check oil YAMAHA FZR SVHO 2013 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2013, Model line: FZR SVHO, Model: YAMAHA FZR SVHO 2013Pages: 104, PDF Size: 4.06 MB

Page 5 of 104

Table of contents

General and important labels ........... 1

Identification numbers .................... 1

Primary Identification (PRI-ID)

number ........................................... 1

Craft Identification Number (CIN) ...... 1

Engine serial number ........................ 1

Manufactured date label .................... 2

Model information ........................... 2

Builder’s plate .................................... 2

Important labels .............................. 4

Warning labels ................................... 5

Other labels ....................................... 9

Safety information ........................... 11

Limitations on who may operate

the watercraft ............................ 11

Cruising limitations ....................... 12

Operation requirements ............... 13

Recommended equipment ........... 15

Hazard information ....................... 16

Watercraft characteristics ............. 16

Safe boating rules ........................ 18

Enjoy your watercraft

responsibly ................................ 18

Description....................................... 20

Watercraft glossary ...................... 20

Location of main components ...... 21

Control function operation ............. 25

Watercraft control functions ......... 25

Remote control transmitter .............. 25

Yamaha Security System ................ 26

Engine stop switch .......................... 27

Engine shut-off switch ..................... 27

Start switch ...................................... 27

Throttle lever ................................... 28

Steering system ............................... 28

Telescopic steering system ............. 29

Cooling water pilot outlets ............... 29

Water separator ............................... 30

Watercraft operation ....................... 31

Watercraft operation functions ..... 31

Reverse system ............................... 31

Quick Shift Trim System

(Q.S.T.S.) ..................................... 32

Watercraft operation modes ......... 33

Low RPM Mode ............................... 33

Instrument operation ...................... 35

Dual analog meter unit ................. 35

Speedometer ................................... 35

Tachometer ..................................... 35

Information display .......................... 36

Equipment operation ...................... 40

Equipment .................................... 40

Seats ............................................... 40

Reboarding grip ............................... 41

Reboarding step .............................. 41

Bow eye ........................................... 42

Stern eyes ....................................... 42

Storage compartments .................... 42

Fire extinguisher holder and

cover ............................................ 45

Operation and handling

requirements ................................... 47

Fuel requirements ........................ 47

Fuel ................................................. 47

Engine oil requirements ............... 49

Engine oil ......................................... 49

Draining the bilge water ............... 50

Draining the bilge water on land ...... 50

Draining the bilge water on water .... 51

Transporting on a trailer ............... 52

First-time operation ........................ 53

Engine break-in ............................ 53

Pre-operation checks ..................... 54

Pre-operation checklist .................... 54

