YAMAHA FZR 2015 Owners Manual

Manufacturer: YAMAHA, Model Year: 2015, Model line: FZR, Model: YAMAHA FZR 2015Pages: 104, PDF Size: 4.29 MB

Page 91 of 104

Maintenance

85

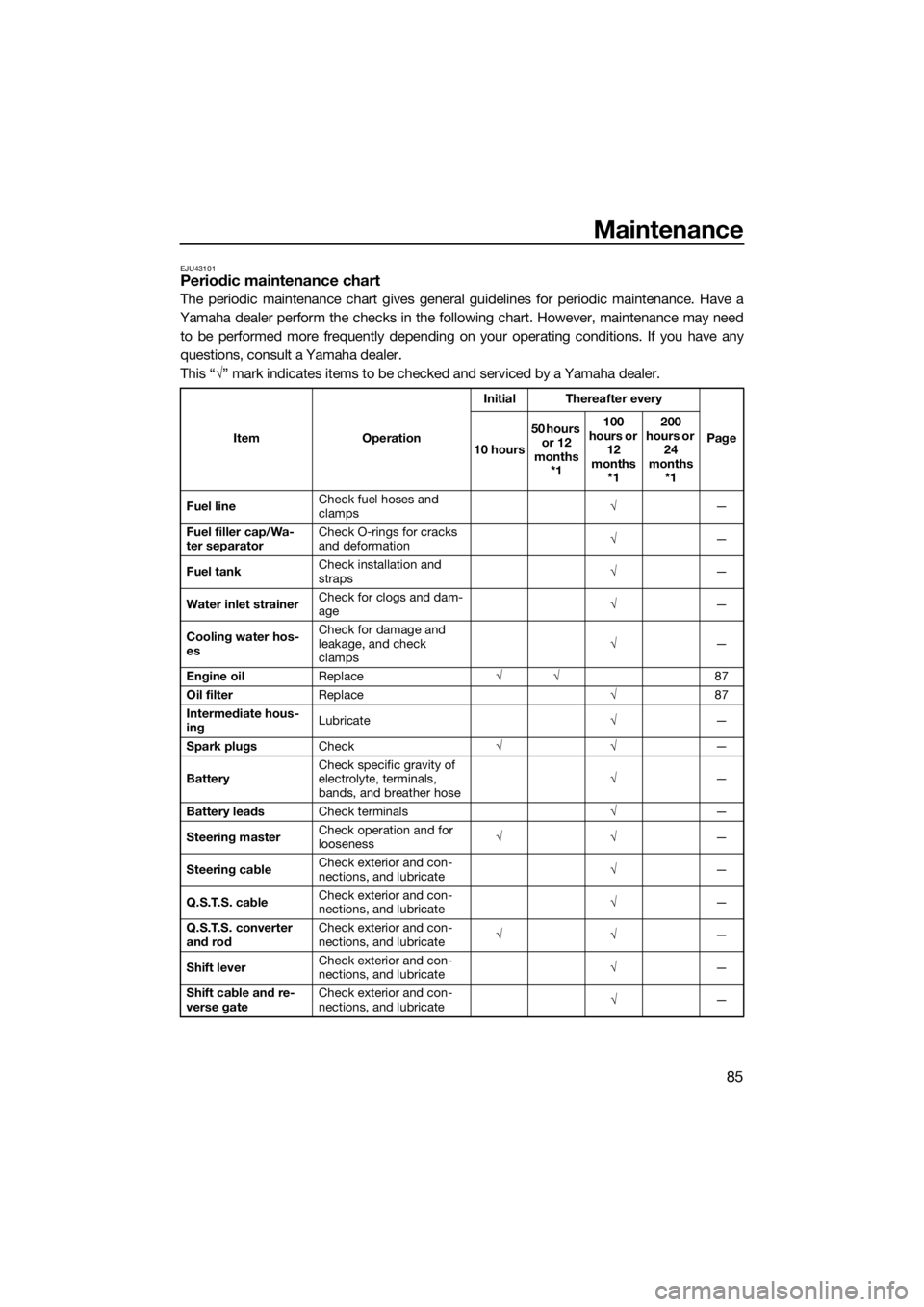

EJU43101Periodic maintenance chart

The periodic maintenance chart gives general guidelines for periodic maintenance. Have a

Yamaha dealer perform the checks in the following chart. However, maintenance may need

to be performed more frequently depending on your operating conditions. If you have any

questions, consult a Yamaha dealer.

This “√” mark indicates items to be checked and serviced by a Yamaha dealer.

