ABS YAMAHA FZ8 S 2014 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: FZ8 S, Model: YAMAHA FZ8 S 2014Pages: 110, PDF Size: 3.01 MB

Page 31 of 110

INSTRUMENT AND CONTROL FUNCTIONS

3-14

3

EAU12944

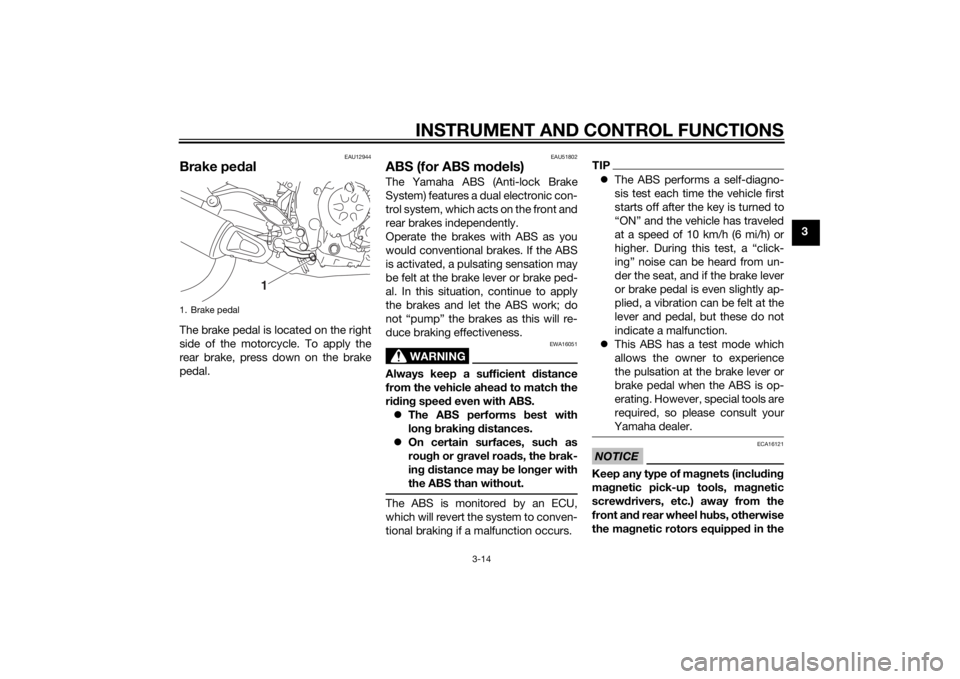

Brake pedalThe brake pedal is located on the right

side of the motorcycle. To apply the

rear brake, press down on the brake

pedal.

EAU51802

ABS (for ABS mo dels)The Yamaha ABS (Anti-lock Brake

System) features a dual electronic con-

trol system, which acts on the front and

rear brakes independently.

Operate the brakes with ABS as you

would conventional brakes. If the ABS

is activated, a pulsating sensation may

be felt at the brake lever or brake ped-

al. In this situation, continue to apply

the brakes and let the ABS work; do

not “pump” the brakes as this will re-

duce braking effectiveness.

WARNING

EWA16051

Always keep a sufficient d istance

from the vehicle ahea d to match the

ri din g speed even with ABS.

The ABS performs best with

lon g b rakin g d istances.

On certain surfaces, such as

rou gh or g ravel roa ds, the b rak-

in g d istance may be lon ger with

the ABS than without.The ABS is monitored by an ECU,

which will revert the system to conven-

tional braking if a malfunction occurs.

TIP The ABS performs a self-diagno-

sis test each time the vehicle first

starts off after the key is turned to

“ON” and the vehicle has traveled

at a speed of 10 km/h (6 mi/h) or

higher. During this test, a “click-

ing” noise can be heard from un-

der the seat, and if the brake lever

or brake pedal is even slightly ap-

plied, a vibration can be felt at the

lever and pedal, but these do not

indicate a malfunction.

