engine YAMAHA EX LIMITED 2021 Owner's Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2021, Model line: EX LIMITED, Model: YAMAHA EX LIMITED 2021Pages: 102, PDF Size: 4.72 MB

Page 54 of 102

Operation and handling requirements

47

(9) Repeat steps 6–8 until the engine oil is atthe proper level.

(10) Securely install the oil tank filler cap and turn it until it stops.

(11) Securely install the seat storage com- partment and seat in their original posi-

tions.EJU40022

Draining the bilge waterECJ01302

Do not run the engine at full throttle when

bilge water remains in the engine com-

partment. The bilge water can splash into

the engine, which can result in severe

damage.

EJU44260Draining the bilge water on land

To drain the bilge water on land:

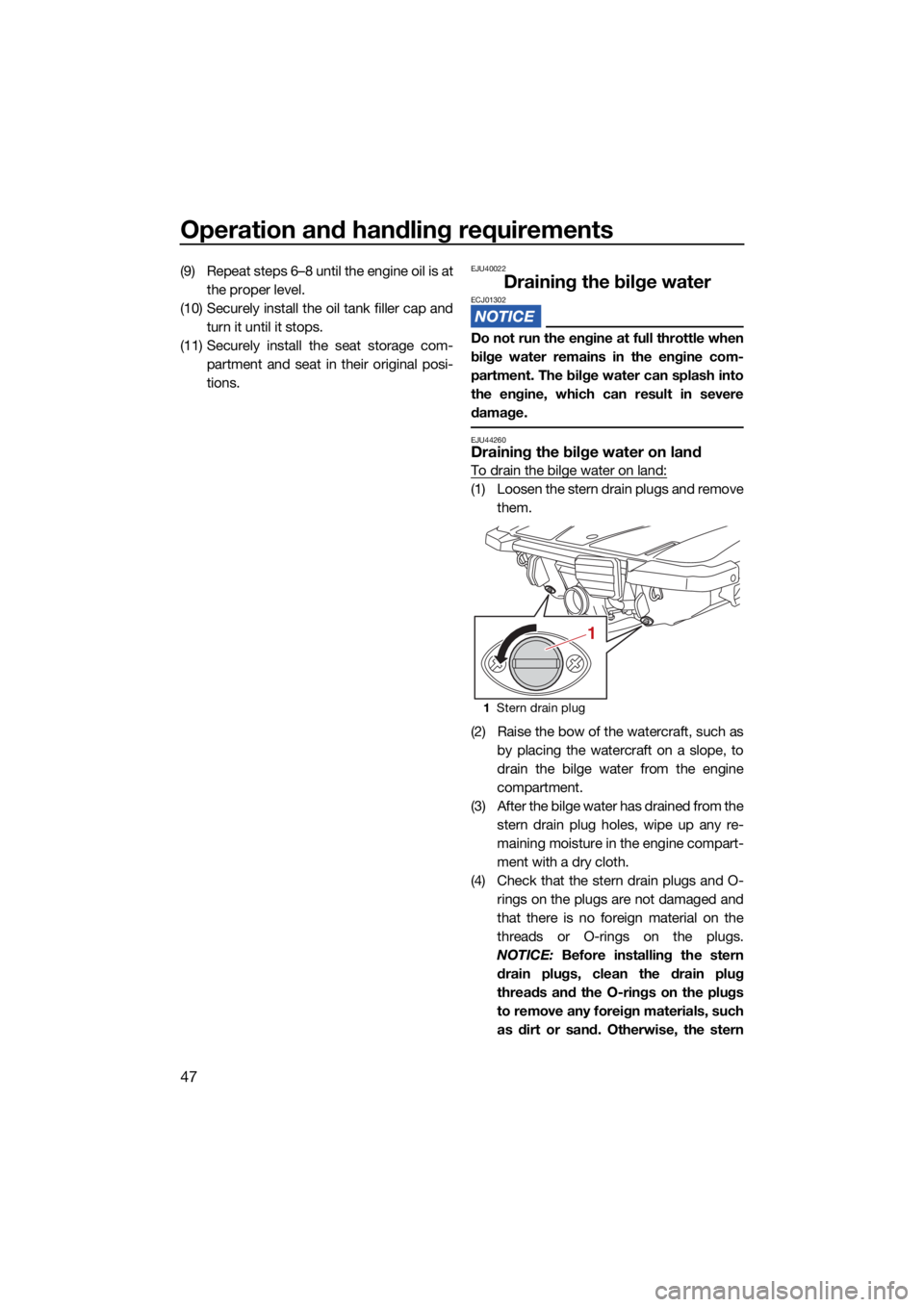

(1) Loosen the stern drain plugs and removethem.

(2) Raise the bow of the watercraft, such as by placing the watercraft on a slope, to

drain the bilge water from the engine

compartment.

(3) After the bilge water has drained from the stern drain plug holes, wipe up any re-

maining moisture in the engine compart-

ment with a dry cloth.