Pre-operation check points .......... 56

Pre-launch checks ........................... 56

UF2R74E0.book Page 1 Wednesday, August 22, 2012 2:26 PM

Page 6 of 104

Table of contents

Post-launch checks ......................... 63

Operation ......................................... 64

Operating your watercraft ............. 64

Getting to know your watercraft ....... 64

Learning to operate your

watercraft ..................................... 64

Riding position ................................. 65

Launching the watercraft ................. 65

Starting the engine on water ........... 65

Stopping the engine ........................ 66

Leaving the watercraft ..................... 66

Operating the watercraft .................. 66

Turning the watercraft ..................... 67

Stopping the watercraft ................... 68

Operating the watercraft in

reverse ......................................... 69

Boarding the watercraft ................... 69

Starting off ....................................... 72

Capsized watercraft ......................... 73

Beaching and docking the

watercraft ..................................... 74

Operating in weeded areas ............. 74

After removing the watercraft from

the water ...................................... 75

Care and storage ............................. 76

Post-operation care ...................... 76

Flushing the cooling water

passages ...................................... 76

Cleaning the watercraft ................... 77

Battery care ..................................... 77

Long-term storage ........................ 80

Cleaning .......................................... 80

Lubrication ....................................... 80

Rustproofing .................................... 80

Maintenance..................................... 82

Maintenance ................................. 82

Tool kit ............................................. 82

Removing and installing the engine

cover ............................................ 82

Periodic maintenance chart ............. 84

Engine oil and oil filter ..................... 85

Specifications.................................. 86

Specifications ................................ 86

Trouble recovery ............................. 87

Troubleshooting ........................... 87

Troubleshooting chart ...................... 87

Emergency procedures ................ 90

Cleaning the jet intake and

impeller ........................................ 90

Jumping the battery ......................... 91

Replacing the fuses ......................... 91

Replacing the bilge pump fuse ........ 93

Towing the watercraft ...................... 94

Submerged watercraft ..................... 95

UF2R74E0.book Page 2 Wednesday, August 22, 2012 2:26 PM

Page 42 of 104

Instrument operation

36

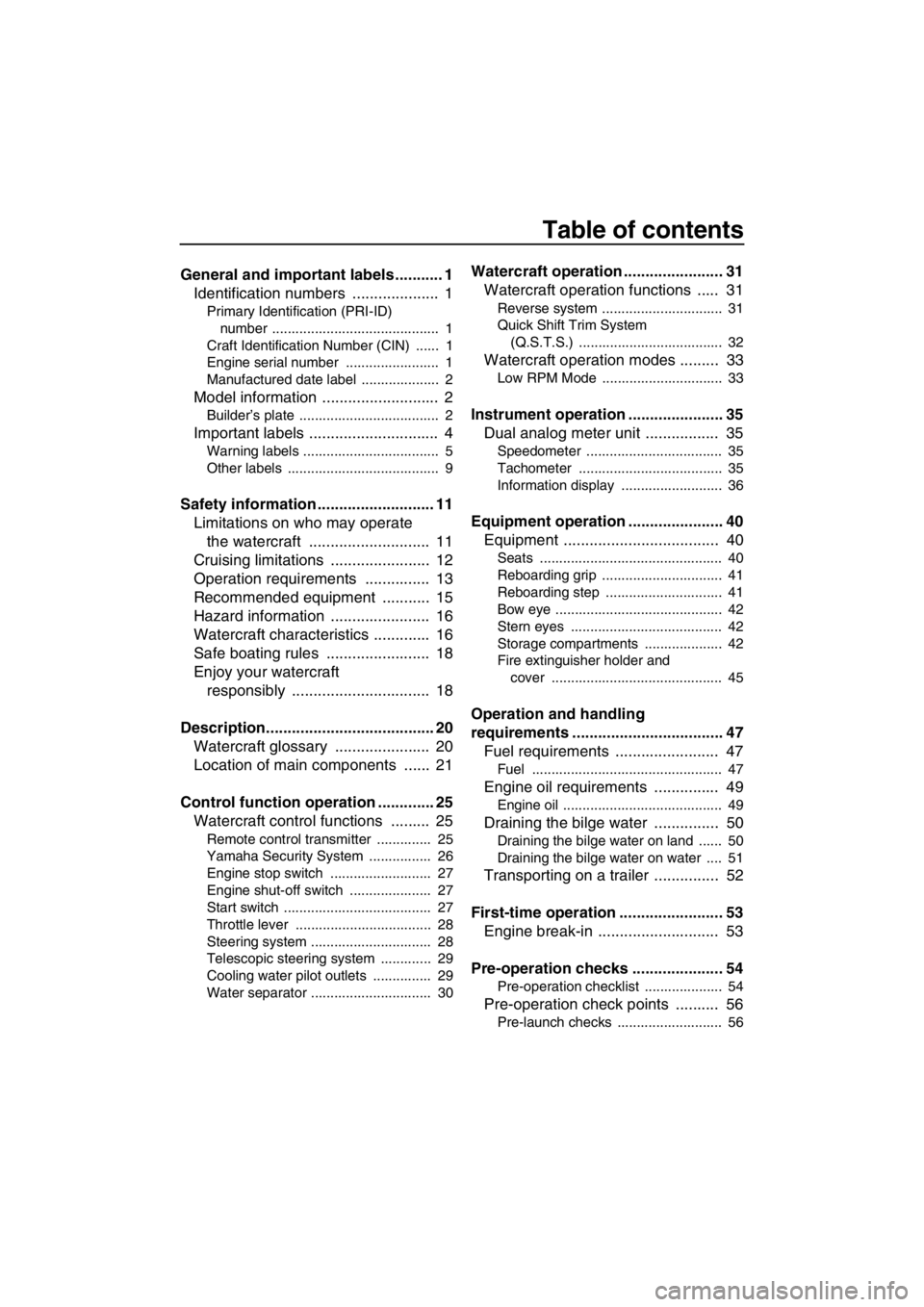

EJU35024Information display

The information display shows watercraft op-

erating conditions.

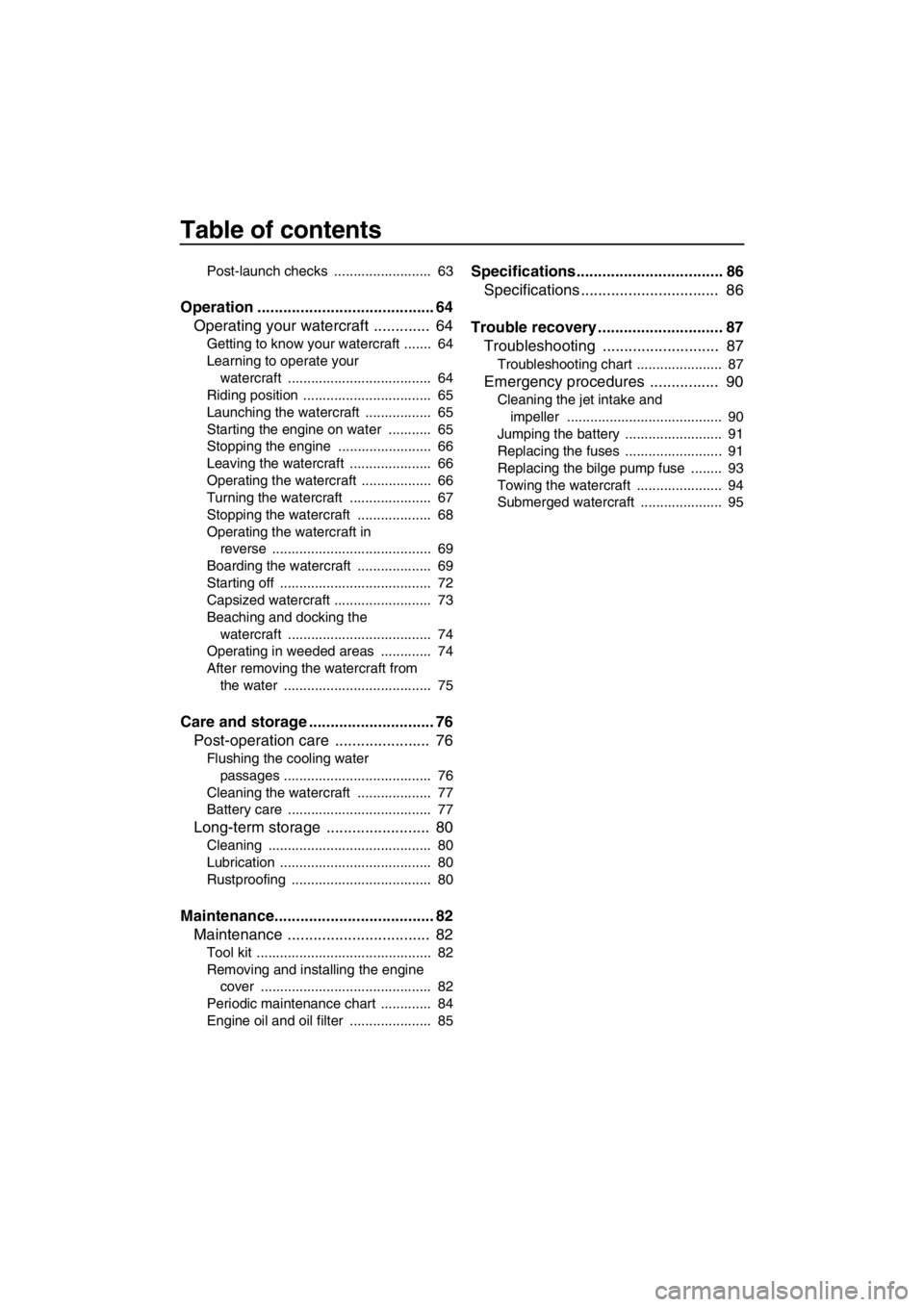

EJU37264Hour meter/voltmeter

The hour meter/voltmeter has both an hour

meter function and a voltmeter function. By

switching the meter, it can be used as either

an hour meter or a voltmeter.

TIP:

The hour meter is selected at the Yamaha

factory.Hour meter

The hour meter shows the total number of

hours that the engine has been running since

the watercraft was new.

TIP:

The elapsed time will be kept even if the bat-

tery terminals have been disconnected.

To switch to the hour meter from the voltme-

ter:

Push the “Hour Volt” button for at least 1 sec-

ond. The display switches to the hour meter

from the voltmeter.

