as possible to the center ofthe vehicle.

Remove loose objects from the bicycle,such as baskets, batteries or child seats.This will help reduce the load on the hitchand the bicycle holder.

Do not place a cover over the bicycle asthis could lead to increased load on thehitch.

Related information

Detachable towbar

* (p. 463)

Driving with a trailer (p. 465)

Detachable towbar

*

Volvo recommends the use of Volvo towbars that are specially designed for the vehicle.

NOTE

The optional detachable trailer hitch may not be available in all markets or on allmodels. Consult your Volvo retailer.

Ball holder

Cotter pin

Towbar assembly

Locking bolt

Safety wire attachment bracket

Page 466 of 693

||

STARTING AND DRIVING

* Option/accessory.

464

Installing the ball holder1. If necessary, remove the cotter pin from

the locking bolt and slide the locking bolt out of the towbar assembly.

2. Slide the ball holder into the towbar assembly.

3. Align the hole in the ball holder with the one in the towbar assembly.

4. Slide the locking bolt through the towbar assembly/ball holder.

5. Insert the cotter pin in the hole at the end of the locking bolt.

WARNING

Be sure the towbar is securely locked in position before attaching anything toit.

Always attach the trailer's safety wiresecurely to the towbar's safety wireattachment bracket.

Removing the ball holder1. Remove the cotter pin from the locking

bolt and slide the locking bolt out of theball holder/towbar assembly.

2. Pull the ball holder out of the towbar assembly.

WARNING

Damage may occur on the towbar if it is not used correctly or if incorrect or faultyaccessories are used, such as:

Overloading of accessory.

Use of incorrect or faulty accessory.

Accessory used for an incorrect pur- pose.

Use of weight-distributing towing sys-tem.

Incorrectly positioned ball mount; seegeometric limits for the towbar.

Stowing the ball holder

WARNING

When not in use, the detachable ball holder should always be properly stowed in thedesignated location under the floor of thecargo compartment.

Driving with a trailerWhen towing a trailer, the original ball holder or equivalent should be used.

The ball mount must fall within the geometric limits for the towbar, for both distance

and

height

. Geometric limits are described on a

type plate located on the towbar.

Related information

Retractable hitch

* (p. 461)

Driving with a trailer (p. 465)

Towing capacity and tongue weight (p. 667)

Page 467 of 693

STARTING AND DRIVING

}}

* Option/accessory.465

Driving with a trailer

There are a number of things to consider when towing a trailer, such as the towbar, thetrailer and how the load is distributed in thetrailer.

Load-carrying capacity is determined by the vehicle's curb weight. The total weight of allpassengers and any installed accessories, e.g.towbar, reduces the vehicle's load-carryingcapacity by the corresponding amount.

Towbars used on the vehicle must beapproved for the applicable use.

Distribute the load on the trailer so thatthe weight on the towbar complies withthe specified maximum towball weight.The tongue weight is calculated as part ofthe vehicle's payload.

Increase the tire pressure to the recom-mended pressure for a full load.

The engine is subjected to more load thanusual when towing a trailer.

Towing a trailer affects the vehicle's han-dling, durability and driving economy.

Do not drive with a heavy trailer when thevehicle is very new. Wait until the mileagehas reached at least 1000 km (620 miles).

On long and steep downgrades, the vehi-cle's brakes are subjected to much moreload than usual. When manually shifting, downshift and adapt speed accordingly.

Follow applicable regulations regarding permitted speed and weight.

Drive slowly when towing a trailer up along and steep incline.

The maximum trailer weights given onlyapply to altitudes up to 1000 meters(3280 feet) above sea level. At higher alti-tudes, engine power (and thus the vehi-cle's climbing ability) is decreased due tothe reduced air density, and the maximumtrailer weight must therefore be reduced.The weight of the vehicle and trailer mustbe decreased by 10% for each additional1000 m (3280 feet) or part thereof.

Avoid driving with a trailer on inclines ofmore than 12%.

Avoid overloading and other incorrect use.

The trailer's brakes must be balanced withthe vehicle's brakes to help ensure safestops (follow applicable local regulations).

NOTE

To facilitate towing a trailer in a vehicle equipped with pneumatic suspension

*,

select: the

Suspension ControlDynamic setting in Individual drive mode.

CAUTION

Bumper-attached trailer hitches must not be used on Volvos, nor shouldsafety chains be attached to thebumper.

Trailer hitches attaching to the vehiclerear axle must not be used.

Never connect a trailer's hydraulicbrake system directly to the vehiclebrake system, nor a trailer's lightingsystem directly to the vehicle lightingsystem. Consult your nearest author-ized Volvo retailer for correct installa-tion.

