drive YAMAHA FZ8 N 2013 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2013, Model line: FZ8 N, Model: YAMAHA FZ8 N 2013Pages: 110, PDF Size: 3.05 MB

Page 6 of 110

TABLE OF CONTENTSSAFETY INFORMATION.................. 1-1

DESCRIPTION .................................. 2-1

Left view ......................................... 2-1

Right view ....................................... 2-3

Controls and instruments ............... 2-5

INSTRUMENT AND CONTROL

FUNCTIONS ...................................... 3-1

Immobilizer system......................... 3-1

Main switch/steering lock............... 3-2

Indicator lights and warning lights............................................ 3-4

Multi-function meter unit ................ 3-8

Handlebar switches ...................... 3-11

Clutch lever .................................. 3-13

Shift pedal .................................... 3-13

Brake lever.................................... 3-13

Brake pedal .................................. 3-14

ABS (for ABS models) .................. 3-14

Fuel tank cap ................................ 3-15

Fuel ............................................... 3-16

Fuel tank breather hose and

overflow hose ............................ 3-17

Catalytic converter ....................... 3-17

Seats ............................................ 3-18

Storage compartment .................. 3-19

Adjusting the front fork ................. 3-20

Adjusting the shock absorber assembly ................................... 3-22

Luggage strap holders ................. 3-24 Sidestand ...................................... 3-24

Ignition circuit cut-off system ....... 3-25

FOR YOUR SAFETY –

PRE-OPERATION CHECKS ............. 4-1

OPERATION AND IMPORTANT

RIDING POINTS ................................ 5-1

Starting the engine .......................... 5-1

Shifting ............................................ 5-2

Tips for reducing fuel consumption ................................ 5-3

Engine break-in ............................... 5-3

Parking ............................................ 5-4

PERIODIC MAINTENANCE AND

ADJUSTMENT ................................... 6-1

Owner’s tool kit ............................... 6-2

Periodic maintenance chart for the emission control system .............. 6-3

General maintenance and lubrication chart ........................... 6-4

Removing and installing the

cowling and panel........................ 6-8

Checking the spark plugs ............... 6-9

Engine oil and oil filter cartridge.... 6-10

Coolant.......................................... 6-13

Replacing the air filter element ..... 6-14

Adjusting the engine idling speed ......................................... 6-16 Checking the throttle grip free

play ............................................ 6-17

Valve clearance............................. 6-17

Tires .............................................. 6-18

Cast wheels .................................. 6-20

Adjusting the clutch lever free play ............................................ 6-20

Checking the brake lever free

play ............................................ 6-21

Brake light switches ..................... 6-22

Checking the front and rear brake pads .......................................... 6-22

Checking the brake fluid level ...... 6-23

Changing the brake fluid .............. 6-24

Drive chain slack........................... 6-25

Cleaning and lubricating the drive chain.......................................... 6-26

Checking and lubricating the cables ........................................ 6-27

Checking and lubricating the

throttle grip and cable ............... 6-27

Checking and lubricating the brake and shift pedals............... 6-28

Checking and lubricating the brake and clutch levers ............. 6-28

Checking and lubricating the

sidestand................................... 6-29

Checking the front fork ................. 6-29

Checking the steering................... 6-30

Checking the wheel bearings ....... 6-31

Battery .......................................... 6-31U2SHE1E0.book Page 1 Tuesday, July 15, 2014 4:04 PM

Page 8 of 110

1-1

1

SAFETY INFORMATION

EAU1028B

Be a Responsible Owner

As the vehicle’s owner, you are re-

sponsible for the safe and proper oper-

ation of your motorcycle.

Motorcycles are single-track vehicles.

Their safe use and operation are de-

pendent upon the use of proper riding

techniques as well as the expertise of

the operator. Every operator should

know the following requirements be-

fore riding this motorcycle.

He or she should: Obtain thorough instructions from

a competent source on all aspects

of motorcycle operation.

Observe the warnings and mainte-

nance requirements in this Own-

er’s Manual.

Obtain qualified training in safe

and proper riding techniques.

Obtain professional technical ser-

vice as indicated in this Owner’s

Manual and/or when made neces-

sary by mechanical conditions.

Never operate a motorcycle with-

out proper training or instruction.

Take a training course. Beginners

should receive training from a cer-

tified instructor. Contact an autho-

rized motorcycle dealer to find out

about the training courses nearest

you.

Safe Ri din g

Perform the pre-operation checks

each time you use the vehicle to make

sure it is in safe operating condition.

Failure to inspect or maintain the vehi-

cle properly increases the possibility of

an accident or equipment damage.

