maintenance YAMAHA CYGNUS L 2012 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2012, Model line: CYGNUS L, Model: YAMAHA CYGNUS L 2012Pages: 76, PDF Size: 1.56 MB

Page 6 of 76

TABLE OF CONTENTSSAFETY INFORMATION ..................1-1

Further safe-riding points ................1-5

DESCRIPTION ..................................2-1

Left view ..........................................2-1

Right view ........................................2-2

Controls and instruments.................2-3

INSTRUMENT AND CONTROL

FUNCTIONS.......................................3-1

Main switch/steering lock ................3-1

Keyhole cover .................................3-2

Indicator lights and warning light ....3-2

Speedometer unit ...........................3-3

Self-diagnosis device ......................3-3

Fuel gauge ......................................3-4

Handlebar switches ........................3-4

Front brake lever ............................3-5

Rear brake lever .............................3-5

Fuel tank cap ..................................3-5

Fuel .................................................3-6

Catalytic converters ........................3-7

Kickstarter .......................................3-8

Seat ................................................3-8

Helmet holders ...............................3-9

Storage compartments ...................3-9

Carrier ...........................................3-11

Luggage hook ...............................3-11

Grab bar .......................................3-11

Sidestand ......................................3-12

Ignition circuit cut-off system ........3-12FOR YOUR SAFETY –

PRE-OPERATION CHECKS............. 4-1

OPERATION AND IMPORTANT

RIDING POINTS................................. 5-1

Starting the engine ......................... 5-1

Starting off ...................................... 5-2

Acceleration and deceleration ........ 5-2

Braking ........................................... 5-2

Tips for reducing fuel

consumption ............................... 5-3

Engine break-in .............................. 5-3

Parking ........................................... 5-4

PERIODIC MAINTENANCE AND

ADJUSTMENT................................... 6-1

Periodic maintenance chart for

the emission control system ....... 6-3

General maintenance and

lubrication chart .......................... 6-4

Removing and installing cowlings

and panels .................................. 6-7

Checking the spark plug ................. 6-9

Engine oil ..................................... 6-10

Final transmission oil .................... 6-12

Air filter and V-belt case air filter

elements ................................... 6-13

Checking the engine idling

speed ........................................ 6-15

Checking the throttle grip free

play ........................................... 6-15Valve clearance ........................... 6-15

Tires ............................................. 6-16

Cast wheels ................................. 6-17

Checking the front brake lever

free play .................................... 6-18

Adjusting the rear brake lever

free play .................................... 6-18

Checking the front brake pads

and rear brake shoes ............... 6-19

Checking the brake fluid level ...... 6-20

Changing the brake fluid .............. 6-21

Checking and lubricating

the cables ................................. 6-21

Checking and lubricating

the throttle grip and cable ......... 6-21

Lubricating the front and

rear brake levers ...................... 6-22

Checking and lubricating the

centerstand and sidestand ....... 6-22

Checking the front fork ................. 6-23

Checking the steering .................. 6-24

Checking the wheel bearings ....... 6-24

Battery ......................................... 6-24

Replacing the fuse ....................... 6-26

Replacing the headlight bulb ....... 6-26

Replacing a front turn signal

light bulb ................................... 6-27

Rear turn signal light and

tail/brake light ........................... 6-28

Replacing the auxiliary light

bulb ........................................... 6-28U1RSE0E0.book Page 1 Tuesday, October 18, 2011 8:56 AM

Page 23 of 76

INSTRUMENT AND CONTROL FUNCTIONS

3-7

3 ately. If gasoline spills on your skin,

wash with soap and water. If gaso-

line spills on your clothing, change

your clothes.

EAU33522

NOTICE

ECA11400

Use only unleaded gasoline. The use

of leaded gasoline will cause severe

damage to internal engine parts,

such as the valves and piston rings,

as well as to the exhaust system.Your Yamaha engine has been de-

signed to use regular unleaded gaso-

line with a research octane number of

95 or higher. If knocking (or pinging) oc-

curs, use a gasoline of a different brand

or premium unleaded fuel. Use of un-

leaded fuel will extend spark plug life

and reduce maintenance costs.