When towing a trailer, the trailer'ssafety chains or wire must be correctlyfastened to the attachment points pro-vided in the trailer hitch on the vehicle.The safety chain or wire must never befastened to or wound around the tow-ing ball.

NOTE

The optional detachable trailer hitch may not be available in all markets or on allmodels. Consult your Volvo retailer.

Page 470 of 693

STARTING AND DRIVING

* Option/accessory.

468

Checking trailer lights

When connecting a trailer, make sure that all of the lights on the trailer are functioningbefore starting to drive.

Trailer turn signals and brake lightsIf one or more of the turn signals or brake lights on the trailer is not working, a symboland message will be displayed in the instru-ment panel. The other lights on the trailermust be checked manually by the driver beforethe vehicle is driven.

Symbol Message

Trailer turn indicator Right

turn indicator malfunction

Trailer turn indicator Left

turn indicator malfunction

Trailer brake light Malfunc-

tion

If any of the trailer's turn signal lights is not working, the turn signal symbol in the instru-ment panel will also flash more quickly thannormal.

Trailer rear fog lightWhen a trailer is connected, the vehicle's rearfog light may not illuminate and rear fog lightfunctionality is instead transferred to the trailer. If this is the case, check to see if thetrailer is equipped with a rear fog light beforeactivating the vehicle's fog lights when drivingwith a trailer to help ensure safe operation.

Checking trailer lights

*

Automatic check

When the trailer has been connected to the vehicle's electrical system, its lights can bechecked by automatically activating them.This function helps the driver check that thetrailer's lights are functioning correctly beforestarting to drive. In order to perform this check, the vehicle must be switched off.

1. When a trailer is connected to the towbar,

the message

Automatic Trailer Lamp

Check will appear in the instrument panel.

2. Acknowledge the message by pressing the O button on the right-side steering

wheel keypad.

> The light check will begin.

3. Get out of the vehicle to perform the check.

> All of the lights on the trailer will beginflashing, and then illuminate separately one at a time.

4. Visually check that all of the trailer's lights are functioning correctly. 5. After a short time, all of the trailer's lights

will start flashing again.

> The light check is completed.

Disabling the automatic check

The automatic light check can be disabled in the center display. 1.Tap

Settings in the Top view.

2. Tap

My CarLights and Lighting.

3. Deselect

Automatic Trailer Lamp

Check.

Manual check

If the automatic check has been disabled, the check can be started manually. 1. Tap

Settings in the Top view.

2. Tap

My CarLights and Lighting.

3. Select

Manual Trailer Lamp Check.

> The light check will begin. Get out of the vehicle to perform the check.

Related information

Driving with a trailer (p. 465)

Page 471 of 693

STARTING AND DRIVING

}}

469

Towing using a towline

This section refers to one vehicle being towed behind another using a towline.

Never attempt to tow a Twin Engine vehicle behind another vehicle as this could damagethe electric motor. The vehicle must instead belifted onto a tow truck and transported with allfour wheels on the bed or lifting platform ofthe truck (no wheels may touch the road).

Towing another vehicleTowing another vehicle requires a lot of power - use the Constant AWD drive mode. This

helps charge the hybrid battery and improve the vehicle's driving and roadholding characte-ristics. Before towing another vehicle, check applica- ble speed limit regulations.

Jump startingNever attempt to tow the vehicle to start theengine, as this could damage the electricmotor. Use an auxiliary battery if the start bat-tery's charge level is so low that the enginecannot be started.

CAUTION

Attempts to tow-start the vehicle could cause damage to the electrical drive motorand three-way catalytic converter.

Related information

Attaching and removing the towing eyelet (p. 469)

Hazard warning flashers (p. 164)

Recovery (p. 470)

Jump starting using another battery(p. 459)

Selecting ignition mode (p. 416)

Transmission (p. 426)