See page 4-1 for a list of pre-operation

checks. This motorcycle is designed to

carry the operator and a passen-

ger.

The failure of motorists to detect

and recognize motorcycles in traf-

fic is the predominating cause of

automobile/motorcycle accidents.

Many accidents have been

caused by an automobile driver

who did not see the motorcycle.

Making yourself conspicuous ap- pears to be very effective in reduc-

ing the chance of this type of

accident.

Therefore:

• Wear a brightly colored jacket.

• Use extra caution when you are approaching and passing

through intersections, since in-

tersections are the most likely

places for motorcycle accidents

to occur.

• Ride where other motorists can see you. Avoid riding in another

motorist’s blind spot.

• Never maintain a motorcycle without proper knowledge.

Contact an authorized motorcy-

cle dealer to inform you on ba-

sic motorcycle maintenance.

Certain maintenance can only

be carried out by certified staff.U2SHE1E0.book Page 1 Tuesday, July 15, 2014 4:04 PM

Page 29 of 110

INSTRUMENT AND CONTROL FUNCTIONS

3-12

3

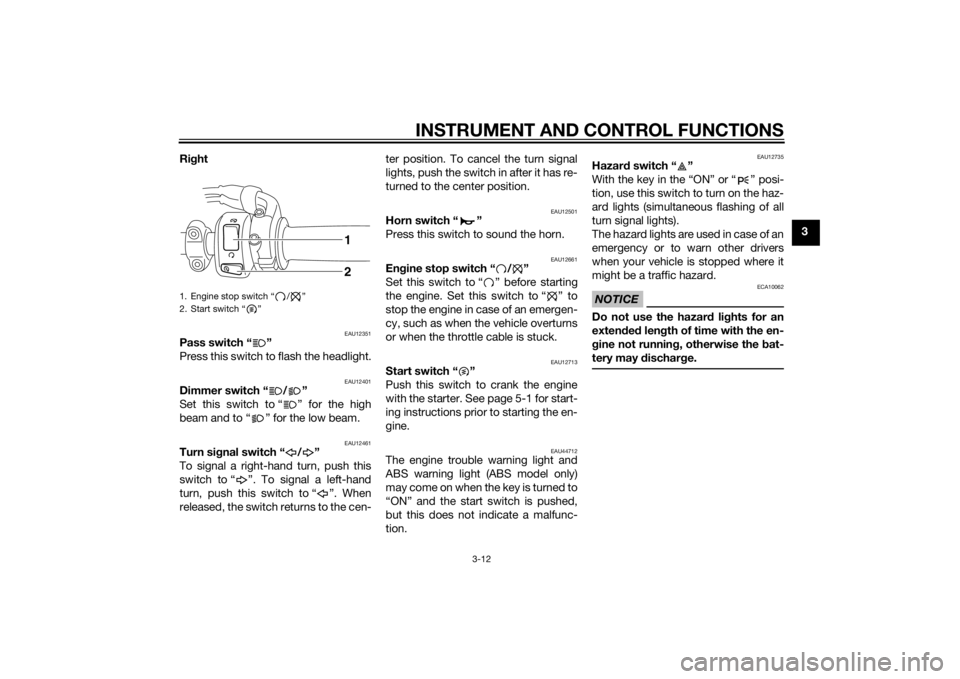

Ri

ght

EAU12351

Pass switch “ ”

Press this switch to flash the headlight.

EAU12401

Dimmer switch “ / ”

Set this switch to “ ” for the high

beam and to “ ” for the low beam.

EAU12461

Turn si gnal switch “ / ”

To signal a right-hand turn, push this

switch to “ ”. To signal a left-hand

turn, push this switch to “ ”. When

released, the switch returns to the cen- ter position. To cancel the turn signal

lights, push the switch in after it has re-

turned to the center position.

EAU12501

Horn switch “ ”

Press this switch to sound the horn.

EAU12661

En

gine stop switch “ / ”

Set this switch to “ ” before starting

the engine. Set this switch to “ ” to

stop the engine in case of an emergen-

cy, such as when the vehicle overturns

or when the throttle cable is stuck.

EAU12713

Start switch “ ”

Push this switch to crank the engine

with the starter. See page 5-1 for start-

ing instructions prior to starting the en-

gine.

EAU44712

The engine trouble warning light and

ABS warning light (ABS model only)

may come on when the key is turned to

“ON” and the start switch is pushed,

but this does not indicate a malfunc-

tion.

