wheel YAMAHA AEROX50 2003 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2003, Model line: AEROX50, Model: YAMAHA AEROX50 2003Pages: 84, PDF Size: 0.96 MB

Page 34 of 84

4

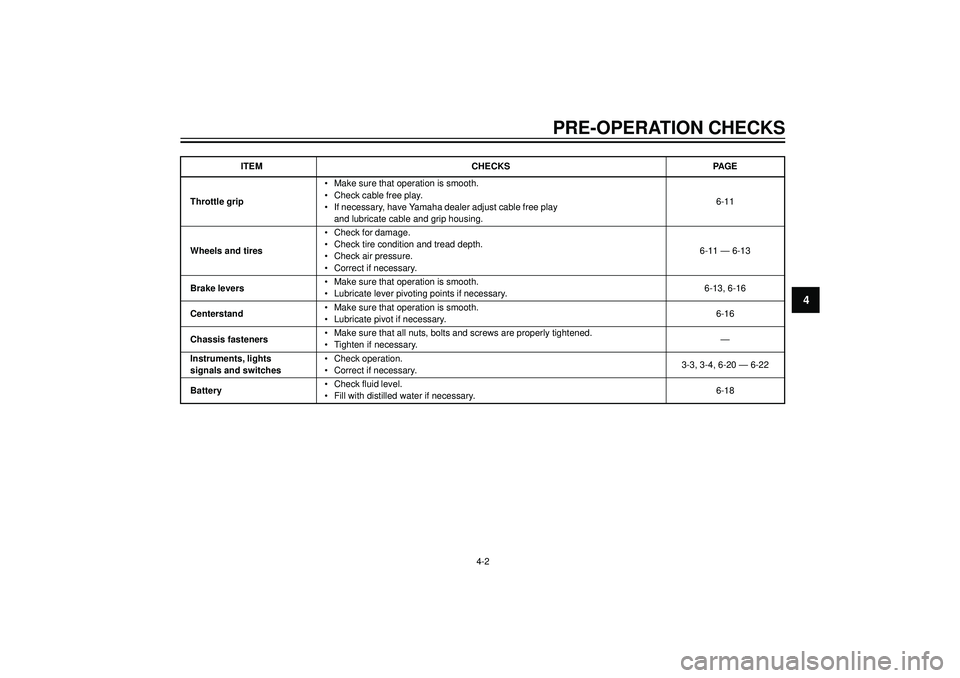

PRE-OPERATION CHECKS

ITEM CHECKS PAGE

• Make sure that operation is smooth.

Throttle grip• Check cable free play.

6-11

• If necessary, have Yamaha dealer adjust cable free play

and lubricate cable and grip housing.

• Check for damage.

Wheels and tires• Check tire condition and tread depth.

6-11 — 6-13

• Check air pressure.

• Correct if necessary.

Brake levers• Make sure that operation is smooth.

6-13, 6-16

• Lubricate lever pivoting points if necessary.

Centerstand• Make sure that operation is smooth.

6-16

• Lubricate pivot if necessary.

Chassis fasteners• Make sure that all nuts, bolts and screws are properly tightened.

—

• Tighten if necessary.

Instruments, lights• Check operation.

3-3, 3-4, 6-20 — 6-22

signals and switches• Correct if necessary.

Battery• Check fluid level.

6-18

• Fill with distilled water if necessary.

4-2

Page 42 of 84

EAU00462

PERIODIC MAINTENANCE AND MINOR REPAIR

Periodic maintenance and lubrication chart ............ 6-2

Removing and installing cowling and panel ............ 6-5

Cowling A ................................................................ 6-5

Panel A .................................................................... 6-5

Checking the spark plug ......................................... 6-6

Final transmission oil .............................................. 6-7

Coolant .................................................................... 6-8

Cleaning the air filter element ................................. 6-9

Adjusting the carburetor ........................................ 6-10

Adjusting the throttle cable free play ..................... 6-11

Tires ...................................................................... 6-11