Voltmeter

The voltmeter shows the battery voltage.

When the battery voltage is normal, the volt-

meter displays approximately 12 volts.

If the battery voltage has dropped significant-

ly, “LO” is displayed on the voltmeter. If the

battery voltage has risen significantly, “HI” is

displayed. If “LO” or “HI” is displayed, immedi-

ately return to shore and have a Yamaha

dealer service the watercraft.

1Fuel level meter

2Fuel indicator

3Engine overheat warning indicator

4Check engine warning indicator

5Oil pressure warning indicator

6Hour meter/voltmeter

1Hour meter/voltmeter

12345

6

1

1“Hour Volt” button

2Hour meter

1

2

UF2R74E0.book Page 36 Wednesday, August 22, 2012 2:26 PM

Page 44 of 104

Instrument operation

38

sounds intermittently. At the same time, the

maximum engine speed is limited.

If the oil pressure warning is activated, imme-

diately reduce the engine speed, return to

shore, and then check the engine oil level.

(See page 49 for information on checking the

engine oil level.) If the oil level is sufficient,

have a Yamaha dealer check the watercraft.

TIP:

Push the “Hour Volt” button to stop the buzz-

er.

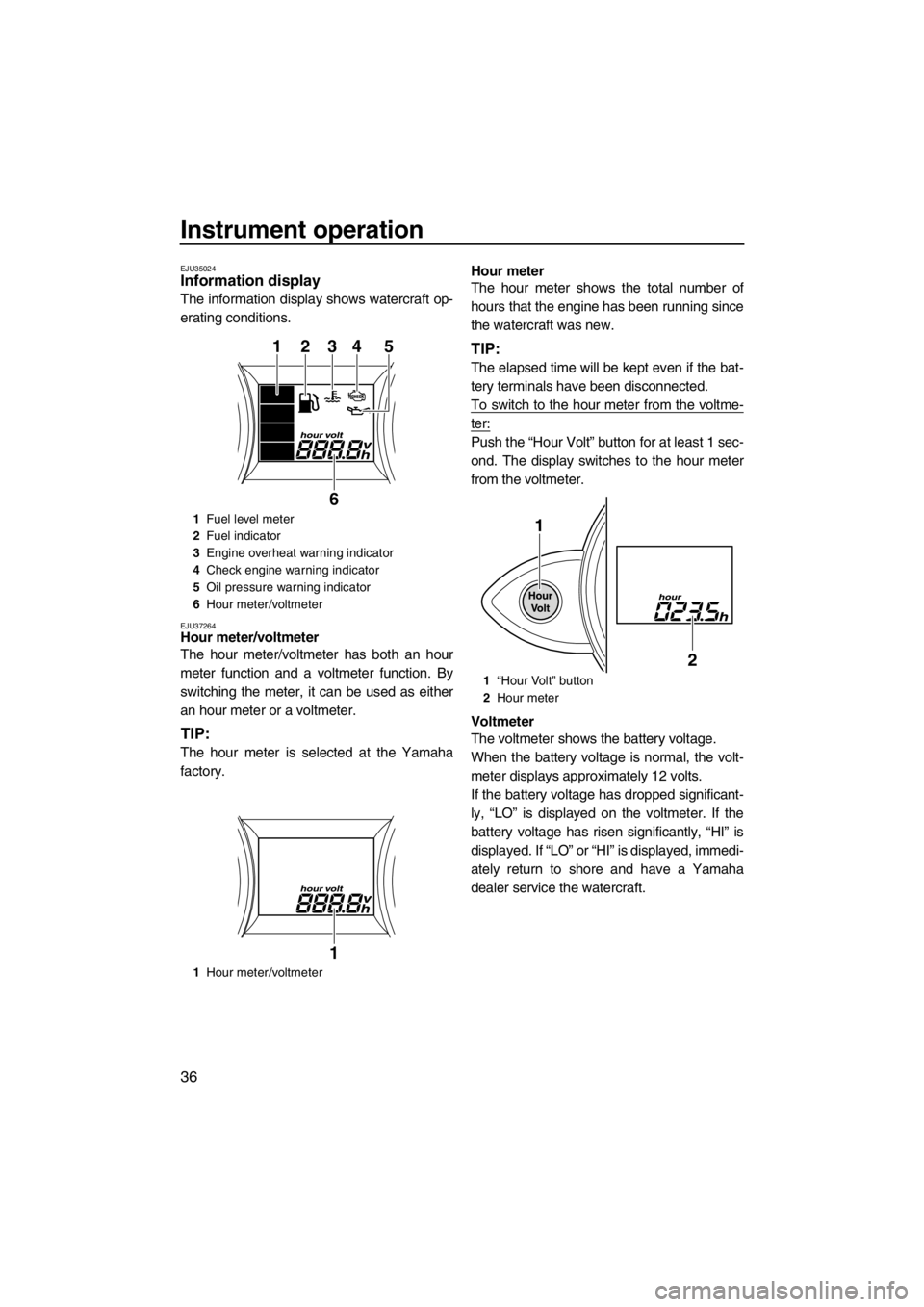

EJU37303Engine overheat warning

If the engine temperature rises significantly,

the engine overheat warning indicator and the

“WARNING” indicator light blink, and the

buzzer sounds intermittently. Then, the en-

gine overheat warning indicator and the

“WARNING” indicator light stop blinking and

remain on, and the buzzer sounds continu-

ously. At the same time, the maximum engine

speed is limited.If the engine overheat warning is activated,

immediately reduce the engine speed, return

to shore, and then make sure that water is be-

ing discharged from the port (left) cooling wa-

ter pilot outlet while the engine is running. If

there is no discharge of water, stop the en-

gine, and then check the jet intake for clog-

ging. (See page 90 for information on the jet

intake.) NOTICE: If you cannot locate and

correct the cause of the overheating, con-

sult a Yamaha dealer. Continuing to oper-

ate at higher speeds could result in severe

engine damage.

[ECJ00041]

TIP:

Push the “Hour Volt” button to stop the buzz-

er.

EJU37312Check engine warning

If a sensor malfunction or a short circuit is de-

tected, the check engine warning indicator

and the “WARNING” indicator light blink, and

the buzzer sounds intermittently.

UF2R74E0.book Page 38 Wednesday, August 22, 2012 2:26 PM

Page 55 of 104

Operation and handling requirements

49

EJU40290

Engine oil requirements EJU41510Engine oil

NOTICE

ECJ00281

Use only 4-stroke engine oil. Usage of 2-

stroke engine oil could result in severe en-

gine damage.

