fork YAMAHA FZ8 N 2013 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2013, Model line: FZ8 N, Model: YAMAHA FZ8 N 2013Pages: 110, PDF Size: 3.05 MB

Page 55 of 110

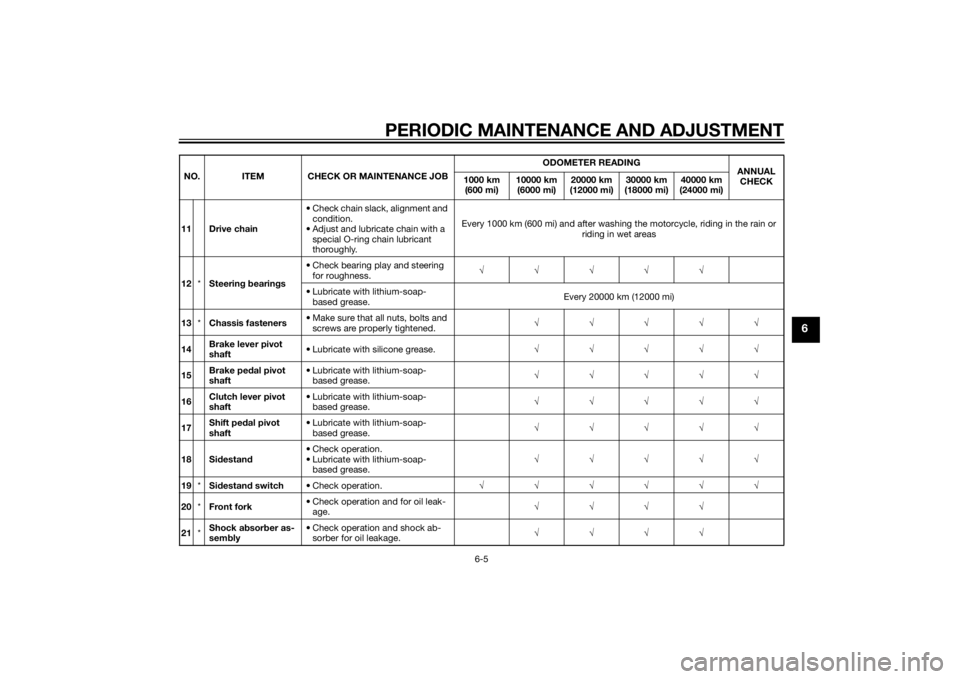

PERIODIC MAINTENANCE AND ADJUSTMENT

6-5

6

11 Drive chain• Check chain slack, alignment and

condition.

• Adjust and lubricate chain with a special O-ring chain lubricant

thoroughly. Every 1000 km (600 mi) and after washing the motorcycle, riding in the rain or

riding in wet areas

12 *Steerin g b earin gs • Check bearing play and steering

for roughness. √√√√√

• Lubricate with lithium-soap- based grease. Every 20000 km (12000 mi)

13 *Chassis fasteners • Make sure that all nuts, bolts and

screws are properly tightened. √√√√√

14 Brake lever pivot

shaft

• Lubricate with silicone grease.

√√√√√

15 Brake ped

al pivot

shaft • Lubricate with lithium-soap-

based grease. √√√√√

16 Clutch lever pivot

shaft • Lubricate with lithium-soap-

based grease. √√√√√

17 Shift ped

al pivot

shaft • Lubricate with lithium-soap-

based grease. √√√√√

18 Si destan d • Check operation.

• Lubricate with lithium-soap-

based grease. √√√√√

19 *Sidestan d switch • Check operation. √√√√√√

20 *Front fork • Check operation and for oil leak-

age. √√√√

21 *Shock a

bsor ber as-

sem bly • Check operation and shock ab-

sorber for oil leakage. √√√√

NO. ITEM CHECK OR MAINTENANCE JOB

ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 10000 km

(6000 mi) 20000 km

(12000 mi) 30000 km

( 18

000 mi) 40000 km

(24000 mi)