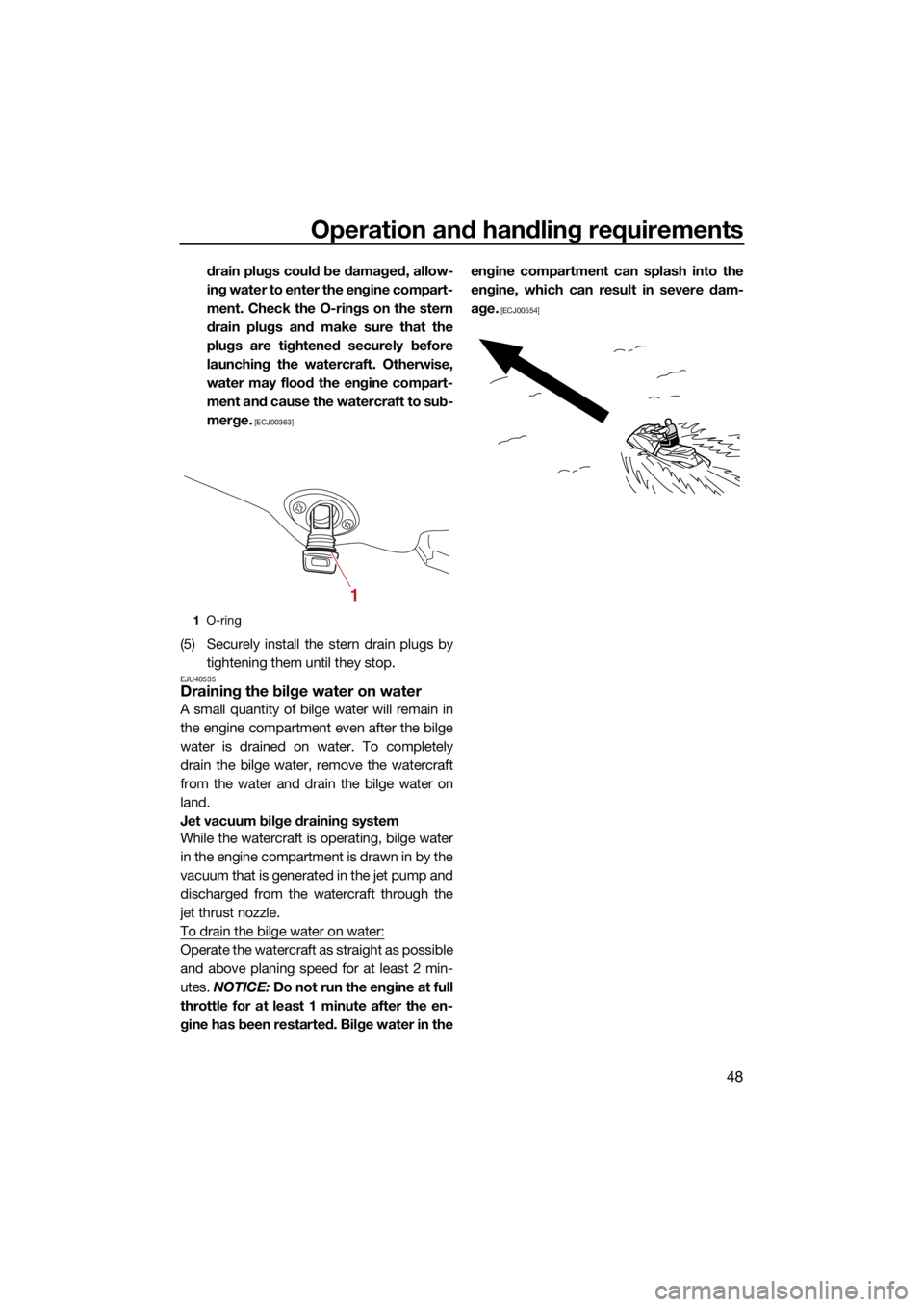

(4) Check that the stern drain plugs and O- rings on the plugs are not damaged and

that there is no foreign material on the

threads or O-rings on the plugs.

NOTICE: Before installing the stern

drain plugs, clean the drain plug

threads and the O-rings on the plugs

to remove any foreign materials, such

as dirt or sand. Otherwise, the stern

1 Stern drain plug

1

UF3Y74E0.book Page 47 Monday, June 22, 2020 5:11 PM

Page 55 of 102

Operation and handling requirements

48

drain plugs could be damaged, allow-

ing water to enter the engine compart-

ment. Check the O-rings on the stern

drain plugs and make sure that the

plugs are tightened securely before

launching the watercraft. Otherwise,

water may flood the engine compart-

ment and cause the watercraft to sub-

merge.

[ECJ00363]

(5) Securely install the stern drain plugs bytightening them until they stop.

EJU40535Draining the bilge water on water

A small quantity of bilge water will remain in

the engine compartment even after the bilge

water is drained on water. To completely

drain the bilge water, remove the watercraft

from the water and drain the bilge water on

land.

Jet vacuum bilge draining system

While the watercraft is operating, bilge water

in the engine compartment is drawn in by the

vacuum that is generated in the jet pump and

discharged from the watercraft through the

jet thrust nozzle.

To drain the bilge water on water:

Operate the watercraft as straight as possible

and above planing speed for at least 2 min-

utes. NOTICE: Do not run the engine at full

throttle for at least 1 minute after the en-

gine has been restarted. Bilge water in the engine compartment can splash into the

engine, which can result in severe dam-

age.

[ECJ00554]

1

O-ring

1

UF3Y74E0.book Page 48 Monday, June 22, 2020 5:11 PM

Page 57 of 102

First-time operation

50

EJU32786

Engine break-inECJ00432

Failure to perform the engine break-in

could result in reduced engine life or even

severe engine damage.

The engine break-in is essential to allow the

various components of the engine to wear

and polish themselves to the correct operat-

ing clearances. This ensures proper perfor-

mance and promotes longer component life.

To perform the engine break-in:

(1) Check the engine oil level. (See page 45for information on checking the engine

oil level.)

(2) Launch the watercraft and start the en- gine. (See page 61 for information on

starting the engine.)

(3) For the first 5 minutes, operate with the engine at idling speed.

(4) For the next 30 minutes, operate with the engine speed below 5000 r/min.

(5) For the next 1 hour, operate with the en- gine speed below 6500 r/min.

