lock YAMAHA BANSHEE 350R 2003 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2003, Model line: BANSHEE 350R, Model: YAMAHA BANSHEE 350R 2003Pages: 398, PDF Size: 4.79 MB

Page 323 of 398

8-77

3. Refill with the same type of brake fluid.

Mixing fluids may result in a harmful chem-

ical reaction and lead to poor brake perfor-

mance.

4. Be careful that water does not enter the

master cylinder when refilling. Water will

significantly lower the boiling point of the

fluid and may result in vapor lock.

5. Brake fluid may deteriorate painted sur-

faces or plastic parts. Always clean up

spilled fluid immediately.

6. Have a Yamaha dealer check the cause if

the brake fluid level goes down.

5FK-9-64-8 4/8/02 1:26 PM Page 78

Page 331 of 398

8-85

EBU00953

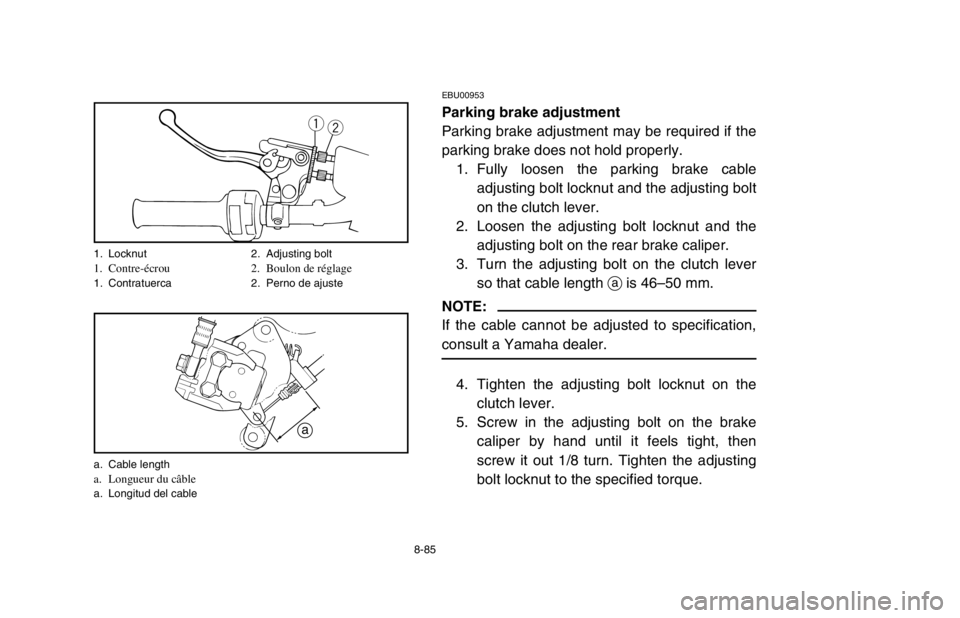

Parking brake adjustment

Parking brake adjustment may be required if the

parking brake does not hold properly.

1. Fully loosen the parking brake cable

adjusting bolt locknut and the adjusting bolt

on the clutch lever.

2. Loosen the adjusting bolt locknut and the

adjusting bolt on the rear brake caliper.

3. Turn the adjusting bolt on the clutch lever

so that cable length ais 46–50 mm.

NOTE:

If the cable cannot be adjusted to specification,

consult a Yamaha dealer.

4. Tighten the adjusting bolt locknut on the

clutch lever.