EAU12735

Hazar d switch “ ”

With the key in the “ON” or “ ” posi-

tion, use this switch to turn on the haz-

ard lights (simultaneous flashing of all

turn signal lights).

The hazard lights are used in case of an

emergency or to warn other drivers

when your vehicle is stopped where it

might be a traffic hazard.NOTICE

ECA10062

Do not use the hazar d lig hts for an

exten ded len gth of time with the en-

g ine not runnin g, otherwise the bat-

tery may d ischarge.

1. Engine stop switch “ / ”

2. Start switch “ ”

12

U2SHE1E0.book Page 12 Tuesday, July 15, 2014 4:04 PM

Page 31 of 110

INSTRUMENT AND CONTROL FUNCTIONS

3-14

3

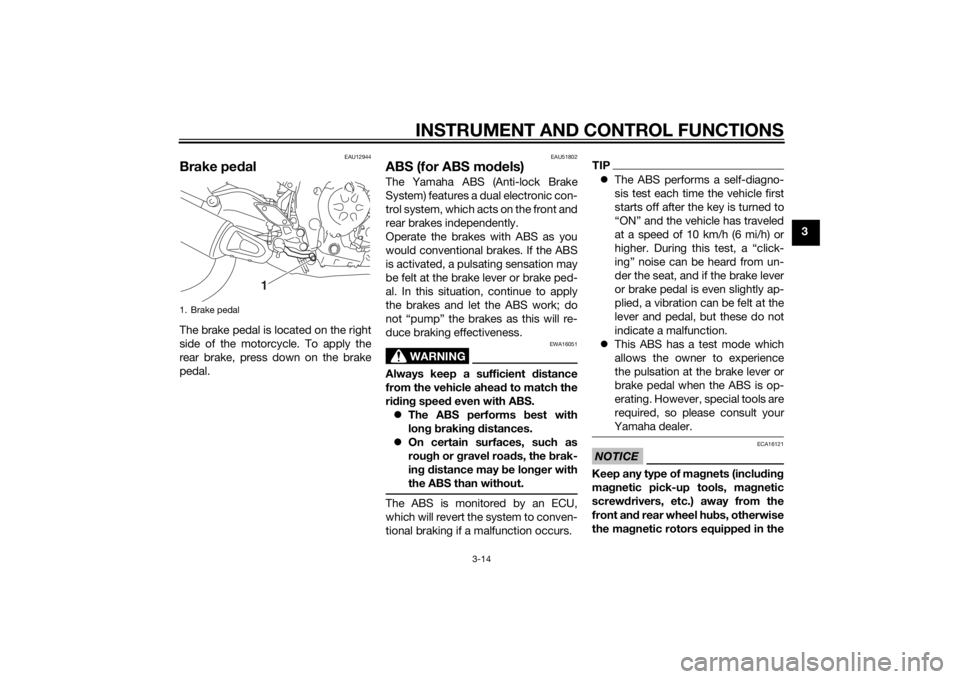

EAU12944

Brake pedalThe brake pedal is located on the right

side of the motorcycle. To apply the

rear brake, press down on the brake

pedal.

EAU51802

ABS (for ABS mo dels)The Yamaha ABS (Anti-lock Brake

System) features a dual electronic con-

trol system, which acts on the front and

rear brakes independently.

Operate the brakes with ABS as you

would conventional brakes. If the ABS

is activated, a pulsating sensation may

be felt at the brake lever or brake ped-

al. In this situation, continue to apply

the brakes and let the ABS work; do

not “pump” the brakes as this will re-

duce braking effectiveness.

WARNING

EWA16051

Always keep a sufficient d istance

from the vehicle ahead to match the

ri din g speed even with ABS.

The ABS performs best with

lon g b rakin g d istances.

On certain surfaces, such as

rou gh or g ravel roa ds, the b rak-

in g d istance may be lon ger with

the ABS than without.The ABS is monitored by an ECU,

which will revert the system to conven-

tional braking if a malfunction occurs.

TIP The ABS performs a self-diagno-

sis test each time the vehicle first

starts off after the key is turned to

“ON” and the vehicle has traveled

at a speed of 10 km/h (6 mi/h) or

higher. During this test, a “click-

ing” noise can be heard from un-

der the seat, and if the brake lever

or brake pedal is even slightly ap-

plied, a vibration can be felt at the

lever and pedal, but these do not

indicate a malfunction.

