ECU YAMAHA FZS 2013 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2013, Model line: FZS, Model: YAMAHA FZS 2013Pages: 106, PDF Size: 5.14 MB

Page 51 of 106

Equipment operation

45

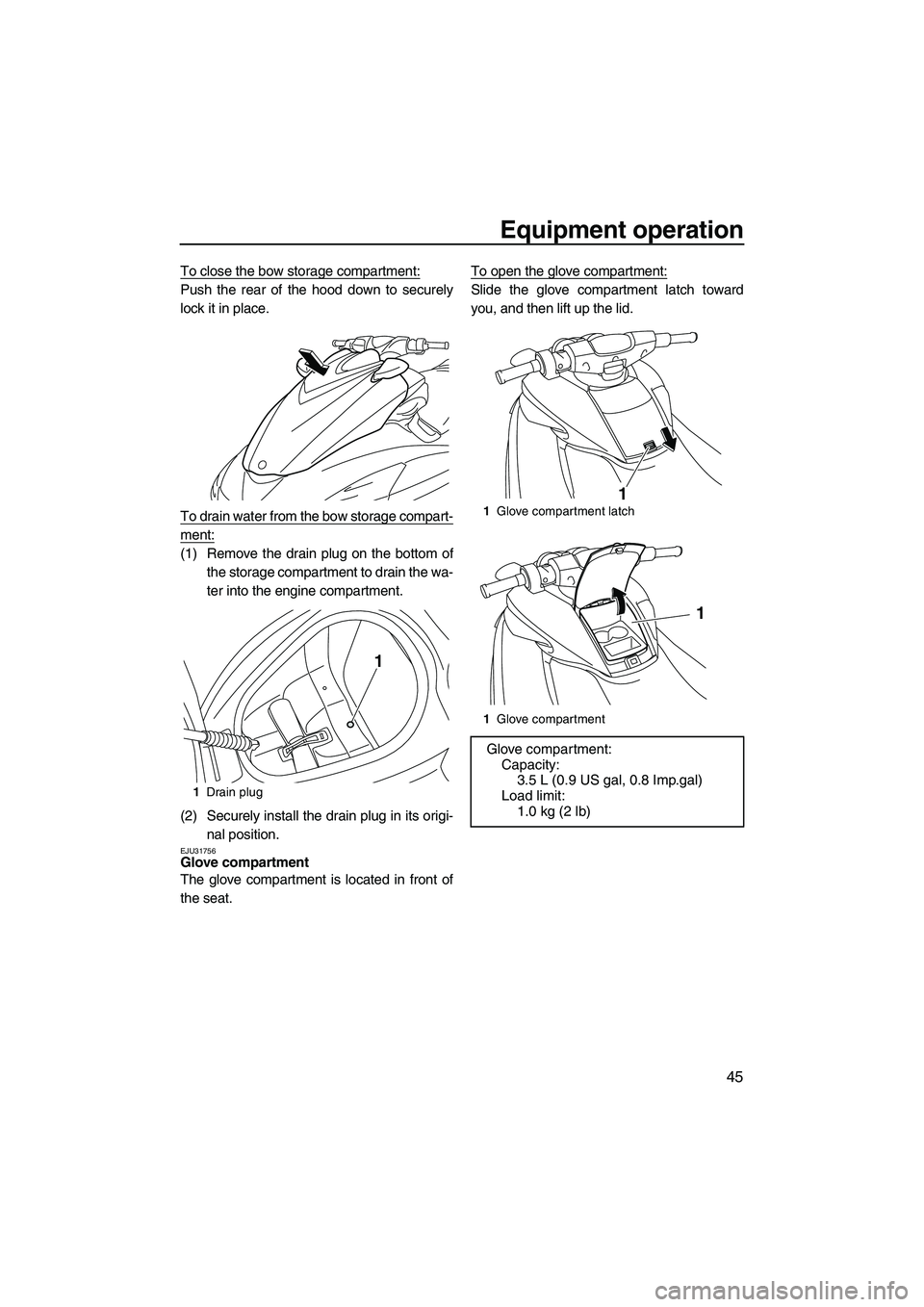

To close the bow storage compartment:

Push the rear of the hood down to securely

lock it in place.