Checking the engine oil level

WARNING

EWJ00340

Engine oil is extremely hot immediately af-

ter the engine is turned off. Coming in con-

tact with or getting any engine oil on your

clothes could result in burns.

NOTICE

ECJ01001

Make sure that debris and water do not en-

ter the oil filler hole. Debris and water in

the engine oil can cause serious engine

damage.

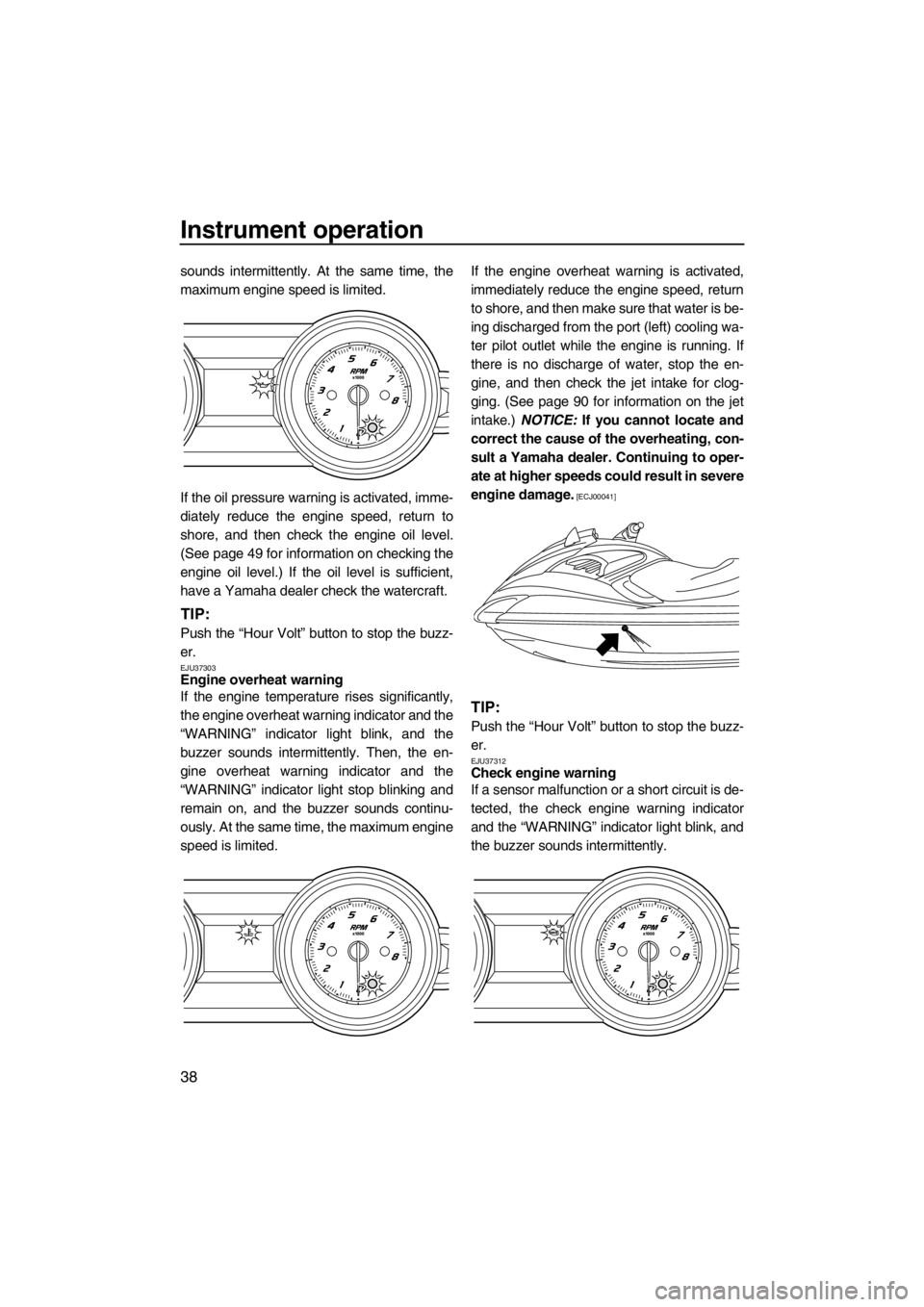

To check the engine oil level:

(1) Place the watercraft in a precisely level

position on land with the engine stopped.

If the engine was running, allow the en-

gine oil to settle by waiting 5 minutes or

more before checking the oil level.