This ABS has a test mode which

allows the owner to experience

the pulsation at the brake lever or

brake pedal when the ABS is op-

erating. However, special tools are

required, so please consult your

Yamaha dealer.NOTICE

ECA16121

Keep any type of mag nets (including

ma gnetic pick-up tools, mag netic

screw drivers, etc.) away from the

front an d rear wheel hu bs, otherwise

the ma gnetic rotors equippe d in the

1. Brake pedal

1

U2SHE1E0.book Page 14 Tuesday, July 15, 2014 4:04 PM

Page 45 of 110

FOR YOUR SAFETY – PRE-OPERATION CHECKS

4-2

4

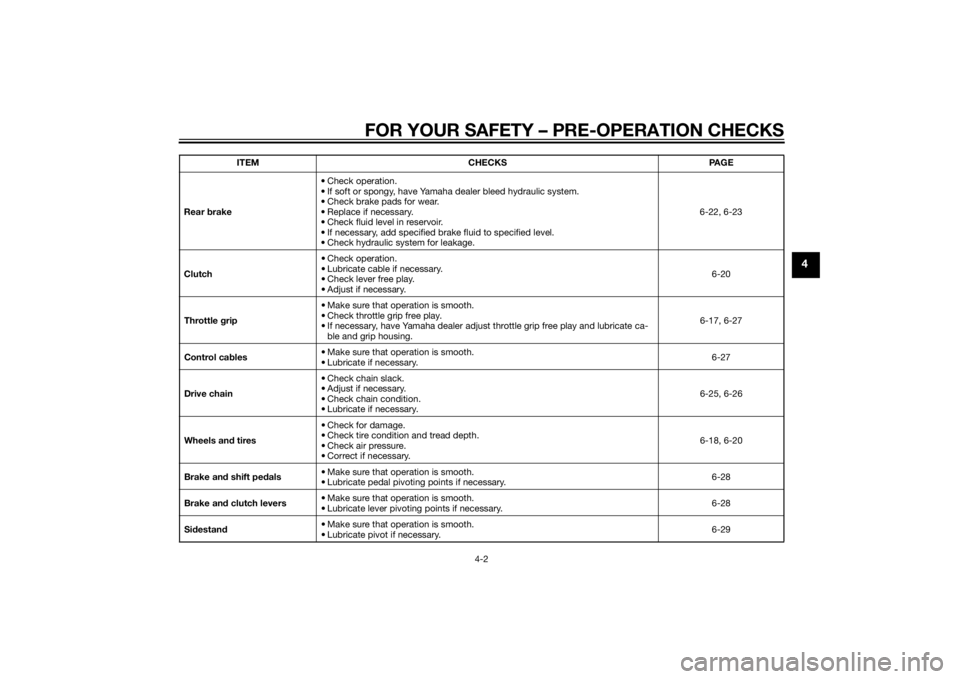

Rear brake • Check operation.

• If soft or spongy, have Yamaha dealer bleed hydraulic system.

• Check brake pads for wear.

• Replace if necessary.

• Check fluid level in reservoir.

• If necessary, add specified brake fluid to specified level.

• Check hydraulic system for leakage. 6-22, 6-23

Clutch • Check operation.

• Lubricate cable if necessary.

• Check lever free play.

• Adjust if necessary.

6-20

Throttle grip • Make sure that operation is smooth.

• Check throttle grip free play.

• If necessary, have Yamaha dealer adjust throttle grip free play and lubricate ca-

ble and grip housing. 6-17, 6-27

Control ca bles • Make sure that operation is smooth.

• Lubricate if necessary. 6-27

Drive chain • Check chain slack.

• Adjust if necessary.

• Check chain condition.

• Lubricate if necessary.

6-25, 6-26

Wheels an d tires • Check for damage.

• Check tire condition and tread depth.

• Check air pressure.

• Correct if necessary.

6-18, 6-20

Brake an d shift pe dals • Make sure that operation is smooth.

• Lubricate pedal pivoting points if necessary. 6-28

Brake an d clutch levers • Make sure that operation is smooth.

• Lubricate lever pivoting points if necessary.

6-28

Si destan d • Make sure that operation is smooth.

• Lubricate pivot if necessary.