This ABS has a test mode which

allows the owner to experience

the pulsation at the brake lever or

brake pedal when the ABS is op-

erating. However, special tools are

required, so please consult your

Yamaha dealer.NOTICE

ECA16121

Keep any type of mag nets (including

ma gnetic pick-up tools, mag netic

screw drivers, etc.) away from the

front an d rear wheel hu bs, otherwise

the ma gnetic rotors equippe d in the

1. Brake pedal

1

U42PE4E0.book Page 14 Wedne sday, August 6, 2014 3:25 PM

Page 32 of 110

INSTRUMENT AND CONTROL FUNCTIONS

3-15

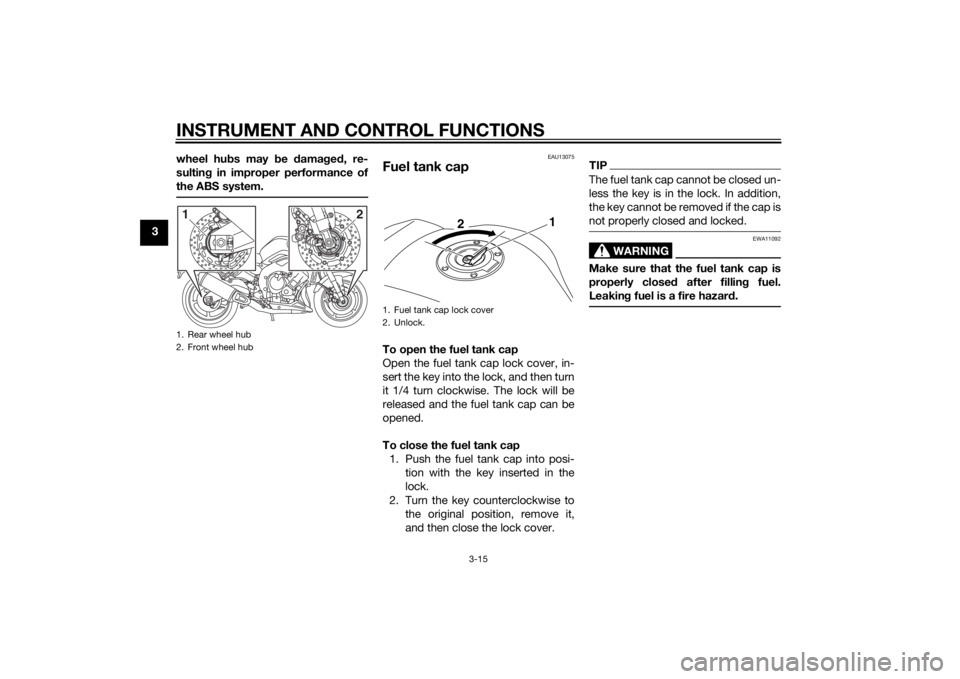

3wheel hu

bs may b e damag ed , re-

sultin g in improper performance of

the ABS system.

EAU13075

Fuel tank capTo open the fuel tank cap

Open the fuel tank cap lock cover, in-

sert the key into the lock, and then turn

it 1/4 turn clockwise. The lock will be

released and the fuel tank cap can be

opened.

To close the fuel tank cap 1. Push the fuel tank cap into posi- tion with the key inserted in the

lock.

2. Turn the key counterclockwise to the original position, remove it,

and then close the lock cover.

TIPThe fuel tank cap cannot be closed un-

less the key is in the lock. In addition,

the key cannot be removed if the cap is

not properly closed and locked.

WARNING

EWA11092

Make sure that the fuel tank cap is

properly close d after fillin g fuel.

Leakin g fuel is a fire hazar d.

1. Rear wheel hub

2. Front wheel hub1

2

1. Fuel tank cap lock cover

2. Unlock.

2 1

U42PE4E0.book Page 15 Wedne

sday, August 6, 2014 3:25 PM

Page 39 of 110

INSTRUMENT AND CONTROL FUNCTIONS

3-22

3

TIPAlthough the total number of clicks of a

damping force adjusting mechanism

may not exactly match the above

specifications due to small differences

in production, the actual number of

clicks always represents the entire ad-

justing range. To obtain a precise ad-justment, it would be advisable to

check the number of clicks of each

damping force adjusting mechanism

and to modify the specifications as

necessary.