(2) Remove the seats. (See page 40 for seat

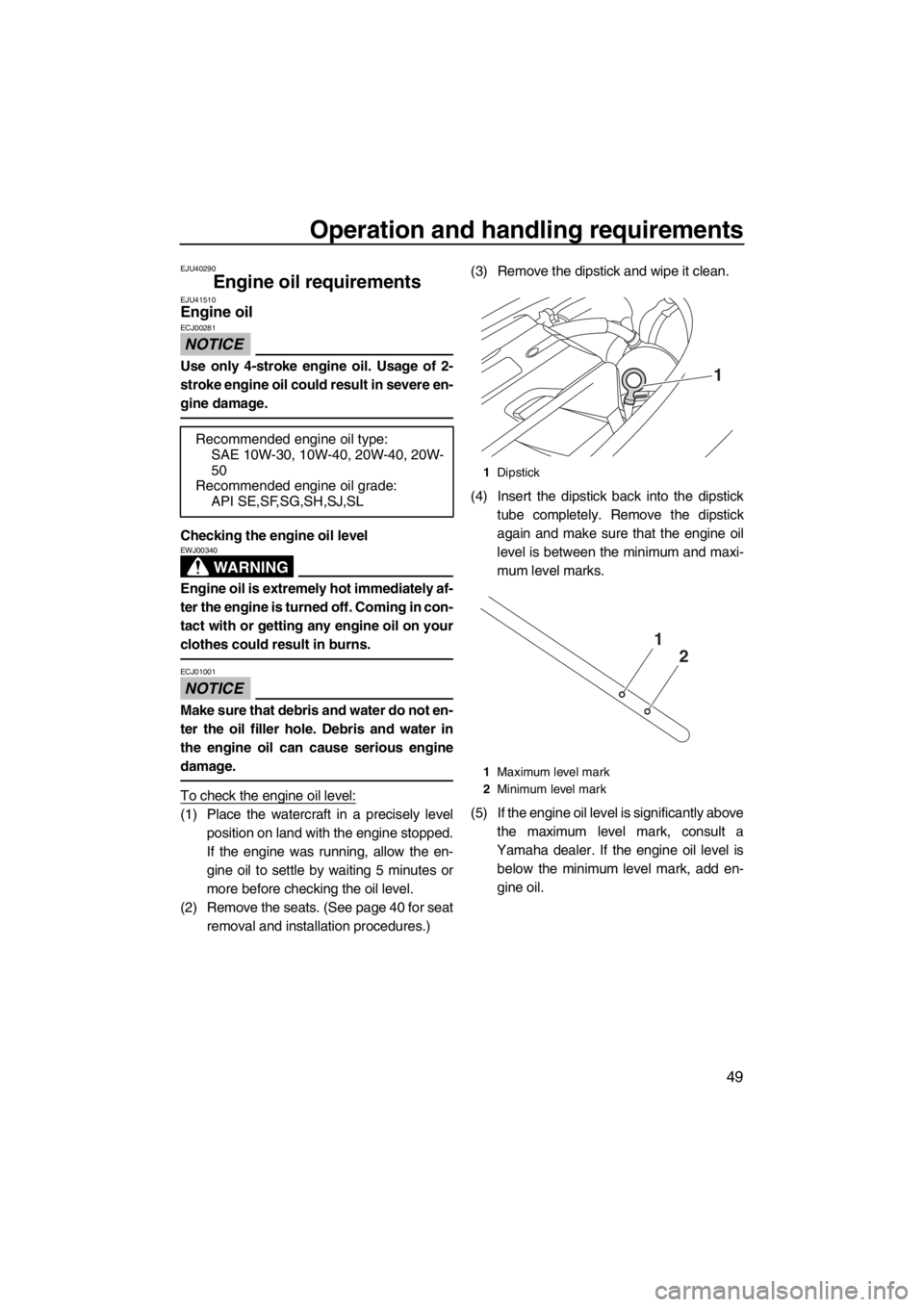

removal and installation procedures.)(3) Remove the dipstick and wipe it clean.

(4) Insert the dipstick back into the dipstick

tube completely. Remove the dipstick

again and make sure that the engine oil

level is between the minimum and maxi-

mum level marks.

(5) If the engine oil level is significantly above

the maximum level mark, consult a

Yamaha dealer. If the engine oil level is

below the minimum level mark, add en-

gine oil. Recommended engine oil type:

SAE 10W-30, 10W-40, 20W-40, 20W-

50

Recommended engine oil grade:

API SE,SF,SG,SH,SJ,SL

1Dipstick

1Maximum level mark

2Minimum level mark

1

2

1

UF2R74E0.book Page 49 Wednesday, August 22, 2012 2:26 PM

Page 56 of 104

Operation and handling requirements

50

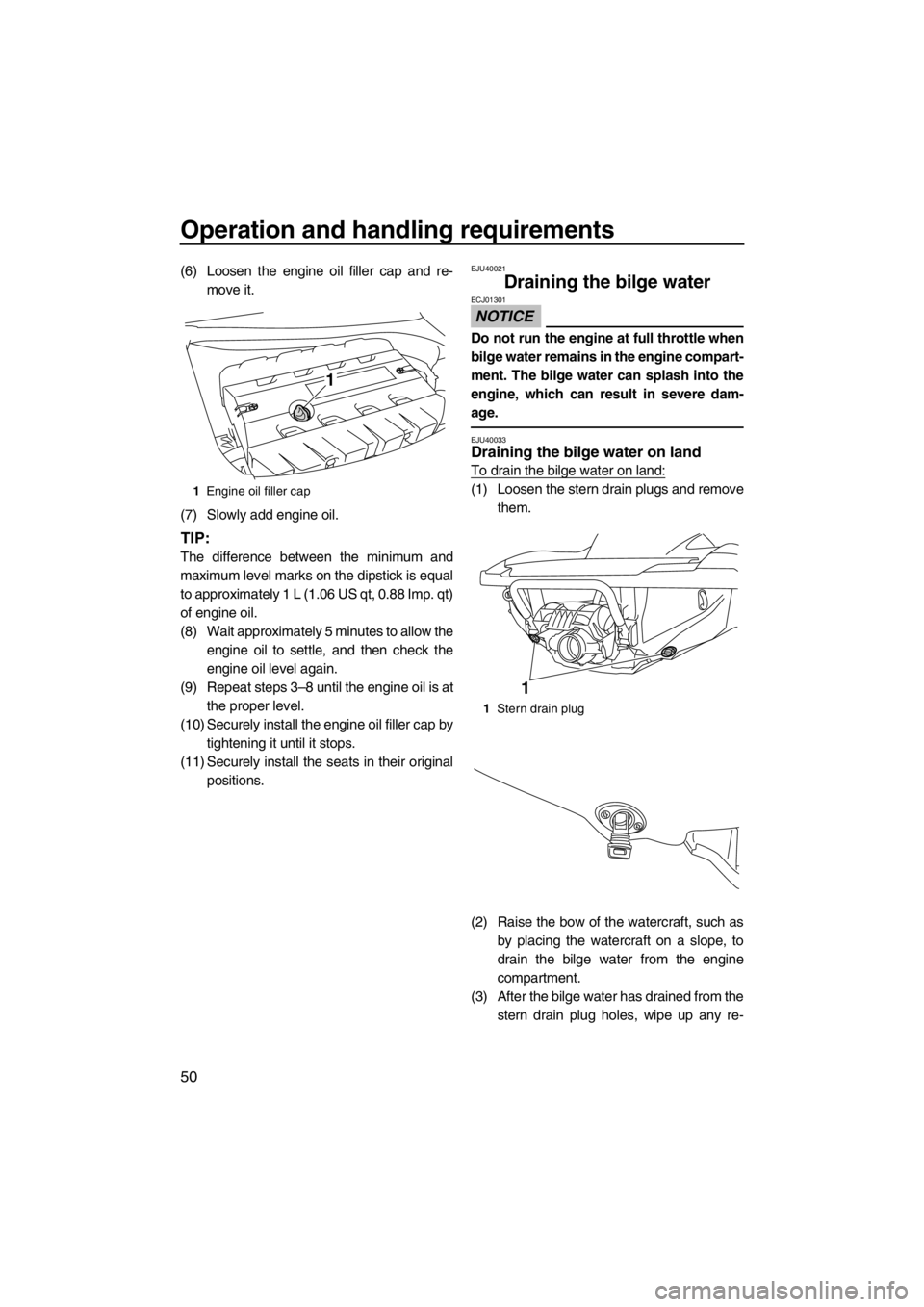

(6) Loosen the engine oil filler cap and re-

move it.

(7) Slowly add engine oil.

