battery YAMAHA FX HO CRUISER 2021 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2021, Model line: FX HO CRUISER, Model: YAMAHA FX HO CRUISER 2021Pages: 116, PDF Size: 4.91 MB

Page 95 of 116

Care and storage

88

egg, or vegetable oil. Call a physician im-

mediately.

Eyes: Flush with water for 15 minutes and

get prompt medical attention.

Batteries produce explosive gases. Keep

sparks, flames, cigarettes, etc., well away.

If using or charging the battery in an en-

closed space, make sure that it is well

ventilated. Always shield your eyes when

working near batteries.

Keep out of the reach of children.

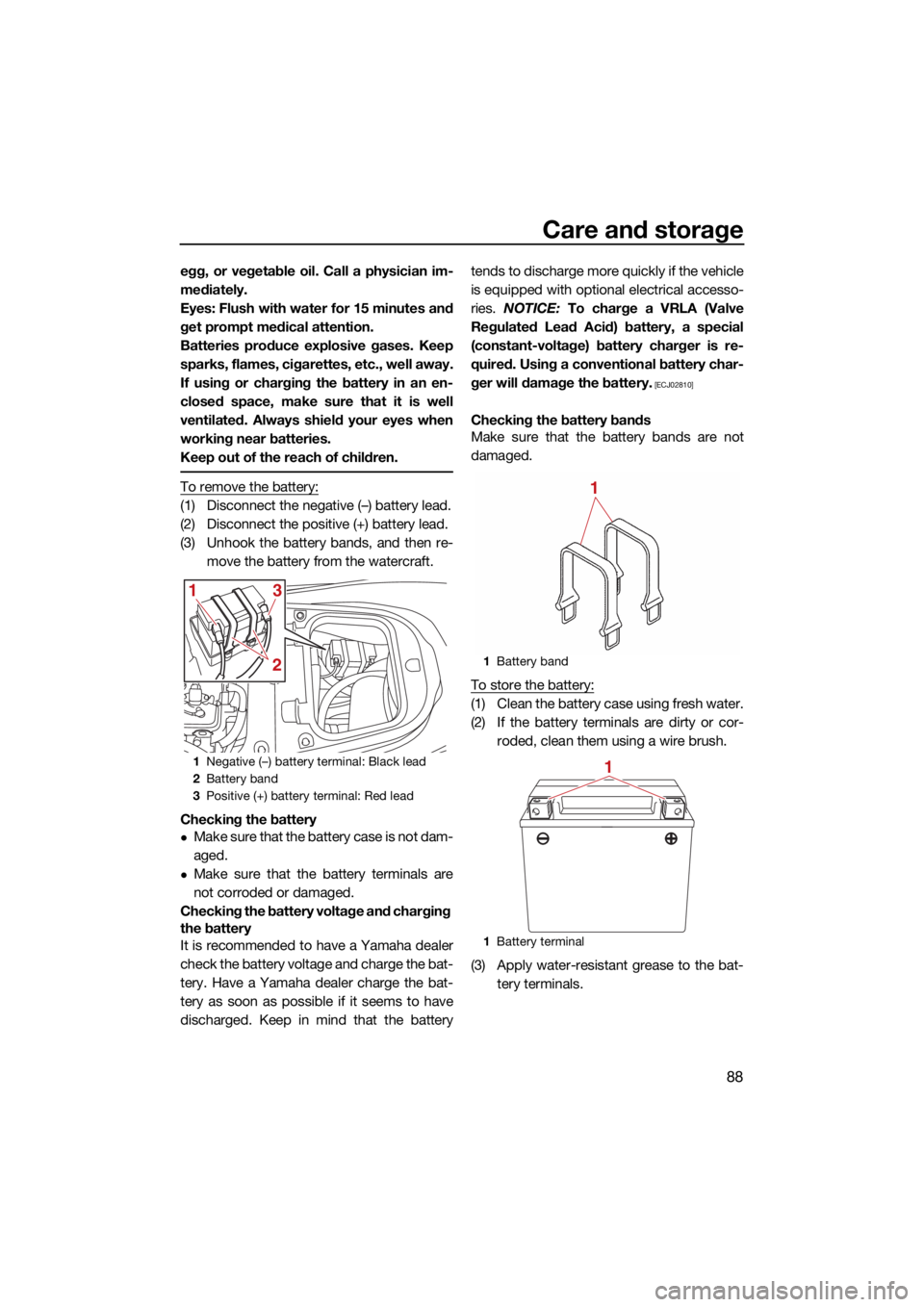

To remove the battery:

(1) Disconnect the negative (–) battery lead.

(2) Disconnect the positive (+) battery lead.

(3) Unhook the battery bands, and then re-move the battery from the watercraft.

Checking the battery

Make sure that the battery case is not dam-

aged.

Make sure that the battery terminals are

not corroded or damaged.

Checking the battery voltage and charging

the battery

It is recommended to have a Yamaha dealer

check the battery voltage and charge the bat-

tery. Have a Yamaha dealer charge the bat-

tery as soon as possible if it seems to have

discharged. Keep in mind that the battery tends to discharge more quickly if the vehicle

is equipped with optional electrical accesso-

ries.

NOTICE: To charge a VRLA (Valve

Regulated Lead Acid) battery, a special

(constant-voltage) battery charger is re-

quired. Using a conventional battery char-

ger will damage the battery.

[ECJ02810]