Item OperationInitial Thereafter every

Page

10 hours50 hours

or 12

months

*1100

hours or

12

months

*1200

hours or

24

months

*1

Fuel lineCheck fuel hoses and

clamps√—

Fuel filler cap/Wa-

ter separatorCheck O-rings for cracks

and deformation√—

Fuel tankCheck installation and

straps√—

Water inlet strainerCheck for clogs and dam-

age√—

Cooling water hos-

esCheck for damage and

leakage, and check

clamps√—

Engine oilReplace√√87

Oil filterReplace√87

Intermediate hous-

ingLubricate√—

Spark plugsCheck√√—

BatteryCheck specific gravity of

electrolyte, terminals,

bands, and breather hose√—

Battery leadsCheck terminals√—

Steering masterCheck operation and for

looseness√√—

Steering cableCheck exterior and con-

nections, and lubricate√—

Q.S.T.S. cableCheck exterior and con-

nections, and lubricate√—

Q.S.T.S. converter

and rodCheck exterior and con-

nections, and lubricate√√—

Shift leverCheck exterior and con-

nections, and lubricate√—

Shift cable and re-

verse gateCheck exterior and con-

nections, and lubricate

√—

UF3L71E0.book Page 85 Monday, June 30, 2014 9:06 AM

Page 92 of 104

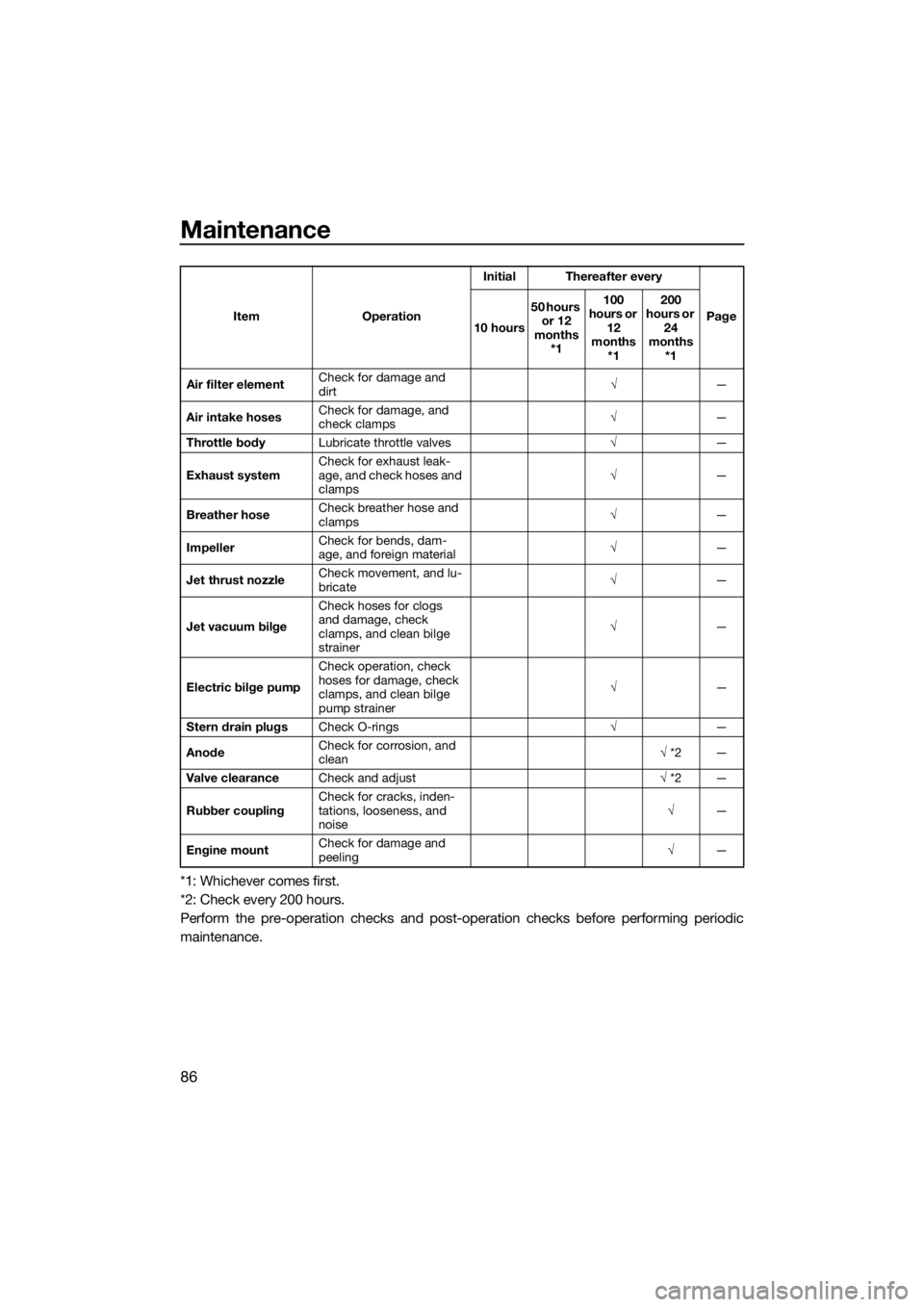

Maintenance

86

*1: Whichever comes first.

*2: Check every 200 hours.

Perform the pre-operation checks and post-operation checks before performing periodic

maintenance.

Air filter elementCheck for damage and

dirt√—

Air intake hosesCheck for damage, and

check clamps√—

Throttle bodyLubricate throttle valves√—

Exhaust systemCheck for exhaust leak-

age, and check hoses and

clamps√—

Breather hoseCheck breather hose and

clamps√—

ImpellerCheck for bends, dam-

age, and foreign material√—

Jet thrust nozzleCheck movement, and lu-

bricate√—

Jet vacuum bilgeCheck hoses for clogs

and damage, check

clamps, and clean bilge

strainer√—

Electric bilge pumpCheck operation, check

hoses for damage, check

clamps, and clean bilge

pump strainer√—

Stern drain plugsCheck O-rings√—

AnodeCheck for corrosion, and

clean√ *2 —

Valve clearanceCheck and adjust√ *2 —

Rubber couplingCheck for cracks, inden-

tations, looseness, and

noise√—

Engine mountCheck for damage and

peeling√— Item OperationInitial Thereafter every

Page

10 hours50 hours

or 12

months

*1100

hours or

12

months

*1200

hours or

24

months

*1

UF3L71E0.book Page 86 Monday, June 30, 2014 9:06 AM

Page 93 of 104

Maintenance

87

EJU36943Engine oil and oil filter

WARNING

EWJ00341

Engine oil is extremely hot immediately af-

ter the engine is turned off. Coming in con-

tact with or getting any engine oil on your

clothes could result in burns.

NOTICE

ECJ00992

Do not run the engine with too much or not

enough oil in the engine, otherwise the en-

gine could be damaged.

It is recommended to have a Yamaha dealer

change the engine oil and the engine oil filter.

However, if you choose to change the oil and

filter on your own, consult a Yamaha dealer.