6-29

ITEM CHECKS PAGE

U2SHE1E0.book Page 2 Tuesday, July 15, 2014 4:04 PM

Page 55 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-5

6

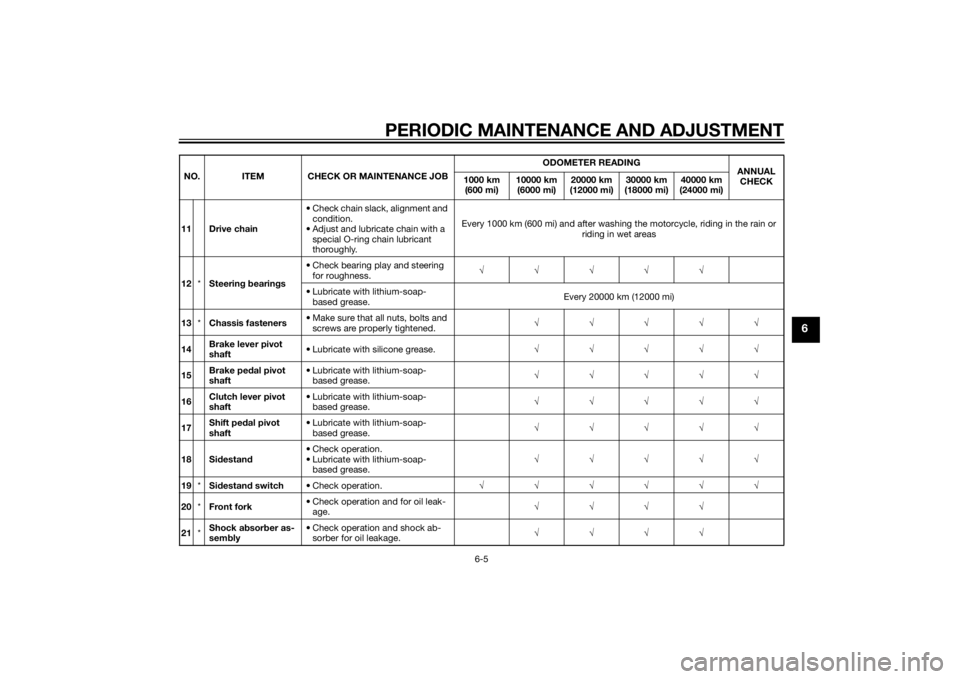

11 Drive chain• Check chain slack, alignment and

condition.

• Adjust and lubricate chain with a special O-ring chain lubricant

thoroughly. Every 1000 km (600 mi) and after washing the motorcycle, riding in the rain or

riding in wet areas

12 *Steerin g b earin gs • Check bearing play and steering

for roughness. √√√√√

• Lubricate with lithium-soap- based grease. Every 20000 km (12000 mi)

13 *Chassis fasteners • Make sure that all nuts, bolts and

screws are properly tightened. √√√√√

14 Brake lever pivot

shaft

• Lubricate with silicone grease.

√√√√√

15 Brake ped

al pivot

shaft • Lubricate with lithium-soap-

based grease. √√√√√

16 Clutch lever pivot

shaft • Lubricate with lithium-soap-

based grease. √√√√√

17 Shift ped

al pivot

shaft • Lubricate with lithium-soap-

based grease. √√√√√

18 Si destan d • Check operation.

• Lubricate with lithium-soap-

based grease. √√√√√

19 *Sidestan d switch • Check operation. √√√√√√

20 *Front fork • Check operation and for oil leak-

age. √√√√

21 *Shock a

bsor ber as-

sem bly • Check operation and shock ab-

sorber for oil leakage. √√√√

NO. ITEM CHECK OR MAINTENANCE JOB

ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 10000 km

(6000 mi) 20000 km

(12000 mi) 30000 km

( 18

000 mi) 40000 km

(24000 mi)