Wheels .................................................................. 6-13

Adjusting the front and rear brake lever

free play ................................................................ 6-13

Checking the front and rear brake pads ................ 6-14

Checking the brake fluid level ............................... 6-14

6 Changing the brake fluid ....................................... 6-15

Adjusting the autolube pump ................................ 6-15

Checking and lubricating the cables ..................... 6-16

Lubricating the front and rear brakes levers .......... 6-16

Checking and lubricating the centerstand ............. 6-16

Checking the front fork .......................................... 6-17

Checking the steering ........................................... 6-17

Checking the wheel bearings ................................ 6-18

Battery ................................................................... 6-18

Replacing the fuse ................................................ 6-20

Replacing a headlight bulb .................................... 6-20

Replacing tail/brake light bulb ............................... 6-21

Replacing a turn signal light bulb .......................... 6-22

Troubleshooting ..................................................... 6-22

Troubleshooting chart ............................................ 6-23

Engine overheating ............................................... 6-24

Page 44 of 84

PERIODIC MAINTENANCE AND MINOR REPAIR

6

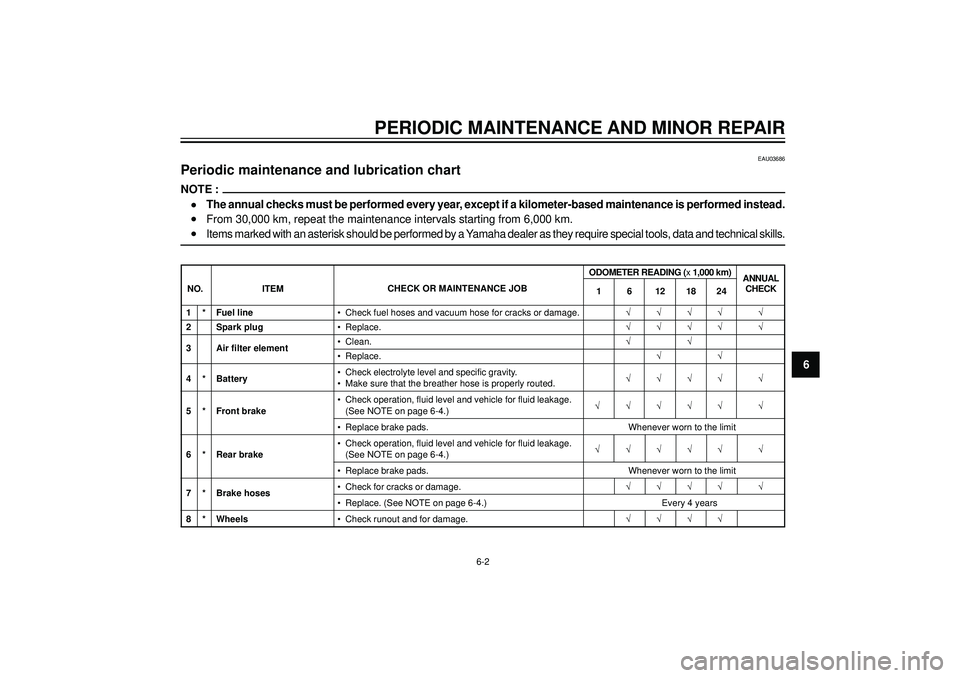

1 * Fuel line• Check fuel hoses and vacuum hose for cracks or damage.√√√√ √

2 Spark plug• Replace.√√√√ √

3 Air filter element• Clean.√√• Replace.√√

4 * Battery• Check electrolyte level and specific gravity.

√√√√ √

• Make sure that the breather hose is properly routed.

• Check operation, fluid level and vehicle for fluid leakage.

√√√√√ √

5 * Front brake(See NOTE on page 6-4.)

• Replace brake pads. Whenever worn to the limit

• Check operation, fluid level and vehicle for fluid leakage.

√√√√√ √

6 * Rear brake(See NOTE on page 6-4.)

• Replace brake pads. Whenever worn to the limit

7 * Brake hoses• Check for cracks or damage.√√√√ √• Replace. (See NOTE on page 6-4.) Every 4 years

8 * Wheels• Check runout and for damage.√√√√

EAU03686

Periodic maintenance and lubrication chart

NOTE :

•The annual checks must be performed every year, except if a kilometer-based maintenance is performed instead.

•From 30,000 km, repeat the maintenance intervals starting from 6,000 km.