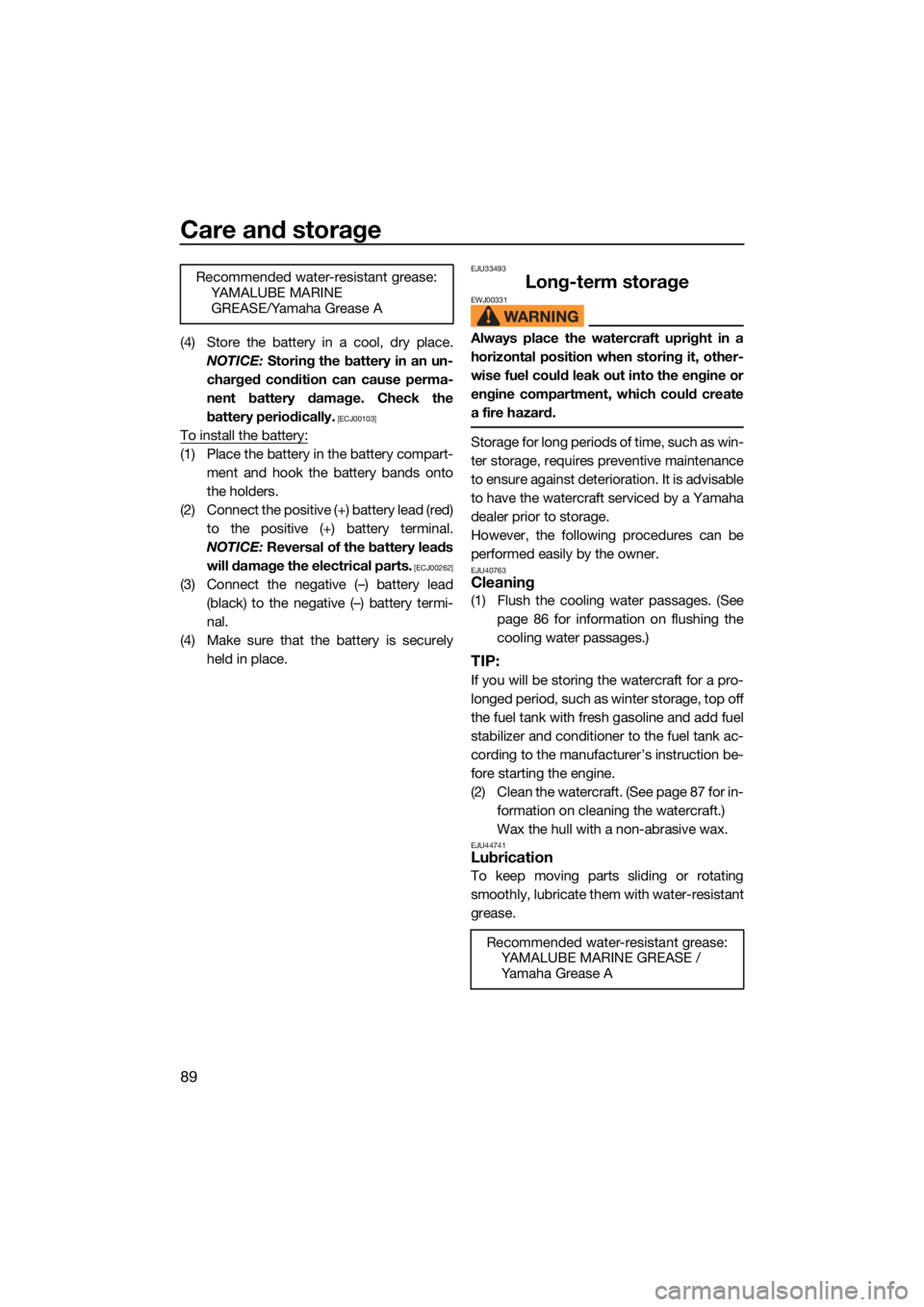

Checking the battery bands

Make sure that the battery bands are not

damaged.

To store the battery:

(1) Clean the battery case using fresh water.

(2) If the battery terminals are dirty or cor- roded, clean them using a wire brush.

(3) Apply water-resistant grease to the bat- tery terminals.

1Negative (–) battery terminal: Black lead

2 Battery band

3 Positive (+) battery terminal: Red lead

1

231

Battery band

1 Battery terminal

1

1

UF3V72E0.book Page 88 Tuesday, June 16, 2020 2:29 PM

Page 96 of 116

Care and storage

89

(4) Store the battery in a cool, dry place.NOTICE: Storing the battery in an un-

charged condition can cause perma-

nent battery damage. Check the

battery periodically.

[ECJ00103]

To install the battery:

(1) Place the battery in the battery compart- ment and hook the battery bands onto

the holders.

(2) Connect the positive (+) battery lead (red) to the positive (+) battery terminal.

NOTICE: Reversal of the battery leads

will damage the electrical parts.

[ECJ00262]

(3) Connect the negative (–) battery lead (black) to the negative (–) battery termi-

nal.

(4) Make sure that the battery is securely held in place.

EJU33493

Long-term storageEWJ00331

Always place the watercraft upright in a

horizontal position when storing it, other-

wise fuel could leak out into the engine or

engine compartment, which could create

a fire hazard.

Storage for long periods of time, such as win-

ter storage, requires preventive maintenance

to ensure against deterioration. It is advisable

to have the watercraft serviced by a Yamaha

dealer prior to storage.

However, the following procedures can be

performed easily by the owner.

EJU40763Cleaning

(1) Flush the cooling water passages. (See

page 86 for information on flushing the

cooling water passages.)

TIP:

If you will be storing the watercraft for a pro-

longed period, such as winter storage, top off

the fuel tank with fresh gasoline and add fuel

stabilizer and conditioner to the fuel tank ac-

cording to the manufacturer’s instruction be-

fore starting the engine.

(2) Clean the watercraft. (See page 87 for in-formation on cleaning the watercraft.)

Wax the hull with a non-abrasive wax.

EJU44741Lubrication

To keep moving parts sliding or rotating

smoothly, lubricate them with water-resistant

grease.

Recommended water-resistant grease:

YAMALUBE MARINE

GREASE/Yamaha Grease A

Recommended water-resistant grease:YAMALUBE MARINE GREASE /

Ya m a h a G r e a s e A

UF3V72E0.book Page 89 Tuesday, June 16, 2020 2:29 PM

Page 100 of 116

Maintenance

93

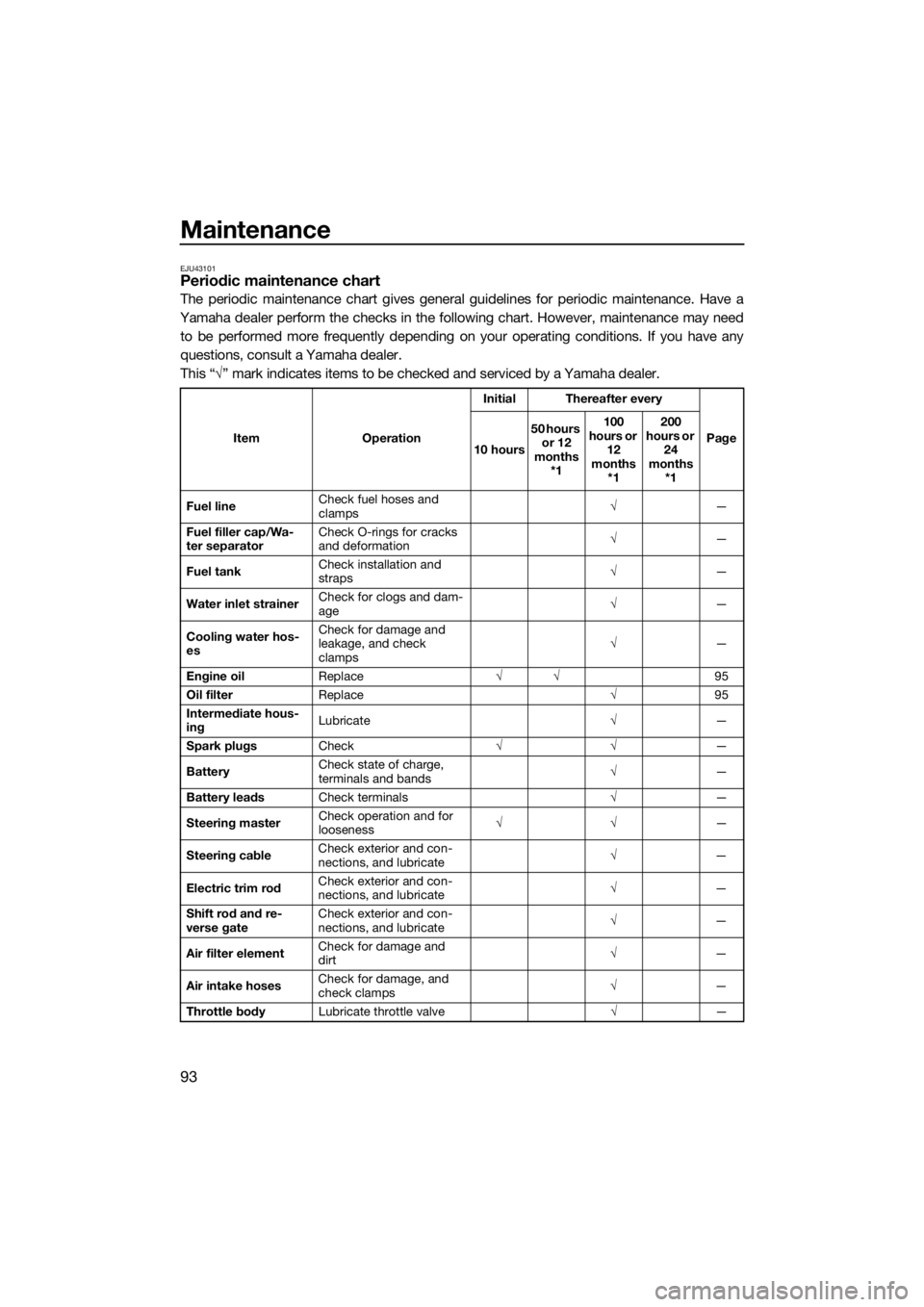

EJU43101Periodic maintenance chart

The periodic maintenance chart gives general guidelines for periodic maintenance. Have a

Yamaha dealer perform the checks in the following chart. However, maintenance may need to be performed more frequently depending on your operating conditions. If you have any

questions, consult a Yamaha dealer.

This “ √” mark indicates items to be checked and serviced by a Yamaha dealer.