5. Screw in the adjusting bolt on the brake

caliper by hand until it feels tight, then

screw it out 1/8 turn. Tighten the adjusting

bolt locknut to the specified torque.

q

w

1. Locknut 2. Adjusting bolt1. Contre-écrou 2. Boulon de réglage1. Contratuerca 2. Perno de ajuste

a

a. Cable lengtha. Longueur du câblea. Longitud del cable

5FK-9-64-8 4/8/02 1:26 PM Page 86

Page 333 of 398

8-87

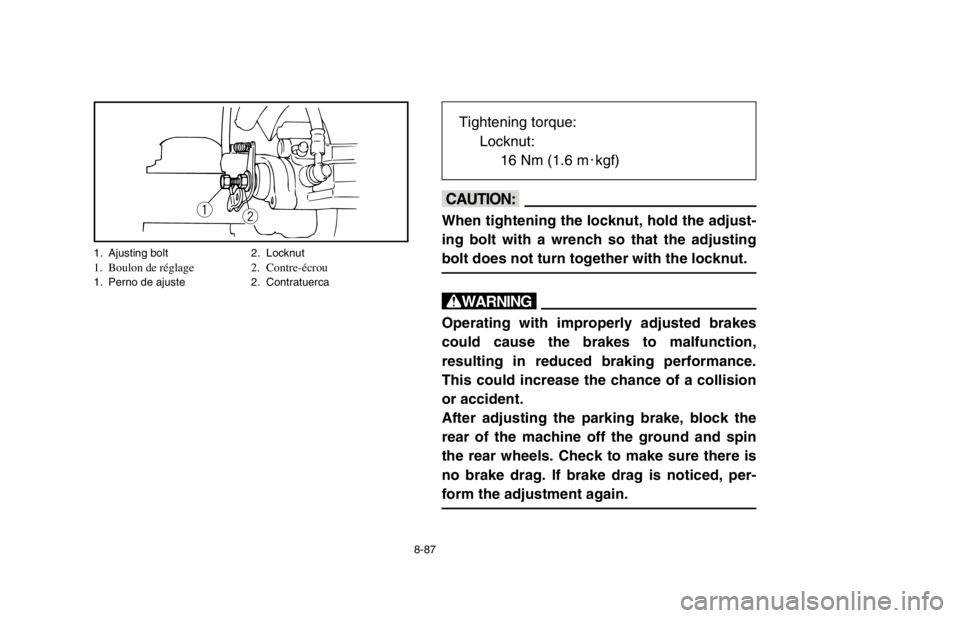

cC

When tightening the locknut, hold the adjust-

ing bolt with a wrench so that the adjusting

bolt does not turn together with the locknut.

w

Operating with improperly adjusted brakes

could cause the brakes to malfunction,

resulting in reduced braking performance.

This could increase the chance of a collision

or accident.

After adjusting the parking brake, block the

rear of the machine off the ground and spin

the rear wheels. Check to make sure there is

no brake drag. If brake drag is noticed, per-

form the adjustment again.

qw

1. Ajusting bolt 2. Locknut1. Boulon de réglage 2. Contre-écrou1. Perno de ajuste 2. Contratuerca

Tightening torque:

Locknut:

16 Nm (1.6 m0kgf)

5FK-9-64-8 4/8/02 1:26 PM Page 88

Page 337 of 398

8-91

EBU00539

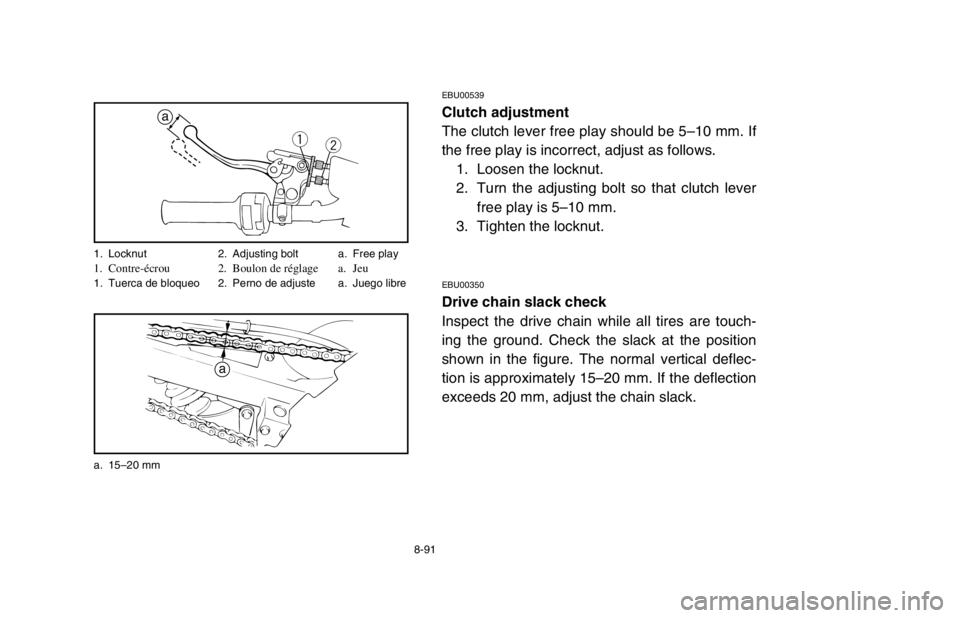

Clutch adjustment

The clutch lever free play should be 5–10 mm. If

the free play is incorrect, adjust as follows.

1. Loosen the locknut.

2. Turn the adjusting bolt so that clutch lever

free play is 5–10 mm.

3. Tighten the locknut.

EBU00350

Drive chain slack check

Inspect the drive chain while all tires are touch-

ing the ground. Check the slack at the position

shown in the figure. The normal vertical deflec-

tion is approximately 15–20 mm. If the deflection

exceeds 20 mm, adjust the chain slack.

q

w

a

a

1. Locknut 2. Adjusting bolt a. Free play1. Contre-écrou 2. Boulon de réglage a. Jeu1. Tuerca de bloqueo 2. Perno de adjuste a. Juego libre

a. 15–20 mm

5FK-9-64-8 4/8/02 1:26 PM Page 92

Page 339 of 398

8-93

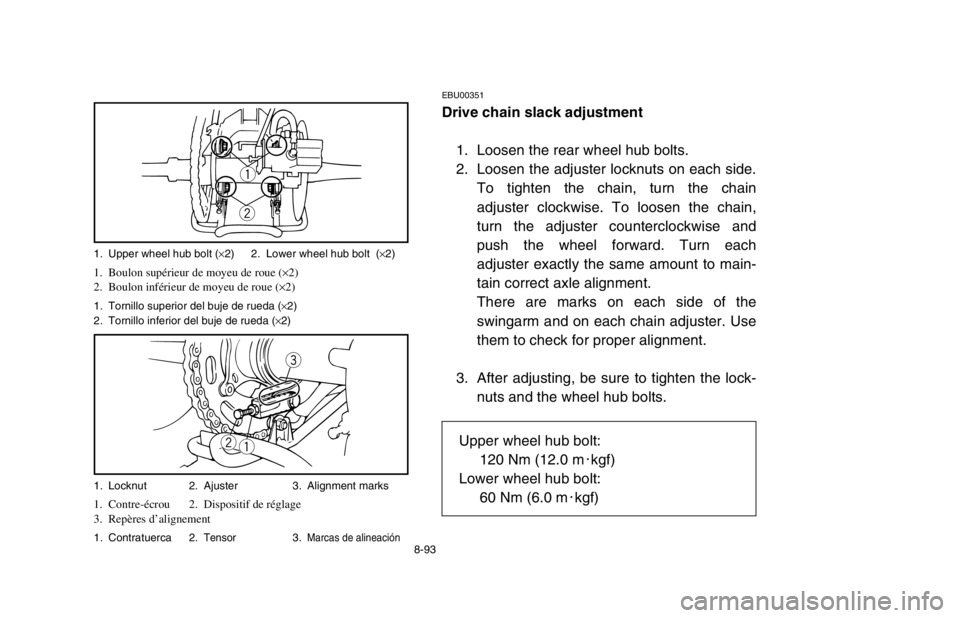

EBU00351

Drive chain slack adjustment

1. Loosen the rear wheel hub bolts.

2. Loosen the adjuster locknuts on each side.

To tighten the chain, turn the chain

adjuster clockwise. To loosen the chain,

turn the adjuster counterclockwise and

push the wheel forward. Turn each

adjuster exactly the same amount to main-

tain correct axle alignment.

