wheel YAMAHA FZ8 S 2012 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2012, Model line: FZ8 S, Model: YAMAHA FZ8 S 2012Pages: 110, PDF Size: 3.01 MB

Page 71 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-21

6

WARNING

EWA10472

Have a Yamaha d ealer replace

excessively worn tires. Besid es

b ein g ille gal, operatin g the vehi-

cle with excessively worn tires

d ecreases ri din g sta bility an d

can lead to loss of control.

The replacement of all wheel

and b rake-relate d parts, inclu d-

in g the tires, shoul d b e left to a

Yamaha dealer, who has the

necessary professional knowl-

e dge an d experience to do so.

Ride at mo derate spee ds after

chan gin g a tire since the tire

surface must first be “ broken

in” for it to develop its optimal

characteristics.

Tire information

This model is equipped with tubeless

tires and tire air valves.

Tires age, even if they have not been

used or have only been used occasion-

ally. Cracking of the tread and sidewall

rubber, sometimes accompanied by

carcass deformation, is an evidence of

ageing. Old and aged tires shall be

checked by tire specialists to ascertain

their suitability for further use.

WARNING

EWA10482

The front an d rear tires shoul d

b e of the same make an d d e-

si gn, otherwise the han dlin g characteristics of the motorcy-

cle may b

e different, which

coul d lea d to an acci dent.

Always make sure that the valve

caps are securely installe d to

prevent air pressure leaka ge.

Use only the tire valves an d

valve cores liste d below to

avoi d tire deflation durin g a

hi gh-spee d ri de.

After extensive tests, only the tires list-

ed below have been approved for this

model by Yamaha.

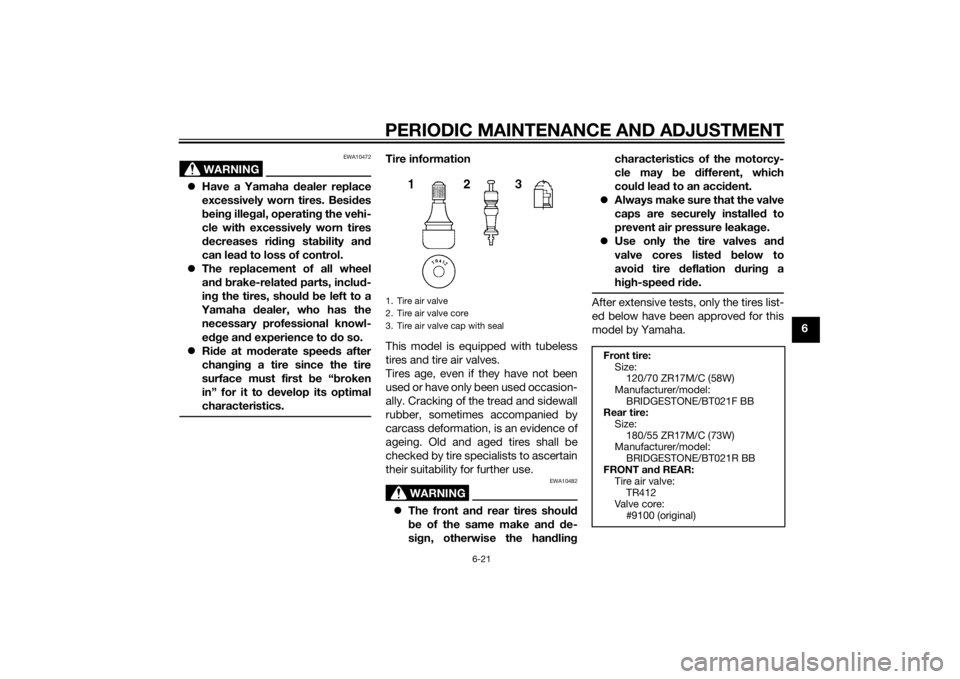

1. Tire air valve

2. Tire air valve core

3. Tire air valve cap with seal

Front tire:

Size: 120/70 ZR17M/C (58W)

Manufacturer/model: BRIDGESTONE/BT021F BB

Rear tire:

Size: 180/55 ZR17M/C (73W)

Manufacturer/model:

BRIDGESTONE/BT021R BB

FRONT and REAR:

Tire air valve:

TR412

Valve core: #9100 (original)

U42PE4E0.book Page 21 Wedne sday, August 6, 2014 3:25 PM

Page 72 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-22

6

WARNING

EWA10601

This motorcycle is fitted with super-

hi gh-spee d tires. Note the following

points in or der to make the most ef-

ficient use of these tires. Use only the specifie d replace-

ment tires. Other tires may run

the dan ger of bursting at super

hi gh spee ds.