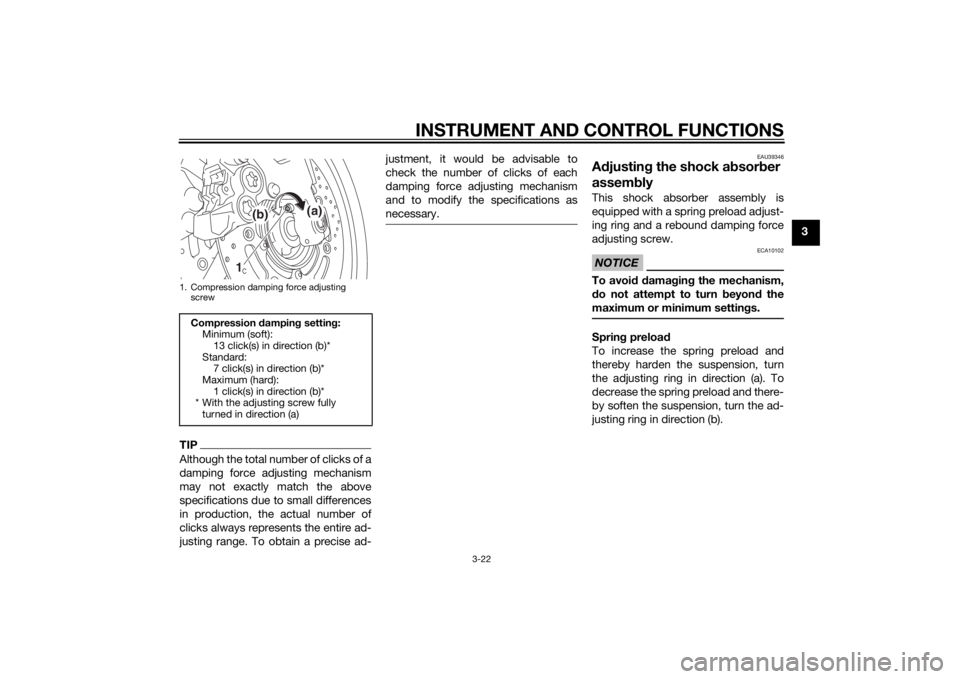

EAU39346

A

djustin g the shock a bsor ber

assem blyThis shock absorber assembly is

equipped with a spring preload adjust-

ing ring and a rebound damping force

adjusting screw.NOTICE

ECA10102

To avoi d d amag ing the mechanism,

d o not attempt to turn beyon d the

maximum or minimum settin gs.Sprin g preloa d

To increase the spring preload and

thereby harden the suspension, turn

the adjusting ring in direction (a). To

decrease the spring preload and there-

by soften the suspension, turn the ad-

justing ring in direction (b).

1. Compression damping force adjusting screwCompression dampin g setting :

Minimum (soft): 13 click(s) in direction (b)*

Standard: 7 click(s) in direction (b)*

Maximum (hard):

1 click(s) in direction (b)*

* With the adjusting screw fully turned in direction (a)

1

(b)

(a)

U42PE4E0.book Page 22 Wedne sday, August 6, 2014 3:25 PM

Page 40 of 110

INSTRUMENT AND CONTROL FUNCTIONS

3-23

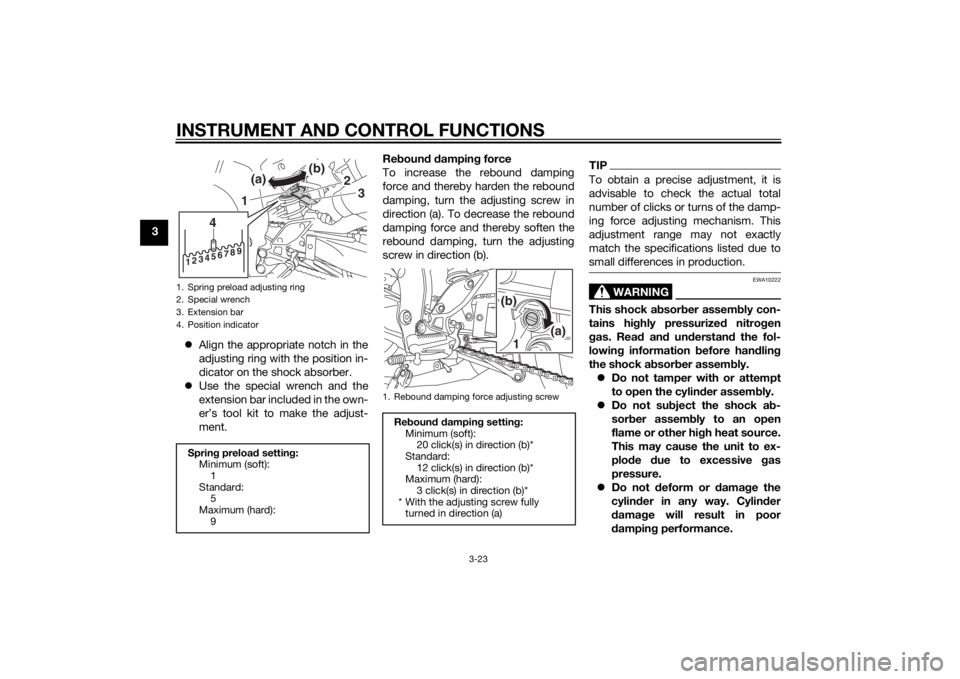

3Align the appropriate notch in the

adjusting ring with the position in-

dicator on the shock absorber.

