torque YAMAHA BRUIN 250 2006 Manuale de Empleo (in Spanish)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: BRUIN 250, Model: YAMAHA BRUIN 250 2006Pages: 396, tamaño PDF: 11.32 MB

Page 126 of 396

5-17

EBU11620

Fittings and fasteners

Always check the tightness of chassis fittings and

fasteners before a ride. Take the machine to a

Yamaha dealer or refer to the Service Manual for

correct tightening torque.

EBU10030

Lights

Check the headlights and tail/brake light to make

sure they are in working condition. Repair as nec-

essary for proper operation.

EBU11700

Switches

Check the operation of all switches. Have a

Yamaha dealer repair as necessary for proper op-

eration.

EBU00499

Battery

Check fluid level and fill if necessary. Use only dis-

tilled water if refilling is necessary. (See pages

8-85–8-91.)

EE.book Page 17 Friday, May 27, 2005 5:00 PM

Page 256 of 396

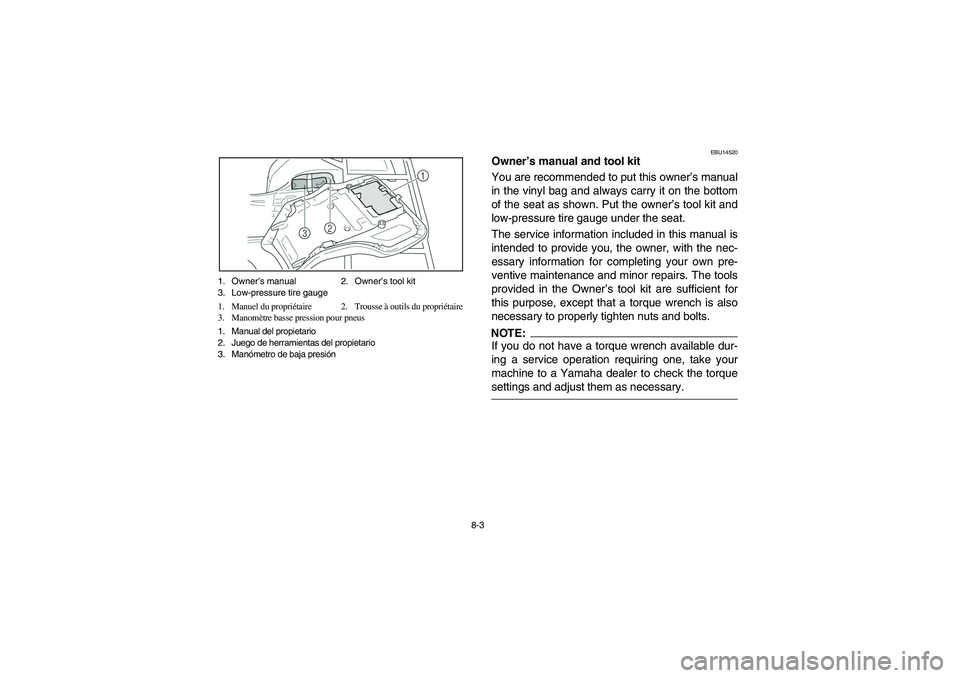

8-3 1. Owner’s manual 2. Owner’s tool kit

3. Low-pressure tire gauge

1. Manuel du propriétaire 2. Trousse à outils du propriétaire

3. Manomètre basse pression pour pneus

1. Manual del propietario

2. Juego de herramientas del propietario

3. Manómetro de baja presión

EBU14520

Owner’s manual and tool kit

You are recommended to put this owner’s manual

in the vinyl bag and always carry it on the bottom

of the seat as shown. Put the owner’s tool kit and

low-pressure tire gauge under the seat.