After the engine break-in is complete, the wa-

tercraft can be operated normally.

UF3Y74E0.book Page 50 Monday, June 22, 2020 5:11 PM

Page 58 of 102

Pre-operation checks

51

EJU31982

EWJ00412

Failure to inspect or maintain the watercraft properly increases the possibility of an ac-

cident or damage to the watercraft. Do not operate the watercraft if you find any prob-

lem. If a problem cannot be corrected by the procedures provided in this manual, have

the watercraft inspected by a Yamaha dealer.

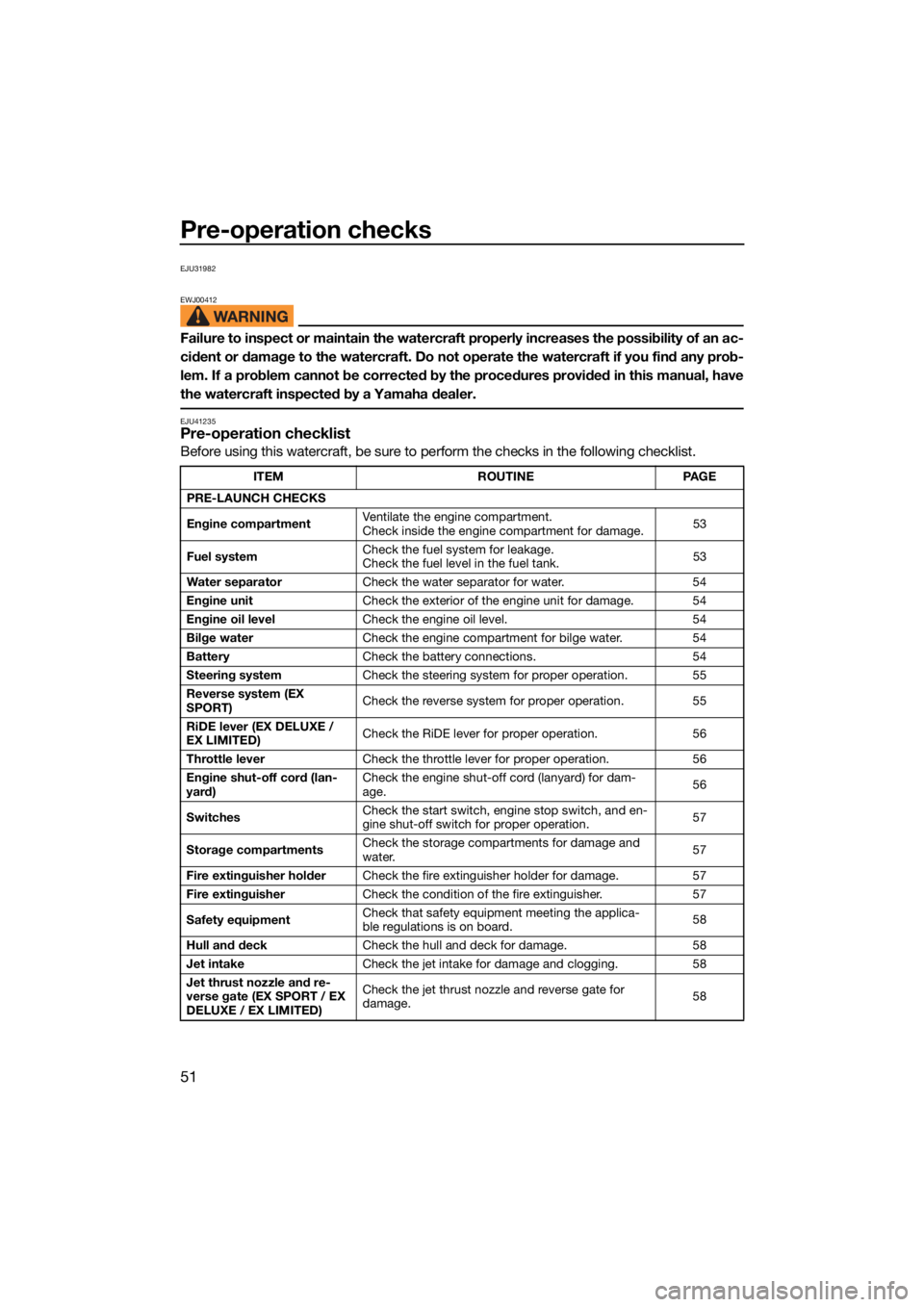

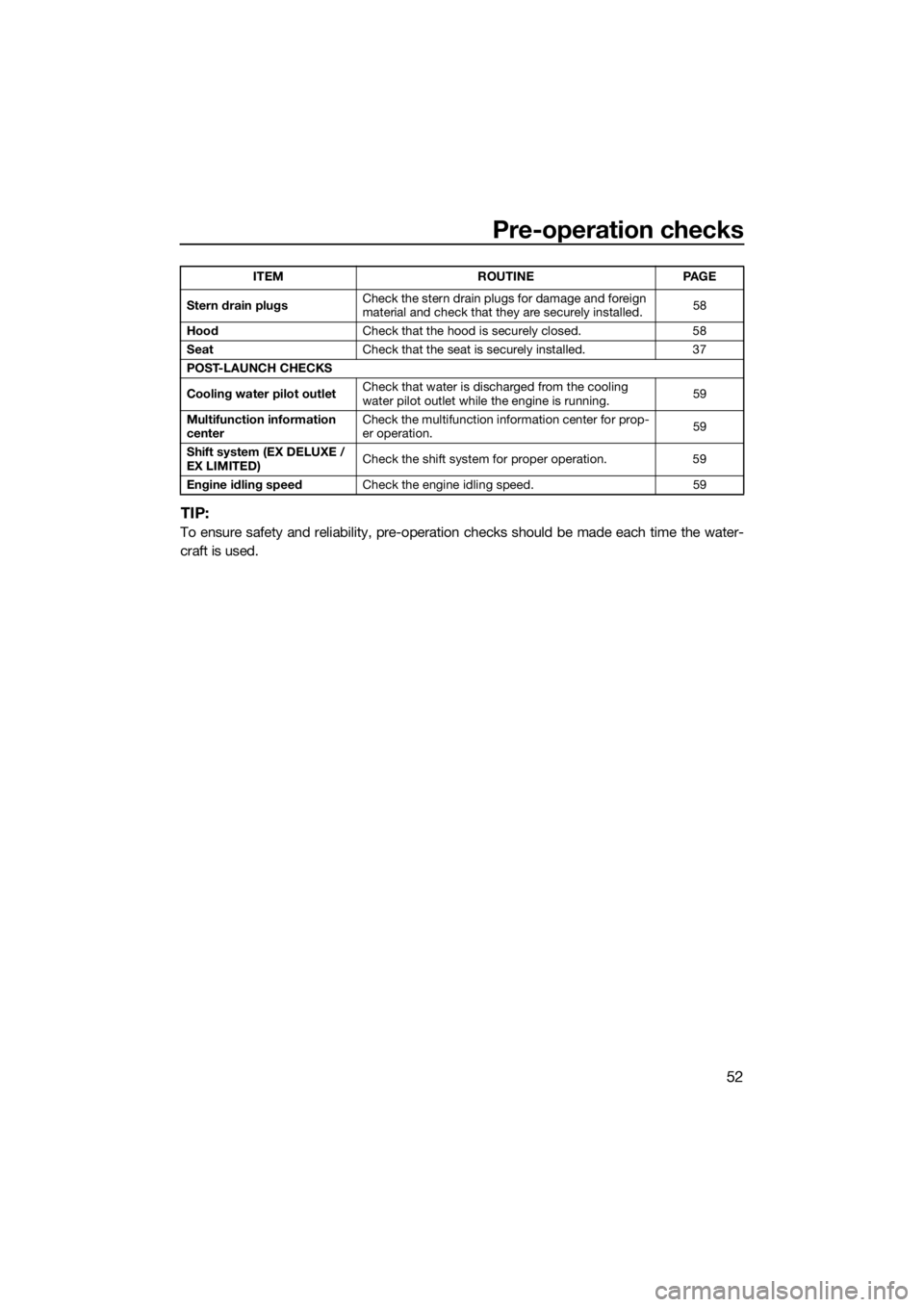

EJU41235Pre-operation checklist

Before using this watercraft, be sure to perform the checks in the following checklist.

ITEMROUTINEPAGE

PRE-LAUNCH CHECKS

Engine compartment Ventilate the engine compartment.

Check inside the engine compartment for damage.

53

Fuel system Check the fuel system for leakage.

Check the fuel level in the fuel tank.

53

Water separator Check the water separator for water. 54

Engine unit Check the exterior of the engine unit for damage. 54

Engine oil level Check the engine oil level. 54

Bilge water Check the engine compartment for bilge water. 54

Battery Check the battery connections. 54

Steering system Check the steering system for proper operation. 55

Reverse system (EX

SPORT) Check the reverse system for proper operation.

55

RiDE lever (EX DELUXE /

EX LIMITED) Check the RiDE lever for proper operation.

56

Throttle lever Check the throttle lever for proper operation. 56

Engine shut-off cord (lan-

yard) Check the engine shut-off cord (lanyard) for dam-

age.

56

Switches Check the start switch, engine stop switch, and en-

gine shut-off switch for proper operation.

57

Storage compartments Check the storage compartments for damage and

water.

57

Fire extinguisher holder Check the fire extinguisher holder for damage. 57