Use the special wrench and the

extension bar included in the own-

er’s tool kit to make the adjust-

ment. Re

boun d d ampin g force

To increase the rebound damping

force and thereby harden the rebound

damping, turn the adjusting screw in

direction (a). To decrease the rebound

damping force and thereby soften the

rebound damping, turn the adjusting

screw in direction (b).

TIPTo obtain a precise adjustment, it is

advisable to check the actual total

number of clicks or turns of the damp-

ing force adjusting mechanism. This

adjustment range may not exactly

match the specifications listed due to

small differences in production.

WARNING

EWA10222

This shock a bsor ber assem bly con-

tains hi ghly pressurize d nitro gen

g as. Rea d an d und erstan d the fol-

lowin g information b efore handlin g

the shock a bsor ber assem bly.

Do not tamper with or attempt

to open the cylin der assem bly.

Do not su bject the shock a b-

sor ber assem bly to an open

flame or other hi gh heat source.

This may cause the unit to ex-

plo de due to excessive gas

pressure.

Do not deform or d amage the

cylin der in any way. Cylin der

d amag e will result in poor

d ampin g performance.

1. Spring preload adjusting ring

2. Special wrench

3. Extension bar

4. Position indicatorSprin g preloa d setting :

Minimum (soft): 1

Standard: 5

Maximum (hard):

912 34 56 789

4

1 (a)

(b)

2

3

1. Rebound damping force adjusting screwRe boun d d ampin g setting :

Minimum (soft): 20 click(s) in direction (b)*

Standard: 12 click(s) in direction (b)*

Maximum (hard):

3 click(s) in direction (b)*

* With the adjusting screw fully turned in direction (a)

1

(b)

(a)

U42PE4E0.book Page 23 Wedne sday, August 6, 2014 3:25 PM

Page 48 of 110

OPERATION AND IMPORTANT RIDING POINTS

5-2

5a warnin

g or in dicator li ght remains

on, see pa ge 3-4 for the correspon d-

in g warnin g an d in dicator li ght cir-

cuit check.

For ABS models:The ABS warning light should

come on when the main switch is

turned to “ON” and then go off af-

ter traveling at a speed of 10 km/h

(6 mi/h) or higher.

NOTICE

ECA17682

If the ABS warnin g lig ht does not

come on an d then g o off as ex-

plaine d a bove, see pa ge 3-4 for the

warnin g lig ht circuit check.2. Shift the transmission into the

neutral position. The neutral indi-

cator light should come on. If not,

ask a Yamaha dealer to check the

electrical circuit.

3. Start the engine by pushing the start switch.

If the engine fails to start, release

the start switch, wait a few sec-

onds, and then try again. Each

starting attempt should be as

short as possible to preserve the battery. Do not crank the engine

more than 10 seconds on any one

attempt.

NOTICE

ECA11043

For maximum en

gine life, never ac-

celerate har d when the en gine is

col d!