To drain water from the bow storage compart-

ment:

(1) Remove the drain plug on the bottom ofthe storage compartment to drain the wa-

ter into the engine compartment.

(2) Securely install the drain plug in its origi- nal position.

EJU31756Glove compartment

The glove compartment is located in front of

the seat. To open the glove compartment:

Slide the glove compartment latch toward

you, and then lift up the lid.

1

Drain plug

1

1Glove compartment latch

1 Glove compartment

Glove compartment:

Capacity: 3.5 L (0.9 US gal, 0.8 Imp.gal)

Load limit:

1.0 kg (2 lb)

1

1

UF2C74E0.book Page 45 Friday, August 3, 2012 2:34 PM

Page 52 of 106

Equipment operation

46

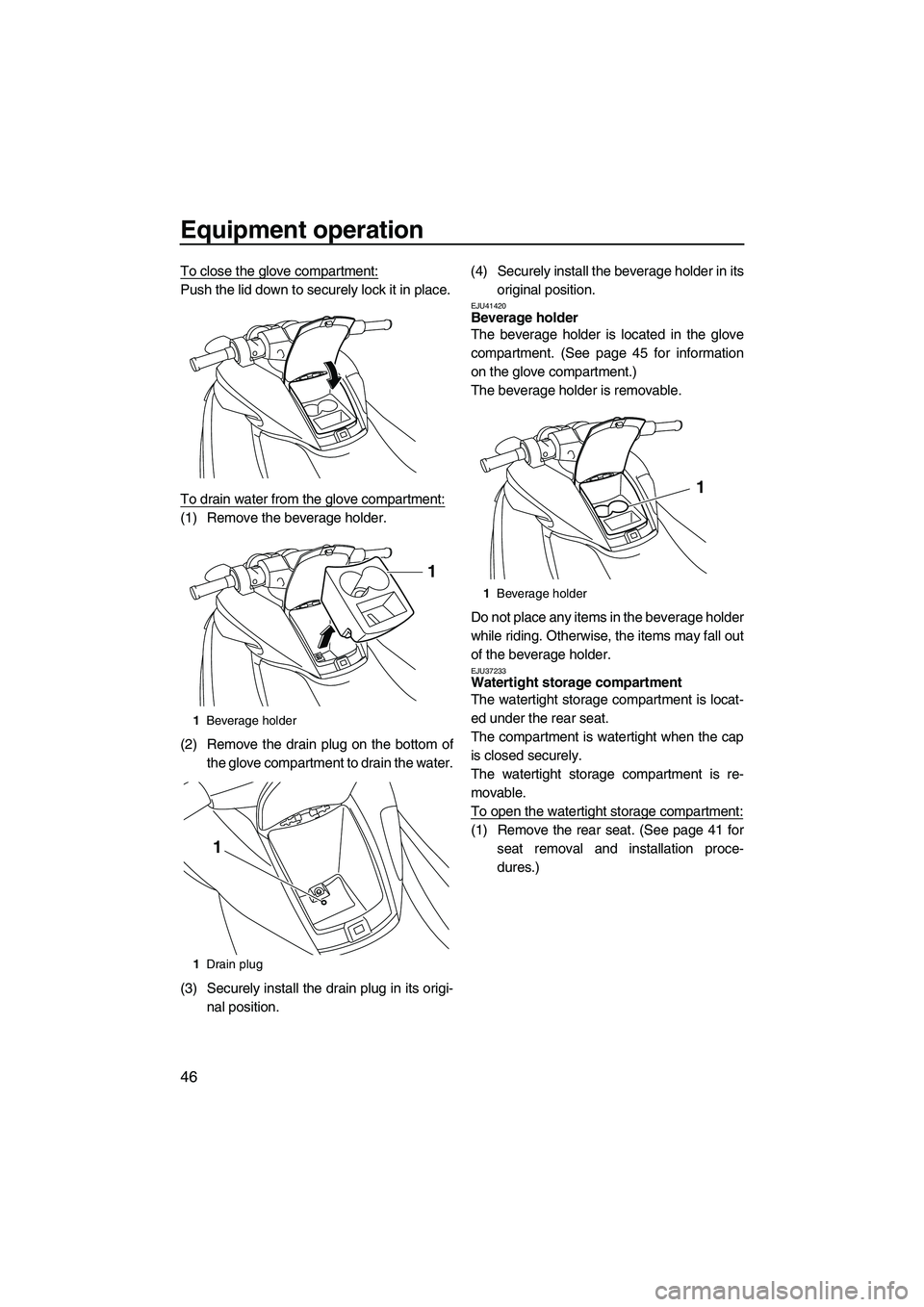

To close the glove compartment:

Push the lid down to securely lock it in place.

To drain water from the glove compartment:

(1) Remove the beverage holder.

(2) Remove the drain plug on the bottom ofthe glove compartment to drain the water.

(3) Securely install the drain plug in its origi- nal position. (4) Securely install the beverage holder in its

original position.

EJU41420Beverage holder

The beverage holder is located in the glove

compartment. (See page 45 for information

on the glove compartment.)

The beverage holder is removable.

Do not place any items in the beverage holder

while riding. Otherwise, the items may fall out

of the beverage holder.

EJU37233Watertight storage compartment

The watertight storage compartment is locat-

ed under the rear seat.

The compartment is watertight when the cap

is closed securely.

The watertight storage compartment is re-

movable.

To open the watertight storage compartment:

(1) Remove the rear seat. (See page 41 forseat removal and installation proce-

dures.)