The service information included in this manual is

intended to provide you, the owner, with the nec-

essary information for completing your own pre-

ventive maintenance and minor repairs. The tools

provided in the Owner’s tool kit are sufficient for

this purpose, except that a torque wrench is also

necessary to properly tighten nuts and bolts.NOTE:_ If you do not have a torque wrench available dur-

ing a service operation requiring one, take your

machine to a Yamaha dealer to check the torque

settings and adjust them as necessary. _

EE.book Page 3 Friday, May 27, 2005 5:00 PM

Page 278 of 396

8-25

10. Install the oil filter element.

11. Install the oil filter element cover by installing

the bolts, and then tightening them to the

specified torque.

12. Install the oil strainer, compression spring,

O-ring and engine oil drain bolt, and then

tighten the engine oil drain bolt to the speci-

fied torque.CAUTION:_ Before installing the engine oil drain bolt, be

sure to install the O-ring, compression spring

and oil strainer. _

Tightening torque:

Oil filter element cover bolt:

10 Nm (1.0 m·kgf)

Tightening torque:

Engine oil drain bolt:

43 Nm (4.3 m·kgf)

EE.book Page 25 Friday, May 27, 2005 5:00 PM

Page 282 of 396

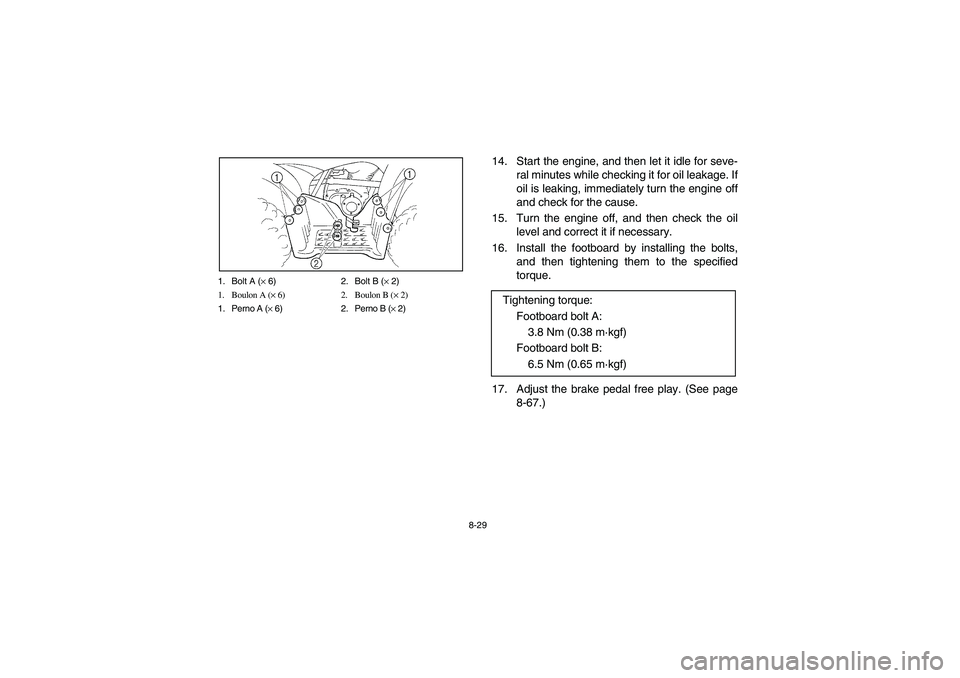

8-29 1. Bolt A (× 6) 2. Bolt B (× 2)

1. Boulon A (× 6) 2. Boulon B (× 2)

1. Perno A (× 6) 2. Perno B (× 2)

14. Start the engine, and then let it idle for seve-

ral minutes while checking it for oil leakage. If

oil is leaking, immediately turn the engine off

and check for the cause.

15. Turn the engine off, and then check the oil

level and correct it if necessary.

16. Install the footboard by installing the bolts,

and then tightening them to the specified

torque.