U2SHE1E0.book Page 5 Tuesday, July 15, 2014 4:04 PM

Page 79 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-29

6

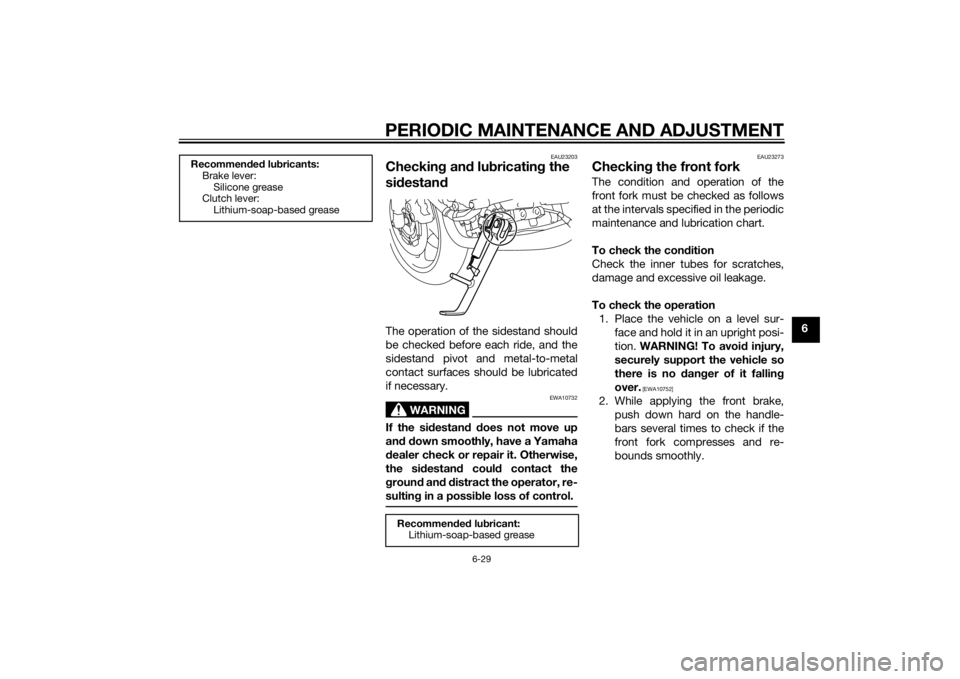

EAU23203

Checking an d lu bricatin g the

si destan dThe operation of the sidestand should

be checked before each ride, and the

sidestand pivot and metal-to-metal

contact surfaces should be lubricated

if necessary.

WARNING

EWA10732

If the sid estand d oes not move up

an d d own smoothly, have a Yamaha

d ealer check or repair it. Otherwise,

the si destan d coul d contact the

g roun d an d d istract the operator, re-

sultin g in a possi ble loss of control.

EAU23273

Checkin g the front forkThe condition and operation of the

front fork must be checked as follows

at the intervals specified in the periodic

maintenance and lubrication chart.

To check the con dition

Check the inner tubes for scratches,

damage and excessive oil leakage.

To check the operation 1. Place the vehicle on a level sur- face and hold it in an upright posi-

tion. WARNING! To avoi d injury,

securely support the vehicle so

there is no d anger of it fallin g

over.

[EWA10752]

2. While applying the front brake, push down hard on the handle-

bars several times to check if the

front fork compresses and re-

bounds smoothly.

Recommen ded lu bricants:

Brake lever:

Silicone grease

Clutch lever:

Lithium-soap-based grease

Recommen ded lu bricant:

Lithium-soap-based grease

U2SHE1E0.book Page 29 Tuesday, July 15, 2014 4:04 PM

Page 80 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-30

6

NOTICE

ECA10591

If any damage is foun d or the front

fork does not operate smoothly,

have a Yamaha d ealer check or re-

pair it.

EAU23284

Checkin g the steerin gWorn or loose steering bearings may

cause danger. Therefore, the operation

of the steering must be checked as fol-

lows at the intervals specified in the

periodic maintenance and lubrication

chart.

1. Place a stand under the engine to raise the front wheel off the

ground. (See page 6-39 for more

information.) WARNING! To

avoi d injury, securely support

the vehicle so there is no dan ger

of it fallin g over.

[EWA10752]

2. Hold the lower ends of the front

fork legs and try to move them for-

ward and backward. If any free

play can be felt, have a Yamaha

dealer check or repair the steer-

ing.

