engine YAMAHA BIG BEAR PRO 400 2003 Service Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2003, Model line: BIG BEAR PRO 400, Model: YAMAHA BIG BEAR PRO 400 2003Pages: 388, PDF Size: 16.15 MB

Page 260 of 388

8-7

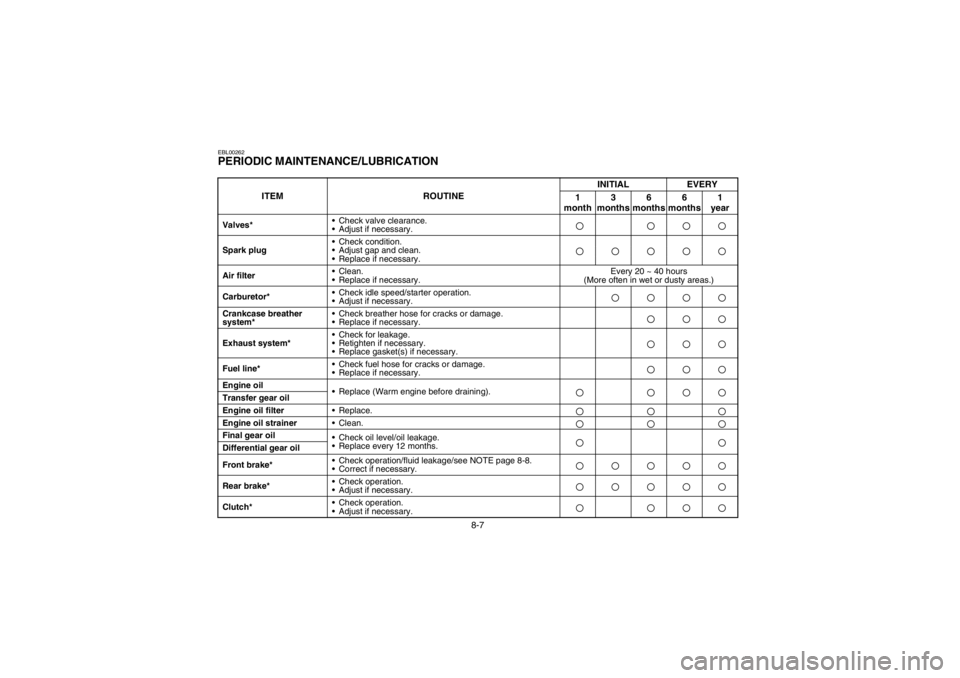

EBL00262PERIODIC MAINTENANCE/LUBRICATION

ITEM ROUTINEINITIAL EVERY

1

month3

months6

months6

months1

year

Valves*•Check valve clearance.

•Adjust if necessary.Spark plug•Check condition.

•Adjust gap and clean.

•Replace if necessary.Air filter•Clean.

•Replace if necessary.Every 20 ~ 40 hours

(More often in wet or dusty areas.)

Carburetor*•Check idle speed/starter operation.

•Adjust if necessary.Crankcase breather

system*•Check breather hose for cracks or damage.

•Replace if necessary.Exhaust system*•Check for leakage.

•Retighten if necessary.

•Replace gasket(s) if necessary.Fuel line*•Check fuel hose for cracks or damage.

•Replace if necessary.Engine oil

•Replace (Warm engine before draining).Transfer gear oil

Engine oil filter

•Replace.Engine oil strainer

•Clean.Final gear oil

•Check oil level/oil leakage.

•Replace every 12 months.Differential gear oil

Front brake*•Check operation/fluid leakage/see NOTE page 8-8.

•Correct if necessary.Rear brake*•Check operation.

•Adjust if necessary.Clutch*•Check operation.