Item OperationInitial Thereafter every

Page

10 hours 50 hours

or 12

months *1 100

hours or 12

months *1 200

hours or 24

months *1

Fuel line Check fuel hoses and

clamps

√

—

Fuel filler cap/Wa-

ter separator Check O-rings for cracks

and deformation

√

—

Fuel tank Check installation and

straps

√

—

Water inlet strainer Check for clogs and dam-

age

√

—

Cooling water hos-

es Check for damage and

leakage, and check

clamps

√

—

Engine oil Replace √√ 95

Oil filter Replace √95

Intermediate hous-

ing Lubricate

√—

Spark plugs Check √√ —

Battery Check state of charge,

terminals and bands

√

—

Battery leads Check terminals √—

Steering master Check operation and for

looseness

√√

—

Steering cable Check exterior and con-

nections, and lubricate

√

—

Electric trim rod Check exterior and con-

nections, and lubricate

√

—

Shift rod and re-

verse gate Check exterior and con-

nections, and lubricate

√

—

Air filter element Check for damage and

dirt

√

—

Air intake hoses Check for damage, and

check clamps

√

—

Thr

ottle body Lubricate throttle valve √—

UF3V72E0.book Page 93 Tuesday, June 16, 2020 2:29 PM

Page 103 of 116

Specifications

96

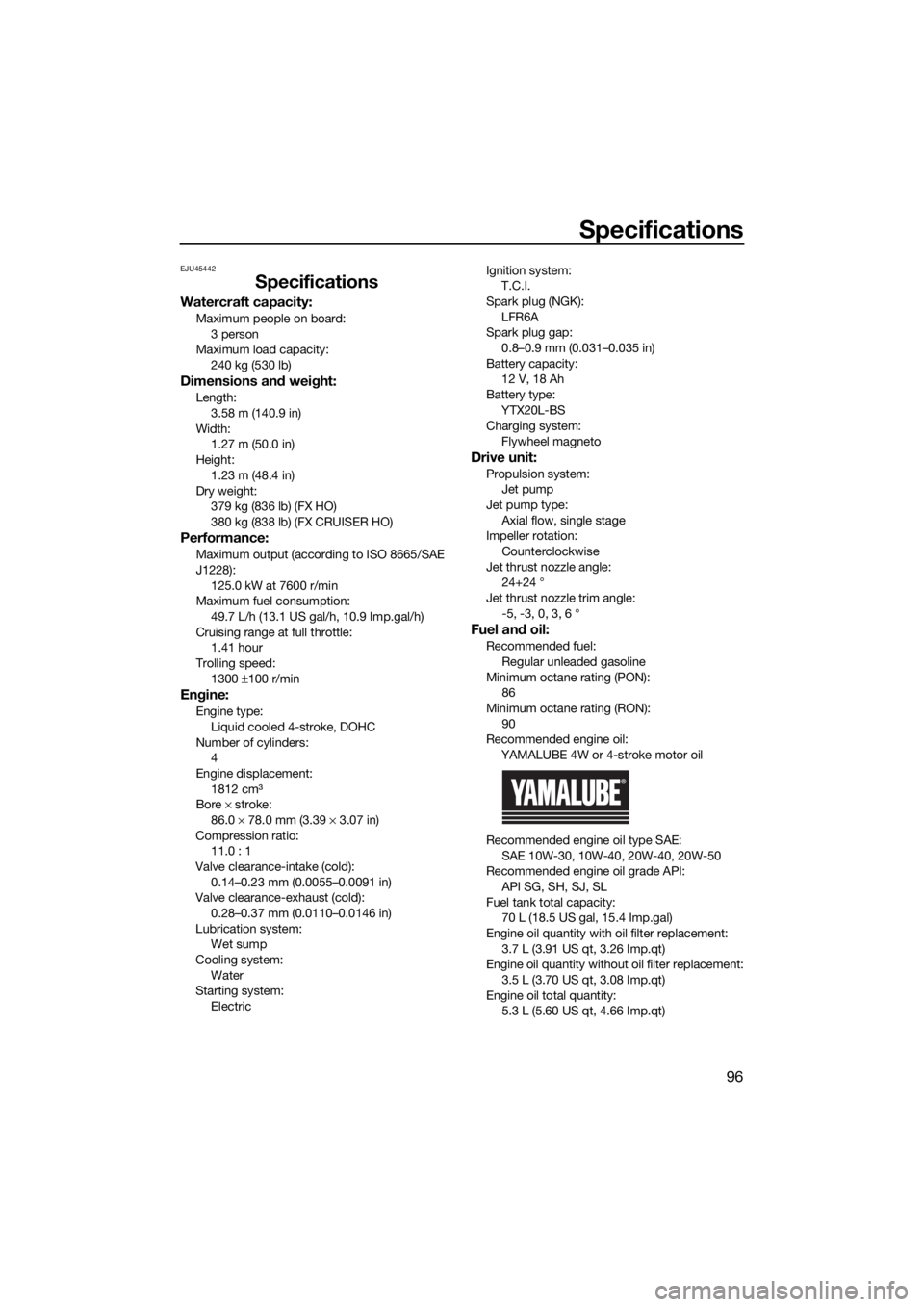

EJU45442

Specifications

Watercraft capacity:

Maximum people on board:3 person

Maximum load capacity: 240 kg (530 lb)

Dimensions and weight:

Length:

3.58 m (140.9 in)

Width: 1.27 m (50.0 in)

Height: 1.23 m (48.4 in)

Dry weight: 379 kg (836 lb) (FX HO)

380 kg (838 lb) (FX CRUISER HO)

Performance:

Maximum output (according to ISO 8665/SAE

J1228):125.0 kW at 7600 r/min

Maximum fuel consumption:

49.7 L/h (13.1 US gal/h, 10.9 Imp.gal/h)

Cruising range at full throttle: 1.41 hour

Trolling speed: 1300 ±100 r/min

Engine:

Engine type:

Liquid cooled 4-stroke, DOHC

Number of cylinders: 4

Engine displacement:

1812 cm³

Bore × stroke:

86.0 × 78.0 mm (3.39 × 3.07 in)

Compression ratio: 11.0 : 1

Valve clearance-intake (cold):

0.14–0.23 mm (0.0055–0.0091 in)

Valve clearance-exhaust (cold): 0.28–0.37 mm (0.0110–0.0146 in)

Lubrication system: Wet sump

Cooling system:

Water

Starting system: Electric Ignition system:

T.C.I.

Spark plug (NGK): LFR6A

Spark plug gap:

0.8–0.9 mm (0.031–0.035 in)

Battery capacity: 12 V, 18 Ah

Battery type: YTX20L-BS

Charging system:

Flywheel magneto

Drive unit:

Propulsion system:Jet pump

Jet pump type: Axial flow, single stage

Impeller rotation:

Counterclockwise

Jet thrust nozzle angle: 24+24 °

Jet thrust nozzle trim angle: -5, -3, 0, 3, 6 °

Fuel and oil:

Recommended fuel:Regular unleaded gasoline

Minimum octane rating (PON): 86

Minimum octane rating (RON):

90

Recommended engine oil: YAMALUBE 4W or 4-stroke motor oil

Recommended engine oil type SAE: SAE 10W-30, 10W-40, 20W-40, 20W-50

Recommended engine oil grade API:

API SG, SH, SJ, SL

Fuel tank total capacity: 70 L (18.5 US gal, 15.4 Imp.gal)

Engine oil quantity with oil filter replacement: 3.7 L (3.91 US qt, 3.26 Imp.qt)

Engine oil quantity without oil filter replacement:

3.5 L (3.70 US qt, 3.08 Imp.qt)

Engine oil total quantity: 5.3 L (5.60 US qt, 4.66 Imp.qt)

UF3V72E0.book Page 96 Tuesday, June 16, 2020 2:29 PM

Page 104 of 116

Trouble recovery

97

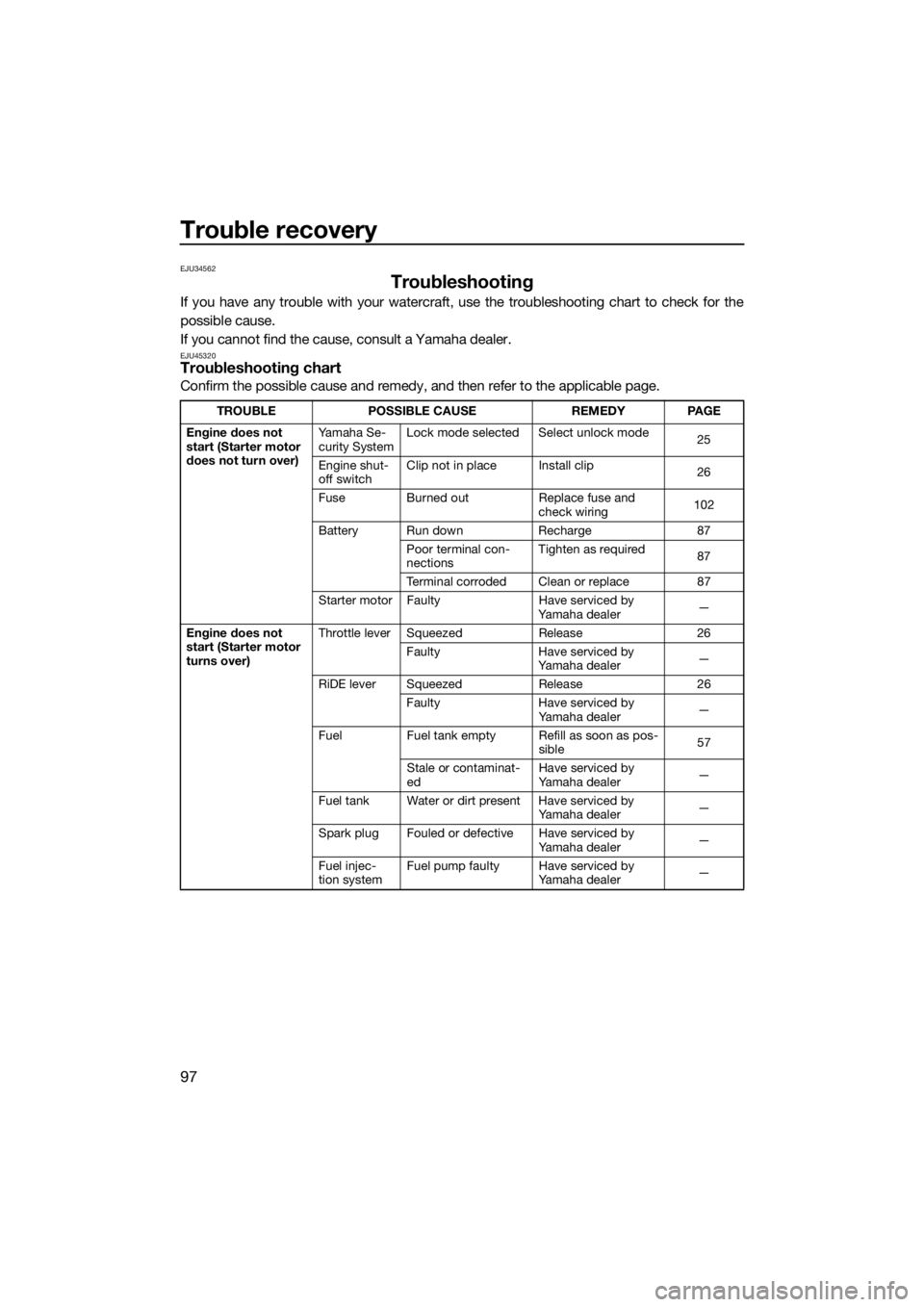

EJU34562

Troubleshooting

If you have any trouble with your watercraft, use the troubleshooting chart to check for the

possible cause.