UF3L71E0.book Page 87 Monday, June 30, 2014 9:06 AM

Page 94 of 104

Specifications

88

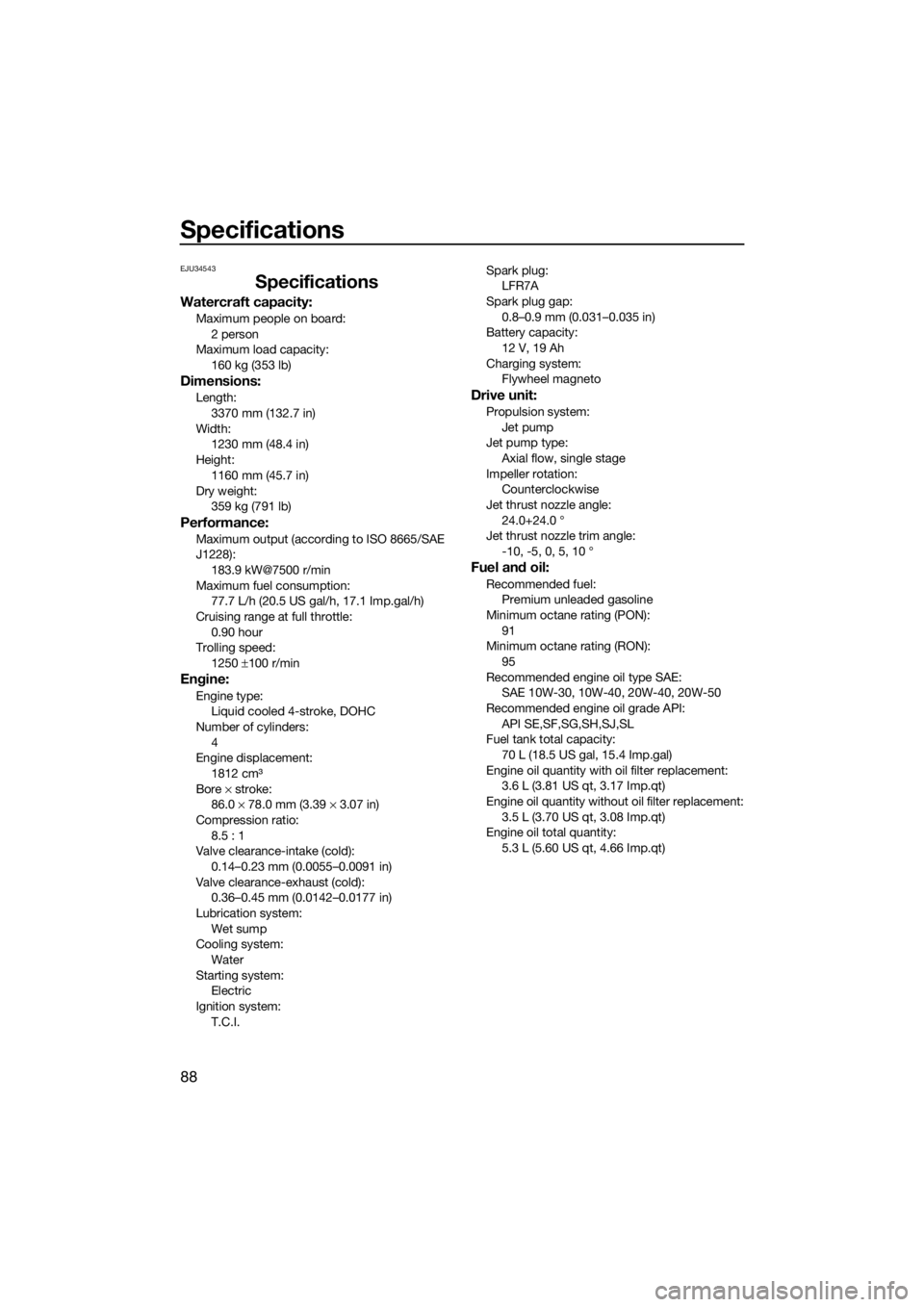

EJU34543

Specifications

Watercraft capacity:

Maximum people on board:

2 person

Maximum load capacity:

160 kg (353 lb)

Dimensions:

Length:

3370 mm (132.7 in)

Width:

1230 mm (48.4 in)

Height:

1160 mm (45.7 in)

Dry weight:

359 kg (791 lb)

Performance:

Maximum output (according to ISO 8665/SAE

J1228):

183.9 kW@7500 r/min

Maximum fuel consumption:

77.7 L/h (20.5 US gal/h, 17.1 Imp.gal/h)

Cruising range at full throttle:

0.90 hour

Trolling speed:

1250 ±100 r/min

Engine:

Engine type:

Liquid cooled 4-stroke, DOHC

Number of cylinders:

4

Engine displacement:

1812 cm³

Bore × stroke:

86.0 × 78.0 mm (3.39 × 3.07 in)

Compression ratio:

8.5 : 1

Valve clearance-intake (cold):

0.14–0.23 mm (0.0055–0.0091 in)

Valve clearance-exhaust (cold):

0.36–0.45 mm (0.0142–0.0177 in)

Lubrication system:

Wet sump

Cooling system:

Water

Starting system:

Electric

Ignition system:

T.C.I.Spark plug:

LFR7A

Spark plug gap:

0.8–0.9 mm (0.031–0.035 in)

Battery capacity:

12 V, 19 Ah

Charging system:

Flywheel magneto

Drive unit:

Propulsion system:

Jet pump

Jet pump type:

Axial flow, single stage

Impeller rotation:

Counterclockwise

Jet thrust nozzle angle:

24.0+24.0 °

Jet thrust nozzle trim angle:

-10, -5, 0, 5, 10 °

Fuel and oil:

Recommended fuel:

Premium unleaded gasoline

Minimum octane rating (PON):

91

Minimum octane rating (RON):

95

Recommended engine oil type SAE:

SAE 10W-30, 10W-40, 20W-40, 20W-50

Recommended engine oil grade API:

API SE,SF,SG,SH,SJ,SL

Fuel tank total capacity:

70 L (18.5 US gal, 15.4 Imp.gal)

Engine oil quantity with oil filter replacement:

3.6 L (3.81 US qt, 3.17 Imp.qt)

Engine oil quantity without oil filter replacement:

3.5 L (3.70 US qt, 3.08 Imp.qt)

Engine oil total quantity:

5.3 L (5.60 US qt, 4.66 Imp.qt)

UF3L71E0.book Page 88 Monday, June 30, 2014 9:06 AM

Page 95 of 104

Trouble recovery

89

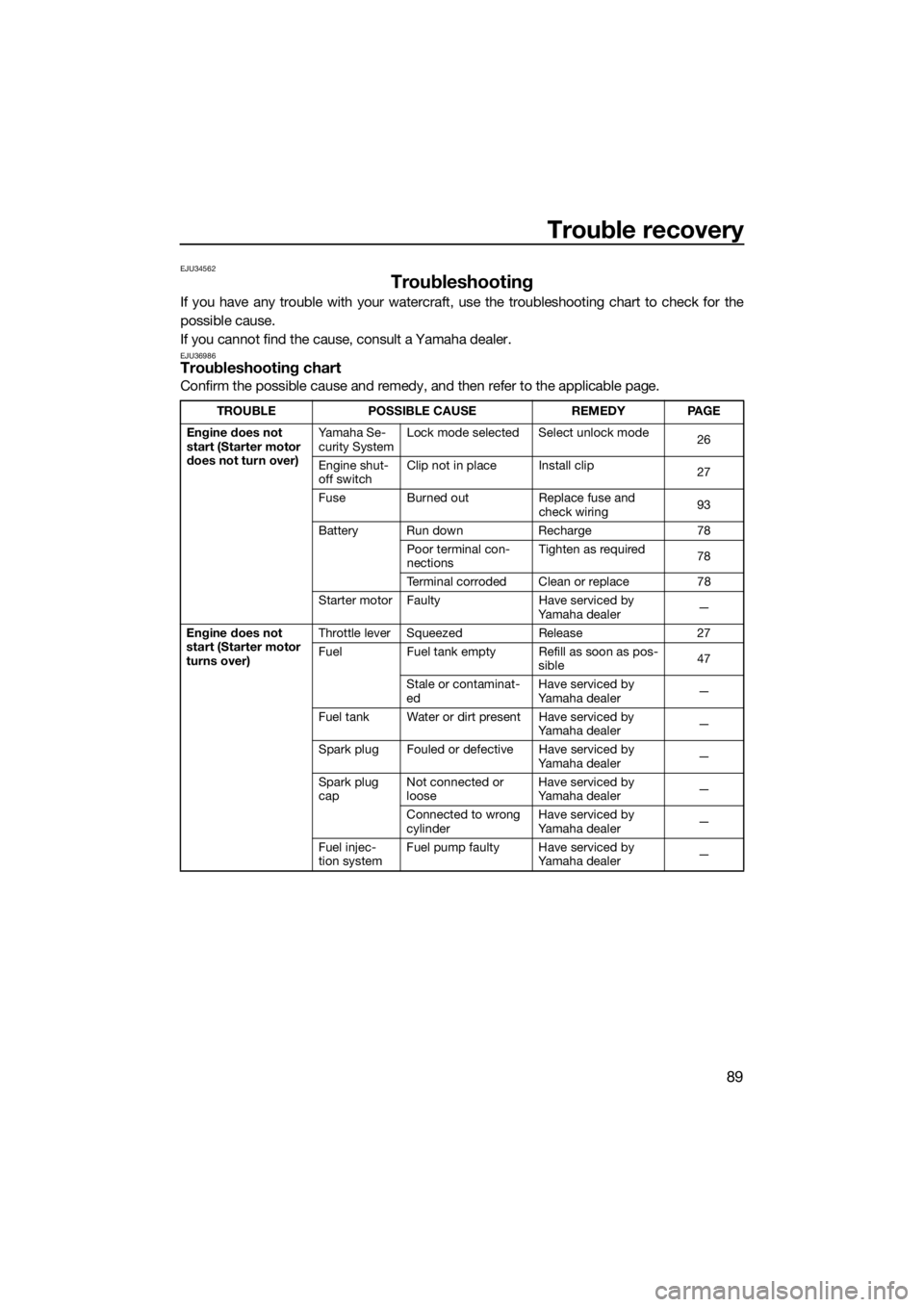

EJU34562

Troubleshooting

If you have any trouble with your watercraft, use the troubleshooting chart to check for the

possible cause.

If you cannot find the cause, consult a Yamaha dealer.

EJU36986Troubleshooting chart

Confirm the possible cause and remedy, and then refer to the applicable page.