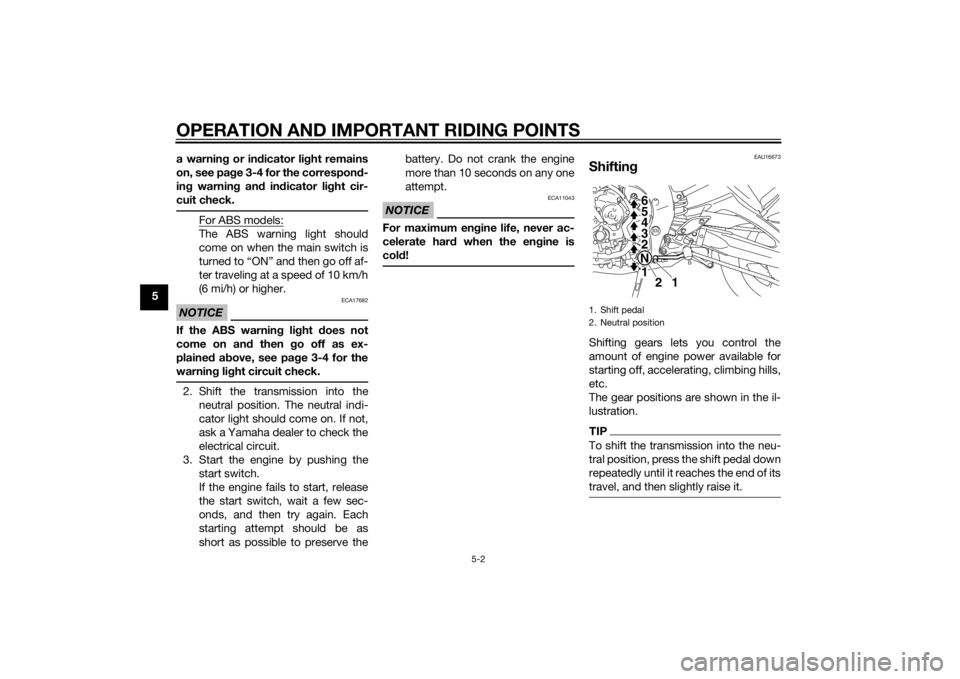

EAU16673

Shiftin gShifting gears lets you control the

amount of engine power available for

starting off, accelerating, climbing hills,

etc.

The gear positions are shown in the il-

lustration.TIPTo shift the transmission into the neu-

tral position, press the shift pedal down

repeatedly until it reaches the end of its

travel, and then slightly raise it.1. Shift pedal

2. Neutral position

1

N

2 3

4

5

6

1

2

U42PE4E0.book Page 2 Wedne

sday, August 6, 2014 3:25 PM

Page 62 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-12

64. If the engine oil is below the mini-

mum level mark, add sufficient oil

of the recommended type to raise

it to the correct level.

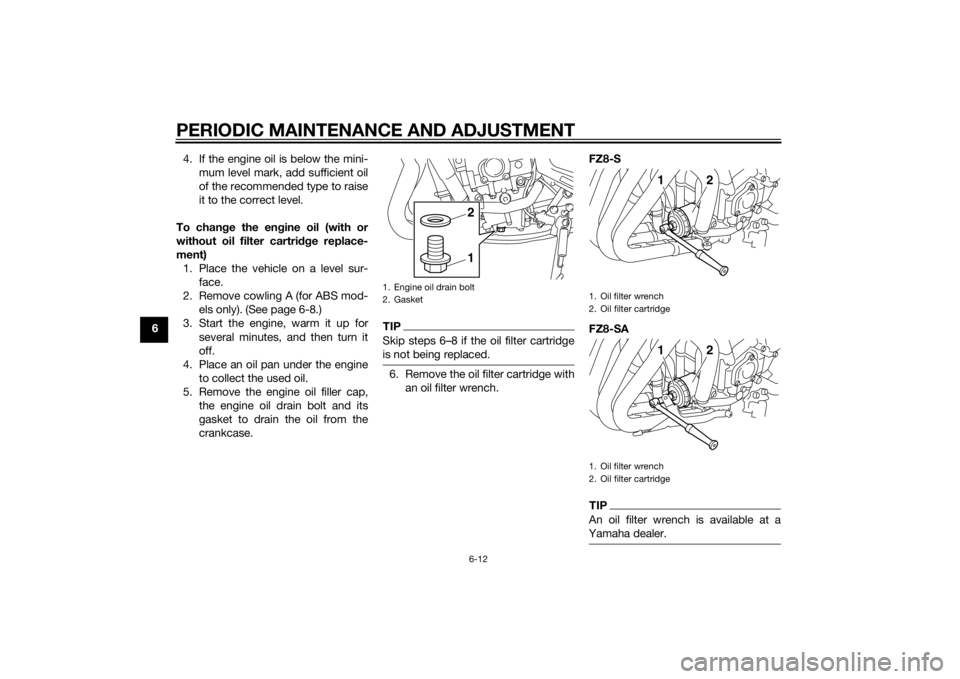

To chan ge the en gine oil (with or

without oil filter cartri dge replace-

ment) 1. Place the vehicle on a level sur- face.

2. Remove cowling A (for ABS mod- els only). (See page 6-8.)

3. Start the engine, warm it up for several minutes, and then turn it

off.

4. Place an oil pan under the engine to collect the used oil.

5. Remove the engine oil filler cap, the engine oil drain bolt and its

gasket to drain the oil from the

crankcase.