U2SHE1E0.book Page 5 Tuesday, July 15, 2014 4:04 PM

Page 75 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-25

6

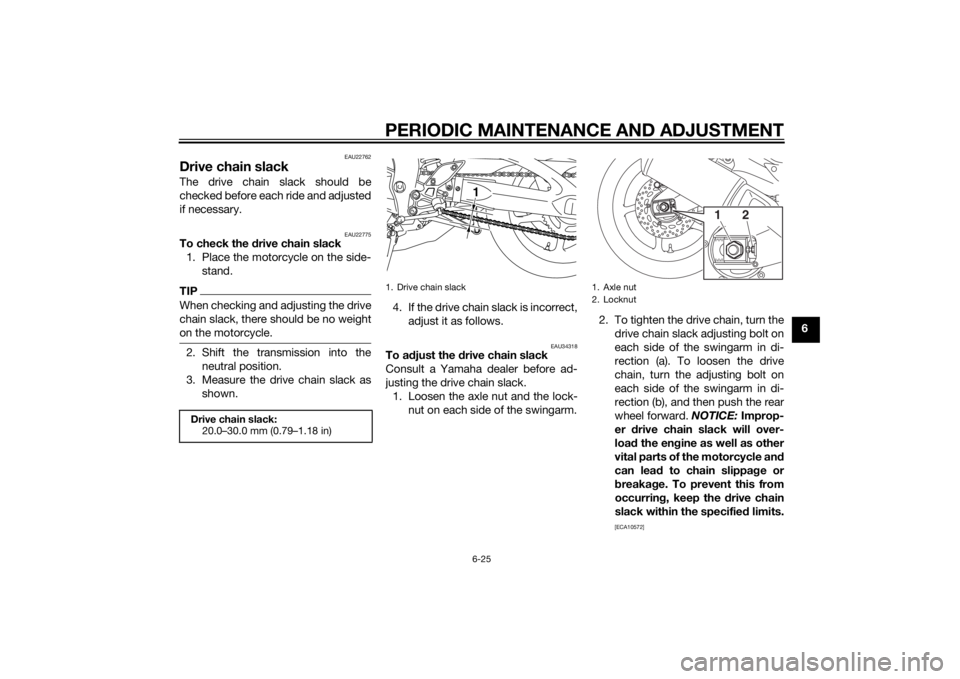

EAU22762

Drive chain slackThe drive chain slack should be

checked before each ride and adjusted

if necessary.

EAU22775

To check the drive chain slack

1. Place the motorcycle on the side- stand.TIPWhen checking and adjusting the drive

chain slack, there should be no weight

on the motorcycle.2. Shift the transmission into the neutral position.

3. Measure the drive chain slack as shown. 4. If the drive chain slack is incorrect,

adjust it as follows.

EAU34318

To a djust the drive chain slack

Consult a Yamaha dealer before ad-

justing the drive chain slack. 1. Loosen the axle nut and the lock- nut on each side of the swingarm. 2. To tighten the drive chain, turn the

drive chain slack adjusting bolt on

each side of the swingarm in di-

rection (a). To loosen the drive

chain, turn the adjusting bolt on

each side of the swingarm in di-

rection (b), and then push the rear

wheel forward. NOTICE: Improp-

er drive chain slack will over-

loa d the en gine as well as other

vital parts of the motorcycle and

can lead to chain slippa ge or

b reakag e. To prevent this from

occurrin g, keep the d rive chain

slack within the specified limits.

[ECA10572]

Drive chain slack:

20.0–30.0 mm (0.79–1.18 in)

1. Drive chain slack

1

1. Axle nut

2. Locknut

1

2

U2SHE1E0.book Page 25 Tuesday, July 15, 2014 4:04 PM

Page 76 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-26

6

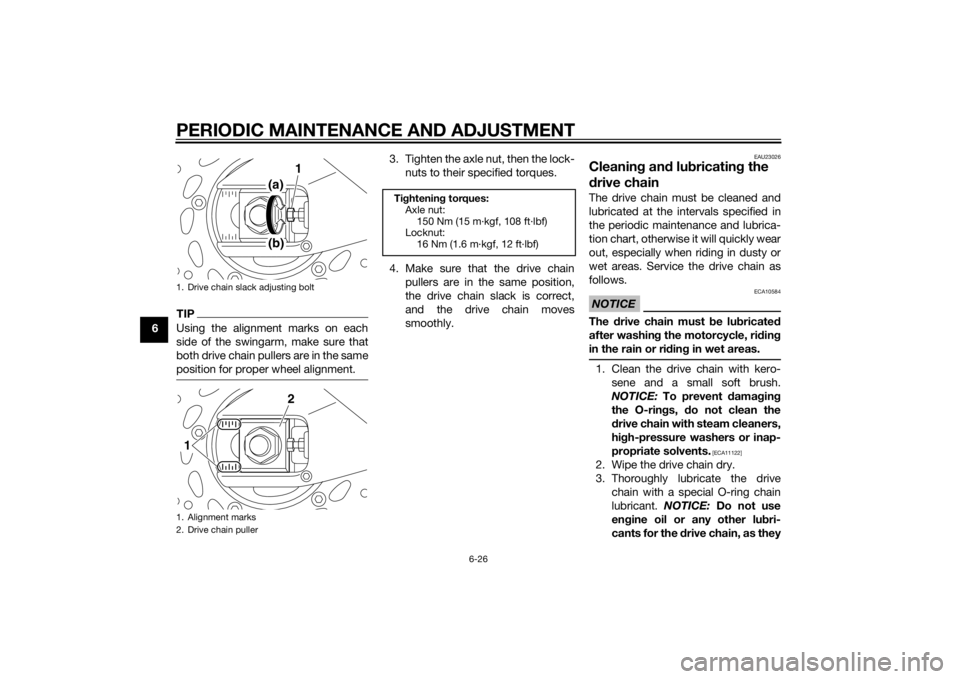

TIPUsing the alignment marks on each

side of the swingarm, make sure that

both drive chain pullers are in the same

position for proper wheel alignment.