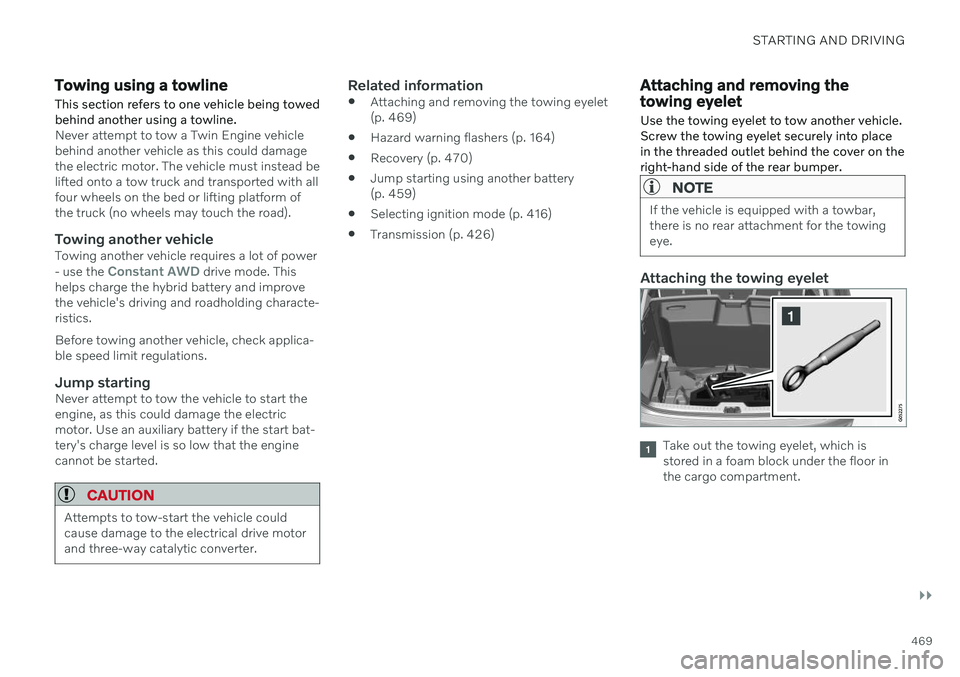

Attaching and removing the towing eyelet

Use the towing eyelet to tow another vehicle. Screw the towing eyelet securely into placein the threaded outlet behind the cover on theright-hand side of the rear bumper.

NOTE

If the vehicle is equipped with a towbar, there is no rear attachment for the towingeye.

Attaching the towing eyelet

Take out the towing eyelet, which is stored in a foam block under the floor inthe cargo compartment.

Page 564 of 693

WHEELS AND TIRES

* Option/accessory.

562

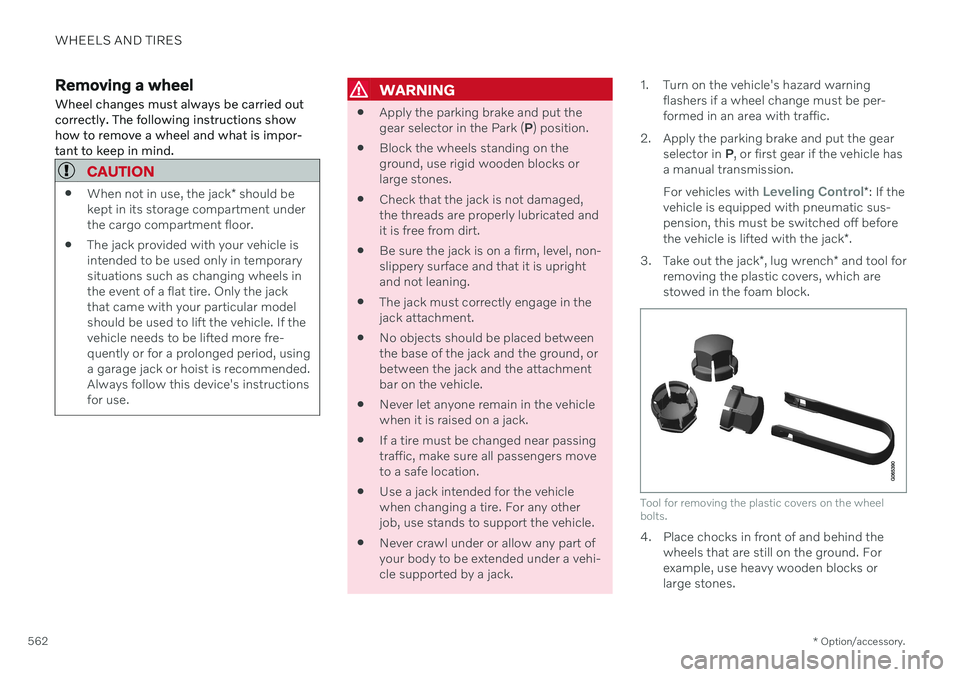

Removing a wheel Wheel changes must always be carried out correctly. The following instructions showhow to remove a wheel and what is impor-tant to keep in mind.

CAUTION

When not in use, the jack

* should be

kept in its storage compartment under the cargo compartment floor.