1Beverage holder

1 Drain plug

1

1

1Beverage holder

1

UF2C74E0.book Page 46 Friday, August 3, 2012 2:34 PM

Page 53 of 106

Equipment operation

47

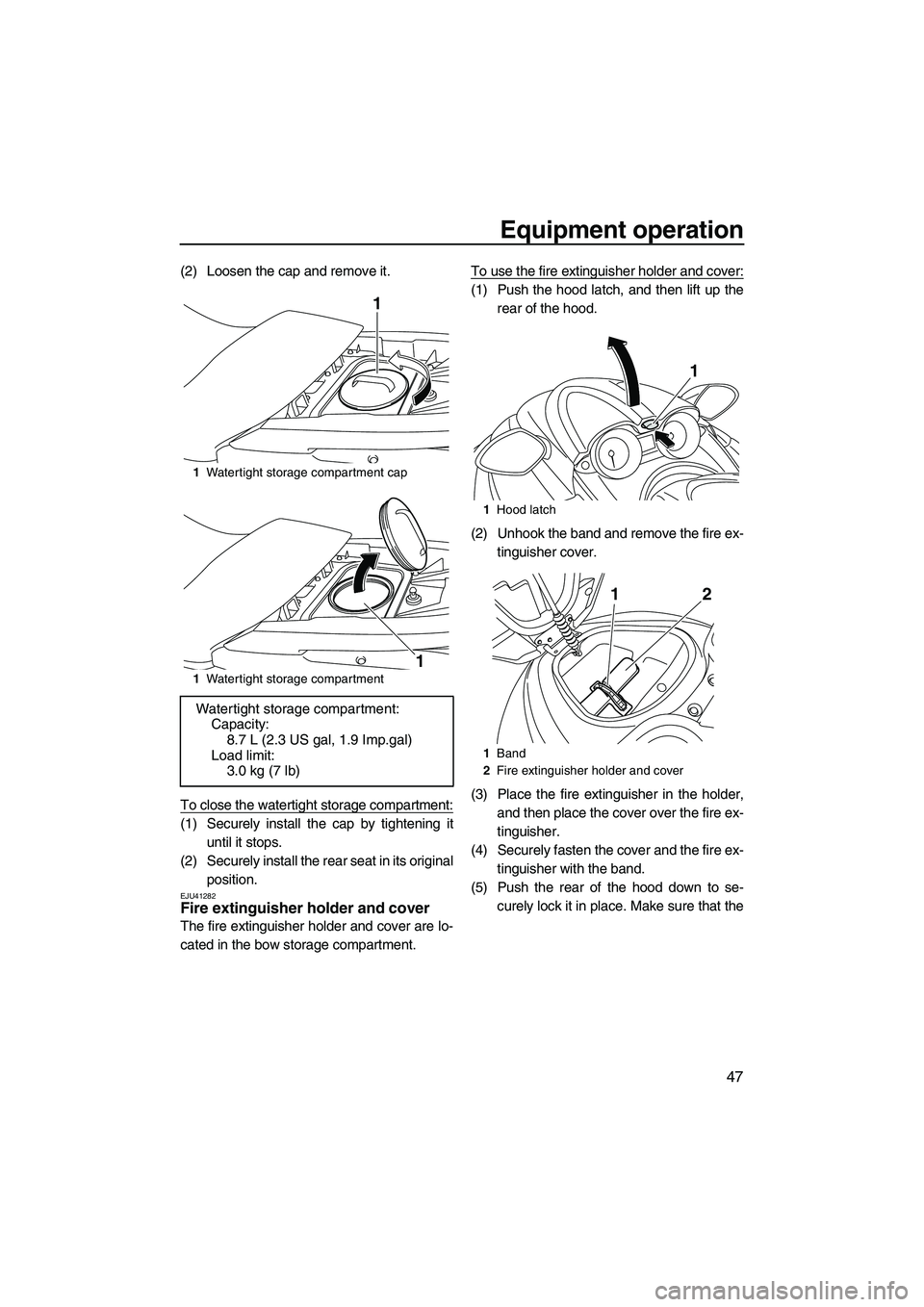

(2) Loosen the cap and remove it.

To close the watertight storage compartment:

(1) Securely install the cap by tightening ituntil it stops.

(2) Securely install the rear seat in its original position.

EJU41282Fire extinguisher holder and cover

The fire extinguisher holder and cover are lo-

cated in the bow storage compartment. To use the fire extinguisher holder and cover:

(1) Push the hood latch, and then lift up the

rear of the hood.

(2) Unhook the band and remove the fire ex- tinguisher cover.

(3) Place the fire extinguisher in the holder, and then place the cover over the fire ex-

tinguisher.

(4) Securely fasten the cover and the fire ex- tinguisher with the band.

(5) Push the rear of the hood down to se- curely lock it in place. Make sure that the

1Watertight storage compartment cap

1 Watertight storage compartment

Watertight storage compartment:

Capacity:8.7 L (2.3 US gal, 1.9 Imp.gal)

Load limit: 3.0 kg (7 lb)

1

1

1Hood latch

1 Band

2 Fire extinguisher holder and cover

1

12

UF2C74E0.book Page 47 Friday, August 3, 2012 2:34 PM

Page 54 of 106

Equipment operation

48

hood is securely closed before using the

watercraft.