TIPSkip steps 6–8 if the oil filter cartridge

is not being replaced.6. Remove the oil filter cartridge withan oil filter wrench. FZ8-S

FZ8-SA

TIPAn oil filter wrench is available at a

Yamaha dealer.

1. Engine oil drain bolt

2. Gasket

12

1. Oil filter wrench

2. Oil filter cartridge

1. Oil filter wrench

2. Oil filter cartridge

1

2

1

2

U42PE4E0.book Page 12 Wedne sday, August 6, 2014 3:25 PM

Page 64 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-14

6

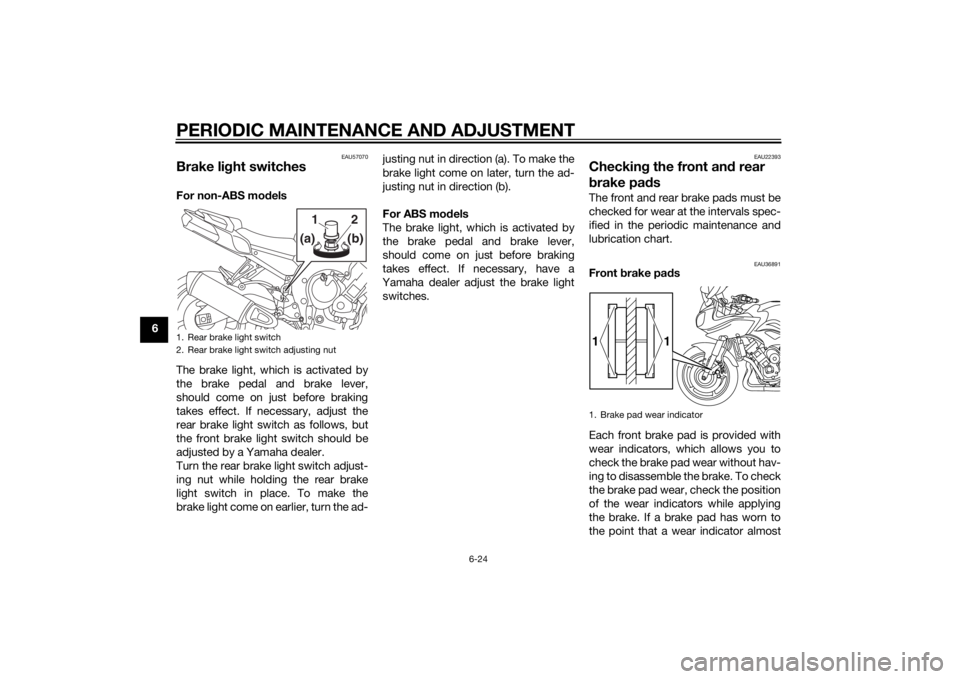

NOTICE

ECA11621

In or der to prevent clutch slip-

pa ge (since the en gine oil also

lu bricates the clutch), do not

mix any chemical additives. Do

not use oils with a d iesel speci-

fication of “CD” or oils of a hi gh-

er quality than specifie d. In

a ddition, do not use oils la beled

“ENERGY CONSERVING II” or

hi gher.

Make sure that no forei gn mate-

rial enters the crankcase.11. Start the engine, and then let it idle for several minutes while checking

it for oil leakage. If oil is leaking,

immediately turn the engine off

and check for the cause.TIPAfter the engine is started, the engine

oil level warning light should go off if

the oil level is sufficient.

NOTICE

ECA10402

If the oil level warnin g lig ht flickers

or remains on even if the oil level is

correct, immed iately turn the en gine

off an d have a Yamaha d ealer check

the vehicle.12. Turn the engine off, wait a few minutes until the oil settles, and

then check the oil level and cor-

rect it if necessary.

13. Install the cowling (for ABS mod- els only).

EAU20071

CoolantThe coolant level should be checked

before each ride. In addition, the cool-

ant must be changed at the intervals

specified in the periodic maintenance

and lubrication chart.

EAU3908A

To check the coolant level1. Place the vehicle on a level sur- face and hold it in an upright posi-

tion.TIPThe coolant level must be

checked on a cold engine since

the level varies with engine tem-

perature.

Make sure that the vehicle is posi-

tioned straight up when checking

the coolant level. A slight tilt to the

side can result in a false reading.2. Check the coolant level in the

coolant reservoir.TIPThe coolant should be between the

minimum and maximum level marks.