The jack provided with your vehicle isintended to be used only in temporarysituations such as changing wheels inthe event of a flat tire. Only the jackthat came with your particular modelshould be used to lift the vehicle. If thevehicle needs to be lifted more fre-quently or for a prolonged period, usinga garage jack or hoist is recommended.Always follow this device's instructionsfor use.

WARNING

Apply the parking brake and put the gear selector in the Park (

P) position.

Block the wheels standing on theground, use rigid wooden blocks orlarge stones.

Check that the jack is not damaged,the threads are properly lubricated andit is free from dirt.

Be sure the jack is on a firm, level, non-slippery surface and that it is uprightand not leaning.

The jack must correctly engage in thejack attachment.

No objects should be placed betweenthe base of the jack and the ground, orbetween the jack and the attachmentbar on the vehicle.

Never let anyone remain in the vehiclewhen it is raised on a jack.

If a tire must be changed near passingtraffic, make sure all passengers moveto a safe location.

Use a jack intended for the vehiclewhen changing a tire. For any otherjob, use stands to support the vehicle.

Never crawl under or allow any part ofyour body to be extended under a vehi-cle supported by a jack. 1. Turn on the vehicle's hazard warning

flashers if a wheel change must be per-formed in an area with traffic.

2. Apply the parking brake and put the gear selector in P, or first gear if the vehicle has

a manual transmission. For vehicles with

Leveling Control* : If the

vehicle is equipped with pneumatic sus- pension, this must be switched off before the vehicle is lifted with the jack *.

3. Take out the jack *, lug wrench * and tool for

removing the plastic covers, which are stowed in the foam block.

Tool for removing the plastic covers on the wheel bolts.

4. Place chocks in front of and behind the wheels that are still on the ground. For example, use heavy wooden blocks orlarge stones.

Page 573 of 693

WHEELS AND TIRES

}}

571

2. Peel off the speed limit sticker from the

side of the compressor. Affix the decal to a clearly visible location on the windshieldto remind the driver not to exceed thisspeed limit. Do not drive faster than80 km/h (50 mph) while using a tire thathas been temporarily repaired with the tiresealing system.

3. Make sure the switch is in the 0 (Off)

position and take out the electric cableand the hose.

4. Unscrew the orange cover on the com- pressor and unscrew the cap on the seal-ing compound bottle.

5. Screw the bottle onto the bottle holder as far as possible. The bottle and the bottle holder are equip- ped with catches to help prevent the seal-ing compound from leaking. Once the bot-tle is screwed into place into the bottleholder, it cannot be unscrewed. The bottle can only be removed by a workshop 18

.

WARNING

Do not unscrew the bottle. It is equipped with a catch to prevent leakage. 6. Unscrew the tire's valve cap and screw

the hose's valve connector as far as possi- ble onto the valve. Be sure the air release valve on the com- pressor's hose is completely closed.

7. Connect the electrical cable to the nearest 12 V outlet and start the vehicle.

NOTE

Make sure that none of the vehicle's other 12 V sockets are used while the compres-sor is running.

WARNING

Never leave children unattended in the vehicle while the engine is running.

WARNING

Inhaling exhaust fumes could lead to seri- ous injury. Never leave the engine runningin an enclosed space or a space withoutsufficient ventilation. 8. Start the compressor by moving the

switch to the I (On) position.

WARNING

Never stand next to a tire being inflated with the compressor. If cracks, bulges, etc.form on the tire, switch off the compressorimmediately. The vehicle should not bedriven. Call roadside assistance to have thevehicle towed to a workshop for inspec-tion/replacement of the tire. Volvo recom-mends an authorized workshop.

NOTE

When the compressor first starts, air pres- sure may temporarily increase up to 6 bar(88 psi) but should decrease again afterapproximately 30 seconds.

9. Inflate the tire for 7 minutes.

CAUTION

To help avoid overheating, the compressor should never be used for more than10 minutes at a time.

18

An authorized Volvo workshop is recommended.

Page 574 of 693

||

WHEELS AND TIRES

57210. Switch off the compressor and check the

inflation pressure using the air pressure gauge. The inflation pressure should bebetween 1.8 bar (22 psi) and 3.5 bar(51 psi). If the inflation pressure is toohigh, use the air release valve to releaseair.

WARNING

If pressure falls below 1.8 bar (22 psi), the hole in the tire may be too large. The vehi-cle should not be driven. Call roadsideassistance to have the vehicle towed to aworkshop for inspection/replacement ofthe tire. Volvo recommends an authorizedworkshop.

11. Switch off the compressor and remove the electrical cable.

12. Unscrew the hose from the tire's valve and screw the valve cap back on.

NOTE

After inflating a tire, always replace the valve cap to help prevent valve damagecaused by gravel, dirt, etc.