UF2C74E0.book Page 48 Friday, August 3, 2012 2:34 PM

Page 56 of 106

Operation and handling requirements

50

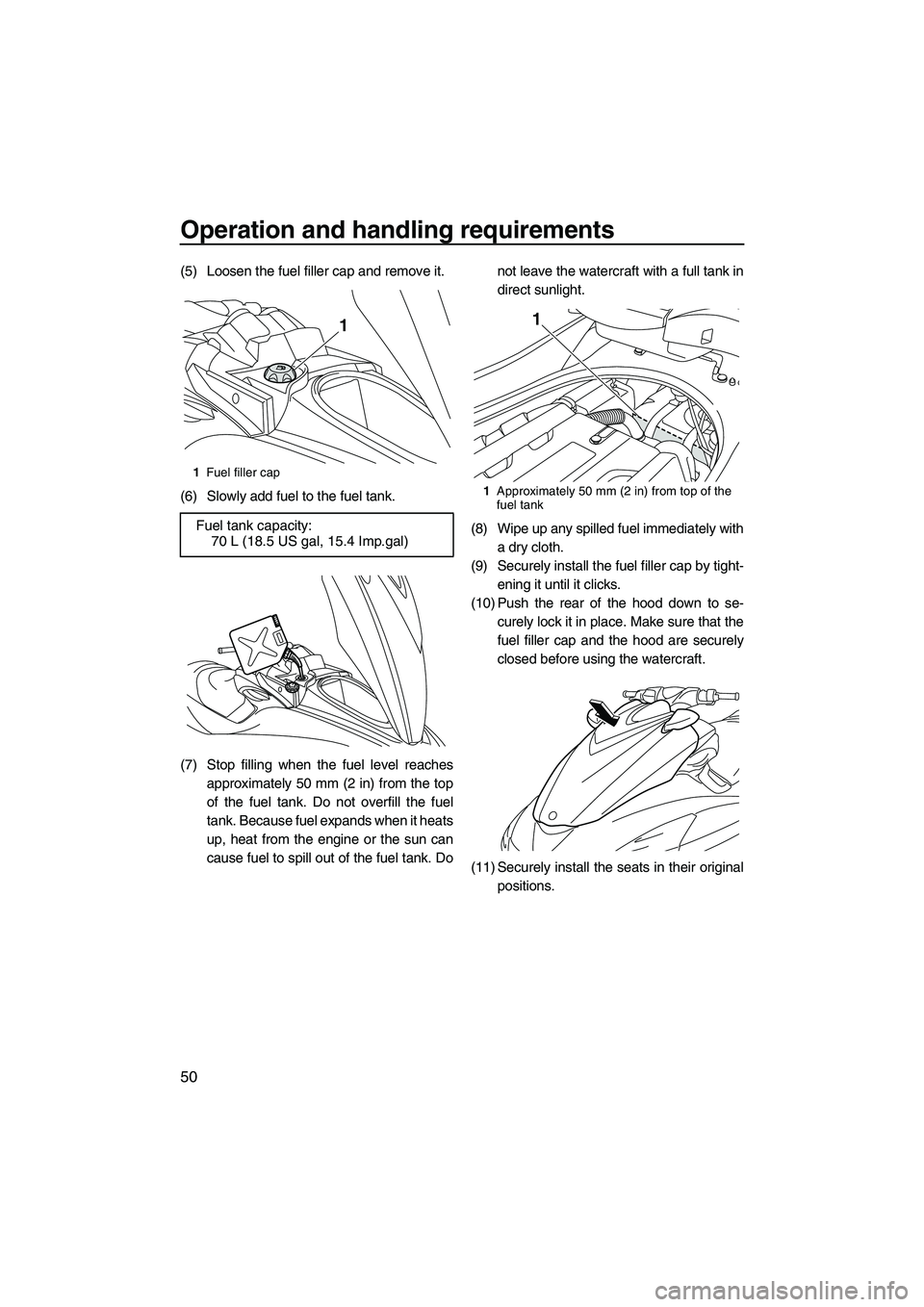

(5) Loosen the fuel filler cap and remove it.

(6) Slowly add fuel to the fuel tank.

(7) Stop filling when the fuel level reachesapproximately 50 mm (2 in) from the top

of the fuel tank. Do not overfill the fuel

tank. Because fuel expands when it heats

up, heat from the engine or the sun can

cause fuel to spill out of the fuel tank. Do not leave the watercraft with a full tank in

direct sunlight.