Bran d-new tires can have a rel-

atively poor g rip on certain roa d

surfaces until they have been

“ b roken in”. Therefore, it is a d-

visa ble before doin g any hi gh-

speed ridin g to ri de conserva-

tively for approximately 100 km

(60 mi) after installin g a new tire.

The tires must b e warmed up

b efore a hi gh-spee d run.

Always a djust the tire air pres-

sure accor din g to the operating

con ditions.

EAU21963

Cast wheelsTo maximize the performance, durabil-

ity, and safe operation of your vehicle,

note the following points regarding the

specified wheels.

The wheel rims should be

checked for cracks, bends, warp-

age or other damage before each

ride. If any damage is found, have

a Yamaha dealer replace the

wheel. Do not attempt even the

smallest repair to the wheel. A de-

formed or cracked wheel must be

replaced.

The wheel should be balanced

whenever either the tire or wheel

has been changed or replaced. An

unbalanced wheel can result in

poor performance, adverse han-

dling characteristics, and a short-

ened tire life.

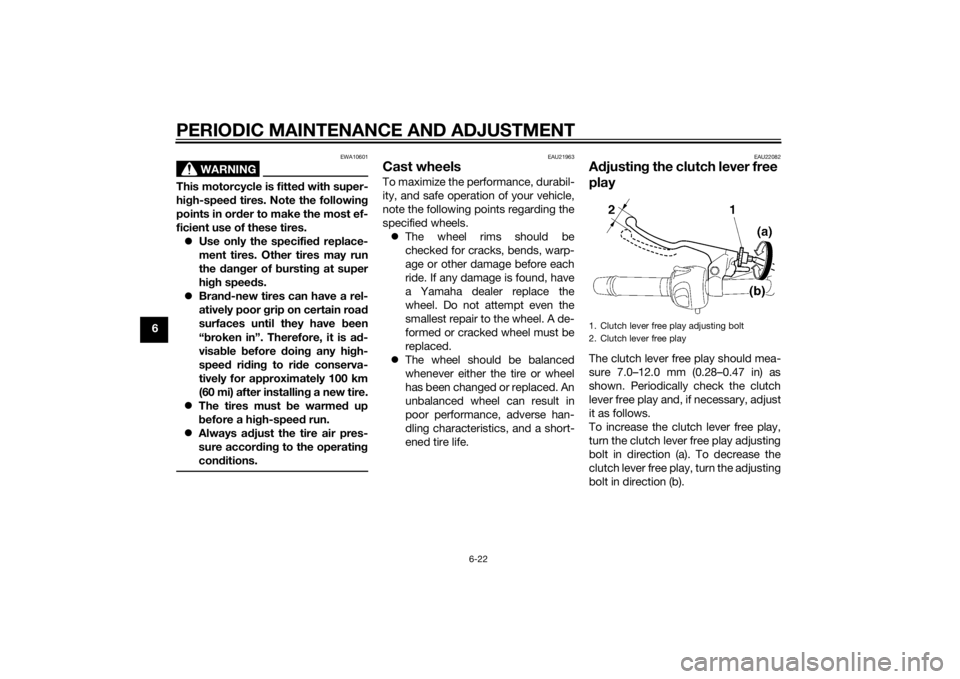

EAU22082

Adjustin g the clutch lever free

playThe clutch lever free play should mea-

sure 7.0–12.0 mm (0.28–0.47 in) as

shown. Periodically check the clutch

lever free play and, if necessary, adjust

it as follows.