EAU13445

Catalytic converters This vehicle is equipped with catalytic

converters in the exhaust system.

WARNING

EWA10862

The exhaust system is hot after op-

eration. To prevent a fire hazard or

burns:●

Do not park the vehicle near

possible fire hazards such as

grass or other materials that

easily burn.

●

Park the vehicle in a place

where pedestrians or children

are not likely to touch the hot

exhaust system.

●

Make sure that the exhaust sys-

tem has cooled down before do-

ing any maintenance work.

●

Do not allow the engine to idle

more than a few minutes. Long

idling can cause a build-up of

heat.

NOTICE

ECA10701

Use only unleaded gasoline. The use

of leaded gasoline will cause unre-

pairable damage to the catalytic

converter.

Recommended fuel:

Regular unleaded gasoline only

Fuel tank capacity:

5.0 L (1.32 US gal, 1.10 Imp.gal)

U1RSE0E0.book Page 7 Tuesday, October 18, 2011 8:56 AM

Page 30 of 76

FOR YOUR SAFETY – PRE-OPERATION CHECKS

4-1

4

EAU15596

Inspect your vehicle each time you use it to make sure the vehicle is in safe operating condition. Always follow the inspection

and maintenance procedures and schedules described in the Owner’s Manual.

WARNING

EWA11151

Failure to inspect or maintain the vehicle properly increases the possibility of an accident or equipment damage.

Do not operate the vehicle if you find any problem. If a problem cannot be corrected by the procedures provided in

this manual, have the vehicle inspected by a Yamaha dealer.Before using this vehicle, check the following points:

ITEM CHECKS PAGE

Fuel Check fuel level in fuel tank.

Refuel if necessary.

Check fuel line for leakage.3-6

Engine oil Check oil level in engine.

If necessary, add recommended oil to specified level.

Check vehicle for oil leakage.6-10

Final transmission oil Check vehicle for oil leakage. 6-12

Front brake Check operation.

If soft or spongy, have Yamaha dealer bleed hydraulic system.

Check brake pads for wear.

Replace if necessary.

Check fluid level in reservoir.

If necessary, add specified brake fluid to specified level.

Check hydraulic system for leakage.6-19, 6-20

Rear brake Check operation.

Lubricate cable if necessary.

Check lever free play.

Adjust if necessary.6-18, 6-19

U1RSE0E0.book Page 1 Tuesday, October 18, 2011 8:56 AM

Page 36 of 76

PERIODIC MAINTENANCE AND ADJUSTMENT

6-1

6

EAUS1823

Periodic inspection, adjustment, and lu-

brication will keep your vehicle in the

safest and most efficient condition pos-

sible. Safety is an obligation of the vehi-

cle owner/operator. The most important

points of vehicle inspection, adjust-

ment, and lubrication are explained on

the following pages.

The intervals given in the periodic

maintenance charts should be simply

considered as a general guide under

normal riding conditions. However, de-

pending on the weather, terrain, geo-

graphical location, and individual use,

the maintenance intervals may need to

be shortened.

WARNING

EWA10321

Failure to properly maintain the ve-

hicle or performing maintenance ac-

tivities incorrectly may increase

your risk of injury or death during

service or while using the vehicle. If

you are not familiar with vehicle ser-

vice, have a Yamaha dealer perform

service.

WARNING

EWA15122

Turn off the engine when performing

maintenance unless otherwise

specified.●

A running engine has moving

parts that can catch on body

parts or clothing and electrical

parts that can cause shocks or

fires.

●

Running the engine while ser-

vicing can lead to eye injury,

burns, fire, or carbon monoxide

poisoning – possibly leading to

death. See page 1-2 for more in-

formation about carbon monox-

ide.WARNING

EWA10330

This scooter is designed for use on

paved roads only. If this scooter is

operated in abnormally dusty, mud-

dy or wet conditions, the air filter el-

ement should be cleaned or

replaced more frequently, otherwise

rapid engine wear may result. Con-

sult a Yamaha dealer for proper

maintenance intervals.