(8) Wipe up any spilled fuel immediately with a dry cloth.

(9) Securely install the fuel filler cap by tight- ening it until it clicks.

(10) Push the rear of the hood down to se- curely lock it in place. Make sure that the

fuel filler cap and the hood are securely

closed before using the watercraft.

(11) Securely install the seats in their original positions.

1Fuel filler cap

Fuel tank capacity:

70 L (18.5 US gal, 15.4 Imp.gal)

1

1Approximately 50 mm (2 in) from top of the

fuel tank

1

UF2C74E0.book Page 50 Friday, August 3, 2012 2:34 PM

Page 58 of 106

Operation and handling requirements

52

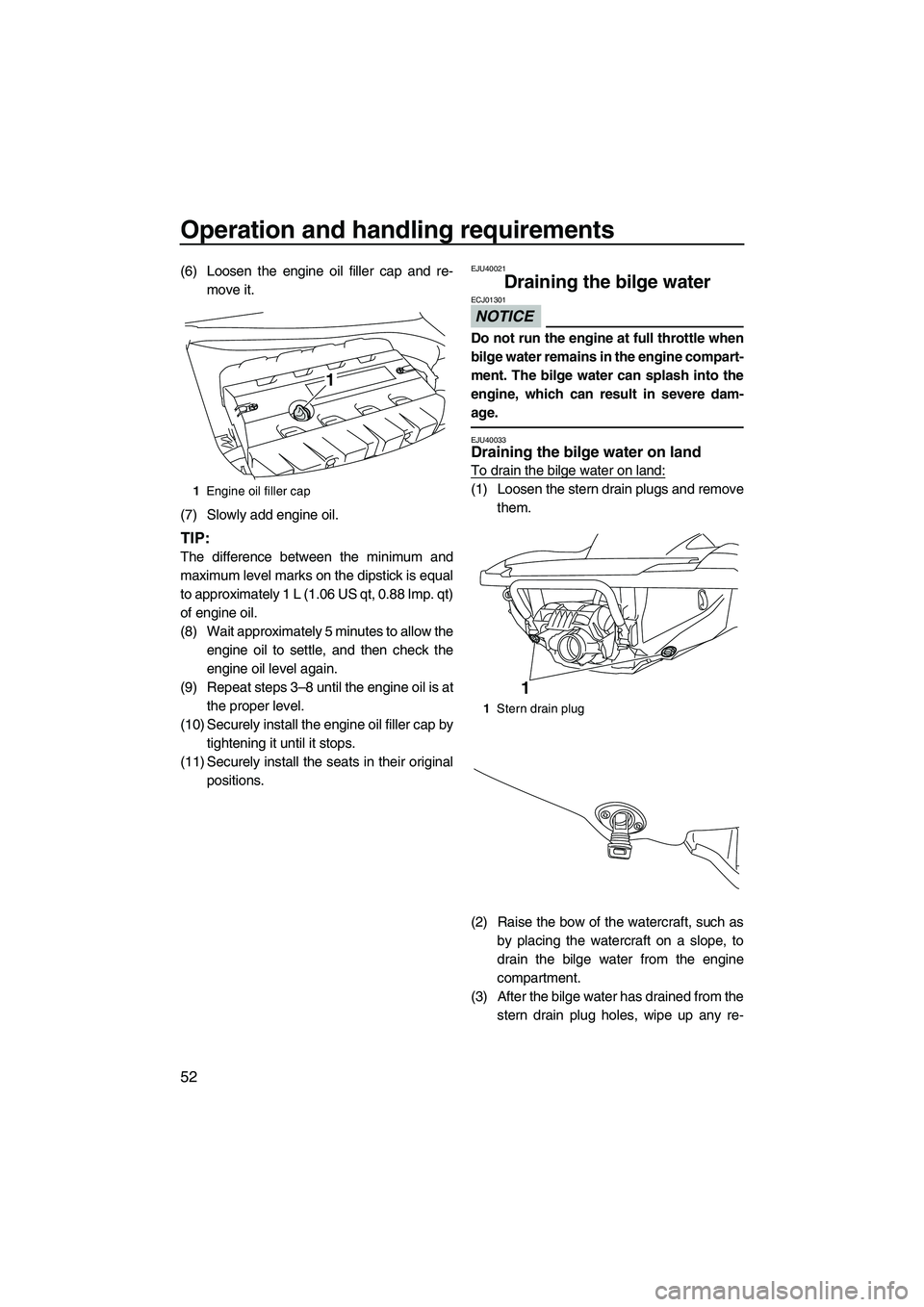

(6) Loosen the engine oil filler cap and re-move it.

(7) Slowly add engine oil.

TIP:

The difference between the minimum and

maximum level marks on the dipstick is equal

to approximately 1 L (1.06 US qt, 0.88 Imp. qt)

of engine oil.

(8) Wait approximately 5 minutes to allow the engine oil to settle, and then check the

engine oil level again.

(9) Repeat steps 3–8 until the engine oil is at the proper level.

(10) Securely install the engine oil filler cap by tightening it until it stops.

(11) Securely install the seats in their original positions.

EJU40021

Draining the bilge water

NOTICE

ECJ01301

Do not run the engine at full throttle when

bilge water remains in the engine compart-

ment. The bilge water can splash into the

engine, which can result in severe dam-

age.

EJU40033Draining the bilge water on land

To drain the bilge water on land:

(1) Loosen the stern drain plugs and removethem.

(2) Raise the bow of the watercraft, such as by placing the watercraft on a slope, to

drain the bilge water from the engine

compartment.

(3) After the bilge water has drained from the stern drain plug holes, wipe up any re-1Engine oil filler cap