To increase the clutch lever free play,

turn the clutch lever free play adjusting

bolt in direction (a). To decrease the

clutch lever free play, turn the adjusting

bolt in direction (b).1. Clutch lever free play adjusting bolt

2. Clutch lever free play

U42PE4E0.book Page 22 Wedne sday, August 6, 2014 3:25 PM

Page 77 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-27

6

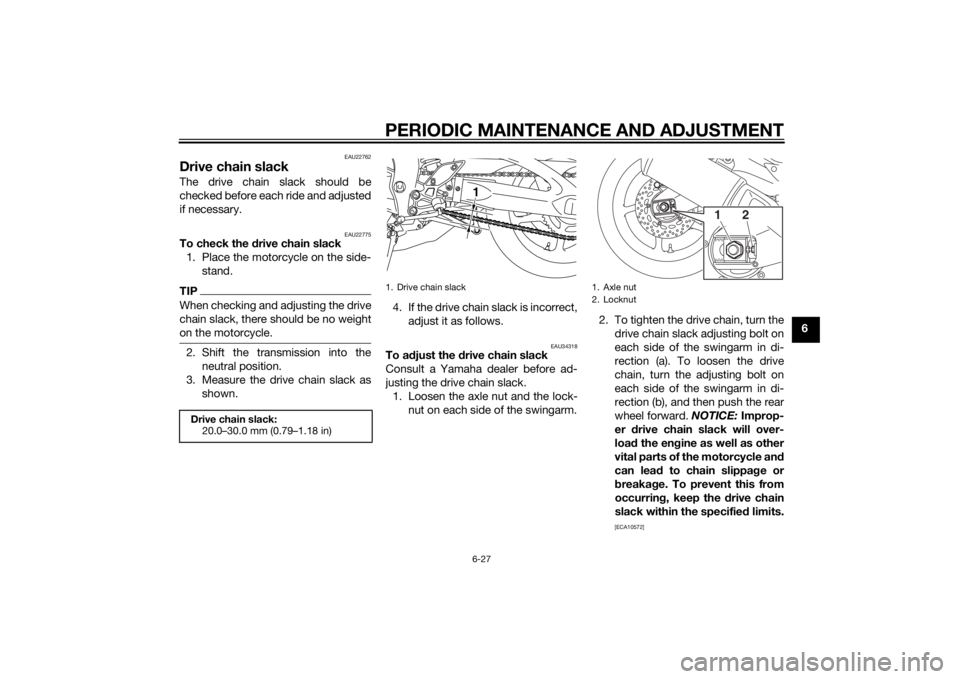

EAU22762

Drive chain slackThe drive chain slack should be

checked before each ride and adjusted

if necessary.

EAU22775

To check the drive chain slack

1. Place the motorcycle on the side- stand.TIPWhen checking and adjusting the drive

chain slack, there should be no weight

on the motorcycle.2. Shift the transmission into the neutral position.

3. Measure the drive chain slack as shown. 4. If the drive chain slack is incorrect,

adjust it as follows.

EAU34318

To a djust the drive chain slack

Consult a Yamaha dealer before ad-

justing the drive chain slack. 1. Loosen the axle nut and the lock- nut on each side of the swingarm. 2. To tighten the drive chain, turn the

drive chain slack adjusting bolt on

each side of the swingarm in di-

rection (a). To loosen the drive

chain, turn the adjusting bolt on

each side of the swingarm in di-

rection (b), and then push the rear

wheel forward. NOTICE: Improp-

er drive chain slack will over-

loa d the en gine as well as other

vital parts of the motorcycle an d

can lead to chain slippa ge or

b reakag e. To prevent this from

occurrin g, keep the d rive chain

slack within the specified limits.

[ECA10572]

Drive chain slack:

20.0–30.0 mm (0.79–1.18 in)

1. Drive chain slack

1

1. Axle nut

2. Locknut

1

2

U42PE4E0.book Page 27 Wedne sday, August 6, 2014 3:25 PM

Page 78 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-28

6

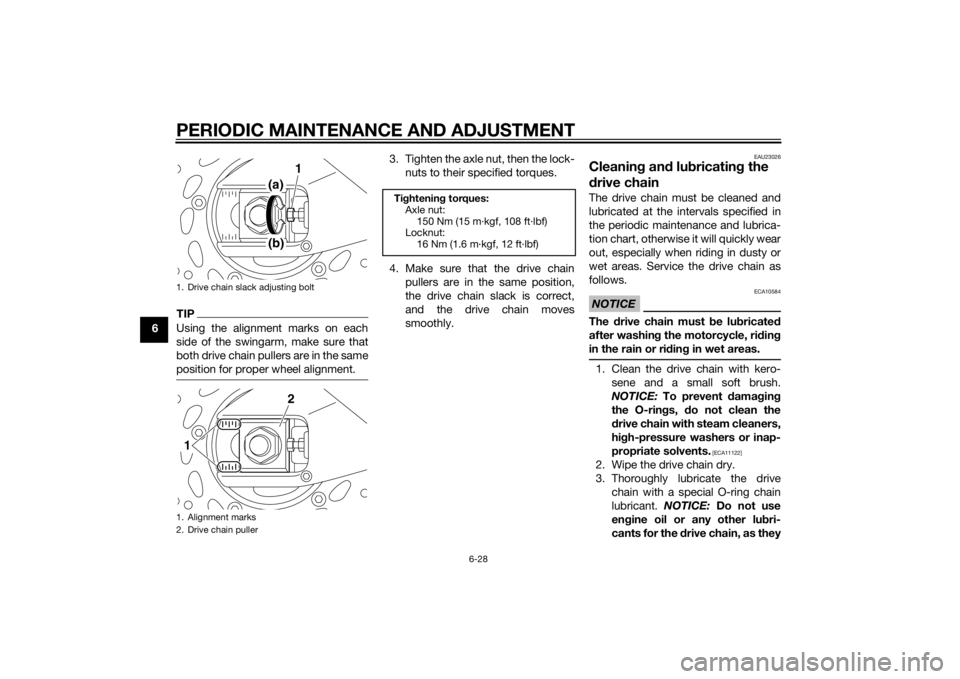

TIPUsing the alignment marks on each

side of the swingarm, make sure that

both drive chain pullers are in the same

position for proper wheel alignment.