•Adjust if necessary.EE.book Page 7 Monday, June 18, 2001 10:18 AM

Page 266 of 388

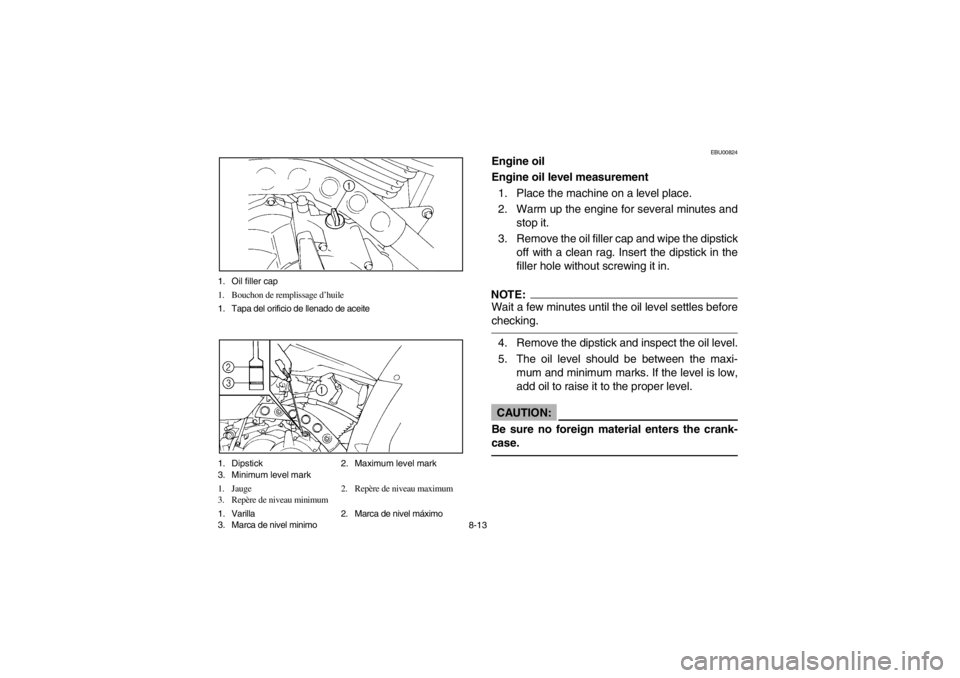

8-13 1. Oil filler cap

1. Bouchon de remplissage d’huile

1. Tapa del orificio de llenado de aceite

1. Dipstick 2. Maximum level mark

3. Minimum level mark

1. Jauge 2. Repère de niveau maximum

3. Repère de niveau minimum

1. Varilla 2. Marca de nivel máximo

3. Marca de nivel minimo

EBU00824

Engine oil

Engine oil level measurement

1. Place the machine on a level place.

2. Warm up the engine for several minutes and

stop it.

3. Remove the oil filler cap and wipe the dipstick

off with a clean rag. Insert the dipstick in the

filler hole without screwing it in.NOTE:_ Wait a few minutes until the oil level settles before

checking. _4. Remove the dipstick and inspect the oil level.

5. The oil level should be between the maxi-

mum and minimum marks. If the level is low,

add oil to raise it to the proper level.CAUTION:_ Be sure no foreign material enters the crank-

case. _

EE.book Page 13 Monday, June 18, 2001 10:18 AM

Page 268 of 388

8-15 1. Clamp

1. Bride

1. Mordaza

1. Drain bolt (engine oil) 2. O-ring

3. Compression spring 4. Oil strainer

1. Boulon de vidange (huile de moteur) 2. Joint torique

3. Ressort de compression 4. Crépine à huile

1. Perno de drenaje (aceite del motor) 2. Junta tórica

3. Muelle de compresión 4. Colador de aceite

Engine oil replacement and oil filter cleaning

1. Place the machine on a level place.

2. Warm up the engine for several minutes and

stop it.

3. Place a container under the engine to collect

the used oil.

4. Remove the clamp.

5. Remove the oil filler cap and drain bolt to

drain the oil.CAUTION:_ When removing the drain bolt, the compres-

sion spring, oil strainer and O-ring will fall out.