U2SHE1E0.book Page 30 Tuesday, July 15, 2014 4:04 PM

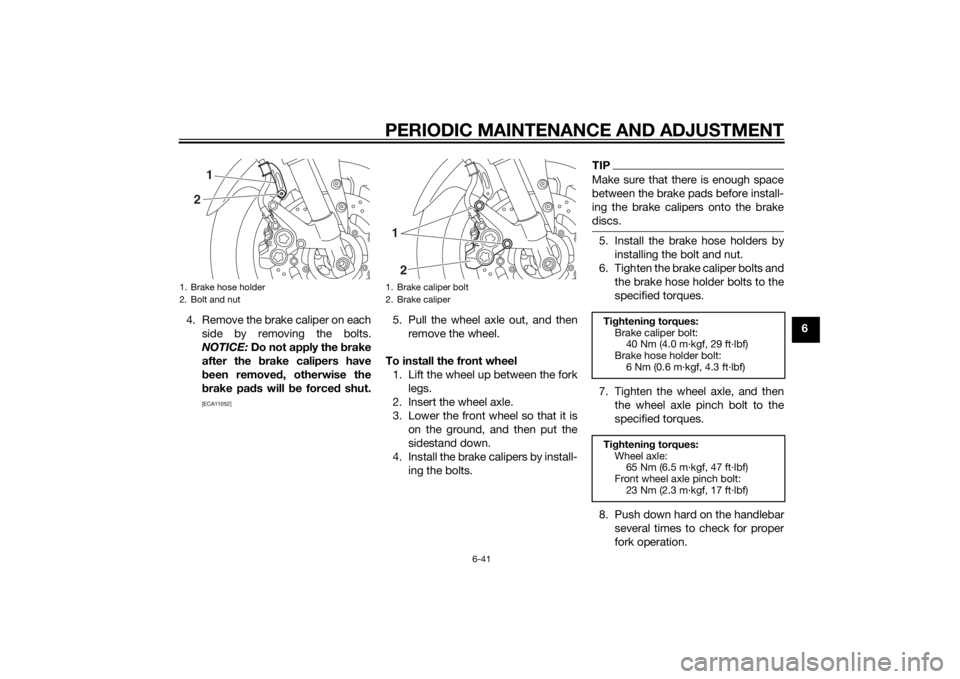

Page 91 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-41

6

4. Remove the brake caliper on each

side by removing the bolts.

NOTICE: Do not apply the brake

after the brake calipers have

b een removed , otherwise the

b rake pad s will be force d shut.

[ECA11052]

5. Pull the wheel axle out, and then

remove the wheel.

To install the front wheel 1. Lift the wheel up between the fork legs.

2. Insert the wheel axle.

3. Lower the front wheel so that it is on the ground, and then put the

sidestand down.

4. Install the brake calipers by install- ing the bolts.

TIPMake sure that there is enough space

between the brake pads before install-

ing the brake calipers onto the brake

discs.5. Install the brake hose holders byinstalling the bolt and nut.

6. Tighten the brake caliper bolts and the brake hose holder bolts to the

specified torques.

7. Tighten the wheel axle, and then the wheel axle pinch bolt to the

specified torques.

8. Push down hard on the handlebar several times to check for proper

fork operation.

1. Brake hose holder

2. Bolt and nut

1

2

1. Brake caliper bolt

2. Brake caliper1

2

Ti ghtenin g torques:

Brake caliper bolt: 40 Nm (4.0 m·kgf, 29 ft·lbf)

Brake hose holder bolt:

6 Nm (0.6 m·kgf, 4.3 ft·lbf)

Ti ghtenin g torques:

Wheel axle: 65 Nm (6.5 m·kgf, 47 ft·lbf)

Front wheel axle pinch bolt:

23 Nm (2.3 m·kgf, 17 ft·lbf)

U2SHE1E0.book Page 41 Tuesday, July 15, 2014 4:04 PM

Page 98 of 110

MOTORCYCLE CARE AND STORAGE

7-2

7off any d

etergent resi due usin g

plenty of water, as it is harmful

to plastic parts.

Do not use any harsh chemical

prod ucts on plastic parts. Be

sure to avoi d using cloths or

spon ges which have been in

contact with stron g or a brasive

cleanin g prod ucts, solvent or

thinner, fuel ( gasoline), rust re-

movers or inhi bitors, brake flui d,

antifreeze or electrolyte.