U42PE4E0.book Page 14 Wedne sday, August 6, 2014 3:25 PM

Page 74 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-24

6

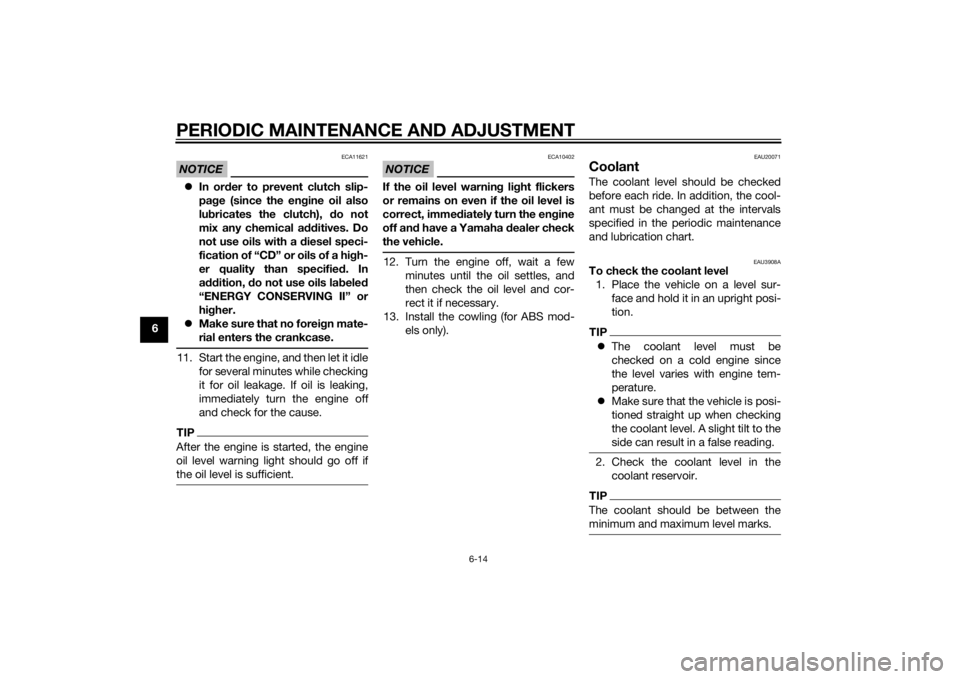

EAU57070

Brake light switchesFor non-ABS mo dels

The brake light, which is activated by

the brake pedal and brake lever,

should come on just before braking

takes effect. If necessary, adjust the

rear brake light switch as follows, but

the front brake light switch should be

adjusted by a Yamaha dealer.

Turn the rear brake light switch adjust-

ing nut while holding the rear brake

light switch in place. To make the

brake light come on earlier, turn the ad- justing nut in direction (a). To make the

brake light come on later, turn the ad-

justing nut in direction (b).

For ABS mo

dels

The brake light, which is activated by

the brake pedal and brake lever,

should come on just before braking

takes effect. If necessary, have a

Yamaha dealer adjust the brake light switches.

EAU22393

Checkin g the front an d rear

b rake pa dsThe front and rear brake pads must be

checked for wear at the intervals spec-

ified in the periodic maintenance and

lubrication chart.

EAU36891

Front brake pa ds

Each front brake pad is provided with

wear indicators, which allows you to

check the brake pad wear without hav-

ing to disassemble the brake. To check

the brake pad wear, check the position

of the wear indicators while applying

the brake. If a brake pad has worn to

the point that a wear indicator almost

1. Rear brake light switch

2. Rear brake light switch adjusting nut

1

2(b)

(a)

1. Brake pad wear indicator

1

1

U42PE4E0.book Page 24 Wedne sday, August 6, 2014 3:25 PM

Page 76 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-26

6

TIPThe rear brake fluid reservoir is located

under the rider seat. (See page 3-18.)

WARNING

EWA16011

Improper maintenance can result in

loss of brakin g a bility. O bserve

these precautions: Insufficient brake flui d may al-

low air to enter the b rake sys-

tem, re ducin g brakin g

performance.

Clean the filler cap before re-

moving . Use only DOT 4 b rake

flui d from a seale d container.

Use only the specified b rake flu-

i d ; otherwise, the ru bber seals

may deteriorate, causin g leak-

a g e.

Refill with the same type of

brake flui d. A ddin g a brake flui d

other than DOT 4 may result in a

harmful chemical reaction.