3. Tighten the axle nut, then the lock-nuts to their specified torques.

4. Make sure that the drive chain pullers are in the same position,

the drive chain slack is correct,

and the drive chain moves

smoothly.

EAU23026

Cleanin g an d lu bricatin g the

d rive chainThe drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly wear

out, especially when riding in dusty or

wet areas. Service the drive chain as

follows.NOTICE

ECA10584

The drive chain must be lu bricated

after washin g the motorcycle, ri din g

in the rain or ri din g in wet areas.1. Clean the drive chain with kero-

sene and a small soft brush.

NOTICE: To prevent d amaging

the O-ring s, do not clean the

d rive chain with steam cleaners,

hi gh-pressure washers or inap-

propriate solvents.

[ECA11122]

2. Wipe the drive chain dry.

3. Thoroughly lubricate the drive chain with a special O-ring chain

lubricant. NOTICE: Do not use

en gine oil or any other lu bri-

cants for the drive chain, as they

1. Drive chain slack adjusting bolt

1. Alignment marks

2. Drive chain puller

1

(a)(b)

2

1

Ti ghtenin g torques:

Axle nut: 150 Nm (15 m·kgf, 108 ft·lbf)

Locknut:

16 Nm (1.6 m·kgf, 12 ft·lbf)

U42PE4E0.book Page 28 Wedne sday, August 6, 2014 3:25 PM

Page 82 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-32

6

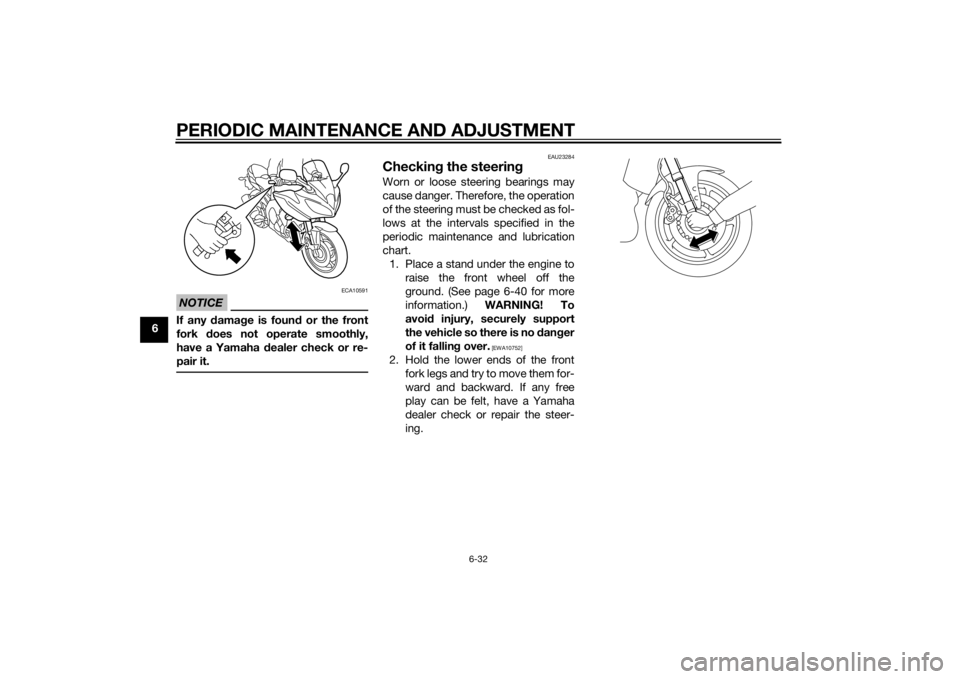

NOTICE

ECA10591

If any damage is foun d or the front

fork does not operate smoothly,

have a Yamaha d ealer check or re-

pair it.

EAU23284

Checkin g the steerin gWorn or loose steering bearings may

cause danger. Therefore, the operation

of the steering must be checked as fol-

lows at the intervals specified in the

periodic maintenance and lubrication

chart.

1. Place a stand under the engine to raise the front wheel off the

ground. (See page 6-40 for more

information.) WARNING! To

avoi d injury, securely support

the vehicle so there is no dan ger

of it fallin g over.