WARNING

EWA15460

Brake discs, calipers, drums, and

linings can become very hot during

use. To avoid possible burns, let

brake components cool before

touching them.

U1RSE0E0.book Page 1 Tuesday, October 18, 2011 8:56 AM

Page 37 of 76

PERIODIC MAINTENANCE AND ADJUSTMENT

6-2

6

EAU17302

Emission controls not only function to

ensure cleaner air, but are also vital to

proper engine operation and maximum

performance. In the following periodic

maintenance charts, the services relat-

ed to emissions control are grouped

separately. These services require

specialized data, knowledge, and

equipment. Maintenance, replacement,

or repair of the emission control devic-

es and systems may be performed by

any repair establishment or individual

that is certified (if applicable). Yamaha

dealers are trained and equipped to

perform these particular services.

U1RSE0E0.book Page 2 Tuesday, October 18, 2011 8:56 AM

Page 38 of 76

PERIODIC MAINTENANCE AND ADJUSTMENT

6-3

6

EAU46871

TIP●

The annual checks must be performed every year, except if a kilometer-based maintenance, or for the UK, a

mileage-based maintenance, is performed instead.

●

From 30000 km (17500 mi), repeat the maintenance intervals starting from 6000 km (3500 mi).

●

Items marked with an asterisk should be performed by a Yamaha dealer as they require special tools, data and technical

skills.

EAU46920

Periodic maintenance chart for the emission control system NO. ITEM CHECK OR MAINTENANCE JOBODOMETER READING

ANNUAL

CHECK 1000 km

(600 mi)6000 km

(3500 mi)12000 km

(7000 mi)18000 km

(10500 mi)24000 km

(14000 mi)

1*Fuel line Check fuel and vacuum hoses for

cracks or damage.√√√√√

2*Fuel cock filter Check condition.√√

3 Spark plug Check condition.

Clean and regap.√√

Replace.√√

4*Valves Check valve clearance.

Adjust.√√√√

5*Air induction sys-

tem Check the air cut-off valve, reed

valve, and hose for damage.

Replace any damaged parts if

necessary.√√√√√

U1RSE0E0.book Page 3 Tuesday, October 18, 2011 8:56 AM

Page 39 of 76

PERIODIC MAINTENANCE AND ADJUSTMENT

6-4

6

EAU17717

General maintenance and lubrication chart NO. ITEM CHECK OR MAINTENANCE JOBODOMETER READING

ANNUAL

CHECK 1000 km

(600 mi)6000 km

(3500 mi)12000 km

(7000 mi)18000 km

(10500 mi)24000 km

(14000 mi)

1 Air filter element Replace.√√

2V-belt case air filter

element Clean.√√√√

3*Front brake Check operation, fluid level and

vehicle for fluid leakage.√√√√√√

Replace brake pads. Whenever worn to the limit

4*Rear brake Check operation and adjust brake

lever free play.√√√√√√

Replace brake shoes. Whenever worn to the limit

5*Brake hose Check for cracks or damage.

Check for correct routing and

clamping.√√√√√

Replace. Every 4 years

6*Wheels Check runout and for damage.√√√√

7*Tires Check tread depth and for dam-

age.

Replace if necessary.

Check air pressure.

Correct if necessary.√√√√√

8*Wheel bearings Check bearing for looseness or

damage.√√√√

U1RSE0E0.book Page 4 Tuesday, October 18, 2011 8:56 AM

Page 40 of 76

PERIODIC MAINTENANCE AND ADJUSTMENT

6-5

6

9*Steering bearings Check bearing play and steering

for roughness.√√√√√

Lubricate with lithium-soap-based

grease.Every 24000 km (14000 mi)

10*Chassis fasteners Make sure that all nuts, bolts and

screws are properly tightened.√√√√√

11Front brake lever

pivot shaft Lubricate with silicone grease.√√√√√

12Rear brake lever

pivot shaft Lubricate with lithium-soap-based

grease.√√√√√

13Sidestand, center-

stand Check operation.