Do not use hi gh-pressure wash-

ers or steam-jet cleaners since

they cause water seepa ge an d

d eterioration in the followin g ar-

eas: seals (of wheel an d swin g-

arm bearin gs, fork an d b rakes),

electric components (couplers,

connectors, instruments,

switches an d lig hts), breather

hoses an d vents.

For motorcycles equippe d with

a win dshield : Do not use stron g

cleaners or har d spon ges as

they will cause dullin g

or

scrat c

hing . Some cleanin g

compoun ds for plastic may

leave scratches on the win d- shield

. Test the pro duct on a

small hidden part of the win d-

shield to make sure that it does

not leave any marks. If the win d-

shield is scratche d, use a quality

plastic polishin g compoun d af-

ter washin g.

After normal useRemove dirt with warm water, a mild

detergent, and a soft, clean sponge,

and then rinse thoroughly with clean

water. Use a toothbrush or bottlebrush

for hard-to-reach areas. Stubborn dirt

and insects will come off more easily if

the area is covered with a wet cloth for

a few minutes before cleaning.

After riding in the rain, near the sea oron salt-sprayed roadsSince sea salt or salt sprayed on roads

during winter are extremely corrosive

in combination with water, carry out

the following steps after each ride in

the rain, near the sea or on salt-

sprayed roads.

TIPSalt sprayed on roads in the winter

may remain well into spring.1. Clean the motorcycle with cold

water and a mild detergent, after

the engine has cooled down.

NOTICE: Do not use warm wa-

ter since it increases the corro-

sive action of the salt.

[ECA10792]

2. Apply a corrosion protection spray on all metal, including chrome-

and nickel-plated, surfaces to pre-

vent corrosion.

After cleanin g

1. Dry the motorcycle with a chamois or an absorbing cloth.

2. Immediately dry the drive chain and lubricate it to prevent it from

rusting.

3. Use a chrome polish to shine chrome, aluminum and stainless-

steel parts, including the exhaust

system. (Even the thermally in-

duced discoloring of stainless-

steel exhaust systems can be re-

moved through polishing.)

U2SHE1E0.book Page 2 Tuesday, July 15, 2014 4:04 PM

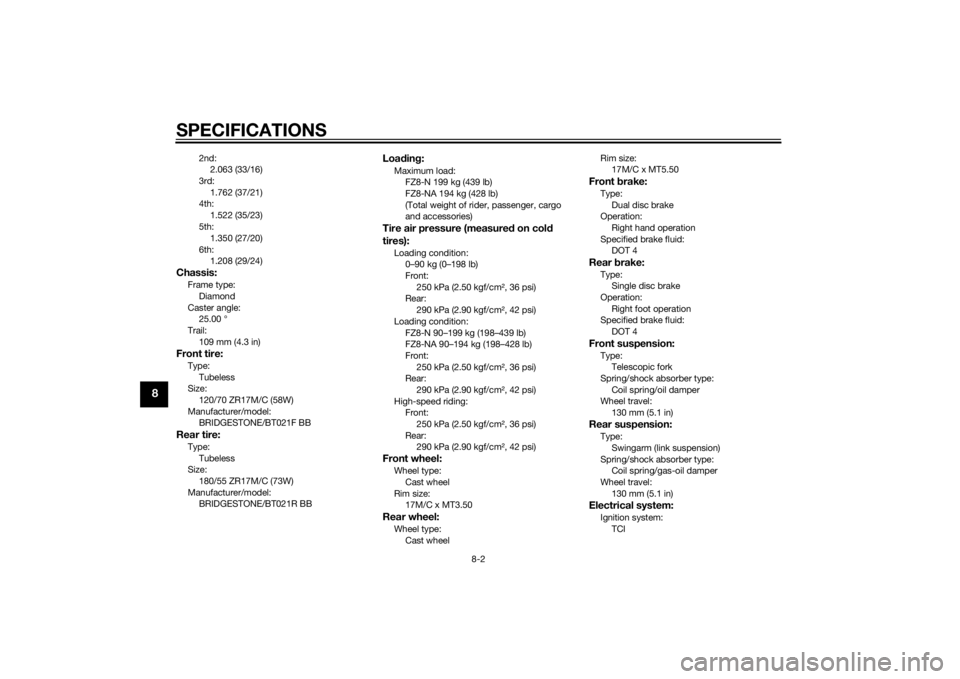

Page 102 of 110

SPECIFICATIONS

8-2

8

2nd:2.063 (33/16)