If you cannot find the cause, consult a Yamaha dealer.

EJU45320Troubleshooting chart

Confirm the possible cause and remedy, and then refer to the applicable page.

TROUBLEPOSSIBLE CAUSE REMEDYPAGE

Engine does not

start (Starter motor

does not turn over) Ya m a h a S e -

curity System

Lock mode selected Select unlock mode

25

Engine shut-

off switch Clip not in place Install clip

26

Fuse Burned out Replace fuse and

check wiring 102

Battery Run down Recharge87

Poor terminal con-

nections Tighten as required

87

Terminal corroded Clean or replace 87

Starter motor Faulty Have serviced by

Yamaha dealer —

Engine does not

start (Starter motor

turns over) Throttle lever Squeezed

Release26

Faulty Have serviced by

Yamaha dealer —

RiDE lever Squeezed Release26

Faulty Have serviced by

Yamaha dealer —

Fuel Fuel tank empty Refill as soon as pos-

sible 57

Stale or contaminat-

ed Have serviced by

Yamaha dealer

—

Fuel tank Water or dirt present Have serviced by Yamaha dealer—

Spark plug Fouled or defective Have serviced by Yamaha dealer—

Fuel injec-

tion system Fuel pump faulty Have serviced by

Yamaha dealer —

UF3V72E0.book Page 97 Tuesday, June 16, 2020 2:29 PM

Page 108 of 116

Trouble recovery

101

ler, jet pump housing, and jet thrust noz-

zle.

If debris is difficult to remove, consult a

Yamaha dealer.

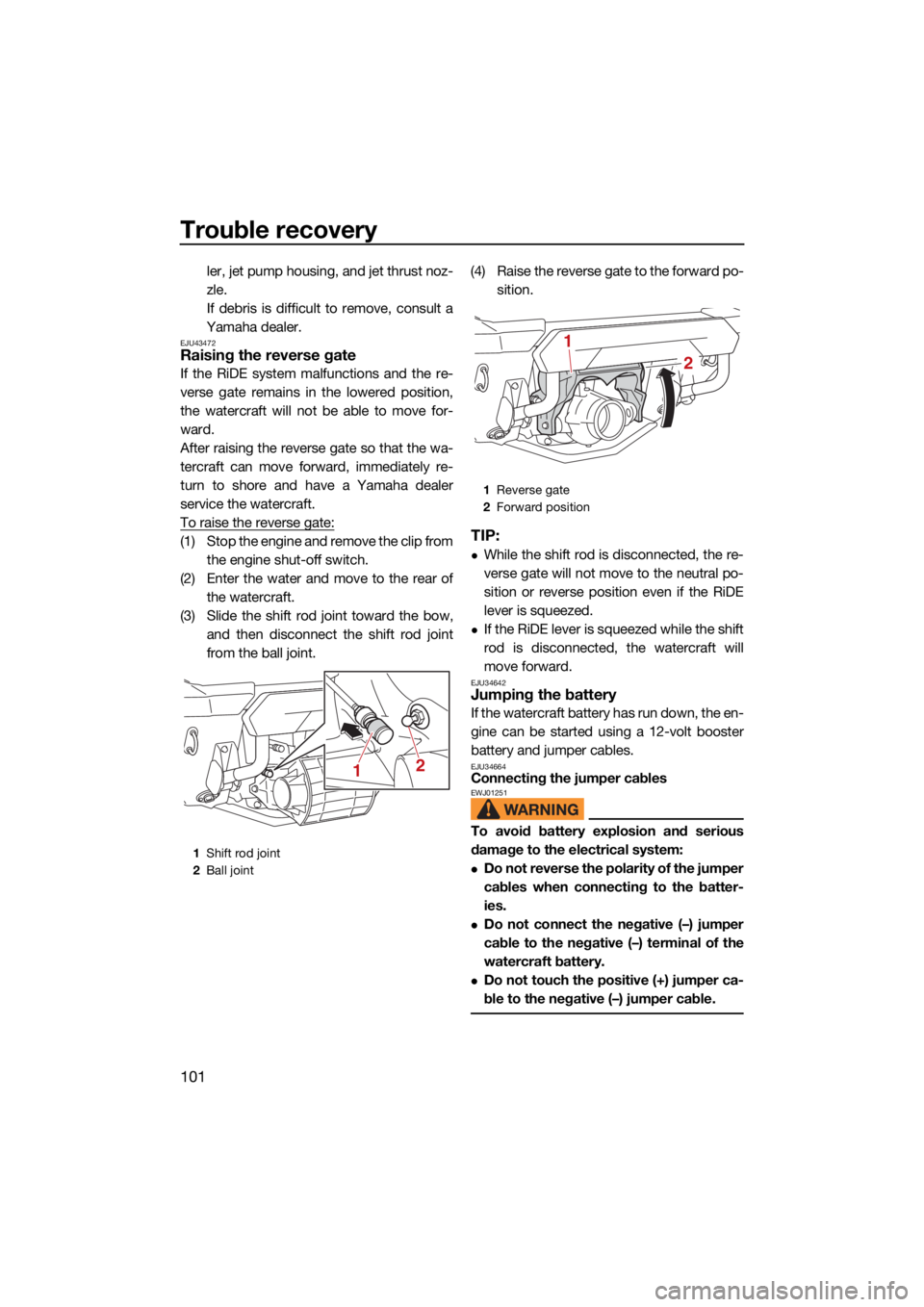

EJU43472Raising the reverse gate

If the RiDE system malfunctions and the re-

verse gate remains in the lowered position,

the watercraft will not be able to move for-

ward.

After raising the reverse gate so that the wa-

tercraft can move forward, immediately re-

turn to shore and have a Yamaha dealer

service the watercraft.

To raise the reverse gate:

(1) Stop the engine and remove the clip from the engine shut-off switch.