17. Adjust the brake pedal free play. (See page

8-67.) Tightening torque:

Footboard bolt A:

3.8 Nm (0.38 m·kgf)

Footboard bolt B:

6.5 Nm (0.65 m·kgf)

EE.book Page 29 Friday, May 27, 2005 5:00 PM

Page 284 of 396

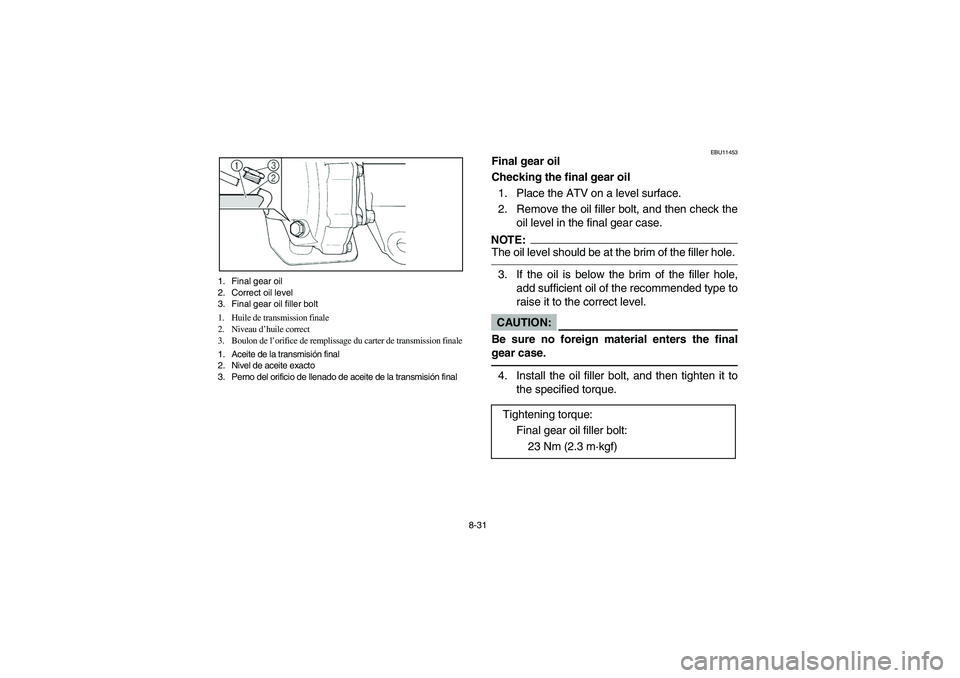

8-31 1. Final gear oil

2. Correct oil level

3. Final gear oil filler bolt

1. Huile de transmission finale

2. Niveau d’huile correct

3. Boulon de l’orifice de remplissage du carter de transmission finale

1. Aceite de la transmisión final

2. Nivel de aceite exacto

3. Perno del orificio de llenado de aceite de la transmisión final

EBU11453

Final gear oil

Checking the final gear oil

1. Place the ATV on a level surface.

2. Remove the oil filler bolt, and then check the

oil level in the final gear case.NOTE:_ The oil level should be at the brim of the filler hole. _3. If the oil is below the brim of the filler hole,

add sufficient oil of the recommended type to

raise it to the correct level.CAUTION:_ Be sure no foreign material enters the final

gear case. _4. Install the oil filler bolt, and then tighten it to

the specified torque.

Tightening torque:

Final gear oil filler bolt:

23 Nm (2.3 m·kgf)

EE.book Page 31 Friday, May 27, 2005 5:00 PM

Page 286 of 396

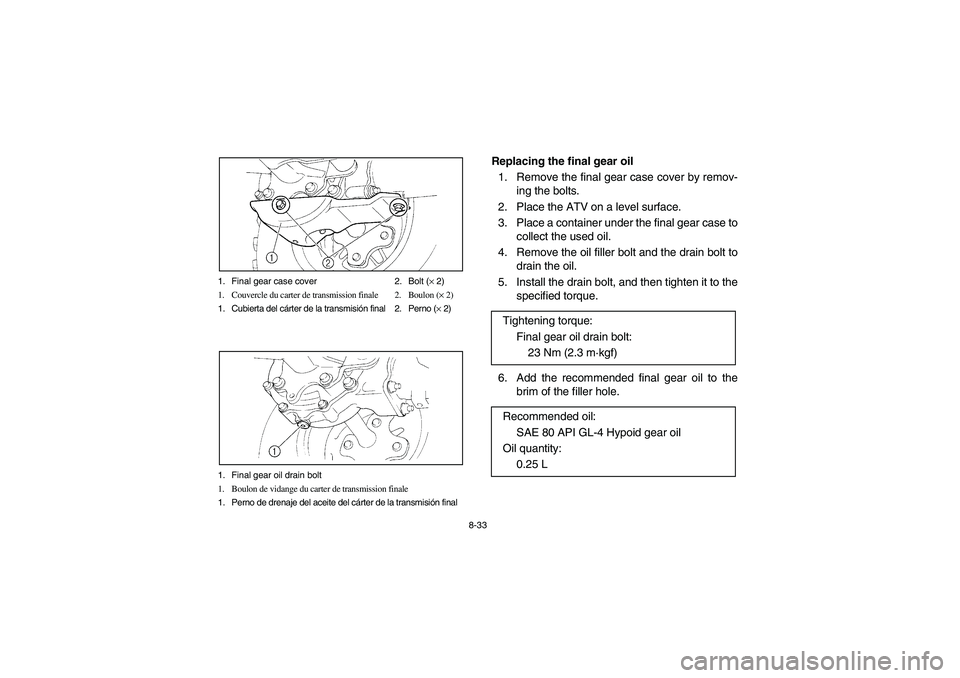

8-33 1. Final gear case cover 2. Bolt (× 2)

1. Couvercle du carter de transmission finale 2. Boulon (× 2)

1. Cubierta del cárter de la transmisión final 2. Perno (× 2)

1. Final gear oil drain bolt

1. Boulon de vidange du carter de transmission finale

1. Perno de drenaje del aceite del cárter de la transmisión final

Replacing the final gear oil

1. Remove the final gear case cover by remov-

ing the bolts.

2. Place the ATV on a level surface.

3. Place a container under the final gear case to

collect the used oil.

4. Remove the oil filler bolt and the drain bolt to

drain the oil.

5. Install the drain bolt, and then tighten it to the

specified torque.

6. Add the recommended final gear oil to the

brim of the filler hole. Tightening torque:

Final gear oil drain bolt:

23 Nm (2.3 m·kgf)

Recommended oil:

SAE 80 API GL-4 Hypoid gear oil

Oil quantity:

0.25 L

EE.book Page 33 Friday, May 27, 2005 5:00 PM

Page 288 of 396

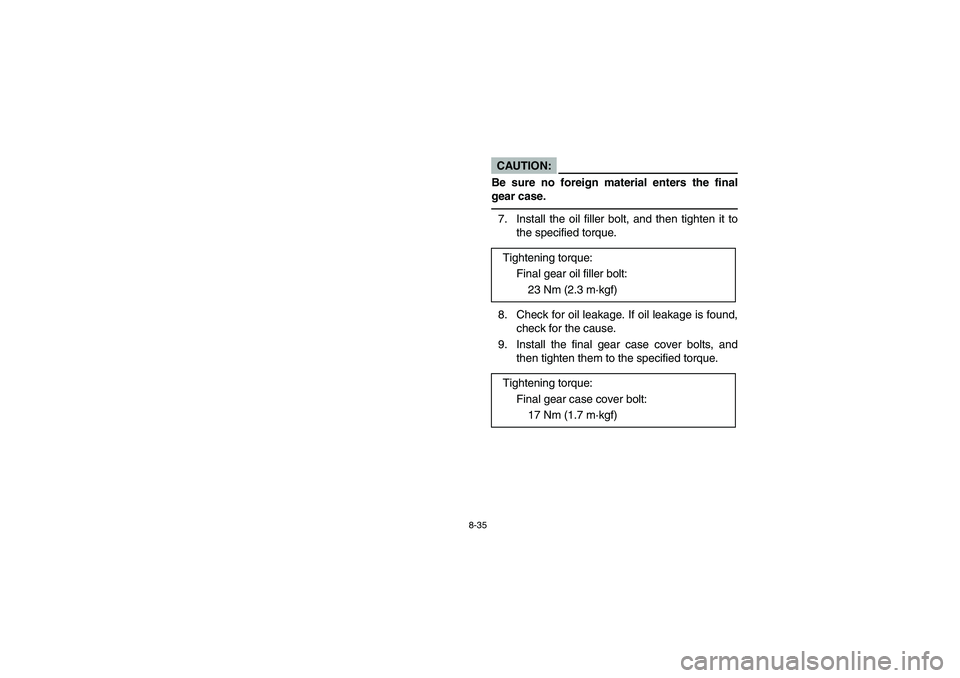

8-35

_CAUTION:

Be sure no foreign material enters the final

gear case. _7. Install the oil filler bolt, and then tighten it to

the specified torque.

8. Check for oil leakage. If oil leakage is found,

check for the cause.

9. Install the final gear case cover bolts, and

then tighten them to the specified torque. Tightening torque:

Final gear oil filler bolt:

23 Nm (2.3 m·kgf)

Tightening torque:

Final gear case cover bolt:

17 Nm (1.7 m·kgf)

EE.book Page 35 Friday, May 27, 2005 5:00 PM

Page 292 of 396

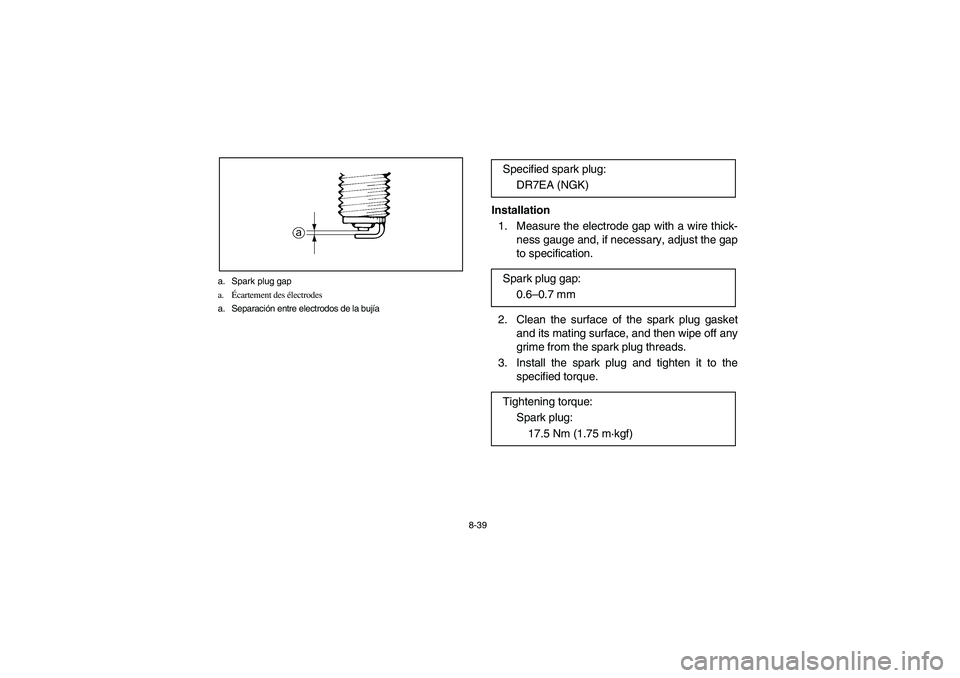

8-39 a. Spark plug gap

a.Écartement des électrodes

a. Separación entre electrodos de la bujía

Installation

1. Measure the electrode gap with a wire thick-

ness gauge and, if necessary, adjust the gap

to specification.