TIP:

The difference between the minimum and

maximum level marks on the dipstick is equal

to approximately 1 L (1.06 US qt, 0.88 Imp. qt)

of engine oil.

(8) Wait approximately 5 minutes to allow the

engine oil to settle, and then check the

engine oil level again.

(9) Repeat steps 3–8 until the engine oil is at

the proper level.

(10) Securely install the engine oil filler cap by

tightening it until it stops.

(11) Securely install the seats in their original

positions.

EJU40021

Draining the bilge water

NOTICE

ECJ01301

Do not run the engine at full throttle when

bilge water remains in the engine compart-

ment. The bilge water can splash into the

engine, which can result in severe dam-

age.

EJU40033Draining the bilge water on land

To drain the bilge water on land:

(1) Loosen the stern drain plugs and remove

them.

(2) Raise the bow of the watercraft, such as

by placing the watercraft on a slope, to

drain the bilge water from the engine

compartment.

(3) After the bilge water has drained from the

stern drain plug holes, wipe up any re-1Engine oil filler cap

1

1Stern drain plug

1

UF2R74E0.book Page 50 Wednesday, August 22, 2012 2:26 PM

Page 59 of 104

First-time operation

53

EJU36665

Engine break-in

NOTICE

ECJ00431

Failure to perform the engine break-in

could result in reduced engine life or even

severe engine damage.

The engine break-in is essential to allow the

various components of the engine to wear

and polish themselves to the correct operat-

ing clearances. This ensures proper perfor-

mance and promotes longer component life.

To perform the engine break-in:

(1) Check the engine oil level. (See page 49

for information on checking the engine oil

level.)

(2) Launch the watercraft and start the en-

gine. (See page 65 for information on

starting the engine.)

(3) For the first 5 minutes, operate with the

engine speed at 2000 r/min.

(4) For the next 30 minutes, operate with the

engine speed below 5000 r/min.

(5) For the next 1 hour, operate with the en-

gine speed below 6000 r/min.

After the engine break-in is complete, the wa-

tercraft can be operated normally.

UF2R74E0.book Page 53 Wednesday, August 22, 2012 2:26 PM

Page 60 of 104

Pre-operation checks

54

EJU31981

WARNING

EWJ00411

Failure to inspect or maintain the watercraft properly increases the possibility of an ac-

cident or damage to the watercraft. Do not operate the watercraft if you find any prob-

lem. If a problem cannot be corrected by the procedures provided in this manual, have

the watercraft inspected by a Yamaha dealer.

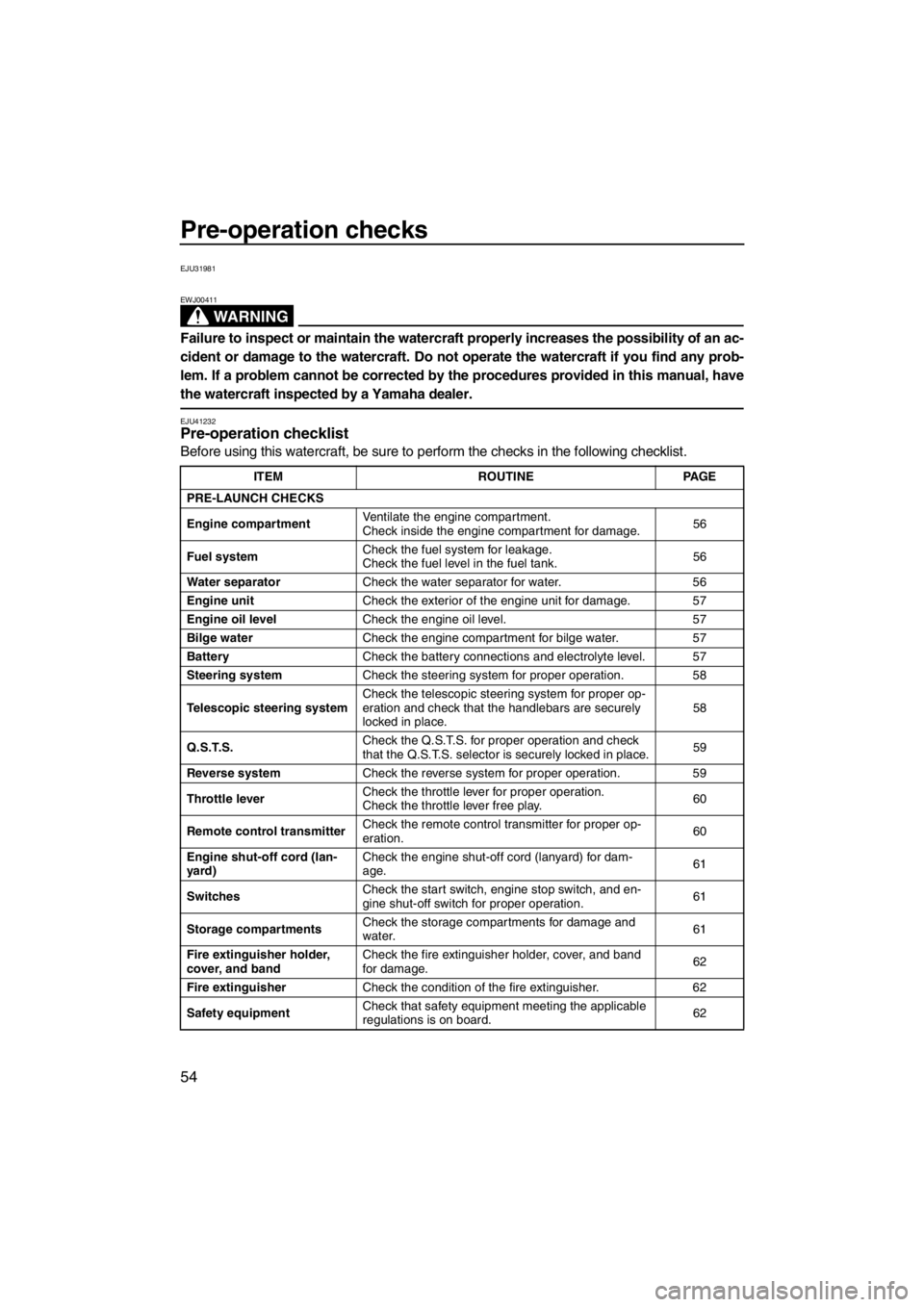

EJU41232Pre-operation checklist

Before using this watercraft, be sure to perform the checks in the following checklist.

ITEM ROUTINE PAGE

PRE-LAUNCH CHECKS

Engine compartmentVentilate the engine compartment.