Fire extinguisher Check the condition of the fire extinguisher. 57

Safety equipment Check that safety equipment meeting the applica-

ble regulations is on board.

58

Hull and deck Check the hull and deck for damage. 58

Jet intake Check the jet intake for damage and clogging. 58

Jet thrust nozzle and re-

verse gate (EX SPORT / EX

DELUXE / EX LIMITED) Check the jet thrust nozzle and reverse gate for

damage.

58

UF3Y74E0.book Page 51 Monday, June 22, 2020 5:11 PM

Page 59 of 102

Pre-operation checks

52

TIP:

To ensure safety and reliability, pre-operation checks should be made each time the water-

craft is used.

Stern drain plugs Check the stern drain plugs for damage and foreign

material and check that they are securely installed.

58

Hood Check that the hood is securely closed. 58

Seat Check that the seat is securely installed. 37

POST-LAUNCH CHECKS

Cooling water pilot outlet Check that water is discharged from the cooling

water pilot outlet while the engine is running.

59

Multifunction information

center Check the multifunction information center for prop-

er operation.

59

Shift system (EX DELUXE /

EX LIMITED) Check the shift system for proper operation. 59

Engine idling speed Check the engine idling speed. 59

ITEM ROUTINE PAGE

UF3Y74E0.book Page 52 Monday, June 22, 2020 5:11 PM

Page 60 of 102

Pre-operation checks

53

EJU32282

Pre-operation check pointsEJU44551Pre-launch checks

Perform the pre-launch checks in the pre-op-

eration checklist while the watercraft is on

land.

To perform the pre-launch checks:

(1) Remove the seat, seat storage compart-ment, and fire extinguisher holder. (See

page 37 for seat removal and installation

procedures, page 41 for information on

the seat storage compartment, and page

42 for information on the fire extinguisher

holder.)