There are marks on each side of the

swingarm and on each chain adjuster. Use

them to check for proper alignment.

3. After adjusting, be sure to tighten the lock-

nuts and the wheel hub bolts.

q

w

e

q w

1. Upper wheel hub bolt (×2) 2. Lower wheel hub bolt (×2)

1. Boulon supérieur de moyeu de roue (×2)

2. Boulon inférieur de moyeu de roue (×2)

1. Tornillo superior del buje de rueda (×2)

2. Tornillo inferior del buje de rueda (×2)

1. Locknut 2. Ajuster 3. Alignment marks

1. Contre-écrou 2. Dispositif de réglage

3. Repères d’alignement

1. Contratuerca 2.Tensor3.Marcas de alineación

Upper wheel hub bolt:

120 Nm (12.0 m0kgf)

Lower wheel hub bolt:

60 Nm (6.0 m0kgf)

5FK-9-64-8 4/8/02 1:26 PM Page 94

Page 353 of 398

8-107

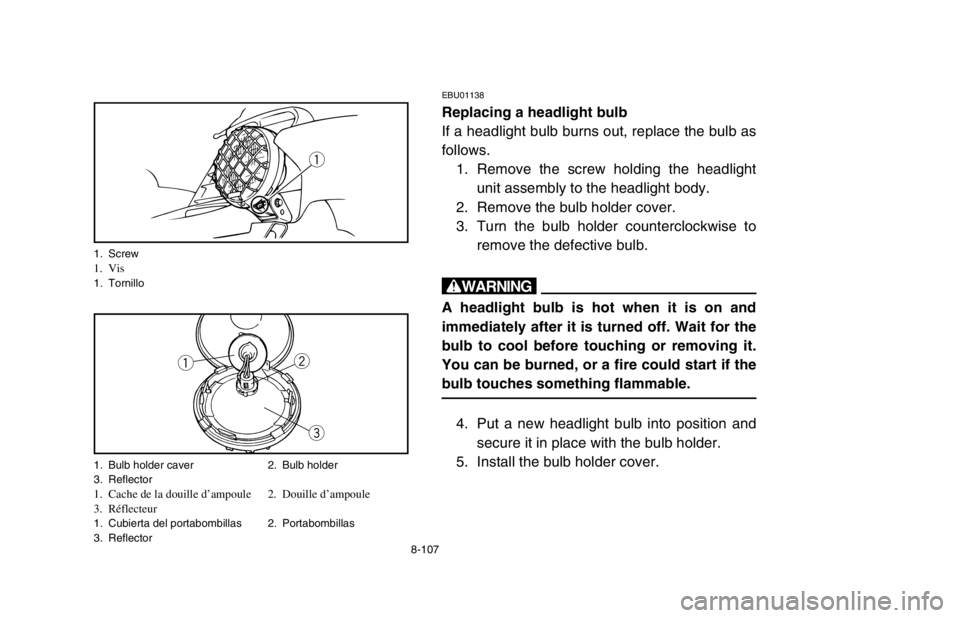

EBU01138

Replacing a headlight bulb

If a headlight bulb burns out, replace the bulb as

follows.

1. Remove the screw holding the headlight

unit assembly to the headlight body.

2. Remove the bulb holder cover.

3. Turn the bulb holder counterclockwise to

remove the defective bulb.

w

A headlight bulb is hot when it is on and

immediately after it is turned off. Wait for the

bulb to cool before touching or removing it.

You can be burned, or a fire could start if the

bulb touches something flammable.

4. Put a new headlight bulb into position and

secure it in place with the bulb holder.