[EWA10752]

2. Hold the lower ends of the front

fork legs and try to move them for-

ward and backward. If any free

play can be felt, have a Yamaha

dealer check or repair the steer-

ing.

U42PE4E0.book Page 32 Wedne sday, August 6, 2014 3:25 PM

Page 83 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-33

6

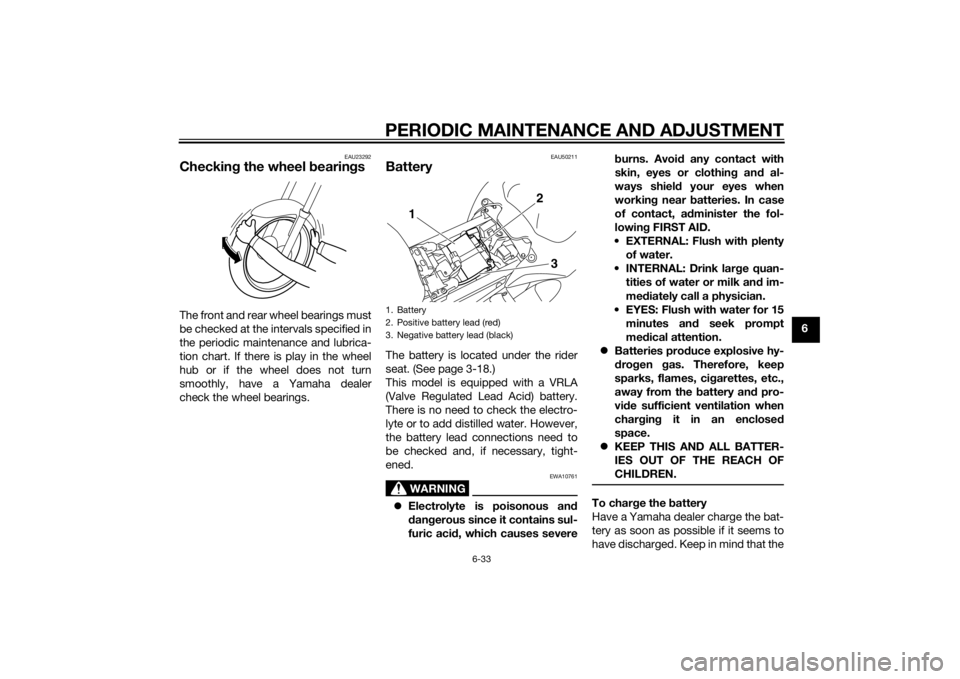

EAU23292

Checking the wheel bearin gsThe front and rear wheel bearings must

be checked at the intervals specified in

the periodic maintenance and lubrica-

tion chart. If there is play in the wheel

hub or if the wheel does not turn

smoothly, have a Yamaha dealer

check the wheel bearings.

EAU50211

BatteryThe battery is located under the rider

seat. (See page 3-18.)

This model is equipped with a VRLA

(Valve Regulated Lead Acid) battery.

There is no need to check the electro-

lyte or to add distilled water. However,

the battery lead connections need to

be checked and, if necessary, tight-

ened.

WARNING

EWA10761

Electrolyte is poisonous an d

d an gerous since it contains sul-

furic aci d, which causes severe b

urns. Avoi d any contact with

skin, eyes or clothin g an d al-

ways shiel d your eyes when

workin g near b atteries. In case

of contact, ad minister the fol-

lowin g FIRST AID.

EXTERNAL: Flush with plenty of water.

INTERNAL: Drink lar ge quan-

tities of water or milk an d im-

me diately call a physician.

EYES: Flush with water for 15 minutes an d seek prompt

me dical attention.

Batteries pro duce explosive hy-

d ro gen gas. Therefore, keep

sparks, flames, ci garettes, etc.,

away from the battery an d pro-

vi de sufficient ventilation when

char gin g it in an enclose d

space.

KEEP THIS AND ALL BATTER-

IES OUT OF THE REACH OF

CHILDREN.