Check inside the engine compartment for damage.56

Fuel systemCheck the fuel system for leakage.

Check the fuel level in the fuel tank.56

Water separatorCheck the water separator for water. 56

Engine unitCheck the exterior of the engine unit for damage. 57

Engine oil levelCheck the engine oil level. 57

Bilge waterCheck the engine compartment for bilge water. 57

BatteryCheck the battery connections and electrolyte level. 57

Steering systemCheck the steering system for proper operation. 58

Telescopic steering systemCheck the telescopic steering system for proper op-

eration and check that the handlebars are securely

locked in place.58

Q.S.T.S.Check the Q.S.T.S. for proper operation and check

that the Q.S.T.S. selector is securely locked in place.59

Reverse systemCheck the reverse system for proper operation. 59

Throttle leverCheck the throttle lever for proper operation.

Check the throttle lever free play.60

Remote control transmitterCheck the remote control transmitter for proper op-

eration.60

Engine shut-off cord (lan-

yard)Check the engine shut-off cord (lanyard) for dam-

age.61

SwitchesCheck the start switch, engine stop switch, and en-

gine shut-off switch for proper operation.61

Storage compartmentsCheck the storage compartments for damage and

water.61

Fire extinguisher holder,

cover, and bandCheck the fire extinguisher holder, cover, and band

for damage.62

Fire extinguisherCheck the condition of the fire extinguisher. 62

Safety equipmentCheck that safety equipment meeting the applicable

regulations is on board.62

UF2R74E0.book Page 54 Wednesday, August 22, 2012 2:26 PM

Page 63 of 104

Pre-operation checks

57

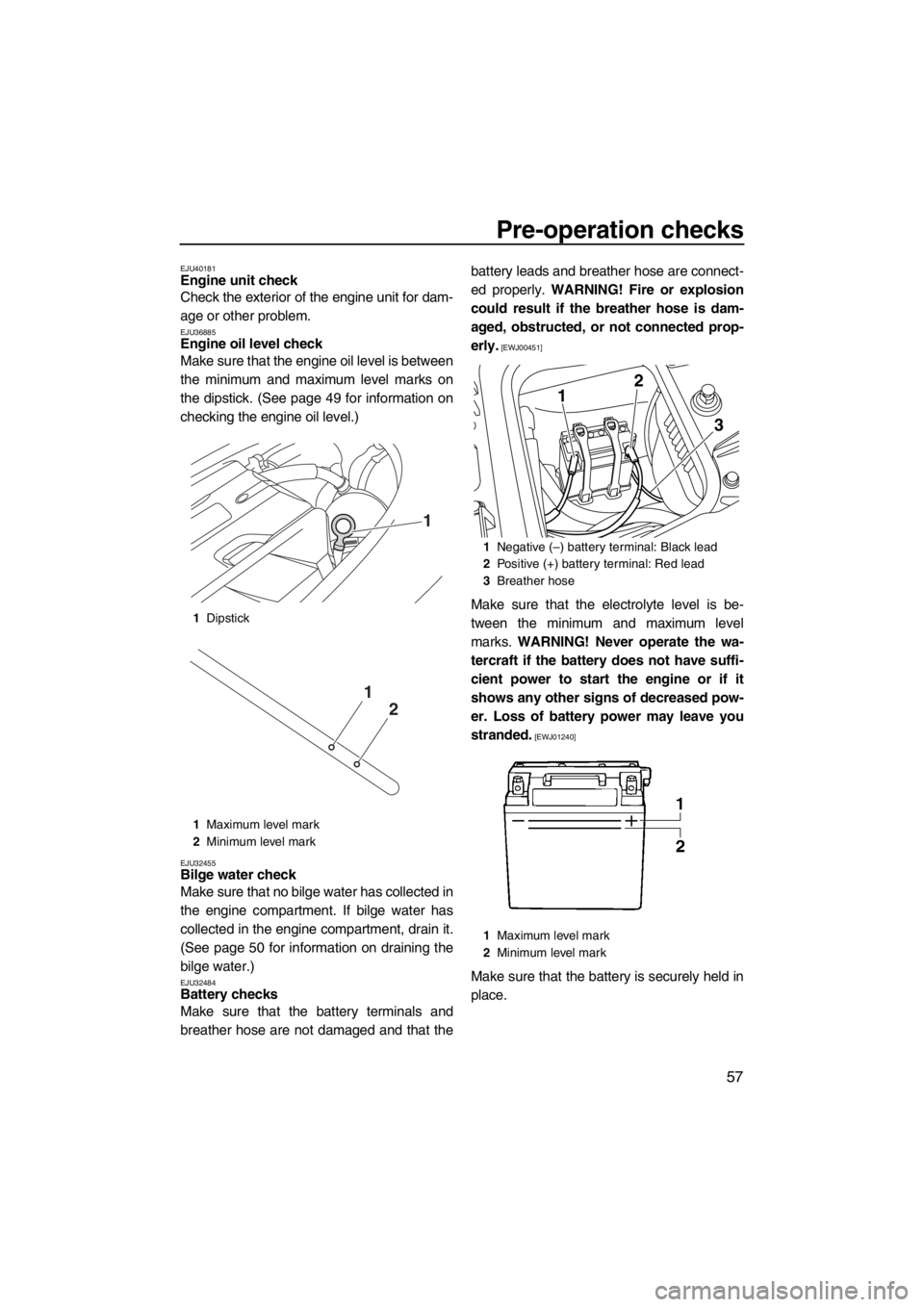

EJU40181Engine unit check

Check the exterior of the engine unit for dam-

age or other problem.

EJU36885Engine oil level check

Make sure that the engine oil level is between

the minimum and maximum level marks on

the dipstick. (See page 49 for information on

checking the engine oil level.)

EJU32455Bilge water check

Make sure that no bilge water has collected in

the engine compartment. If bilge water has

collected in the engine compartment, drain it.

(See page 50 for information on draining the

bilge water.)