3rd: 1.762 (37/21)

4th:

1.522 (35/23)

5th: 1.350 (27/20)

6th: 1.208 (29/24)

Chassis:Frame type:Diamond

Caster angle: 25.00 °

Trail:

109 mm (4.3 in)Front tire:Type:Tubeless

Size:

120/70 ZR17M/C (58W)

Manufacturer/model: BRIDGESTONE/BT021F BBRear tire:Type:

Tubeless

Size: 180/55 ZR17M/C (73W)

Manufacturer/model: BRIDGESTONE/BT021R BB

Loa din g:Maximum load:

FZ8-N 199 kg (439 lb)

FZ8-NA 194 kg (428 lb)

(Total weight of rider, passenger, cargo

and accessories)Tire air pressure (measure d on col d

tires):Loading condition:

0–90 kg (0–198 lb)

Front:

250 kPa (2.50 kgf/cm², 36 psi)

Rear: 290 kPa (2.90 kgf/cm², 42 psi)

Loading condition: FZ8-N 90–199 kg (198–439 lb)

FZ8-NA 90–194 kg (198–428 lb)

Front: 250 kPa (2.50 kgf/cm², 36 psi)

Rear:

290 kPa (2.90 kgf/cm², 42 psi)

High-speed riding: Front:

250 kPa (2.50 kgf/cm², 36 psi)

Rear: 290 kPa (2.90 kgf/cm², 42 psi)Front wheel:Wheel type:

Cast wheel

Rim size: 17M/C x MT3.50Rear wheel:Wheel type:

Cast wheel Rim size:

17M/C x MT5.50

Front brake:Type:

Dual disc brake

Operation: Right hand operation

Specified brake fluid: DOT 4Rear brake:Type:

Single disc brake

Operation: Right foot operation

Specified brake fluid:

DOT 4Front suspension:Type:Telescopic fork

Spring/shock absorber type:

Coil spring/oil damper

Wheel travel: 130 mm (5.1 in)Rear suspension:Type:

Swingarm (link suspension)