To char ge the b attery

Have a Yamaha dealer charge the bat-

tery as soon as possible if it seems to

have discharged. Keep in mind that the

1. Battery

2. Positive battery lead (red)

3. Negative battery lead (black)

1

2

3

U42PE4E0.book Page 33 Wedne sday, August 6, 2014 3:25 PM

Page 90 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-40

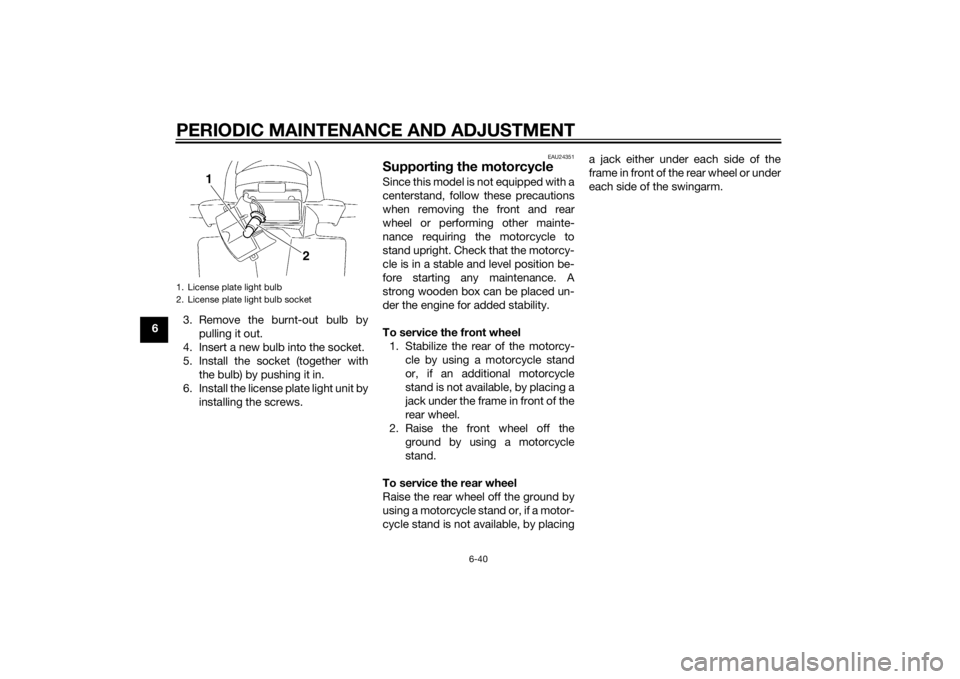

63. Remove the burnt-out bulb by

pulling it out.

4. Insert a new bulb into the socket.

5. Install the socket (together with the bulb) by pushing it in.

6. Install the license plate light unit by installing the screws.

EAU24351

Supportin g the motorcycleSince this model is not equipped with a

centerstand, follow these precautions

when removing the front and rear

wheel or performing other mainte-

nance requiring the motorcycle to

stand upright. Check that the motorcy-

cle is in a stable and level position be-

fore starting any maintenance. A

strong wooden box can be placed un-

der the engine for added stability.

To service the front wheel

1. Stabilize the rear of the motorcy- cle by using a motorcycle stand

or, if an additional motorcycle

stand is not available, by placing a

jack under the frame in front of the

rear wheel.

2. Raise the front wheel off the ground by using a motorcycle

stand.

To service the rear wheel

Raise the rear wheel off the ground by

using a motorcycle stand or, if a motor-

cycle stand is not available, by placing a jack either under each side of the

frame in front of the rear wheel or under

each side of the swingarm.