3. Tighten the axle nut, then the lock-nuts to their specified torques.

4. Make sure that the drive chain pullers are in the same position,

the drive chain slack is correct,

and the drive chain moves

smoothly.

EAU23026

Cleanin g an d lu bricatin g the

d rive chainThe drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly wear

out, especially when riding in dusty or

wet areas. Service the drive chain as

follows.NOTICE

ECA10584

The drive chain must be lu bricated

after washin g the motorcycle, ri din g

in the rain or ri din g in wet areas.1. Clean the drive chain with kero-

sene and a small soft brush.

NOTICE: To prevent d amaging

the O-ring s, do not clean the

d rive chain with steam cleaners,

hi gh-pressure washers or inap-

propriate solvents.

[ECA11122]

2. Wipe the drive chain dry.

3. Thoroughly lubricate the drive chain with a special O-ring chain

lubricant. NOTICE: Do not use

en gine oil or any other lu bri-

cants for the drive chain, as they

1. Drive chain slack adjusting bolt

1. Alignment marks

2. Drive chain puller

1

(a)(b)

2

1

Ti ghtenin g torques:

Axle nut: 150 Nm (15 m·kgf, 108 ft·lbf)

Locknut:

16 Nm (1.6 m·kgf, 12 ft·lbf)

U2SHE1E0.book Page 26 Tuesday, July 15, 2014 4:04 PM

Page 92 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-42

6

EAU44802

Rear wheel (for non-ABS

models)

WARNING

EWA14841

For the ABS mo del, have a Yamaha

d ealer remove an d install the wheel.

EAU56701

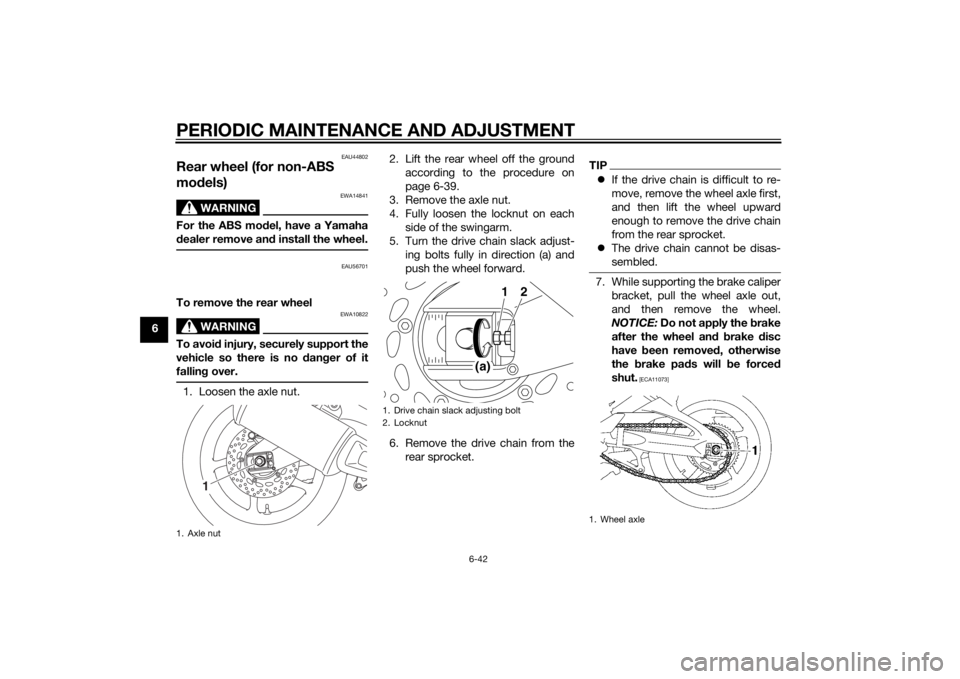

To remove the rear wheel

WARNING

EWA10822

To avoi d injury, securely support the

vehicle so there is no dan ger of it

fallin g over.1. Loosen the axle nut. 2. Lift the rear wheel off the ground

according to the procedure on

page 6-39.

3. Remove the axle nut.

4. Fully loosen the locknut on each side of the swingarm.

5. Turn the drive chain slack adjust- ing bolts fully in direction (a) and

push the wheel forward.

6. Remove the drive chain from the rear sprocket.

TIPIf the drive chain is difficult to re-

move, remove the wheel axle first,

and then lift the wheel upward

enough to remove the drive chain

from the rear sprocket.