(2) Perform the checks and make sure that there are no malfunctioning items or oth-

er problems.

(3) After completing these checks, securely install the seat storage compartment, fire

extinguisher holder, and seat in their

original positions.

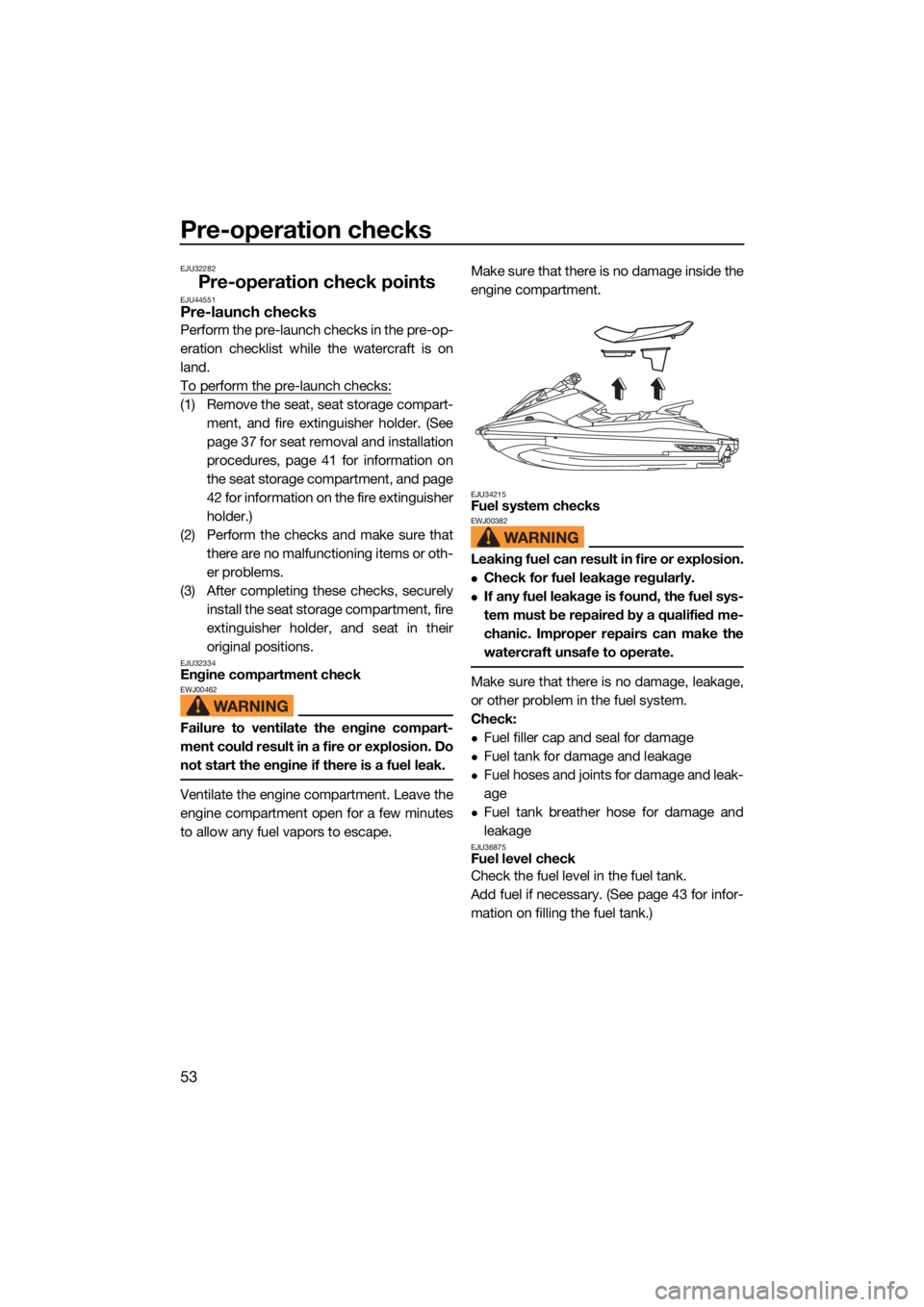

EJU32334Engine compartment checkEWJ00462

Failure to ventilate the engine compart-

ment could result in a fire or explosion. Do

not start the engine if there is a fuel leak.

Ventilate the engine compartment. Leave the

engine compartment open for a few minutes

to allow any fuel vapors to escape. Make sure that there is no damage inside the

engine compartment.

EJU34215Fuel system checksEWJ00382

Leaking fuel can result in fire or explosion.

Check for fuel leakage regularly.

If any fuel leakage is found, the fuel sys-

tem must be repaired by a qualified me-

chanic. Improper repairs can make the

watercraft unsafe to operate.

Make sure that there is no damage, leakage,

or other problem in the fuel system.

Check:

Fuel filler cap and seal for damage

Fuel tank for damage and leakage

Fuel hoses and joints for damage and leak-

age

Fuel tank breather hose for damage and

leakage

EJU36875Fuel level check

Check the fuel level in the fuel tank.

Add fuel if necessary. (See page 43 for infor-

mation on filling the fuel tank.)