1. License plate light bulb

2. License plate light bulb socket

1

2

U42PE4E0.book Page 40 Wedne sday, August 6, 2014 3:25 PM

Page 91 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-41

6

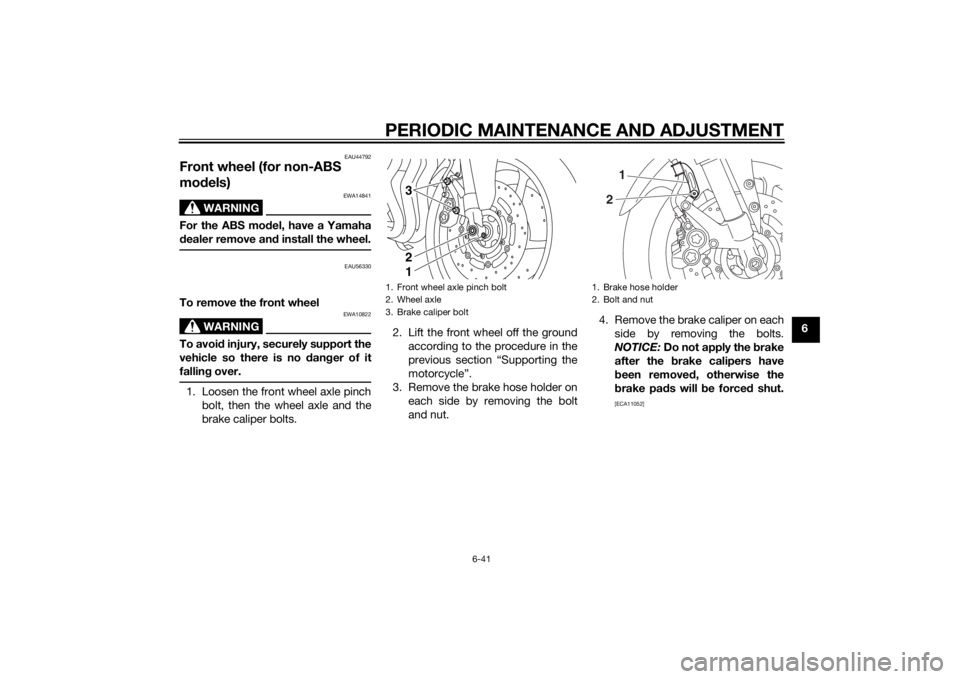

EAU44792

Front wheel (for non-ABS

models)

WARNING

EWA14841

For the ABS mo del, have a Yamaha

d ealer remove an d install the wheel.

EAU56330

To remove the front wheel

WARNING

EWA10822

To avoi d injury, securely support the

vehicle so there is no dan ger of it

fallin g over.1. Loosen the front wheel axle pinch

bolt, then the wheel axle and the

brake caliper bolts. 2. Lift the front wheel off the ground

according to the procedure in the

previous section “Supporting the

motorcycle”.

3. Remove the brake hose holder on each side by removing the bolt

and nut. 4. Remove the brake caliper on each

side by removing the bolts.

NOTICE: Do not apply the b rake

after the b rake calipers have

b een remove d, otherwise the

b rake pad s will be forced shut.

[ECA11052]

1. Front wheel axle pinch bolt

2. Wheel axle

3. Brake caliper bolt

3

2

1

1. Brake hose holder

2. Bolt and nut

1

2

U42PE4E0.book Page 41 Wedne sday, August 6, 2014 3:25 PM

Page 92 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-42

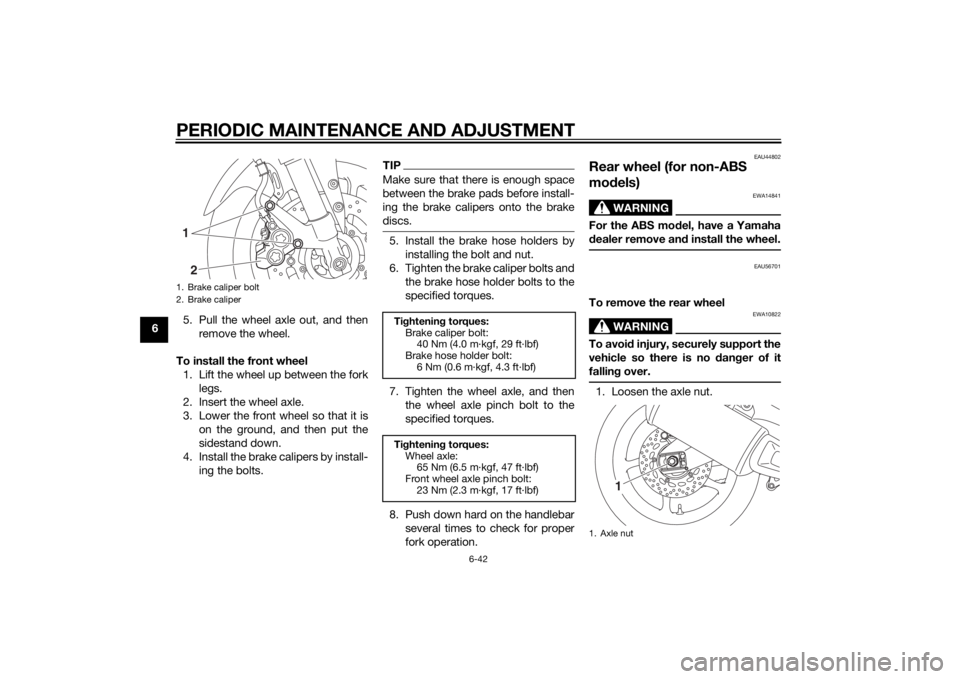

65. Pull the wheel axle out, and then

remove the wheel.

To install the front wheel 1. Lift the wheel up between the fork legs.

2. Insert the wheel axle.

3. Lower the front wheel so that it is on the ground, and then put the

sidestand down.

4. Install the brake calipers by install- ing the bolts.

TIPMake sure that there is enough space

between the brake pads before install-

ing the brake calipers onto the brake

discs.5. Install the brake hose holders byinstalling the bolt and nut.

6. Tighten the brake caliper bolts and the brake hose holder bolts to the

specified torques.

7. Tighten the wheel axle, and then the wheel axle pinch bolt to the

specified torques.