TROUBLE POSSIBLE CAUSE REMEDY PAGE

Engine does not

start (Starter motor

does not turn over)Ya m a h a S e -

curity SystemLock mode selected Select unlock mode

26

Engine shut-

off switchClip not in place Install clip

27

Fuse Burned out Replace fuse and

check wiring93

Battery Run down Recharge 78

Poor terminal con-

nectionsTighten as required

78

Terminal corroded Clean or replace 78

Starter motor Faulty Have serviced by

Yamaha dealer—

Engine does not

start (Starter motor

turns over)Throttle lever Squeezed Release 27

Fuel Fuel tank empty Refill as soon as pos-

sible47

Stale or contaminat-

edHave serviced by

Yamaha dealer—

Fuel tank Water or dirt present Have serviced by

Yamaha dealer—

Spark plug Fouled or defective Have serviced by

Yamaha dealer—

Spark plug

capNot connected or

looseHave serviced by

Yamaha dealer—

Connected to wrong

cylinderHave serviced by

Yamaha dealer—

Fuel injec-

tion systemFuel pump faulty Have serviced by

Yamaha dealer—

UF3L71E0.book Page 89 Monday, June 30, 2014 9:06 AM

Page 96 of 104

Trouble recovery

90

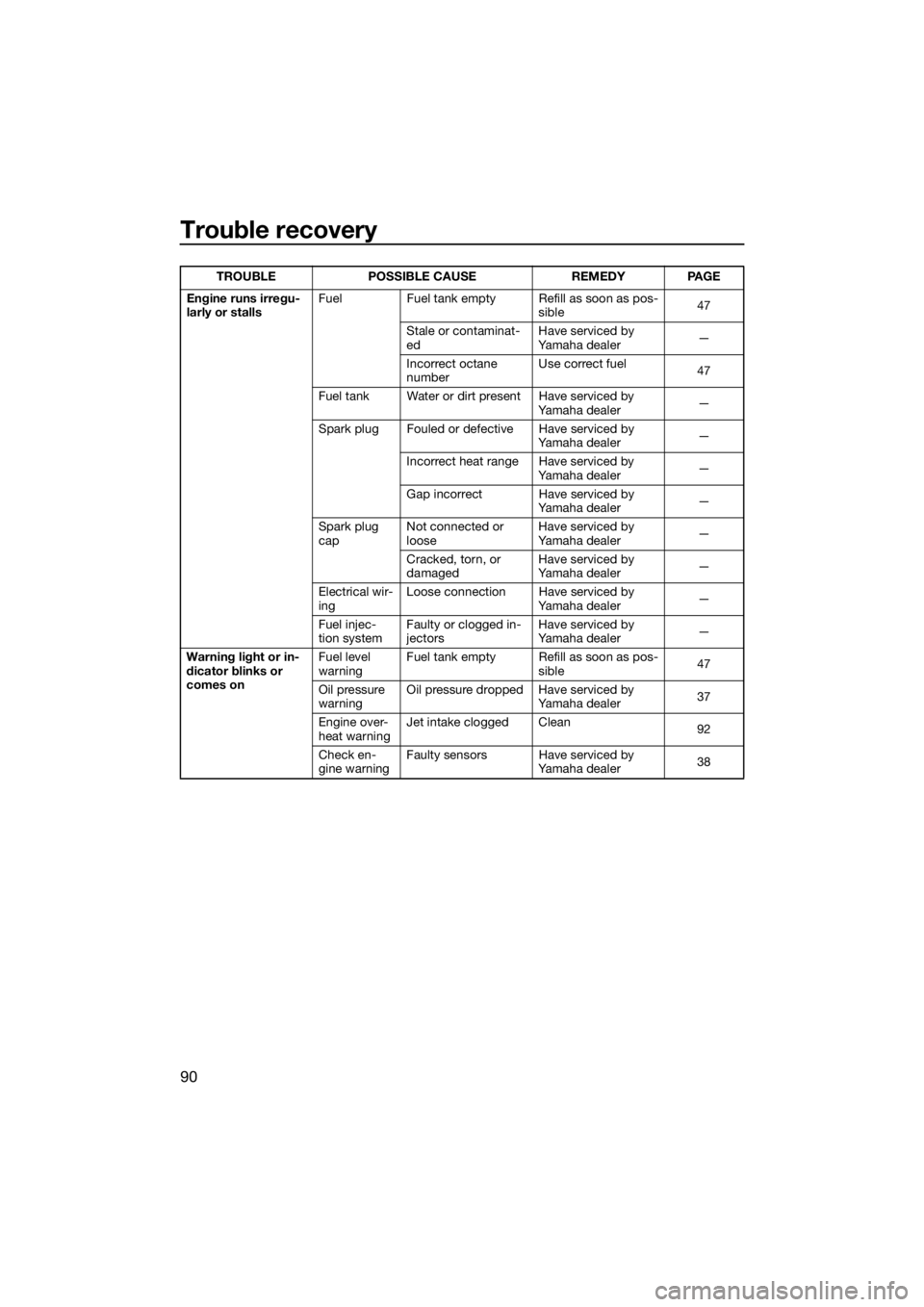

Engine runs irregu-

larly or stallsFuel Fuel tank empty Refill as soon as pos-

sible47

Stale or contaminat-

edHave serviced by

Yamaha dealer—

Incorrect octane

numberUse correct fuel

47

Fuel tank Water or dirt present Have serviced by

Yamaha dealer—

Spark plug Fouled or defective Have serviced by

Yamaha dealer—

Incorrect heat range Have serviced by

Yamaha dealer—

Gap incorrect Have serviced by

Yamaha dealer—

Spark plug

capNot connected or

looseHave serviced by

Yamaha dealer—

Cracked, torn, or

damagedHave serviced by

Yamaha dealer—

Electrical wir-

ingLoose connection Have serviced by

Yamaha dealer—

Fuel injec-

tion systemFaulty or clogged in-

jectorsHave serviced by

Yamaha dealer—

Warning light or in-

dicator blinks or

comes onFuel level

warningFuel tank empty Refill as soon as pos-