Be careful that water or dust

d oes not enter the brake flui d

reservoir when refillin g. Water

will si gnificantly lower the boil-

in g point of the flui d an d may re-

sult in vapor lock, an d d ir

t may

clo g the ABS hy draulic unit

valves.

NOTICE

ECA17641

Brake flui d may damag e painted

surfaces or plastic parts. Always

clean up spille d flui d imme diately.As the brake pads wear, it is normal for

the brake fluid level to gradually go

down. A low brake fluid level may indi-

cate worn brake pads and/or brake

system leakage; therefore, be sure to

check the brake pads for wear and the

brake system for leakage. If the brake

fluid level goes down suddenly, have a

Yamaha dealer check the cause before further riding.

EAU22733

Chan gin g the brake flui dHave a Yamaha dealer change the

brake fluid at the intervals specified in

the periodic maintenance and lubrica-

tion chart. In addition, have the oil seals

of the master cylinders and calipers as

well as the brake hoses replaced at the

intervals listed below or whenever they

are damaged or leaking.

Oil seals: Replace every two

years.

Brake hoses: Replace every four

years.

Specifie d b rake flui d:

DOT 4

U42PE4E0.book Page 26 Wedne sday, August 6, 2014 3:25 PM

Page 85 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-35

6

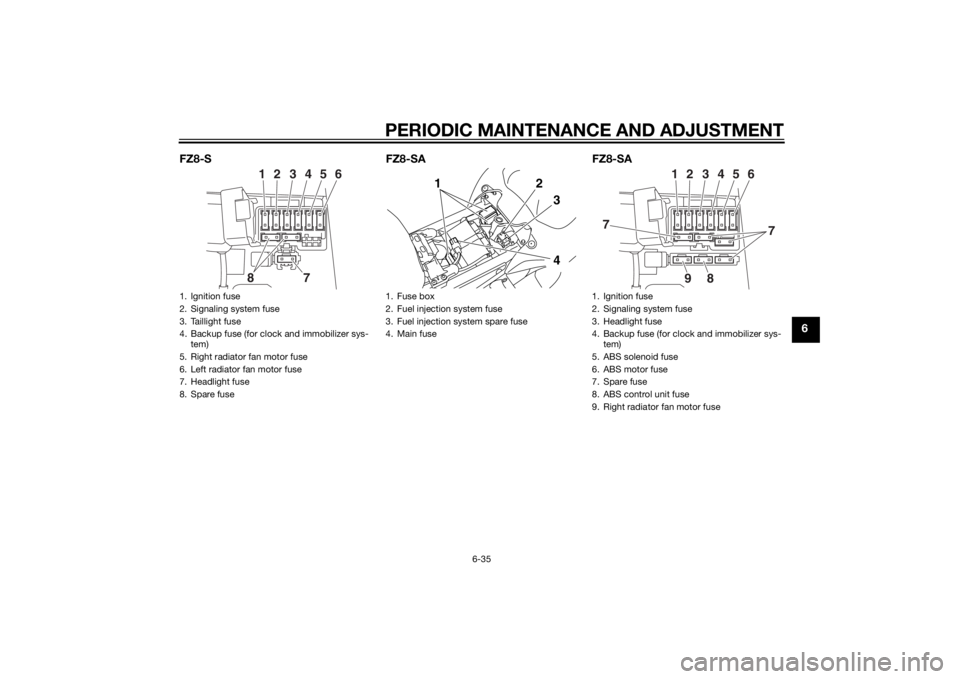

FZ8-S FZ8-SA FZ8-SA

1. Ignition fuse

2. Signaling system fuse

3. Taillight fuse

4. Backup fuse (for clock and immobilizer sys-

tem)

5. Right radiator fan motor fuse

6. Left radiator fan motor fuse

7. Headlight fuse

8. Spare fuse

18

7

2

3

4

5

6

1. Fuse box

2. Fuel injection system fuse

3. Fuel injection system spare fuse

4. Main fuse

4

1

2

3

1. Ignition fuse

2. Signaling system fuse

3. Headlight fuse

4. Backup fuse (for clock and immobilizer sys- tem)

5. ABS solenoid fuse

6. ABS motor fuse

7. Spare fuse

8. ABS control unit fuse

9. Right radiator fan motor fuse

1

8

92

3

4

5

6

7

7

U42PE4E0.book Page 35 Wedne sday, August 6, 2014 3:25 PM