Lubricate with lithium-soap-based

grease.√√√√√

14*Sidestand switch Check operation.√√√√√√

15*Front fork Check operation and for oil leak-

age.√√√√

16*Shock absorber as-

sembly Check operation and shock ab-

sorber for oil leakage.√√√√

17 Engine oil Change. (See page 6-10.)

Check oil level and vehicle for oil

leakage.√Every 2000 km (1200 mi)

18*Engine oil strainer Clean.√

19Final transmission

oil Check vehicle for oil leakage.

Change.√√√√√√

20*V- b e l t Replace. Every 12000 km (7000 mi) NO. ITEM CHECK OR MAINTENANCE JOBODOMETER READING

ANNUAL

CHECK 1000 km

(600 mi)6000 km

(3500 mi)12000 km

(7000 mi)18000 km

(10500 mi)24000 km

(14000 mi)

U1RSE0E0.book Page 5 Tuesday, October 18, 2011 8:56 AM

Page 41 of 76

PERIODIC MAINTENANCE AND ADJUSTMENT

6-6

6

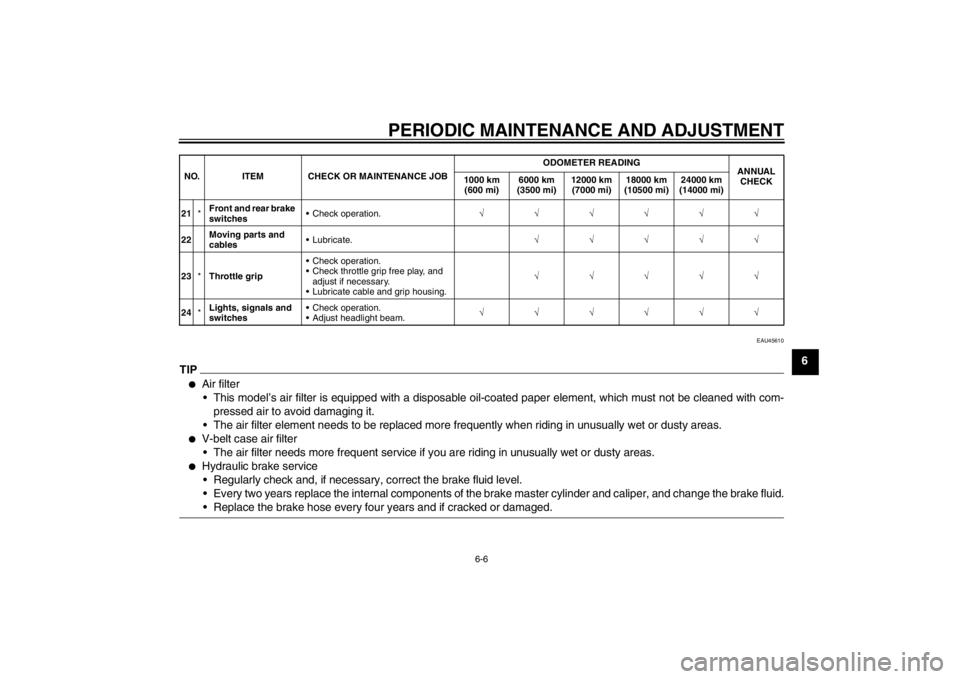

EAU45610

TIP●

Air filter

This model’s air filter is equipped with a disposable oil-coated paper element, which must not be cleaned with com-

pressed air to avoid damaging it.

The air filter element needs to be replaced more frequently when riding in unusually wet or dusty areas.

●

V-belt case air filter

The air filter needs more frequent service if you are riding in unusually wet or dusty areas.

●

Hydraulic brake service

Regularly check and, if necessary, correct the brake fluid level.