sible47

Oil pressure

warningOil pressure dropped Have serviced by

Yamaha dealer37

Engine over-

heat warningJet intake clogged Clean

92

Check en-

gine warningFaulty sensors Have serviced by

Yamaha dealer38 TROUBLE POSSIBLE CAUSE REMEDY PAGE

UF3L71E0.book Page 90 Monday, June 30, 2014 9:06 AM

Page 97 of 104

Trouble recovery

91

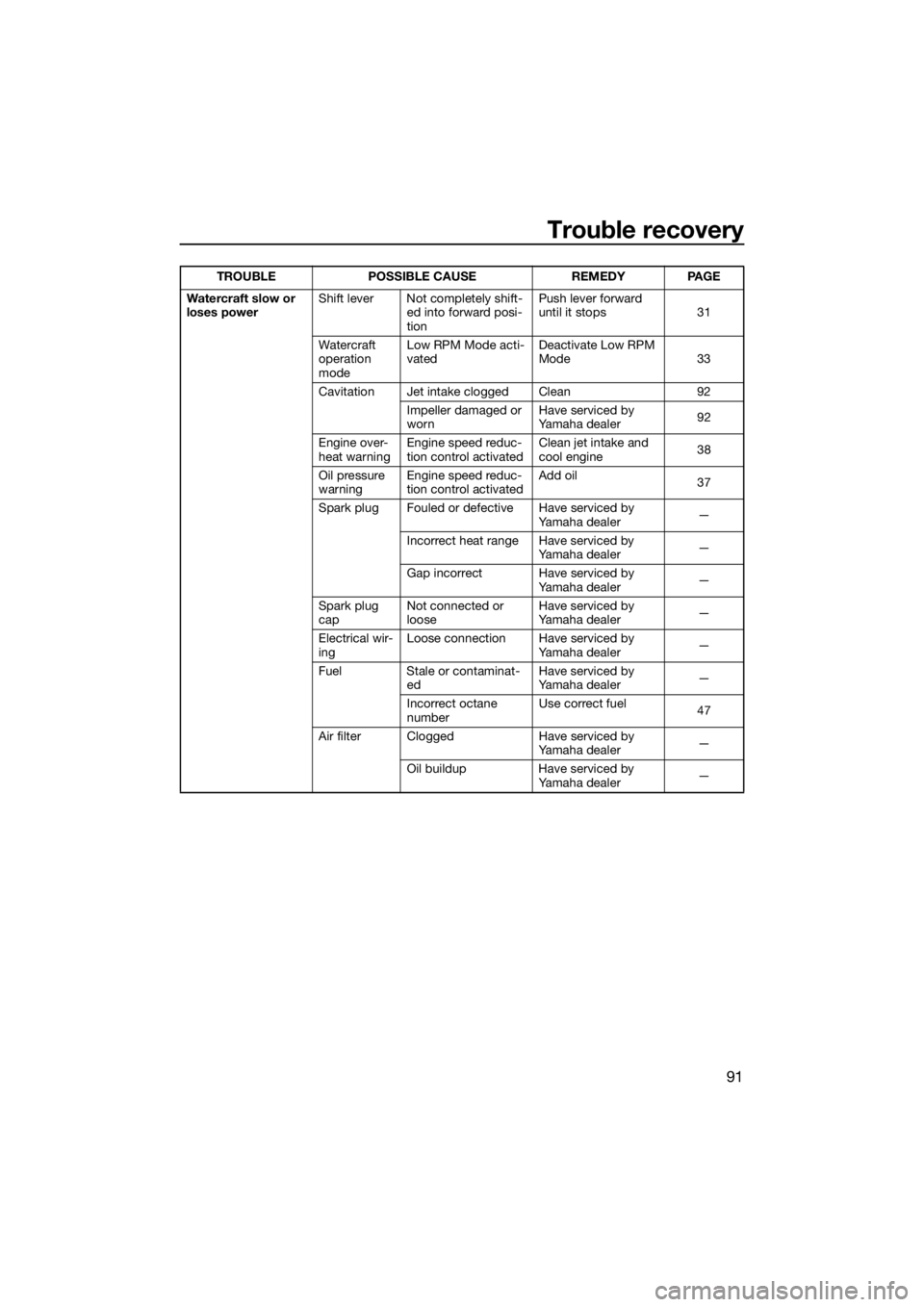

Watercraft slow or

loses powerShift lever Not completely shift-

ed into forward posi-

tionPush lever forward

until it stops 31

Watercraft

operation

modeLow RPM Mode acti-

vatedDeactivate Low RPM

Mode 33

Cavitation Jet intake clogged Clean 92

Impeller damaged or

wornHave serviced by

Yamaha dealer92

Engine over-

heat warningEngine speed reduc-

tion control activatedClean jet intake and

cool engine38

Oil pressure

warningEngine speed reduc-

tion control activatedAdd oil

37

Spark plug Fouled or defective Have serviced by

Yamaha dealer—

Incorrect heat range Have serviced by

Yamaha dealer—

Gap incorrect Have serviced by

Yamaha dealer—

Spark plug

capNot connected or

looseHave serviced by

Yamaha dealer—

Electrical wir-

ingLoose connection Have serviced by

Yamaha dealer—

Fuel Stale or contaminat-

edHave serviced by

Yamaha dealer—

Incorrect octane

numberUse correct fuel

47

Air filter Clogged Have serviced by

Yamaha dealer—

Oil buildup Have serviced by

Yamaha dealer— TROUBLE POSSIBLE CAUSE REMEDY PAGE

UF3L71E0.book Page 91 Monday, June 30, 2014 9:06 AM

Page 98 of 104

Trouble recovery

92

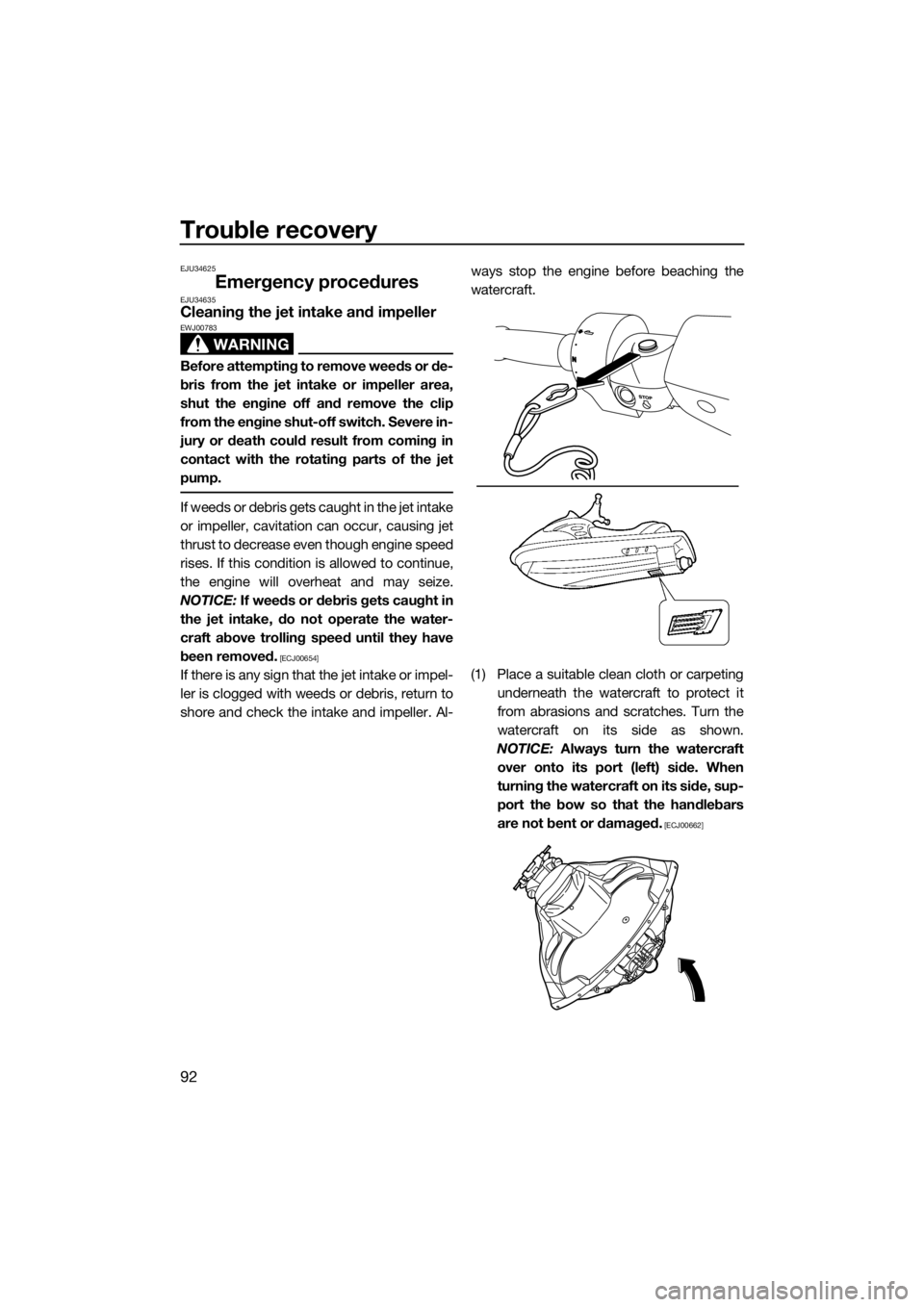

EJU34625

Emergency proceduresEJU34635Cleaning the jet intake and impeller

WARNING

EWJ00783

Before attempting to remove weeds or de-

bris from the jet intake or impeller area,

shut the engine off and remove the clip

from the engine shut-off switch. Severe in-

jury or death could result from coming in

contact with the rotating parts of the jet

pump.