•Items marked with an asterisk should be performed by a Yamaha dealer as they require special tools, data and technical skills.

ODOMETER READING (x 1,000 km)

NO. ITEMCHECK OR MAINTENANCE JOB

1

ANNUAL

CHECK

6121824

6-2

Page 45 of 84

PERIODIC MAINTENANCE AND MINOR REPAIR

6

• Check tread depth and for damage.

9 * Tires• Replace if necessary.

√√√√ √

• Check air pressure.

• Correct if necessary.

10 * Wheel bearings• Check bearing for looseness or damage.√√√√

11 * Steering bearings• Check bearing play and steering for roughness.√√√√√• Lubricate with lithium-soap-based grease. Every 24,000 km

12 * Chassis fasteners• Make sure that all nuts, bolts and screws are

√√√√ √

properly tightened.

13 Centerstand• Check operation.

√√√√ √

• Lubricate.

14 * Front fork• Check operation and for oil leakage.√√√√

15 * Shock absorber assembly• Check operation and shock absorber for oil leakage.√√√√

16 * Carburetor• Check starter (chocke) operation.

√√√√√ √

• Adjust engine idling speed.

17 * Autolube pump• Check operation.

√√√√

• Bleed if necessary.

18 Final transmission oil• Check vehicle for oil leakage.√√ √• Change.√√√

19 * V-belt• Replace. Every 10,000 km

20 * Front and rear brake

• Check operation.√√√√√ √

switches

ODOMETER READING (x 1,000 km)

NO. ITEMCHECK OR MAINTENANCE JOB

1

ANNUAL

CHECK

6121824

6-3

Page 49 of 84

PERIODIC MAINTENANCE AND MINOR REPAIR

6

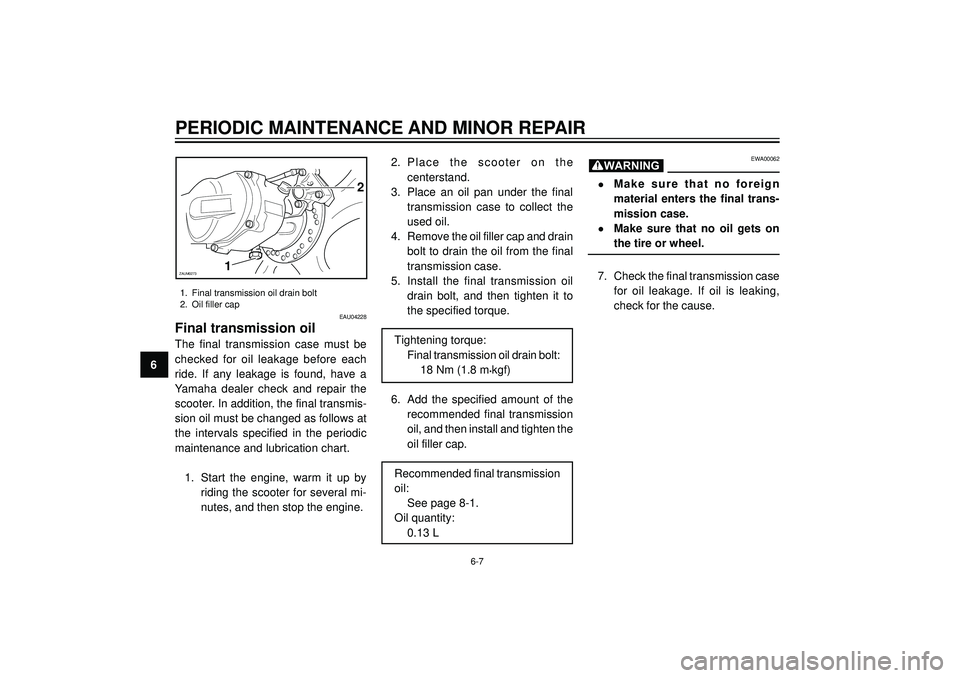

EWA00062

•Make sure that no foreign

material enters the final trans-

mission case.

•Make sure that no oil gets on

the tire or wheel.

7. Check the final transmission case

for oil leakage. If oil is leaking,

check for the cause.