8. Push down hard on the handlebar several times to check for proper

fork operation.

EAU44802

Rear wheel (for non-ABS

mo dels)

WARNING

EWA14841

For the ABS mo del, have a Yamaha

d ealer remove an d install the wheel.

EAU56701

To remove the rear wheel

WARNING

EWA10822

To avoi d injury, securely support the

vehicle so there is no dan ger of it

fallin g over.1. Loosen the axle nut.

1. Brake caliper bolt

2. Brake caliper1

2

Ti ghtenin g torques:

Brake caliper bolt: 40 Nm (4.0 m·kgf, 29 ft·lbf)

Brake hose holder bolt:

6 Nm (0.6 m·kgf, 4.3 ft·lbf)

Ti ghtenin g torques:

Wheel axle: 65 Nm (6.5 m·kgf, 47 ft·lbf)

Front wheel axle pinch bolt:

23 Nm (2.3 m·kgf, 17 ft·lbf)

1. Axle nut

1

U42PE4E0.book Page 42 Wedne sday, August 6, 2014 3:25 PM

Page 93 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-43

6

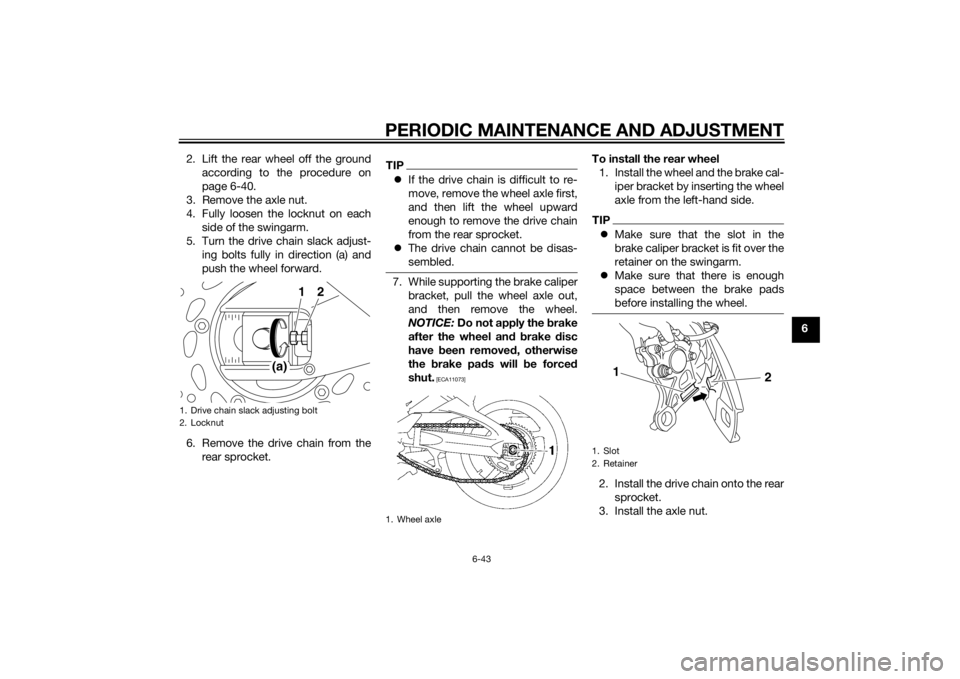

2. Lift the rear wheel off the ground

according to the procedure on

page 6-40.

3. Remove the axle nut.

4. Fully loosen the locknut on each side of the swingarm.

5. Turn the drive chain slack adjust- ing bolts fully in direction (a) and

push the wheel forward.

6. Remove the drive chain from the rear sprocket.

TIPIf the drive chain is difficult to re-

move, remove the wheel axle first,

and then lift the wheel upward

enough to remove the drive chain

from the rear sprocket.

The drive chain cannot be disas-

sembled.7. While supporting the brake caliper

bracket, pull the wheel axle out,

and then remove the wheel.

NOTICE: Do not apply the b rake

after the wheel an d b rake disc

have been removed , otherwise

the brake pad s will be forced

shut.

[ECA11073]

To install the rear wheel 1. Install the wheel and the brake cal- iper bracket by inserting the wheel

axle from the left-hand side.TIPMake sure that the slot in the

brake caliper bracket is fit over the

retainer on the swingarm.

Make sure that there is enough

space between the brake pads

before installing the wheel.2. Install the drive chain onto the rear

sprocket.

3. Install the axle nut.

1. Drive chain slack adjusting bolt

2. Locknut

2

(a)

1

1. Wheel axle

1. Slot

2. Retainer

1

2

U42PE4E0.book Page 43 Wedne sday, August 6, 2014 3:25 PM