Use plastic valve caps only. Metal capscould corrode and become difficult toremove.

13. Put the protective hose cover onto the

hose to help prevent leakage of any resid- ual sealing compound. Return the equip-ment to the cargo compartment.

14. Immediately drive the vehicle at least 3 km (2 miles) at a maximum speed of80 km/h (50 mph) to allow the sealingcompound to seal the tire, and thenrecheck the inflation pressure.

WARNING

During the tire's first revolution, some seal- ing compound may spray out of the punc-ture hole. Before driving away, make surethat no one is near the vehicle who couldbe sprayed with sealing compound. Makesure no one is within 2 meters(7 feet) ofthe vehicle.

15. Rechecking the inflation pressure Connect the hose to the tire's valve and screw the hose connector onto the valveas far as possible. The compressor mustbe switched off. 16. Check the inflation pressure on the air

pressure gauge.

If the pressure is under 1.3 bar (19 psi),the tire is not sufficiently sealed. Thevehicle should not be driven. Call road-side assistance to have the vehicletowed.

If the inflation pressure is higher than1.3 bar (19 psi), the tire must be inflatedto the inflation pressure specified onthe tire pressure decal on the driver'sside door pillar (1 bar = 100 kPa =14.5 psi). If the inflation pressure is toohigh, use the air release valve to releaseair.

WARNING

Check inflation pressure regularly.

Volvo recommends driving to the nearest authorized Volvo workshop to have the tirereplaced/repaired. Inform the workshop thatthe tire contains sealing compound. The sealing compound bottle and the hose must be replaced after use. Volvo recom-mends contacting an authorized Volvo work-shop for replacement.

Page 576 of 693

||

WHEELS AND TIRES

574

Related information

Recommended tire pressure (p. 555)

Using the tire sealing system (p. 569)

Tire sealing system (p. 568)

Determining the vehicle's permitted weight

Properly loading your vehicle will provide maximum return of vehicle design perform-ance.

Weight designationsBefore loading your vehicle, familiarize your- self with the following terms for determiningyour vehicle's weight ratings, with or without atrailer, from the vehicle's Federal/CanadianMotor Vehicle Safety Standards (FMVSS/CMVSS) label, and the vehicle's tire informa-tion placard:

Curb weight

The weight of the vehicle including a full tank of fuel and all standard equipment. It does notinclude passengers, cargo, or optional equip-ment.

Capacity weight

All weight added to the curb weight, including cargo and optional equipment. When towing,towbar weight is also part of cargo weight.

Permissible axle weight

The maximum allowable weight that can be carried by a single axle (front or rear). Thesenumbers are shown on the Federal/CanadianMotor Vehicle Safety Standards (FMVSS/CMVSS) label. The total load on each axlemust never exceed its maximum permissibleweight.

Gross vehicle weight (GVW)

The vehicle's curb weight + cargo + passen- gers.

Steps for Determining Correct Load

Limit

1. Locate the statement "the combined weight of occupants and cargo shouldnever exceed XXX kg or XXX lbs." on yourvehicle's placard.

2. Determine the combined weight of the driver and passengers that will be riding inyour vehicle.

3. Subtract the combined weight of the driver and passengers from XXX kg or XXXlbs.

4. The resulting figure equals the available amount of cargo and luggage loadcapacity. For example, if the "XXX"amount equals 1400 lbs. and there will befive 150 lb. passengers in your vehicle, theamount of available cargo and luggageload capacity is 650 lbs. (1400 - 750 (5 ×150) = 650 lbs.)

5. Determine the combined weight of lug- gage and cargo being loaded on the vehi-cle. That weight may not safely exceed theavailable cargo and luggage load capacitycalculated in Step 4.

Page 638 of 693

||

MAINTENANCE AND SERVICE

* Option/accessory.

636

Positions

Function Ampere Type

– –

MCaseA

Central electrical module

40

MCaseA

Pneumatic suspension

* compressor 40

MCaseA

MCaseA

Rear electric heater (right-hand side) 30

Electrical outlets in the tunnel console between the rear seatsB

30B

MCaseA

Rear electric heater (left-hand side)

30

MCaseA

Power front passenger seat

*

Door module right side, rear 20

MCaseA

Control module for reduction of nitrous oxides (diesel)

30

MCaseA

Power rear seat (right-hand side) B

20

Power tailgate* 25

MCaseA

Power front passenger seat

*

Door module right side, front 20

MCaseA

Towbar

* control module 40

MCaseA

Seat belt tensioner module (right side)

40

MCaseA

Internal relay windings

5 Micro