Take care not to lose these parts. _

EE.book Page 15 Monday, June 18, 2001 10:18 AM

Page 270 of 388

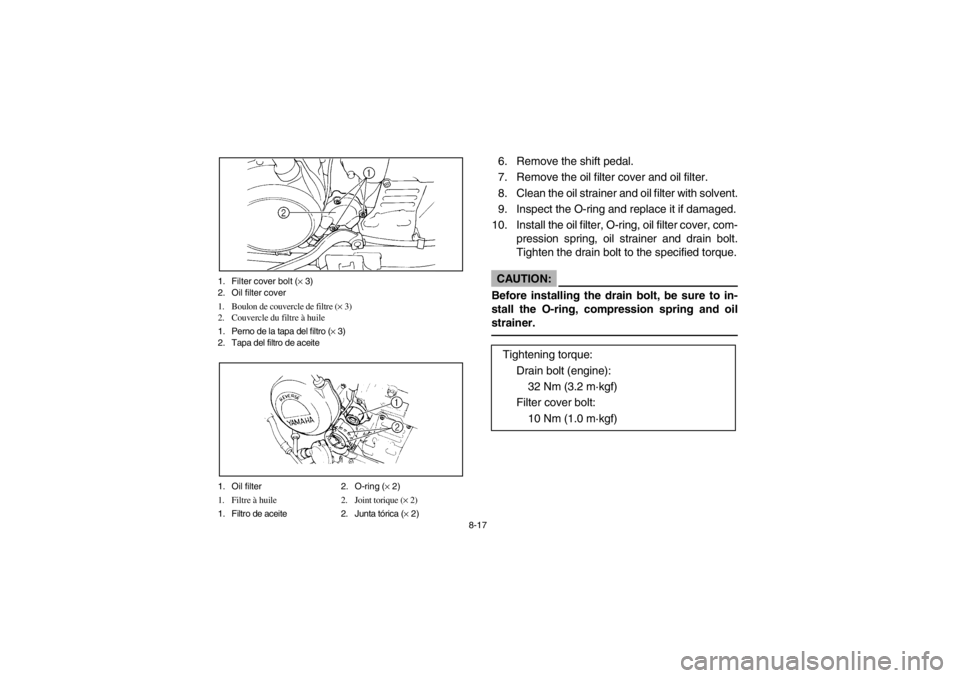

8-17 1. Filter cover bolt (× 3)

2. Oil filter cover

1. Boulon de couvercle de filtre (× 3)

2. Couvercle du filtre à huile

1. Perno de la tapa del filtro (× 3)

2. Tapa del filtro de aceite

1. Oil filter 2. O-ring (× 2)

1. Filtre à huile 2. Joint torique (× 2)

1. Filtro de aceite 2. Junta tórica (× 2)

6. Remove the shift pedal.

7. Remove the oil filter cover and oil filter.

8. Clean the oil strainer and oil filter with solvent.

9. Inspect the O-ring and replace it if damaged.

10. Install the oil filter, O-ring, oil filter cover, com-

pression spring, oil strainer and drain bolt.

Tighten the drain bolt to the specified torque.CAUTION:_ Before installing the drain bolt, be sure to in-

stall the O-ring, compression spring and oil

strainer. _

Tightening torque:

Drain bolt (engine):

32 Nm (3.2 m·kgf)

Filter cover bolt:

10 Nm (1.0 m·kgf)

EE.book Page 17 Monday, June 18, 2001 10:18 AM

Page 272 of 388

8-19

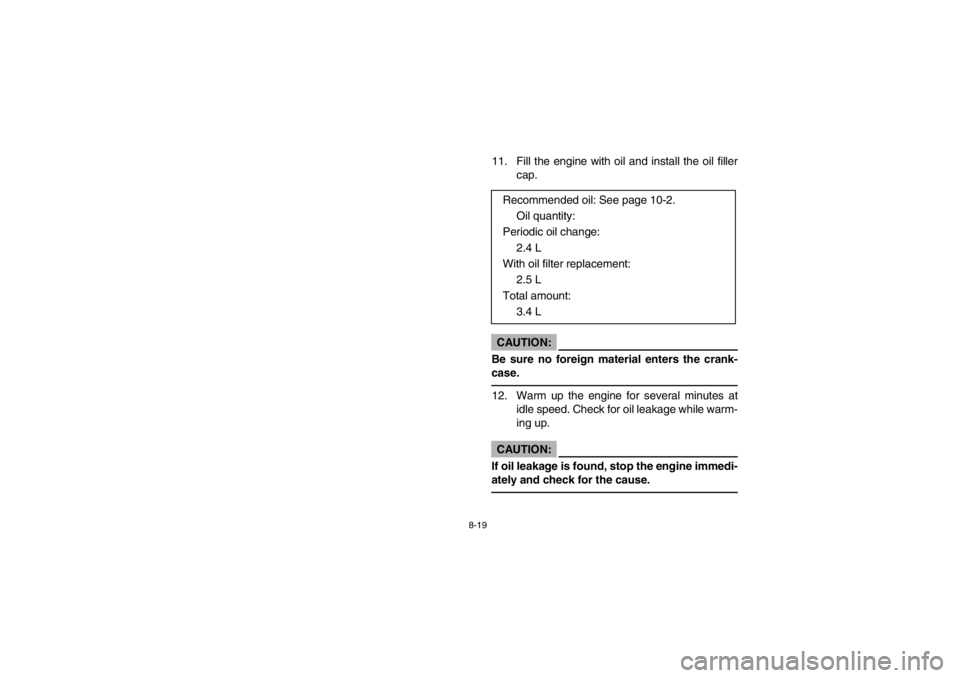

11. Fill the engine with oil and install the oil filler

cap.CAUTION:_ Be sure no foreign material enters the crank-

case. _12. Warm up the engine for several minutes at

idle speed. Check for oil leakage while warm-

ing up.CAUTION:_ If oil leakage is found, stop the engine immedi-

ately and check for the cause. _

Recommended oil: See page 10-2.

Oil quantity:

Periodic oil change:

2.4 L

With oil filter replacement:

2.5 L

Total amount:

3.4 L

EE.book Page 19 Monday, June 18, 2001 10:18 AM

Page 274 of 388

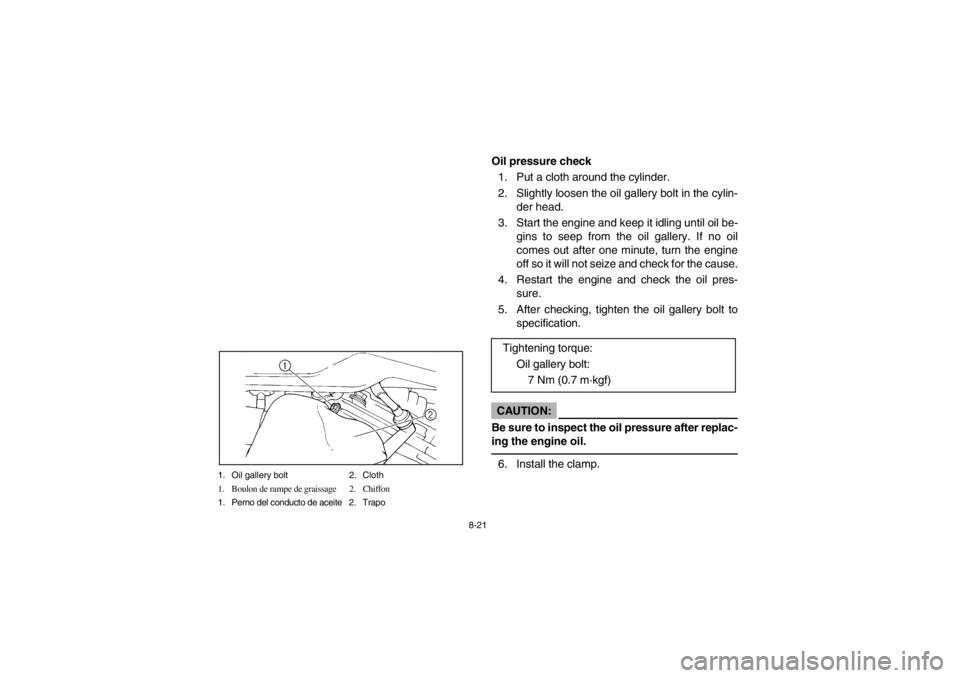

8-21 1. Oil gallery bolt 2. Cloth

1. Boulon de rampe de graissage 2. Chiffon

1. Perno del conducto de aceite 2. Trapo

Oil pressure check

1. Put a cloth around the cylinder.

2. Slightly loosen the oil gallery bolt in the cylin-

der head.

3. Start the engine and keep it idling until oil be-

gins to seep from the oil gallery. If no oil

comes out after one minute, turn the engine

off so it will not seize and check for the cause.

4. Restart the engine and check the oil pres-

sure.

5. After checking, tighten the oil gallery bolt to

specification.CAUTION:_ Be sure to inspect the oil pressure after replac-

ing the engine oil. _6. Install the clamp.Tightening torque:

Oil gallery bolt:

7 Nm (0.7 m·kgf)

EE.book Page 21 Monday, June 18, 2001 10:18 AM

Page 276 of 388

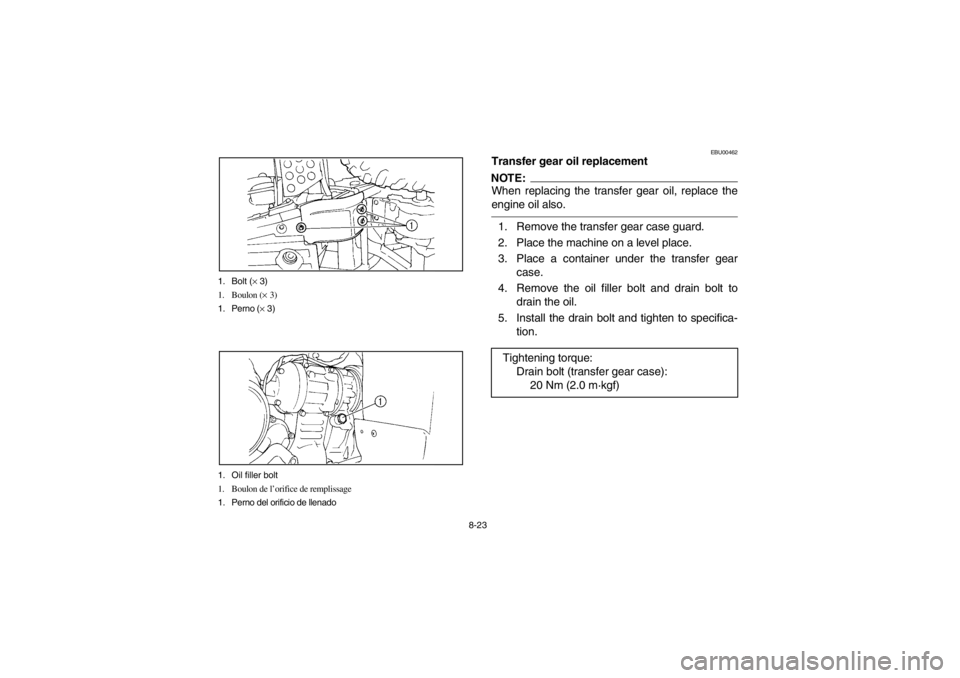

8-23 1. Bolt (× 3)

1. Boulon (× 3)

1. Perno (× 3)

1. Oil filler bolt

1. Boulon de l’orifice de remplissage

1. Perno del orificio de llenado

EBU00462

Transfer gear oil replacementNOTE:When replacing the transfer gear oil, replace the

engine oil also.1. Remove the transfer gear case guard.