WARNING

EAU04228

Final transmission oil

The final transmission case must be

checked for oil leakage before each

ride. If any leakage is found, have a

Yamaha dealer check and repair the

scooter. In addition, the final transmis-

sion oil must be changed as follows at

the intervals specified in the periodic

maintenance and lubrication chart.

1. Start the engine, warm it up by

riding the scooter for several mi-

nutes, and then stop the engine.2. Place the scooter on the

centerstand.

3. Place an oil pan under the final

transmission case to collect the

used oil.

4. Remove the oil filler cap and drain

bolt to drain the oil from the final

transmission case.

5. Install the final transmission oil

drain bolt, and then tighten it to

the specified torque.

Tightening torque:

Final transmission oil drain bolt:

18 Nm (1.8 m

•kgf)

6. Add the specified amount of the

recommended final transmission

oil, and then install and tighten the

oil filler cap.

Recommended final transmission

oil:

See page 8-1.

Oil quantity:

0.13 L

12ZAUM0273

1. Final transmission oil drain bolt

2. Oil filler cap

6-7

Page 55 of 84

PERIODIC MAINTENANCE AND MINOR REPAIR

6

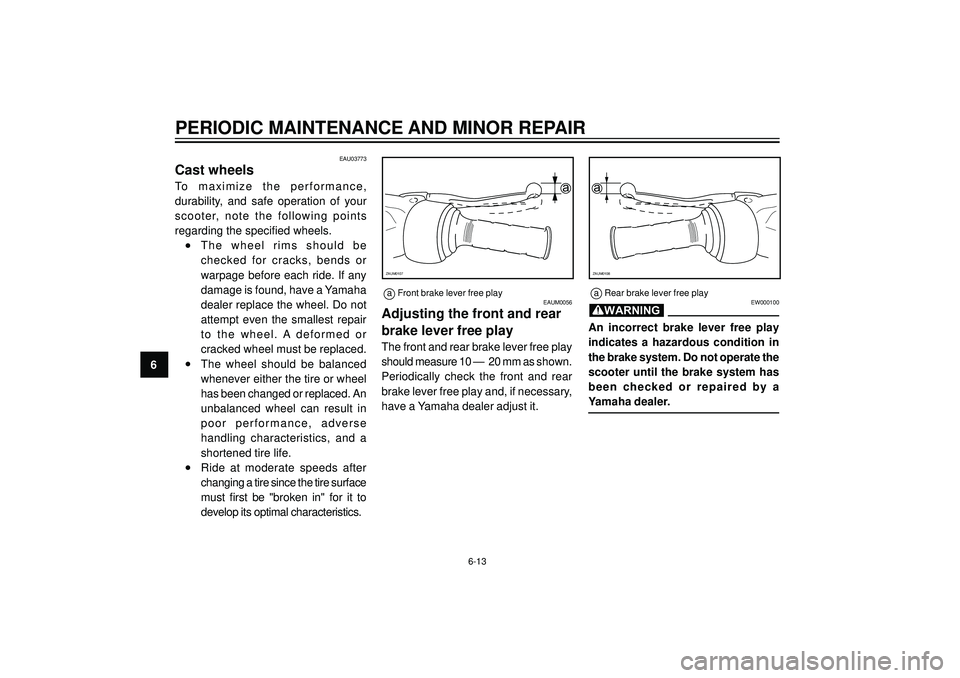

EAUM0056

Adjusting the front and rear

brake lever free play

The front and rear brake lever free play

should measure 10 — 20 mm as shown.

Periodically check the front and rear

brake lever free play and, if necessary,

have a Yamaha dealer adjust it.

EW000100

An incorrect brake lever free play

indicates a hazardous condition in

the brake system. Do not operate the

scooter until the brake system has

been checked or repaired by a

Yamaha dealer.

WARNING

a

ZAUM0107

a

ZAUM0108

a Front brake lever free playa Rear brake lever free play

6-13

EAU03773

Cast wheels

To maximize the performance,

durability, and safe operation of your

scooter, note the following points

regarding the specified wheels.

•The wheel rims should be

checked for cracks, bends or

warpage before each ride. If any

damage is found, have a Yamaha

dealer replace the wheel. Do not

attempt even the smallest repair

to the wheel. A deformed or

cracked wheel must be replaced.