(2) Enter the water and move to the rear of the watercraft.

(3) Slide the shift rod joint toward the bow, and then disconnect the shift rod joint

from the ball joint. (4) Raise the reverse gate to the forward po-

sition.TIP:

While the shift rod is disconnected, the re-

verse gate will not move to the neutral po-

sition or reverse position even if the RiDE

lever is squeezed.

If the RiDE lever is squeezed while the shift

rod is disconnected, the watercraft will

move forward.

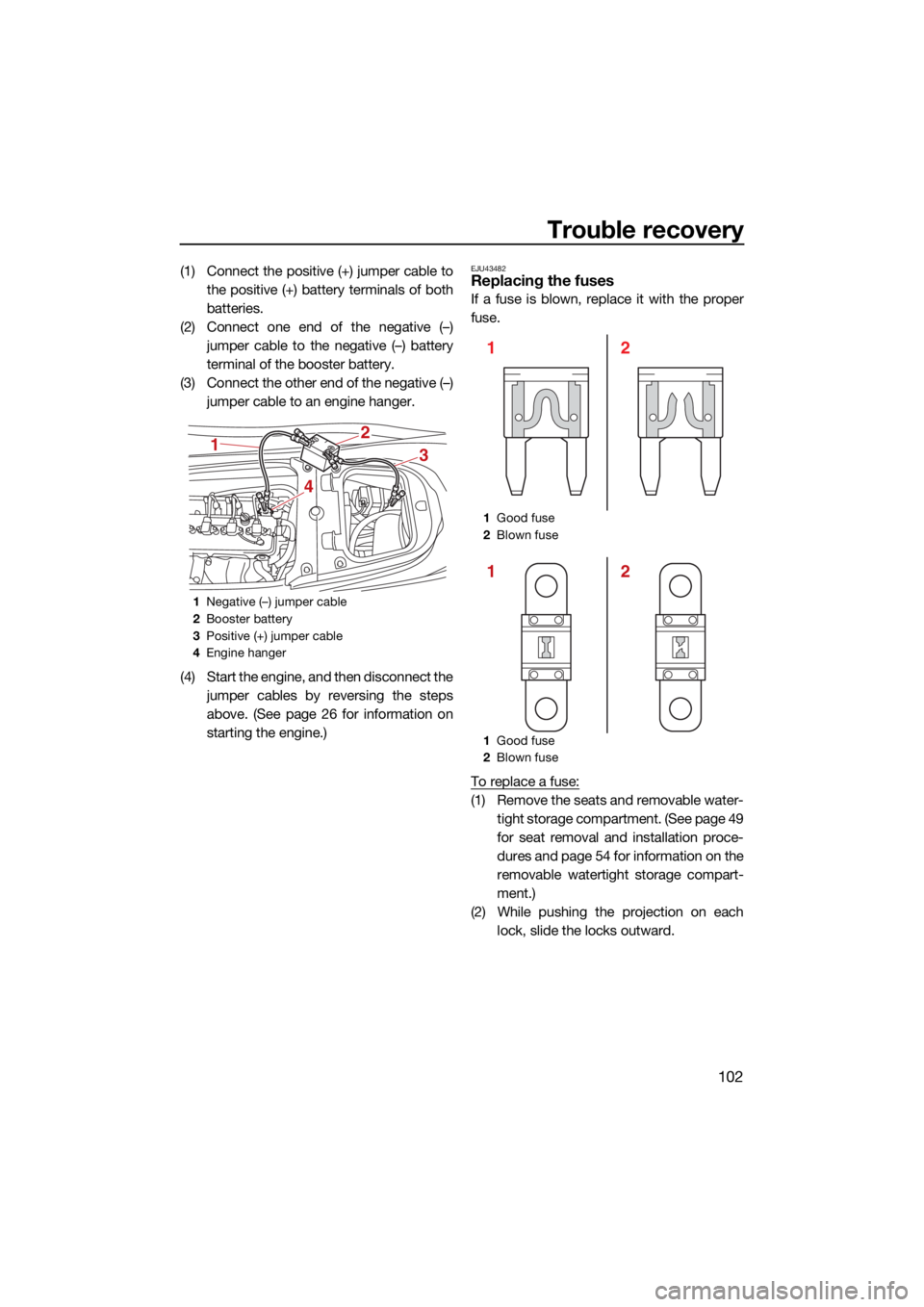

EJU34642Jumping the battery

If the watercraft battery has run down, the en-

gine can be started using a 12-volt booster

battery and jumper cables.

EJU34664Connecting the jumper cablesEWJ01251

To avoid battery explosion and serious

damage to the electrical system:

Do not reverse the polarity of the jumper

cables when connecting to the batter-

ies.

Do not connect the negative (–) jumper

cable to the negative (–) terminal of the

watercraft battery.

Do not touch the positive (+) jumper ca-

ble to the negative (–) jumper cable.

1Shift rod joint

2 Ball joint

1 2

1

Reverse gate

2 Forward position

2

1

UF3V72E0.book Page 101 Tuesday, June 16, 2020 2:29 PM

Page 109 of 116

Trouble recovery

102

(1) Connect the positive (+) jumper cable tothe positive (+) battery terminals of both

batteries.

(2) Connect one end of the negative (–) jumper cable to the negative (–) battery

terminal of the booster battery.

(3) Connect the other end of the negative (–) jumper cable to an engine hanger.

(4) Start the engine, and then disconnect the jumper cables by reversing the steps

above. (See page 26 for information on

starting the engine.)EJU43482Replacing the fuses

If a fuse is blown, replace it with the proper

fuse.

To replace a fuse:

(1) Remove the seats and removable water-tight storage compartment. (See page 49

for seat removal and installation proce-

dures and page 54 for information on the

removable watertight storage compart-

ment.)

(2) While pushing the projection on each lock, slide the locks outward.