If weeds or debris gets caught in the jet intake

or impeller, cavitation can occur, causing jet

thrust to decrease even though engine speed

rises. If this condition is allowed to continue,

the engine will overheat and may seize.

NOTICE: If weeds or debris gets caught in

the jet intake, do not operate the water-

craft above trolling speed until they have

been removed.

[ECJ00654]

If there is any sign that the jet intake or impel-

ler is clogged with weeds or debris, return to

shore and check the intake and impeller. Al-ways stop the engine before beaching the

watercraft.

(1) Place a suitable clean cloth or carpeting

underneath the watercraft to protect it

from abrasions and scratches. Turn the

watercraft on its side as shown.

NOTICE: Always turn the watercraft

over onto its port (left) side. When

turning the watercraft on its side, sup-

port the bow so that the handlebars

are not bent or damaged.

[ECJ00662]

UF3L71E0.book Page 92 Monday, June 30, 2014 9:06 AM

Page 99 of 104

Trouble recovery

93

(2) Remove any weeds or debris from

around the jet intake, drive shaft, impel-

ler, jet pump housing, and jet thrust noz-

zle.

If debris is difficult to remove, consult a

Yamaha dealer.

EJU34642Jumping the battery

If the watercraft battery has run down, the en-

gine can be started using a 12-volt booster

battery and jumper cables.

EJU34664Connecting the jumper cables

WARNING

EWJ01251

To avoid battery explosion and serious

damage to the electrical system:

Do not reverse the polarity of the jumper

cables when connecting to the batter-

ies.

Do not connect the negative (–) jumper

cable to the negative (–) terminal of the

watercraft battery.

Do not touch the positive (+) jumper ca-

ble to the negative (–) jumper cable.

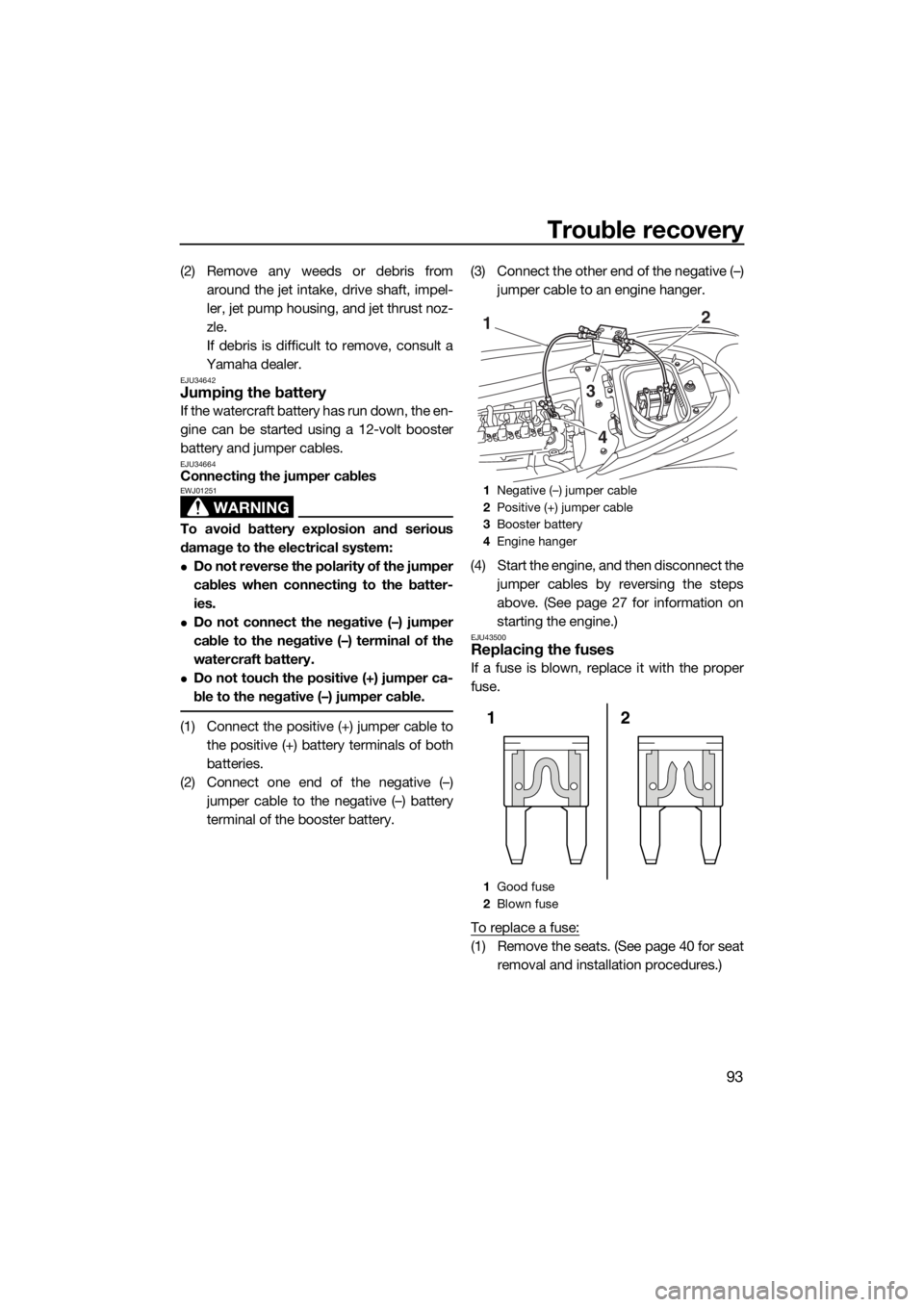

(1) Connect the positive (+) jumper cable to

the positive (+) battery terminals of both

batteries.