Spring/shock absorber type: Coil spring/gas-oil damper

Wheel travel: 130 mm (5.1 in)Electrical system:Ignition system:TCI

U2SHE1E0.book Page 2 Tuesday, July 15, 2014 4:04 PM

Page 106 of 110

10-1

10

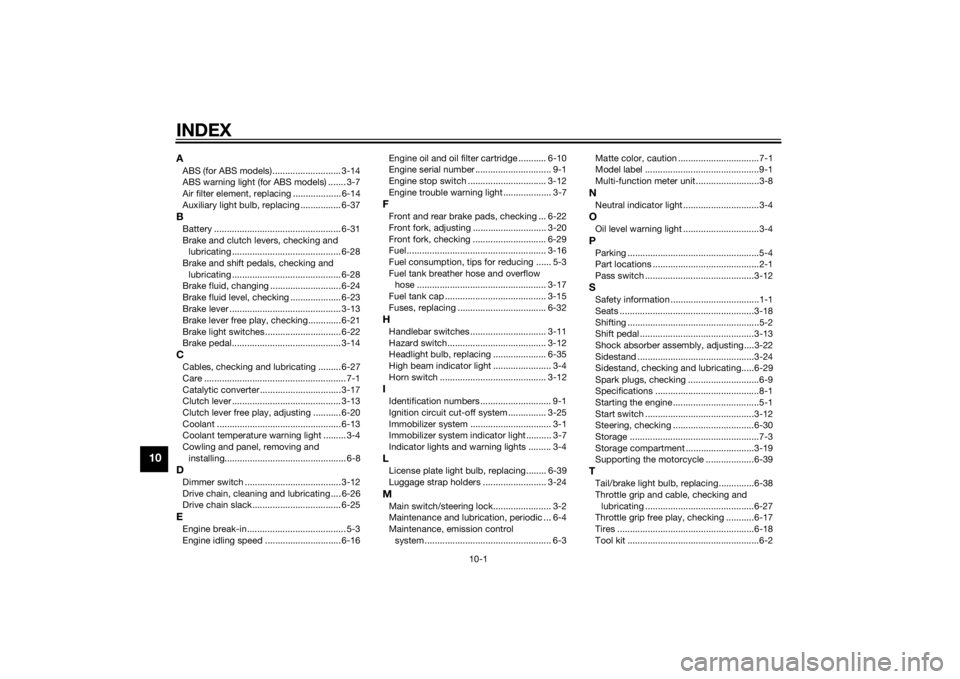

INDEXAABS (for ABS models) ........................... 3-14

ABS warning light (for ABS models) ....... 3-7

Air filter element, replacing ................... 6-14

Auxiliary light bulb, replacing ................ 6-37BBattery .................................................. 6-31

Brake and clutch levers, checking and lubricating ........................................... 6-28

Brake and shift pedals, checking and lubricating ........................................... 6-28

Brake fluid, changing ............................ 6-24

Brake fluid level, checking .................... 6-23

Brake lever ............................................ 3-13

Brake lever free play, checking............. 6-21

Brake light switches.............................. 6-22

Brake pedal........................................... 3-14CCables, checking and lubricating ......... 6-27

Care ........................................................ 7-1

Catalytic converter ................................ 3-17

Clutch lever ........................................... 3-13

Clutch lever free play, adjusting ........... 6-20

Coolant ................................................. 6-13

Coolant temperature warning light ......... 3-4

Cowling and panel, removing and

installing................................................ 6-8DDimmer switch ...................................... 3-12

Drive chain, cleaning and lubricating .... 6-26

Drive chain slack................................... 6-25EEngine break-in....................................... 5-3

Engine idling speed .............................. 6-16 Engine oil and oil filter

cartridge ........... 6-10

Engine serial number .............................. 9-1

Engine stop switch ............................... 3-12

Engine trouble warning light ................... 3-7

FFront and rear brake pads, checking ... 6-22

Front fork, adjusting ............................. 3-20

Front fork, checking ............................. 6-29

Fuel ....................................................... 3-16

Fuel consumption, tips for reducing ...... 5-3

Fuel tank breather hose and overflow hose ................................................... 3-17

Fuel tank cap ........................................ 3-15

Fuses, replacing ................................... 6-32HHandlebar switches .............................. 3-11

Hazard switch....................................... 3-12

Headlight bulb, replacing ..................... 6-35

High beam indicator light ....................... 3-4

Horn switch .......................................... 3-12IIdentification numbers ............................ 9-1

Ignition circuit cut-off system ............... 3-25

Immobilizer system ................................ 3-1

Immobilizer system indicator light .......... 3-7

Indicator lights and warning lights ......... 3-4LLicense plate light bulb, replacing........ 6-39

Luggage strap holders ......................... 3-24MMain switch/steering lock....................... 3-2

Maintenance and lubrication, periodic ... 6-4

Maintenance, emission control

system.................................................. 6-3 Matte color, caution ................................7-1

Model label .............................................9-1

Multi-function meter unit .........................3-8

NNeutral indicator light ..............................3-4OOil level warning light ..............................3-4PParking ....................................................5-4

Part locations ..........................................2-1

Pass switch ...........................................3-12SSafety information ...................................1-1

Seats .....................................................3-18

Shifting ....................................................5-2

Shift pedal .............................................3-13

Shock absorber assembly, adjusting ....3-22

Sidestand ..............................................3-24

Sidestand, checking and lubricating.....6-29

Spark plugs, checking ............................6-9

Specifications .........................................8-1

Starting the engine ..................................5-1

Start switch ...........................................3-12

Steering, checking ................................6-30

Storage ...................................................7-3

Storage compartment ...........................3-19

Supporting the motorcycle ...................6-39TTail/brake light bulb, replacing..............6-38

Throttle grip and cable, checking and

lubricating ...........................................6-27

Throttle grip free play, checking ...........6-17

Tires ......................................................6-18

Tool kit ....................................................6-2

U2SHE1E0.book Page 1 Tuesday, July 15, 2014 4:04 PM