1Negative (–) jumper cable

2 Booster battery

3 Positive (+) jumper cable

4 Engine hanger

1

4

3

2

1Good fuse

2 Blown fuse

1 Good fuse

2 Blown fuse

2

1

2

1

UF3V72E0.book Page 102 Tuesday, June 16, 2020 2:29 PM

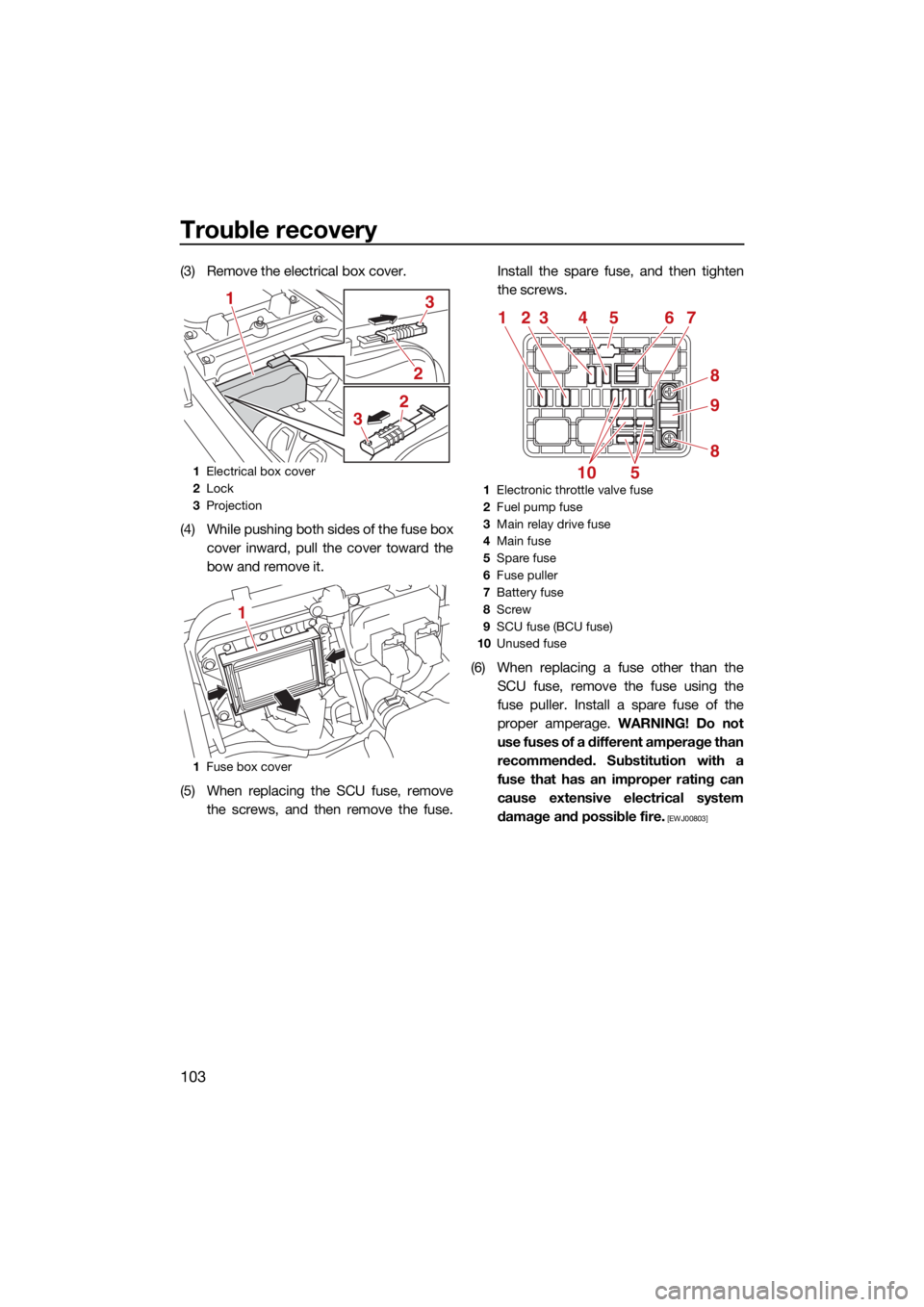

Page 110 of 116

Trouble recovery

103

(3) Remove the electrical box cover.

(4) While pushing both sides of the fuse boxcover inward, pull the cover toward the

bow and remove it.

(5) When replacing the SCU fuse, remove the screws, and then remove the fuse. Install the spare fuse, and then tighten

the screws.

(6) When replacing a fuse other than the SCU fuse, remove the fuse using the

fuse puller. Install a spare fuse of the

proper amperage. WARNING! Do not

use fuses of a different amperage than

recommended. Substitution with a

fuse that has an improper rating can

cause extensive electrical system

damage and possible fire.

[EWJ00803]

1 Electrical box cover

2 Lock

3 Projection

1 Fuse box cover

2

3

2

3

1

1

1Electronic throttle valve fuse

2 Fuel pump fuse

3 Main relay drive fuse

4 Main fuse

5 Spare fuse

6 Fuse puller

7 Battery fuse

8 Screw

9 SCU fuse (BCU fuse)

10 Unused fuse

1

5

23 4 5 6 7

8

9

8

10

UF3V72E0.book Page 103 Tuesday, June 16, 2020 2:29 PM

Page 111 of 116

Trouble recovery

104

(7) Securely install the fuse box cover in itsoriginal position.

(8) Securely install the electrical box cover in its original position.

(9) Slide the locks to their original positions to securely lock the electrical box cover

in place.

(10) Securely install the removable watertight storage compartment and seats in their

original positions.

If the fuse immediately blows again, the elec-

trical system may be defective. If this occurs,

have a Yamaha dealer service the watercraft.

EJU34716Towing the watercraftEWJ00812

The operator of the towing boat must

keep speed to a minimum and avoid

traffic or obstacles which could be a

hazard to the operator on the water-

craft.

The towline should be long enough so

that the watercraft will not collide with

the towing boat when slowing down.

If the watercraft becomes inoperative in the

water, it can be towed to shore. To tow the watercraft:

Use a towline that is three times the com-

bined length of the towing boat and the wa-

tercraft.