2. Clean the surface of the spark plug gasket

and its mating surface, and then wipe off any

grime from the spark plug threads.

3. Install the spark plug and tighten it to the

specified torque. Specified spark plug:

DR7EA (NGK)

Spark plug gap:

0.6–0.7 mm

Tightening torque:

Spark plug:

17.5 Nm (1.75 m·kgf)

EE.book Page 39 Friday, May 27, 2005 5:00 PM

Page 294 of 396

8-41

NOTE:_ If a torque wrench is not available when you are in-

stalling a spark plug, a good estimate of the correct

torque is 1/4 to 1/2 turn past finger tight. Have the

spark plug tightened to the specified torque as

soon as possible. _4. Install the spark plug cap.

EE.book Page 41 Friday, May 27, 2005 5:00 PM

Page 328 of 396

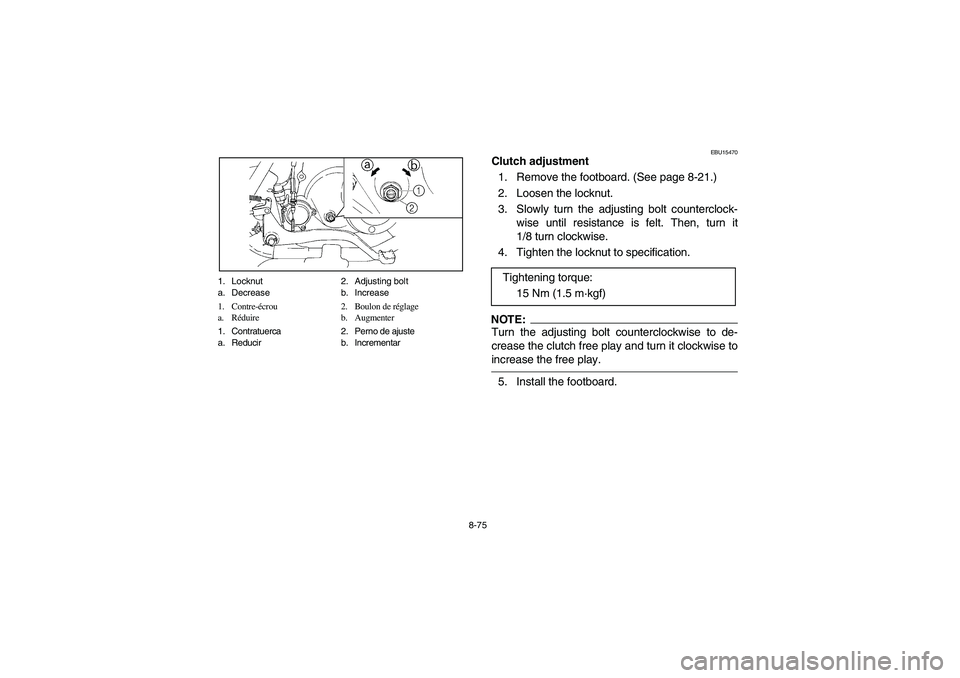

8-75 1. Locknut 2. Adjusting bolt

a. Decrease b. Increase

1. Contre-écrou 2. Boulon de réglage

a. Réduire b. Augmenter

1. Contratuerca 2. Perno de ajuste

a. Reducir b. Incrementar

EBU15470

Clutch adjustment

1. Remove the footboard. (See page 8-21.)

2. Loosen the locknut.

3. Slowly turn the adjusting bolt counterclock-

wise until resistance is felt. Then, turn it

1/8 turn clockwise.

4. Tighten the locknut to specification.NOTE:_ Turn the adjusting bolt counterclockwise to de-

crease the clutch free play and turn it clockwise to

increase the free play. _5. Install the footboard. Tightening torque:

15 Nm (1.5 m·kgf)

EE.book Page 75 Friday, May 27, 2005 5:00 PM