UF3Y74E0.book Page 53 Monday, June 22, 2020 5:11 PM

Page 61 of 102

Pre-operation checks

54

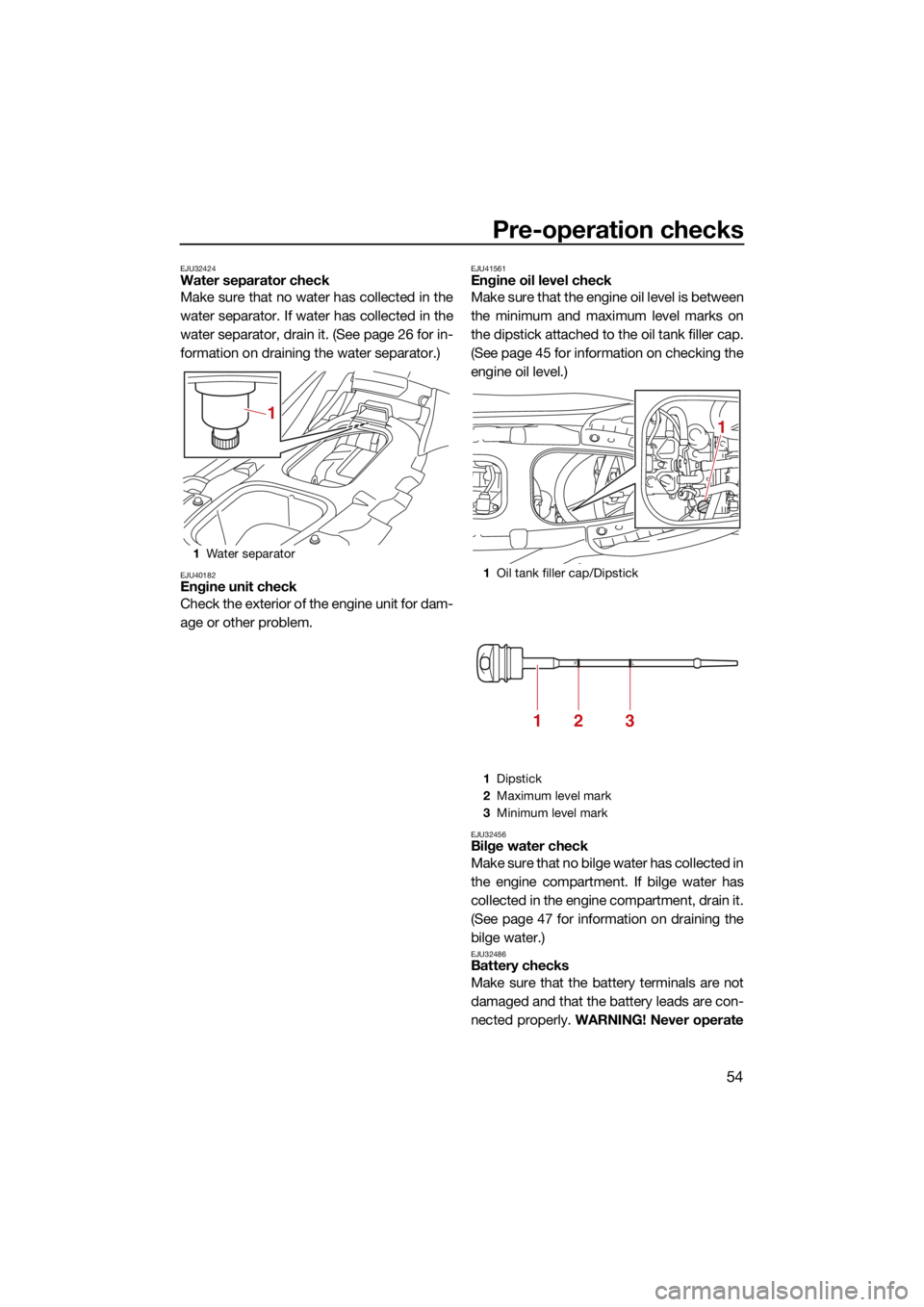

EJU32424Water separator check

Make sure that no water has collected in the

water separator. If water has collected in the

water separator, drain it. (See page 26 for in-

formation on draining the water separator.)

EJU40182Engine unit check

Check the exterior of the engine unit for dam-

age or other problem.

EJU41561Engine oil level check

Make sure that the engine oil level is between

the minimum and maximum level marks on

the dipstick attached to the oil tank filler cap.

(See page 45 for information on checking the

engine oil level.)

EJU32456Bilge water check

Make sure that no bilge water has collected in

the engine compartment. If bilge water has

collected in the engine compartment, drain it.

(See page 47 for information on draining the

bilge water.)