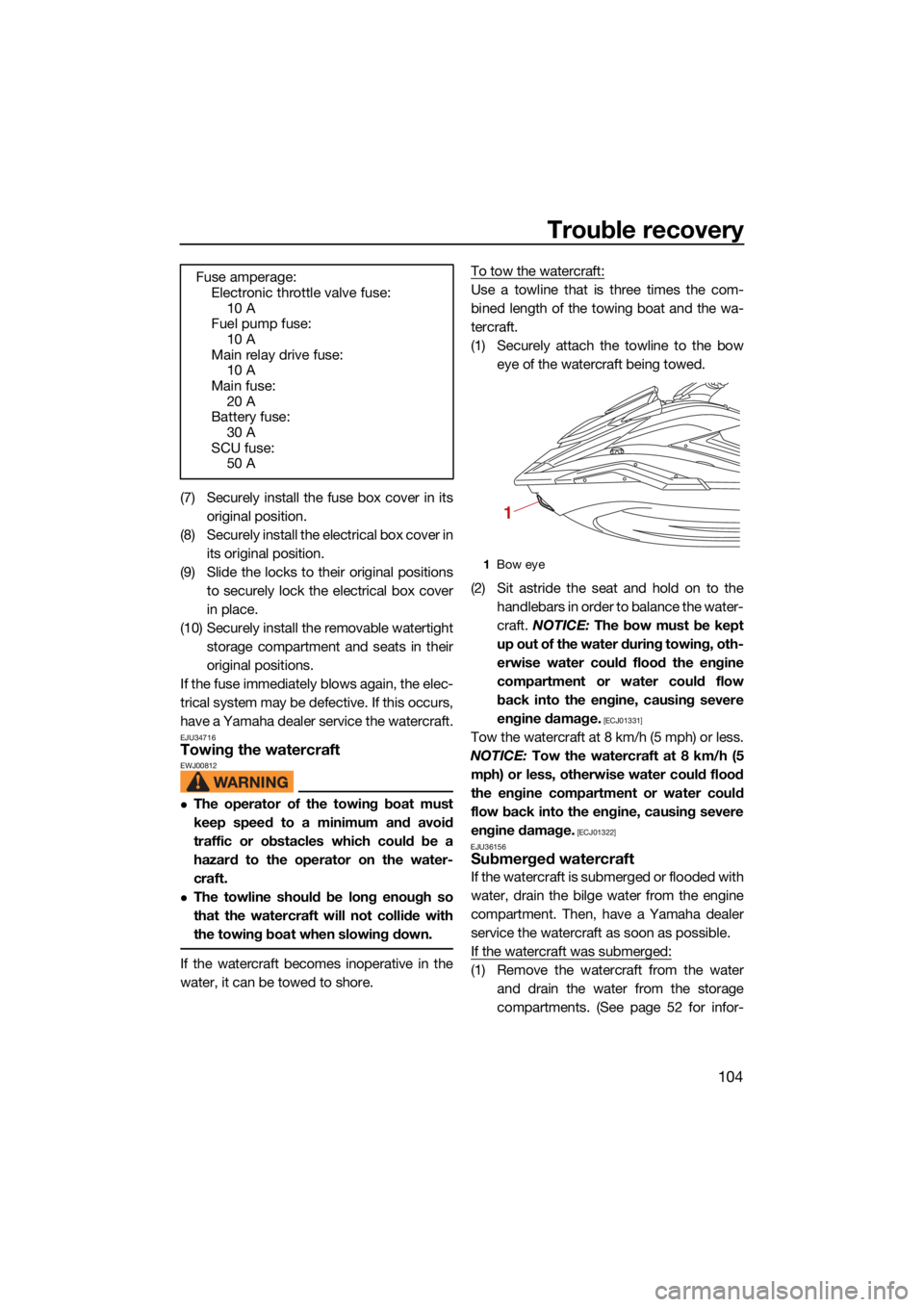

(1) Securely attach the towline to the bow

eye of the watercraft being towed.

(2) Sit astride the seat and hold on to the handlebars in order to balance the water-

craft. NOTICE: The bow must be kept

up out of the water during towing, oth-

erwise water could flood the engine

compartment or water could flow

back into the engine, causing severe

engine damage.

[ECJ01331]

Tow the watercraft at 8 km/h (5 mph) or less.

NOTICE: Tow the watercraft at 8 km/h (5

mph) or less, otherwise water could flood

the engine compartment or water could

flow back into the engine, causing severe

engine damage.

[ECJ01322]

EJU36156

Submerged watercraft

If the watercraft is submerged or flooded with

water, drain the bilge water from the engine

compartment. Then, have a Yamaha dealer

service the watercraft as soon as possible.

If the watercraft was submerged:

(1) Remove the watercraft from the water and drain the water from the storage

compartments. (See page 52 for infor-

Fuse amperage:

Electronic throttle valve fuse:

10 A

Fuel pump fuse: 10 A

Main relay drive fuse: 10 A

Main fuse:

20 A

Battery fuse: 30 A

SCU fuse: 50 A

1Bow eye

1

UF3V72E0.book Page 104 Tuesday, June 16, 2020 2:29 PM

Page 113 of 116

106

Index

A

Adjustable tilt steering system ................. 28

Adjustable tilt steering system checks .... 68

After removing the watercraft from the water ..................................................... 85

B

Battery care.............................................. 87

Battery checks ......................................... 67

Battery, jumping..................................... 101

Beaching and docking the watercraft ...... 84

Beverage holder ....................................... 54

Bilge water check..................................... 67

Bilge water, draining ................................ 61

Bilge water, draining on land ................... 61

Bilge water, draining on water ................. 61

Boarding alone ......................................... 80

Boarding and starting off from a dock ..... 83

Boarding the watercraft ........................... 80

Boarding with passenger(s) ..................... 81

Bow eye ................................................... 51

Bow storage compartment ...................... 52

Builder’s plate ............................................ 2

C

Capsized watercraft ................................. 83

Cleaning ................................................... 89

Cleaning the watercraft ............................ 87

Cleat ......................................................... 51

Cooling water pilot outlet ......................... 29

Cooling water pilot outlet check .............. 72

Craft Identification Number (CIN)............... 1

Cruise assist............................................. 38

Cruising limitations................................... 11

D

Drive control mode................................... 36

Drive control mode screen ....................... 44

E

Electric trim system.................................. 32

Electric trim system check ....................... 70

Emergency procedures .......................... 100

Engine break-in ........................................ 63

Engine compartment check ..................... 66

Engine cover, removing and installing ..... 91

Engine idling speed check ....................... 73

Engine lock screen ................................... 46

Engine oil ................................................. 59 Engine oil and oil filter .............................. 95

Engine oil level check ............................... 67

Engine oil requirements ........................... 59

Engine serial number ................................. 1

Engine shut-off cord (lanyard) check ....... 69

Engine shut-off switch ............................. 26

Engine stop switch ................................... 26

Engine unit check ..................................... 67

Enjoy your watercraft responsibly ............ 19

Equipment ................................................ 49

F

Fire extinguisher check ............................ 71

Fire extinguisher holder and cover........... 55

Fire extinguisher holder, cover, and

band checks ......................................... 70

Flushing the cooling water passages....... 86

Fuel .......................................................... 57

Fuel level check........................................ 66

Fuel requirements .................................... 57

Fuel system checks ................................. 66

Fuses, replacing ..................................... 102

G

Getting to know your watercraft .............. 74

Glossary, watercraft ................................. 20

Glove compartment ................................. 53

H

Handgrip .................................................. 50

Hazard information................................... 15

Home screen ............................................ 42

Hood check .............................................. 72

Hull and deck check ................................ 71

I

Identification numbers ............................... 1

Information screen ................................... 43

J

Jet intake and impeller, cleaning............ 100

Jet intake checks ..................................... 71

Jet thrust nozzle and reverse gate check .................................................... 71

Jumper cables, connecting .................... 101

L

Labels, important ....................................... 4

Labels, other .............................................. 8

Labels, warning .......................................... 5

Launching the watercraft ......................... 75

UF3V72E0.book Page 106 Tuesday, June 16, 2020 2:29 PM