5. Install the bulb holder cover.

q

1. Screw 1. Vis 1. Tornillo

e qw

1. Bulb holder caver 2. Bulb holder

3. Reflector

1. Cache de la douille d’ampoule 2. Douille d’ampoule

3. Réflecteur

1. Cubierta del portabombillas 2. Portabombillas

3. Reflector

5FK-9-64-8 4/8/02 1:26 PM Page 108

Page 357 of 398

8-111

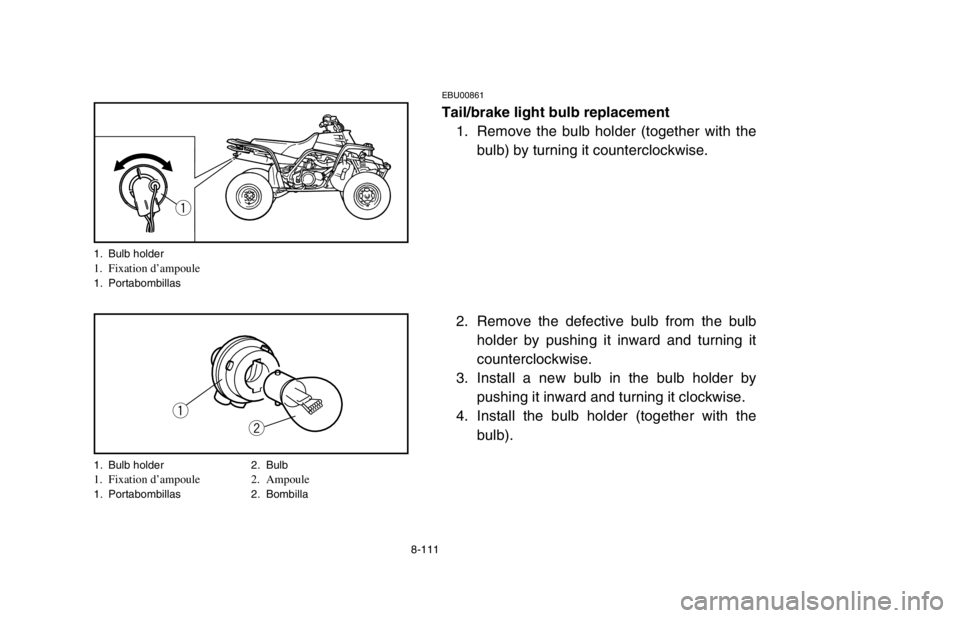

EBU00861

Tail/brake light bulb replacement

1. Remove the bulb holder (together with the

bulb) by turning it counterclockwise.

2. Remove the defective bulb from the bulb

holder by pushing it inward and turning it

counterclockwise.

3. Install a new bulb in the bulb holder by

pushing it inward and turning it clockwise.

4. Install the bulb holder (together with the

bulb).

q

q

w

1. Bulb holder1. Fixation d’ampoule1. Portabombillas

1. Bulb holder 2. Bulb

1. Fixation d’ampoule 2. Ampoule1. Portabombillas 2. Bombilla

5FK-9-64-8 4/8/02 1:26 PM Page 112

Page 369 of 398

9-1

EBU00416

CLEANING AND STORAGE

A. CLEANING

Frequent, thorough cleaning of your machine

will not only enhance its appearance but will

improve its general performance and extend the

useful life of many components.

1. Before cleaning the machine:

a. Block off the end of the exhaust pipe to

prevent water entry. A plastic bag and

strong rubber band may be used.

b. Make sure the spark plugs and all filler

caps are properly installed.

2. If the engine case is excessively greasy,

apply degreaser with a paint brush. Do not

apply degreaser to the chain, sprockets or

wheel axles.

3. Rinse the dirt and degreaser off with a gar-

den hose. Use only enough pressure to do

the job.

5FK-9-64-9~11 4/8/02 2:35 PM Page 2

Page 377 of 398

9-9

5. Block up the frame to raise all wheels off

the ground.

6. Tie a plastic bag over the exhaust pipe out-

let to prevent moisture from entering.

7. If storing in a humid or salt-air atmosphere,

coat all exposed metal surfaces with a light

film of oil. Do not apply oil to any rubber

parts or the seat cover.

NOTE:

Make any necessary repairs before storing the

machine.

5FK-9-64-9~11 4/8/02 2:35 PM Page 10