2. Place the machine on a level place.

3. Place a container under the transfer gear

case.

4. Remove the oil filler bolt and drain bolt to

drain the oil.

5. Install the drain bolt and tighten to specifica-

tion.

Tightening torque:

Drain bolt (transfer gear case):

20 Nm (2.0 m·kgf)

EE.book Page 23 Monday, June 18, 2001 10:18 AM

Page 278 of 388

8-25 1. Drain bolt

1. Boulon de vidange

1. Perno de drenaje

6. Fill the transfer gear case with oil.CAUTION:

Be sure no foreign material enters the transfer

gear case.7. Install the filler bolt and tighten to specifica-

tion.

8. Check for oil leakage. If oil leakage is found,

check for the cause.

9. Reinstall the transfer gear case guard.Recommended oil: See page 10-2

Quantity:

Transfer gear oil and engine oil with

filter replacement:

2.8 L

Tightening torque:

Filler bolt (transfer gear case):

23 Nm (2.3 m·kgf)

EE.book Page 25 Monday, June 18, 2001 10:18 AM

Page 290 of 388

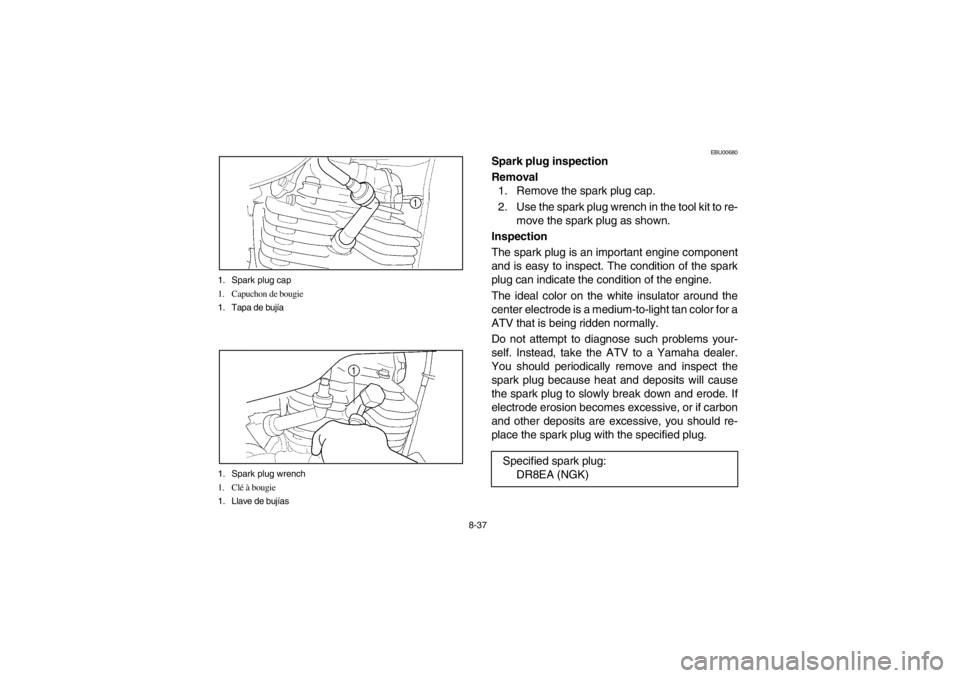

8-37 1. Spark plug cap

1. Capuchon de bougie

1. Tapa de bujía

1. Spark plug wrench

1. Clé à bougie

1. Llave de bujías

EBU00680

Spark plug inspection

Removal

1. Remove the spark plug cap.

2. Use the spark plug wrench in the tool kit to re-

move the spark plug as shown.