Every two years replace the internal components of the brake master cylinder and caliper, and change the brake fluid.

Replace the brake hose every four years and if cracked or damaged.

21*Front and rear brake

switches Check operation.√√√√√√

22Moving parts and

cables Lubricate.√√√√√

23*Throttle grip Check operation.

Check throttle grip free play, and

adjust if necessary.

Lubricate cable and grip housing.√√√√√

24*Lights, signals and

switches Check operation.

Adjust headlight beam.√√√√√√ NO. ITEM CHECK OR MAINTENANCE JOBODOMETER READING

ANNUAL

CHECK 1000 km

(600 mi)6000 km

(3500 mi)12000 km

(7000 mi)18000 km

(10500 mi)24000 km

(14000 mi)

U1RSE0E0.book Page 6 Tuesday, October 18, 2011 8:56 AM

Page 42 of 76

PERIODIC MAINTENANCE AND ADJUSTMENT

6-7

6

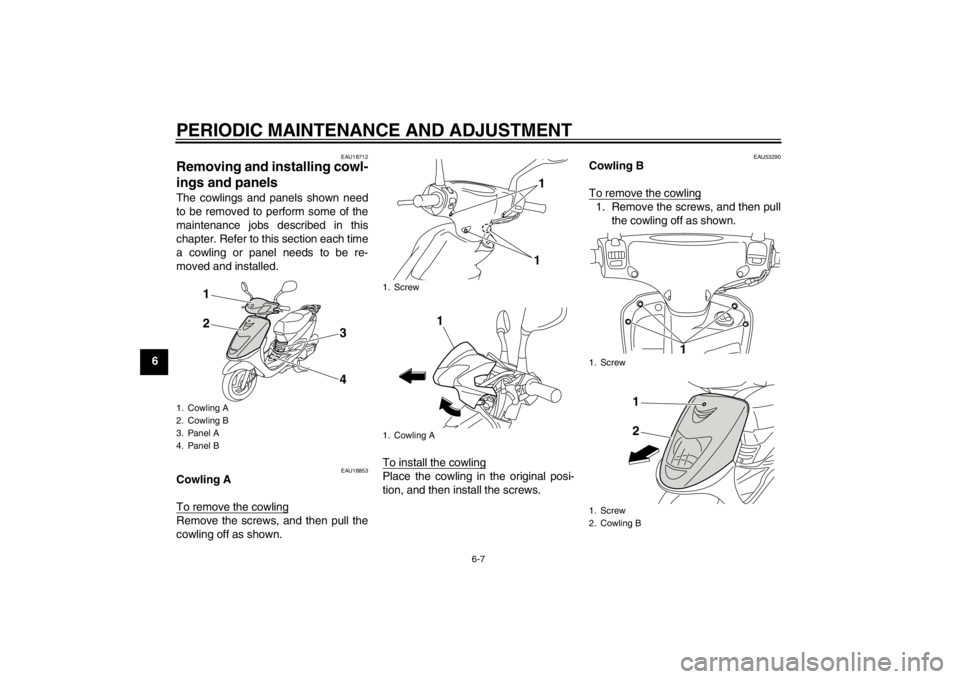

EAU18712

Removing and installing cowl-

ings and panels The cowlings and panels shown need

to be removed to perform some of the

maintenance jobs described in this

chapter. Refer to this section each time

a cowling or panel needs to be re-

moved and installed.

EAU18853

Cowling A

To remove the cowlingRemove the screws, and then pull the

cowling off as shown.To install the cowling

Place the cowling in the original posi-

tion, and then install the screws.

EAU53290

Cowling B

To remove the cowling1. Remove the screws, and then pull

the cowling off as shown.

1. Cowling A

2. Cowling B

3. Panel A

4. Panel B

12

34

1. Screw

1. Cowling A

11

1

1. Screw

1. Screw

2. Cowling B

1

12

U1RSE0E0.book Page 7 Tuesday, October 18, 2011 8:56 AM