•The wheel should be balanced

whenever either the tire or wheel

has been changed or replaced. An

unbalanced wheel can result in

poor performance, adverse

handling characteristics, and a

shortened tire life.

•Ride at moderate speeds after

changing a tire since the tire surface

must first be "broken in" for it to

develop its optimal characteristics.

Page 59 of 84

PERIODIC MAINTENANCE AND MINOR REPAIR

6

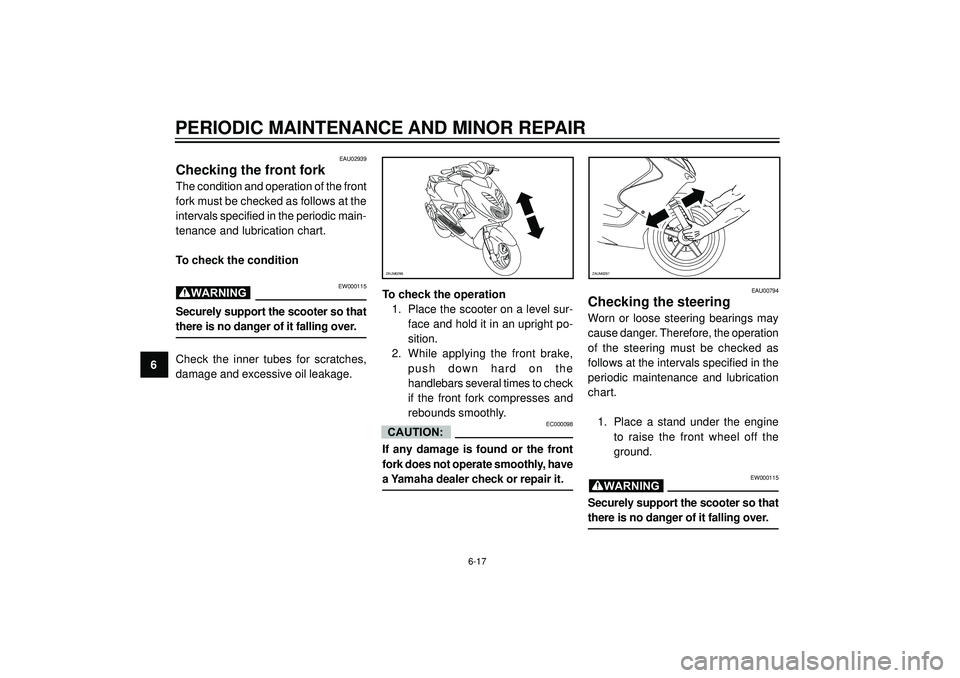

EAU02939

Checking the front fork

The condition and operation of the front

fork must be checked as follows at the

intervals specified in the periodic main-

tenance and lubrication chart.

To check the condition

EW000115

Securely support the scooter so that

there is no danger of it falling over.

Check the inner tubes for scratches,

damage and excessive oil leakage.

WARNINGTo check the operation

1. Place the scooter on a level sur-

face and hold it in an upright po-

sition.

2. While applying the front brake,

push down hard on the

handlebars several times to check

if the front fork compresses and

rebounds smoothly.

EC000098

If any damage is found or the front

fork does not operate smoothly, have

a Yamaha dealer check or repair it.

CAUTION:

EAU00794

Checking the steering

Worn or loose steering bearings may

cause danger. Therefore, the operation

of the steering must be checked as

follows at the intervals specified in the

periodic maintenance and lubrication

chart.

1. Place a stand under the engine

to raise the front wheel off the

ground.

EW000115

Securely support the scooter so that

there is no danger of it falling over.

WARNING

6-17

ZAUM0296ZAUM0297

Page 60 of 84

PERIODIC MAINTENANCE AND MINOR REPAIR

6

EAU01144

Checking the wheel bearings

The front and rear wheel bearings must

be checked at the intervals specified in

the periodic maintenance and

lubrication chart. If there is play in the

wheel hub or if the wheel does not turn

smoothly, have a Yamaha dealer check

the wheel bearings.