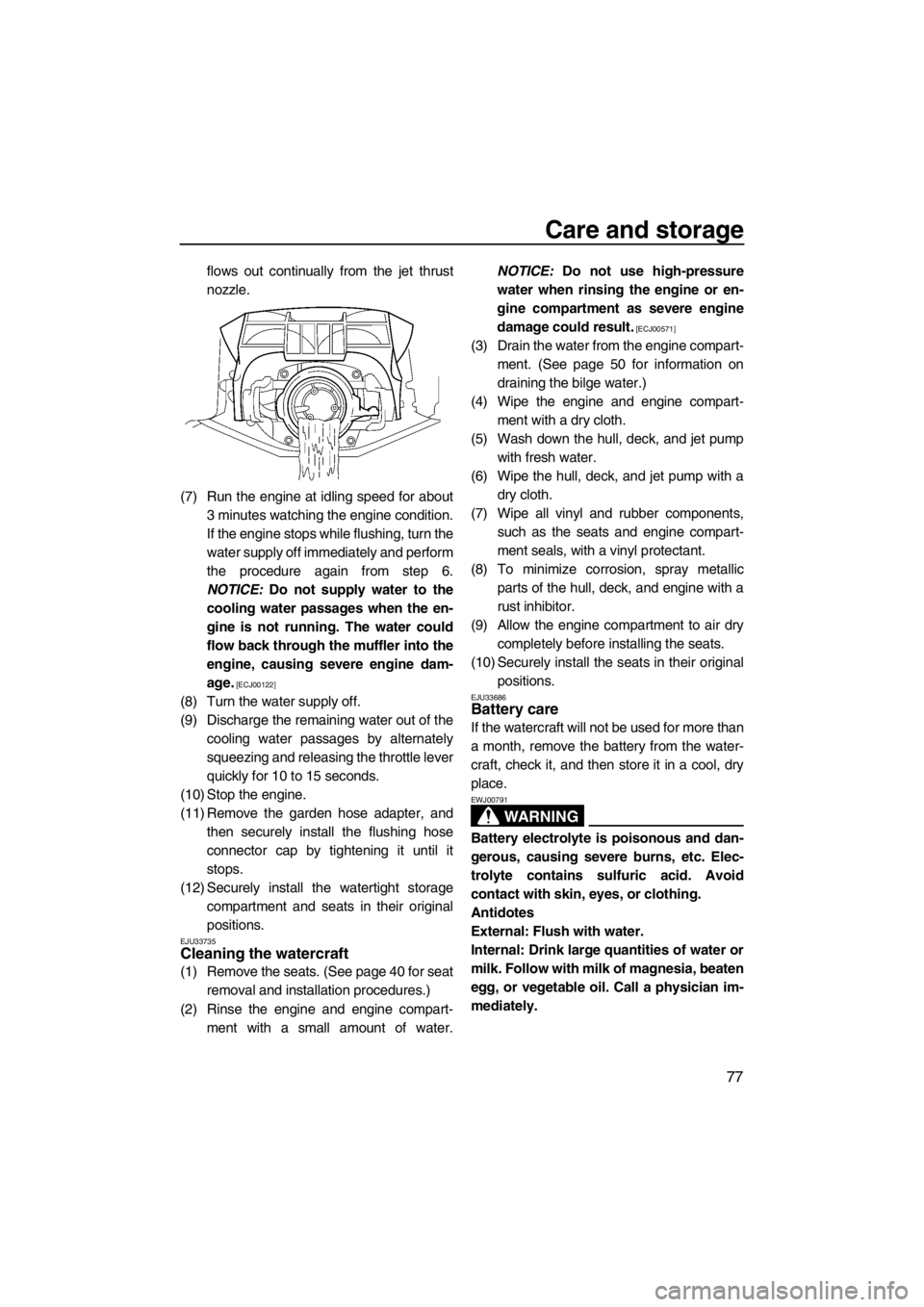

EJU32484Battery checks

Make sure that the battery terminals and

breather hose are not damaged and that thebattery leads and breather hose are connect-

ed properly. WARNING! Fire or explosion

could result if the breather hose is dam-

aged, obstructed, or not connected prop-

erly.

[EWJ00451]

Make sure that the electrolyte level is be-

tween the minimum and maximum level

marks. WARNING! Never operate the wa-

tercraft if the battery does not have suffi-

cient power to start the engine or if it

shows any other signs of decreased pow-

er. Loss of battery power may leave you

stranded.

[EWJ01240]

Make sure that the battery is securely held in

place.

1Dipstick

1Maximum level mark

2Minimum level mark

1

2

1

1Negative (–) battery terminal: Black lead

2Positive (+) battery terminal: Red lead

3Breather hose

1Maximum level mark

2Minimum level mark

12

3

UF2R74E0.book Page 57 Wednesday, August 22, 2012 2:26 PM

Page 83 of 104

Care and storage

77

flows out continually from the jet thrust

nozzle.

(7) Run the engine at idling speed for about

3 minutes watching the engine condition.

If the engine stops while flushing, turn the

water supply off immediately and perform

the procedure again from step 6.

NOTICE: Do not supply water to the

cooling water passages when the en-

gine is not running. The water could

flow back through the muffler into the

engine, causing severe engine dam-

age.

[ECJ00122]

(8) Turn the water supply off.

(9) Discharge the remaining water out of the

cooling water passages by alternately

squeezing and releasing the throttle lever

quickly for 10 to 15 seconds.

(10) Stop the engine.

(11) Remove the garden hose adapter, and

then securely install the flushing hose

connector cap by tightening it until it

stops.

(12) Securely install the watertight storage

compartment and seats in their original

positions.

EJU33735Cleaning the watercraft

(1) Remove the seats. (See page 40 for seat

removal and installation procedures.)

(2) Rinse the engine and engine compart-

ment with a small amount of water.NOTICE: Do not use high-pressure

water when rinsing the engine or en-

gine compartment as severe engine

damage could result.

[ECJ00571]

(3) Drain the water from the engine compart-

ment. (See page 50 for information on

draining the bilge water.)

(4) Wipe the engine and engine compart-

ment with a dry cloth.

(5) Wash down the hull, deck, and jet pump

with fresh water.

(6) Wipe the hull, deck, and jet pump with a

dry cloth.

(7) Wipe all vinyl and rubber components,

such as the seats and engine compart-

ment seals, with a vinyl protectant.

(8) To minimize corrosion, spray metallic

parts of the hull, deck, and engine with a

rust inhibitor.

(9) Allow the engine compartment to air dry

completely before installing the seats.

(10) Securely install the seats in their original

positions.

EJU33686Battery care

If the watercraft will not be used for more than

a month, remove the battery from the water-

craft, check it, and then store it in a cool, dry

place.

WARNING

EWJ00791

Battery electrolyte is poisonous and dan-

gerous, causing severe burns, etc. Elec-

trolyte contains sulfuric acid. Avoid

contact with skin, eyes, or clothing.

Antidotes

External: Flush with water.

Internal: Drink large quantities of water or

milk. Follow with milk of magnesia, beaten

egg, or vegetable oil. Call a physician im-

mediately.

UF2R74E0.book Page 77 Wednesday, August 22, 2012 2:26 PM