Inspection

The spark plug is an important engine component

and is easy to inspect. The condition of the spark

plug can indicate the condition of the engine.

The ideal color on the white insulator around the

center electrode is a medium-to-light tan color for a

ATV that is being ridden normally.

Do not attempt to diagnose such problems your-

self. Instead, take the ATV to a Yamaha dealer.

You should periodically remove and inspect the

spark plug because heat and deposits will cause

the spark plug to slowly break down and erode. If

electrode erosion becomes excessive, or if carbon

and other deposits are excessive, you should re-

place the spark plug with the specified plug.

Specified spark plug:

DR8EA (NGK)

EE.book Page 37 Monday, June 18, 2001 10:18 AM

Page 298 of 388

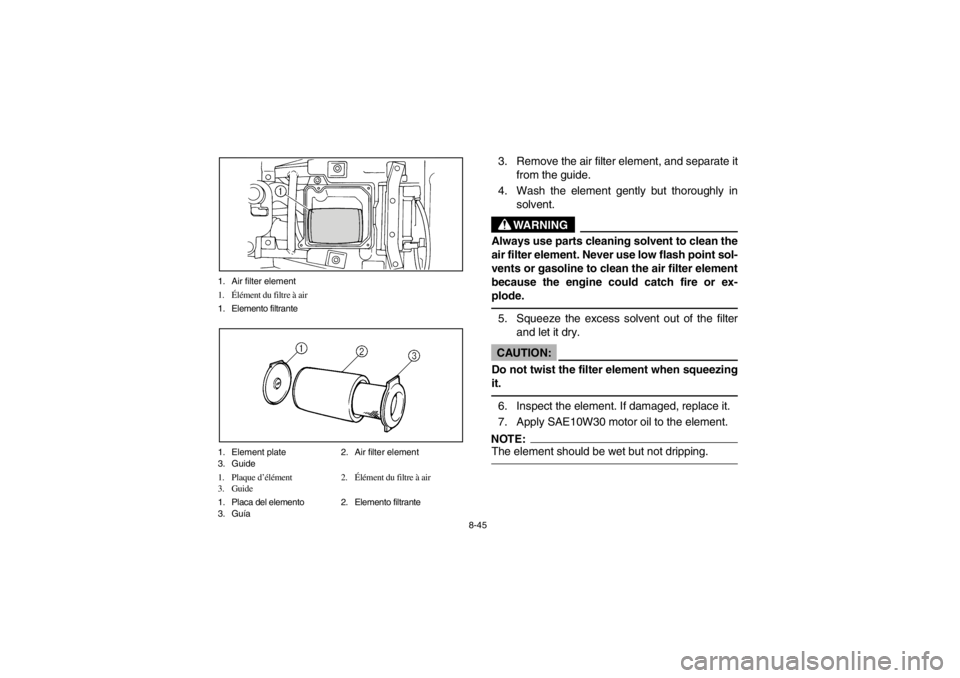

8-45 1. Air filter element

1.Élément du filtre à air

1. Elemento filtrante

1. Element plate 2. Air filter element

3. Guide

1. Plaque d’élément 2.Élément du filtre à air

3. Guide

1. Placa del elemento 2. Elemento filtrante

3. Guía

3. Remove the air filter element, and separate it

from the guide.

4. Wash the element gently but thoroughly in

solvent.

WARNING

Always use parts cleaning solvent to clean the

air filter element. Never use low flash point sol-

vents or gasoline to clean the air filter element

because the engine could catch fire or ex-

plode.5. Squeeze the excess solvent out of the filter

and let it dry.CAUTION:

Do not twist the filter element when squeezing

it.6. Inspect the element. If damaged, replace it.

7. Apply SAE10W30 motor oil to the element.NOTE:The element should be wet but not dripping.

EE.book Page 45 Monday, June 18, 2001 10:18 AM