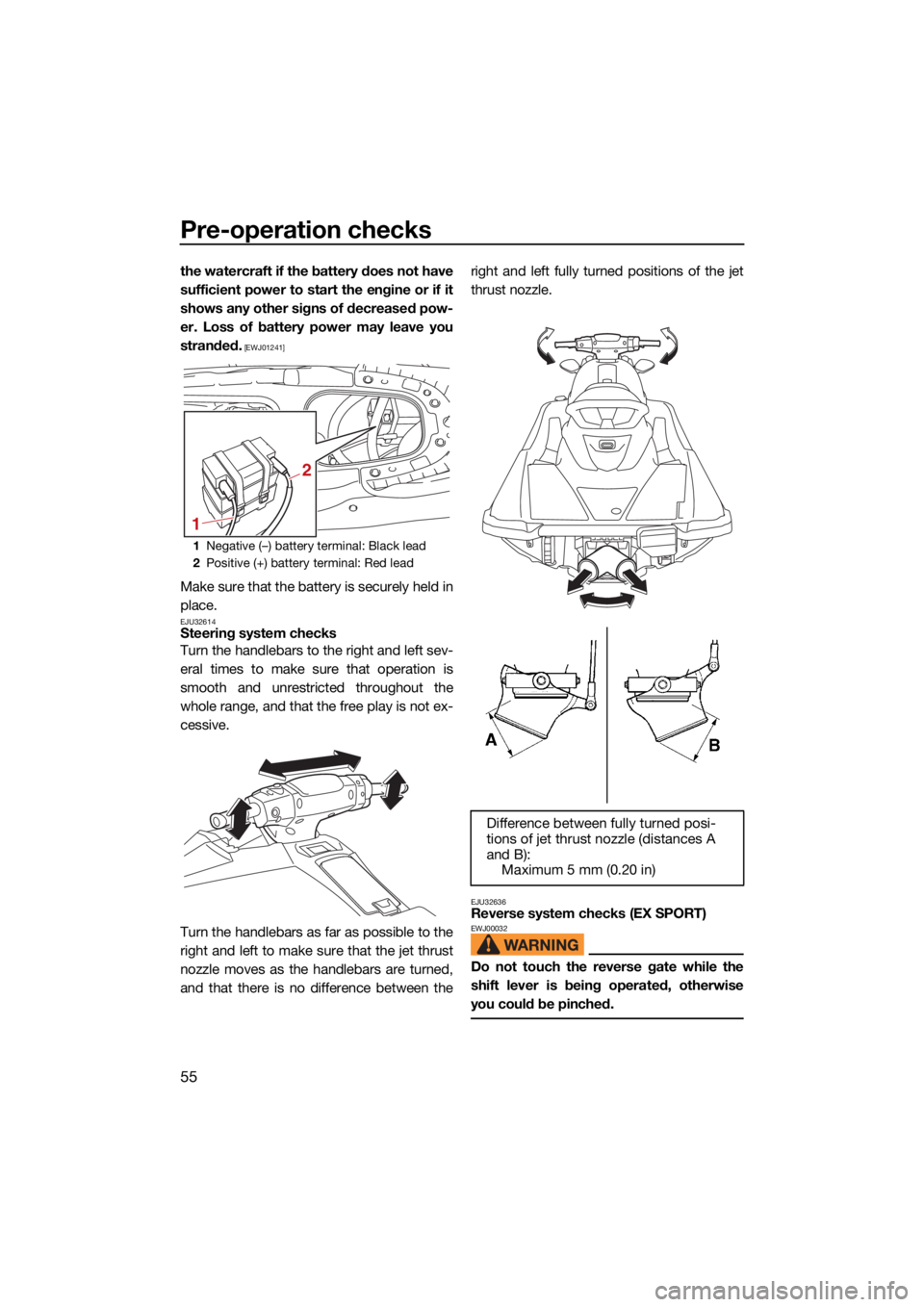

EJU32486Battery checks

Make sure that the battery terminals are not

damaged and that the battery leads are con-

nected properly. WARNING! Never operate

1Water separator

1

1Oil tank filler cap/Dipstick

1 Dipstick

2 Maximum level mark

3 Minimum level mark

1

213

UF3Y74E0.book Page 54 Monday, June 22, 2020 5:11 PM

Page 62 of 102

Pre-operation checks

55

the watercraft if the battery does not have

sufficient power to start the engine or if it

shows any other signs of decreased pow-

er. Loss of battery power may leave you

stranded.

[EWJ01241]

Make sure that the battery is securely held in

place.

EJU32614Steering system checks

Turn the handlebars to the right and left sev-

eral times to make sure that operation is

smooth and unrestricted throughout the

whole range, and that the free play is not ex-

cessive.

Turn the handlebars as far as possible to the

right and left to make sure that the jet thrust

nozzle moves as the handlebars are turned,

and that there is no difference between the right and left fully turned positions of the jet

thrust nozzle.

EJU32636Reverse system checks (EX SPORT)EWJ00032

Do not touch the reverse gate while the

shift lever is being operated, otherwise

you could be pinched.

1

Negative (–) battery terminal: Black lead

2 Positive (+) battery terminal: Red lead

1

2

Difference between fully turned posi-

tions of jet thrust nozzle (distances A

and B):

Maximum 5 mm (0.20 in)