(2) Connect one end of the negative (–)

jumper cable to the negative (–) battery

terminal of the booster battery.(3) Connect the other end of the negative (–)

jumper cable to an engine hanger.

(4) Start the engine, and then disconnect the

jumper cables by reversing the steps

above. (See page 27 for information on

starting the engine.)

EJU43500Replacing the fuses

If a fuse is blown, replace it with the proper

fuse.

To replace a fuse:

(1) Remove the seats. (See page 40 for seat

removal and installation procedures.)

1Negative (–) jumper cable

2Positive (+) jumper cable

3Booster battery

4Engine hanger

1Good fuse

2Blown fuse

2

3 1

4

2 1

UF3L71E0.book Page 93 Monday, June 30, 2014 9:06 AM

Page 100 of 104

Trouble recovery

94

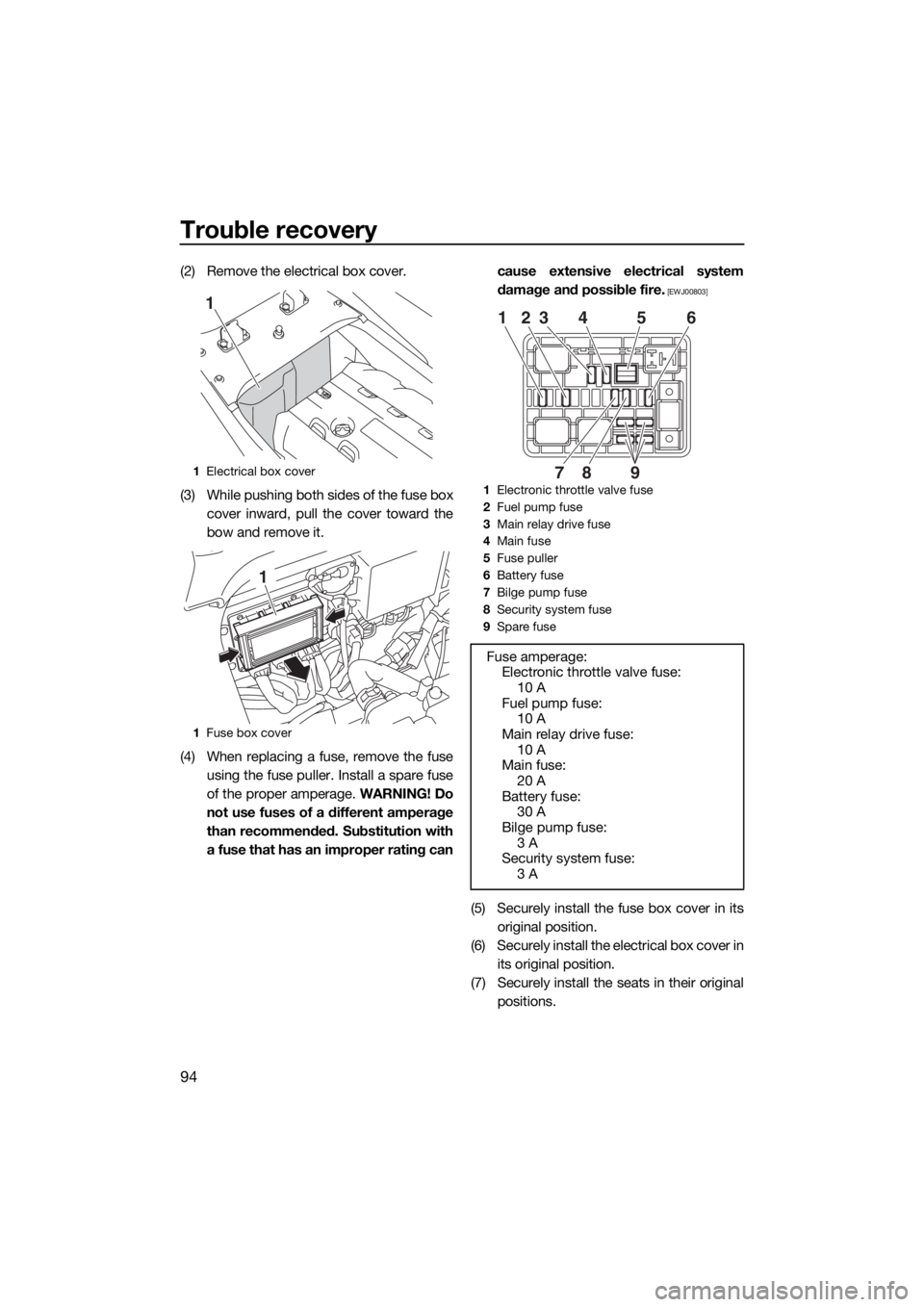

(2) Remove the electrical box cover.

(3) While pushing both sides of the fuse box

cover inward, pull the cover toward the

bow and remove it.

(4) When replacing a fuse, remove the fuse

using the fuse puller. Install a spare fuse

of the proper amperage. WARNING! Do

not use fuses of a different amperage

than recommended. Substitution with

a fuse that has an improper rating cancause extensive electrical system

damage and possible fire.

[EWJ00803]

(5) Securely install the fuse box cover in its

original position.

(6) Securely install the electrical box cover in

its original position.

(7) Securely install the seats in their original

positions.

1Electrical box cover

1Fuse box cover

1

1

1Electronic throttle valve fuse

2Fuel pump fuse

3Main relay drive fuse

4Main fuse

5Fuse puller

6Battery fuse

7Bilge pump fuse

8Security system fuse

9Spare fuse

Fuse amperage:

Electronic throttle valve fuse:

10 A

Fuel pump fuse:

10 A

Main relay drive fuse:

10 A

Main fuse:

20 A

Battery fuse:

30 A

Bilge pump fuse:

3 A

Security system fuse:

3 A

1

9 23 4 5 6

8 7

UF3L71E0.book Page 94 Monday, June 30, 2014 9:06 AM