1

ZAUM0281

1. Battery

EAUM0049

Battery

A poorly maintained battery will corrode

and discharge quickly. The electrolyte

level, battery lead connections and

breather hose routing should be

checked before each ride and at the

intervals specified in the periodic main-

tenance and lubrication chart.

To check the electrolyte level

1. Place the scooter on a level sur-

face and hold it in an upright posi-

tion.

NOTE :

Make sure that the scooter is positioned

straight up when checking the

electrolyte level.

2. Remove panel A. (See page 6-5

for panel removal and installation

procedures.)

3. Check the electrolyte level in the

battery.

NOTE :

The electrolyte should be between the

minimum and maximum level marks.

1

2+UPPER

LOWER

ZAUM0106

1. Maximum level

2. Minimum level

6-18

2. Hold the lower ends of the front

fork legs and try to move them

forward and backward. If any free

play can be felt, have a Yamaha

dealer check or repair the

steering.

Page 69 of 84

SCOOTER CARE AND STORAGE

7

Care

While the open design of a scooter

reveals the attractiveness of the

technology, it also makes it more

vulnerable. Rust and corrosion can

develop even if high-quality

components are used. A rusty exhaust

pipe may go unnoticed on a car,

however, it detracts from the overall

appearance of a scooter. Frequent and

proper care does not only comply with

the terms of the warranty, but it will also

keep your scooter looking good, extend

its life and optimize its performance.Before cleaning

1. Cover the muffler outlet with a

plastic bag after the engine has

cooled down.

2. Make sure that all caps and covers

as well as all electrical couplers

and connectors, including the

spark plug cap, are tightly

installed.

3. Remove extremely stubborn dirt,

like oil burnt onto the crankcase,

with a degreasing agent and a

brush, but never apply such

products onto seals, gaskets and

wheel axles. Always rinse the dirt

and degreaser off with water.CleaningECA00011

•Avoid using strong acidic wheel

cleaners, especially on spoked

wheels. If such products are

used on hard-to-remove dirt, do

not leave the cleaner on the

affected area any longer than

instructed. Also, thoroughly

rinse the area off with water,

immediately dry it, and then

apply a corrosion protection

spray.

•Improper cleaning can damage

windshields, cowlings, panels

and other plastic parts. Use

only a soft, clean cloth or

sponge with mild detergent and

water to clean plastic.

CAUTION:

7-1

Page 70 of 84

SCOOTER CARE AND STORAGE

7

•Do not use any harsh chemical

products on plastic parts. Be

sure to avoid using cloths or

sponges which have been in

contact with strong or abrasive

cleaning products, solvent or

thinner, fuel (gasoline), rust

removers or inhibitors, brake

fluid, antifreeze or electrolyte.

•Do not use high-pressure

washers or steam-jet cleaners

since they cause water

seepage and deterioration in

the following areas: seals (of

wheel and swingarm bearings,

fork and brakes), electric

components (couplers,

connectors, instruments,

switches and lights), breather

hoses and vents.

•For scooters equipped with a

windshield: Do not use strong

cleaners or hard sponges as

they will cause dulling or

scratching. Some cleaning

compounds for plastic may

leave scratches on the

windshield. Test the product on

a small hidden part of the

windshield to make sure that it

does not leave any marks. If the

windshield is scratched, use a

quality plastic polishing

compound after washing.

After normal use

Remove dirt with warm water, a mild

detergent, and a soft, clean sponge,

and then rinse thoroughly with clean

water. Use a toothbrush or bottlebrush

for hard-to-reach areas. Stubborn dirt

and insects will come off more easily if

the area is covered with a wet cloth for

a few minutes before cleaning.

After riding in the rain, near the sea

or on salt-sprayed roads

Since sea salt or salt sprayed on the

roads during winter are extremely cor-

rosive in combination with water, carry

out the following steps after each ride

in the rain, near the sea or on salt-

sprayed roads.

NOTE :

Salt sprayed on roads in the winter may

remain well into spring.

1. Clean the scooter with cold water

and a mild detergent after the

engine has cooled down.

ECA00012

Do not use warm water since it

increases the corrosive action of the

salt.

2. Apply a corrosion protection spray

on all metal, including chrome-

and nickel-plated, surfaces to

prevent corrosion.

CAUTION:

7-2