The drive chain cannot be disas-

sembled.7. While supporting the brake caliper

bracket, pull the wheel axle out,

and then remove the wheel.

NOTICE: Do not apply the b rake

after the wheel an d b rake disc

have been removed , otherwise

the brake pa ds will be forced

shut.

[ECA11073]

1. Axle nut

1

1. Drive chain slack adjusting bolt

2. Locknut

2

(a)

1

1. Wheel axle

U2SHE1E0.book Page 42 Tuesday, July 15, 2014 4:04 PM

Page 93 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-43

6

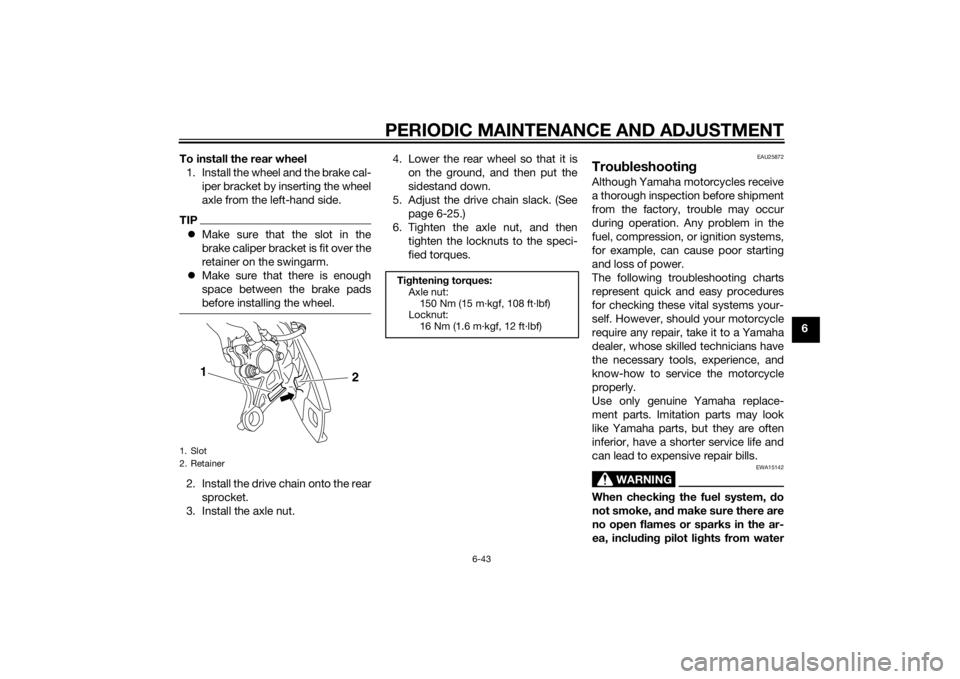

To install the rear wheel

1. Install the wheel and the brake cal- iper bracket by inserting the wheel

axle from the left-hand side.

TIPMake sure that the slot in the

brake caliper bracket is fit over the

retainer on the swingarm.

Make sure that there is enough

space between the brake pads

before installing the wheel.2. Install the drive chain onto the rear

sprocket.

3. Install the axle nut. 4. Lower the rear wheel so that it is

on the ground, and then put the

sidestand down.

5. Adjust the drive chain slack. (See page 6-25.)

6. Tighten the axle nut, and then tighten the locknuts to the speci-

fied torques.

EAU25872

Trou bleshootin gAlthough Yamaha motorcycles receive

a thorough inspection before shipment

from the factory, trouble may occur

during operation. Any problem in the

fuel, compression, or ignition systems,

for example, can cause poor starting

and loss of power.

The following troubleshooting charts

represent quick and easy procedures

for checking these vital systems your-

self. However, should your motorcycle

require any repair, take it to a Yamaha

dealer, whose skilled technicians have

the necessary tools, experience, and

know-how to service the motorcycle

properly.

Use only genuine Yamaha replace-

ment parts. Imitation parts may look

like Yamaha parts, but they are often

inferior, have a shorter service life and

can lead to expensive repair bills.

WARNING

EWA15142

When checkin g the fuel system, d o

not smoke, an d make sure there are

no open flames or sparks in the ar-

ea, inclu din g pilot li ghts from water

1. Slot

2. Retainer

1

2

Ti ghtenin g torques:

Axle nut: 150 Nm (15 m·kgf, 108 ft·lbf)

Locknut:

16 Nm (1.6 m·kgf, 12 ft·lbf)

U2SHE1E0.book Page 43 Tuesday, July 15, 2014 4:04 PM