UF3Y74E0.book Page 55 Monday, June 22, 2020 5:11 PM

Page 63 of 102

Pre-operation checks

56

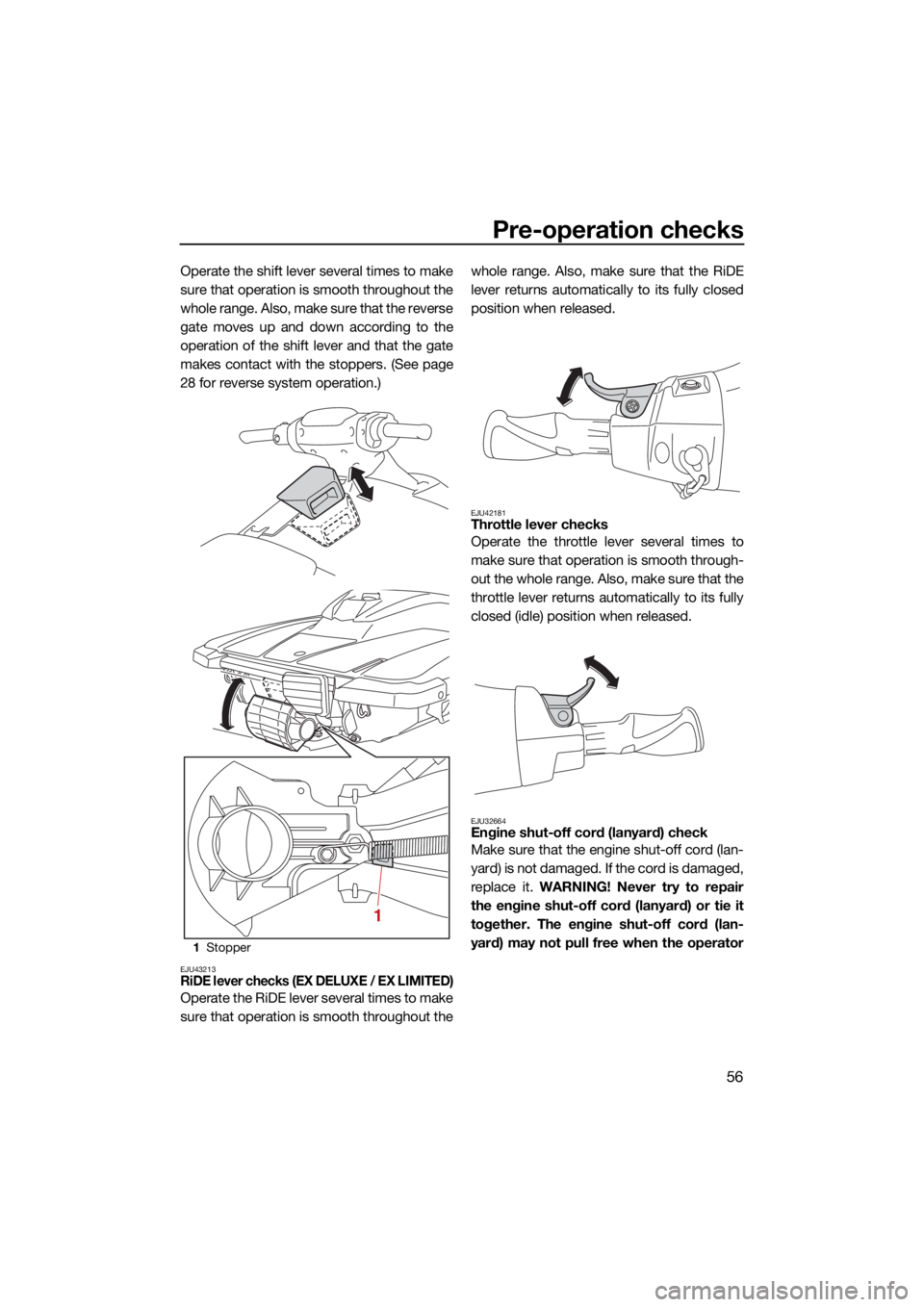

Operate the shift lever several times to make

sure that operation is smooth throughout the

whole range. Also, make sure that the reverse

gate moves up and down according to the

operation of the shift lever and that the gate

makes contact with the stoppers. (See page

28 for reverse system operation.)

EJU43213RiDE lever checks (EX DELUXE / EX LIMITED)

Operate the RiDE lever several times to make

sure that operation is smooth throughout thewhole range. Also, make sure that the RiDE

lever returns automatically to its fully closed

position when released.

EJU42181Throttle lever checks

Operate the throttle lever several times to

make sure that operation is smooth through-

out the whole range. Also, make sure that the

throttle lever returns automatically to its fully

closed (idle) position when released.

EJU32664Engine shut-off cord (lanyard) check

Make sure that the engine shut-off cord (lan-

yard) is not damaged. If the cord is damaged,

replace it.

WARNING! Never try to repair

the engine shut-off cord (lanyard) or tie it

together. The engine shut-off cord (lan-

yard) may not pull free when the operator

1 Stopper

1

UF3Y74E0.book Page 56 Monday, June 22, 2020 5:11 PM

Page 64 of 102

![YAMAHA EX LIMITED 2021 Owners Guide Pre-operation checks

57

falls off, allowing the watercraft to contin-

ue to run and cause an accident.

[EWJ01221]

EJU40692

Switch checksECJ01311

Do not run the engine over 4000 r/min on

land. Also, d YAMAHA EX LIMITED 2021 Owners Guide Pre-operation checks

57

falls off, allowing the watercraft to contin-

ue to run and cause an accident.

[EWJ01221]

EJU40692

Switch checksECJ01311

Do not run the engine over 4000 r/min on

land. Also, d](/img/51/49486/w960_49486-63.png)

Pre-operation checks

57

falls off, allowing the watercraft to contin-

ue to run and cause an accident.

[EWJ01221]

EJU40692

Switch checksECJ01311

Do not run the engine over 4000 r/min on

land. Also, do not run the engine for more

than 15 seconds without supplying water,

otherwise the engine could overheat.

Check the start switch, the engine stop

switch, and the engine shut-off switch for

proper operation. (See pages 24 to 24 for in-

formation on operating each switch.)

To check the operation of the switches:

(1) Push the start switch to make sure that the engine starts. (2) As soon as the engine starts running,

push the engine stop switch to make

sure that the engine stops immediately.

(3) Restart the engine, and then pull the en- gine shut-off cord (lanyard) to remove

the clip from the engine shut-off switch

to make sure that the engine stops im-

mediately.

EJU40102Storage compartment checks

Make sure that the storage compartments

are not damaged and that water has not col-

lected in the compartments. (See page 39 for

information on the storage compartments.)

EJU44670Fire extinguisher holder checks

Make sure that the fire extinguisher holder is

installed in the correct direction and is not

damaged. (See page 42 for information on

the fire extinguisher holder.)

EJU44630Fire extinguisher check

Check that there is a full fire extinguisher on

board.

To check the fire extinguisher, see the in-

structions supplied by the fire extinguisher

manufacturer. Always keep the fire extin-

guisher stored in the holder.

Always carry a fire extinguisher on board. A

fire extinguisher is not standard equipment

with this watercraft. If you do not have one,

contact a Yamaha dealer or a fire extinguish-

1Start switch

2 Engine stop switch

3 Engine shut-off switch

4 Clip

5 Engine shut-off cord (lanyard)

1

3

4

25

UF3Y74E0.book Page 57 Monday, June 22, 2020 5:11 PM