1

1Stern drain plug

1

UF2C74E0.book Page 52 Friday, August 3, 2012 2:34 PM

Page 59 of 106

Operation and handling requirements

53

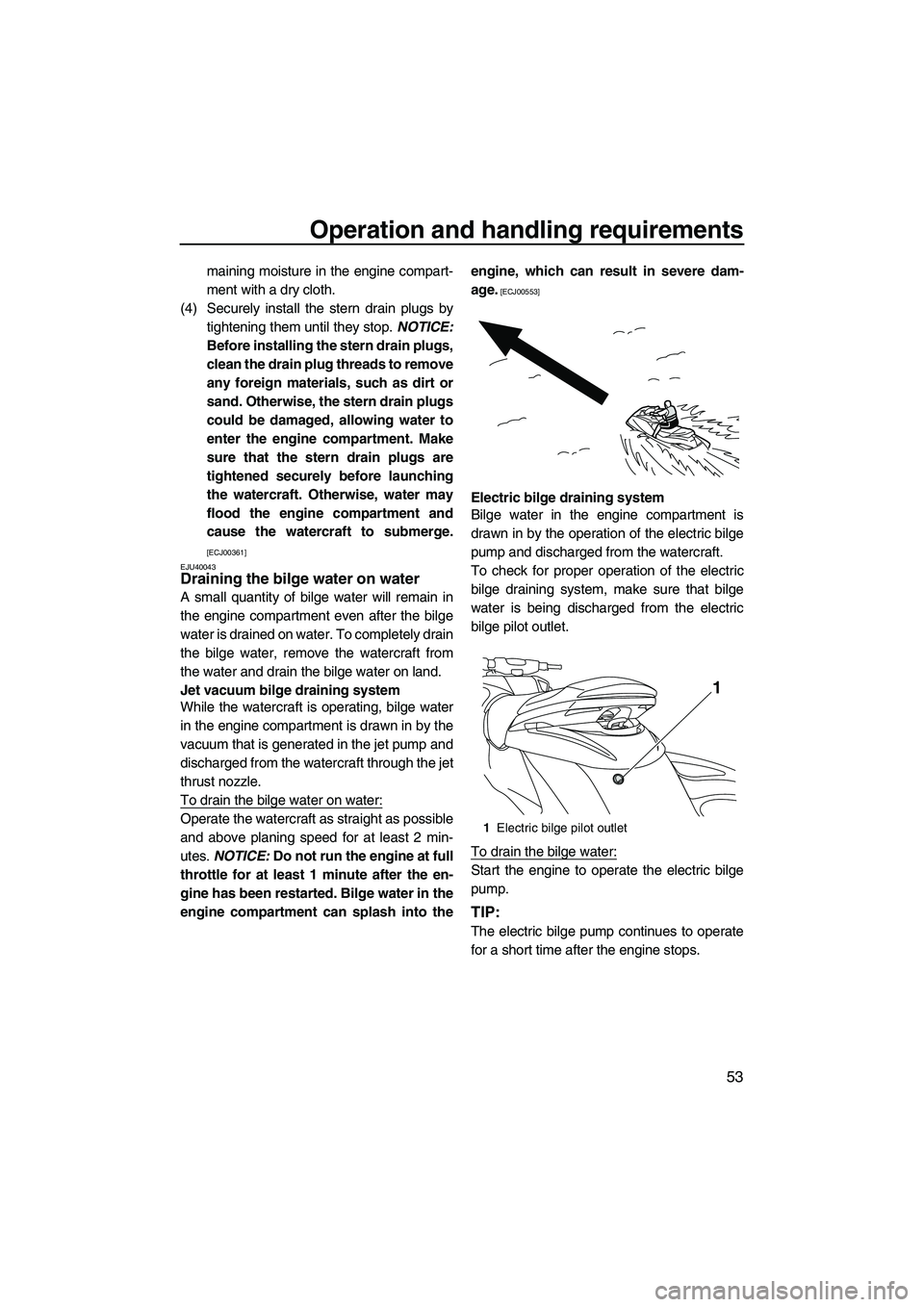

maining moisture in the engine compart-

ment with a dry cloth.

(4) Securely install the stern drain plugs by tightening them until they stop. NOTICE:

Before installing the stern drain plugs,

clean the drain plug threads to remove

any foreign materials, such as dirt or

sand. Otherwise, the stern drain plugs

could be damaged, allowing water to

enter the engine compartment. Make

sure that the stern drain plugs are

tightened securely before launching

the watercraft. Otherwise, water may

flood the engine compartment and

cause the watercraft to submerge.

[ECJ00361]

EJU40043

Draining the bilge water on water

A small quantity of bilge water will remain in

the engine compartment even after the bilge

water is drained on water. To completely drain

the bilge water, remove the watercraft from

the water and drain the bilge water on land.

Jet vacuum bilge draining system

While the watercraft is operating, bilge water

in the engine compartment is drawn in by the

vacuum that is generated in the jet pump and

discharged from the watercraft through the jet

thrust nozzle.

To drain the bilge water on water:

Operate the watercraft as straight as possible

and above planing speed for at least 2 min-

utes. NOTICE: Do not run the engine at full

throttle for at least 1 minute after the en-

gine has been restarted. Bilge water in the

engine compartment can splash into the engine, which can result in severe dam-

age.

[ECJ00553]

Electric bilge draining system

Bilge water in the engine compartment is

drawn in by the operation of the electric bilge

pump and discharged from the watercraft.

To check for proper operation of the electric

bilge draining system, make sure that bilge

water is being discharged from the electric

bilge pilot outlet.

To drain the bilge water:

Start the engine to operate the electric bilge

pump.

TIP:

The electric bilge pump continues to operate

for a short time after the engine stops.

1

Electric bilge pilot outlet

1

UF2C74E0.book Page 53 Friday, August 3, 2012 2:34 PM

Page 60 of 106

Operation and handling requirements

54

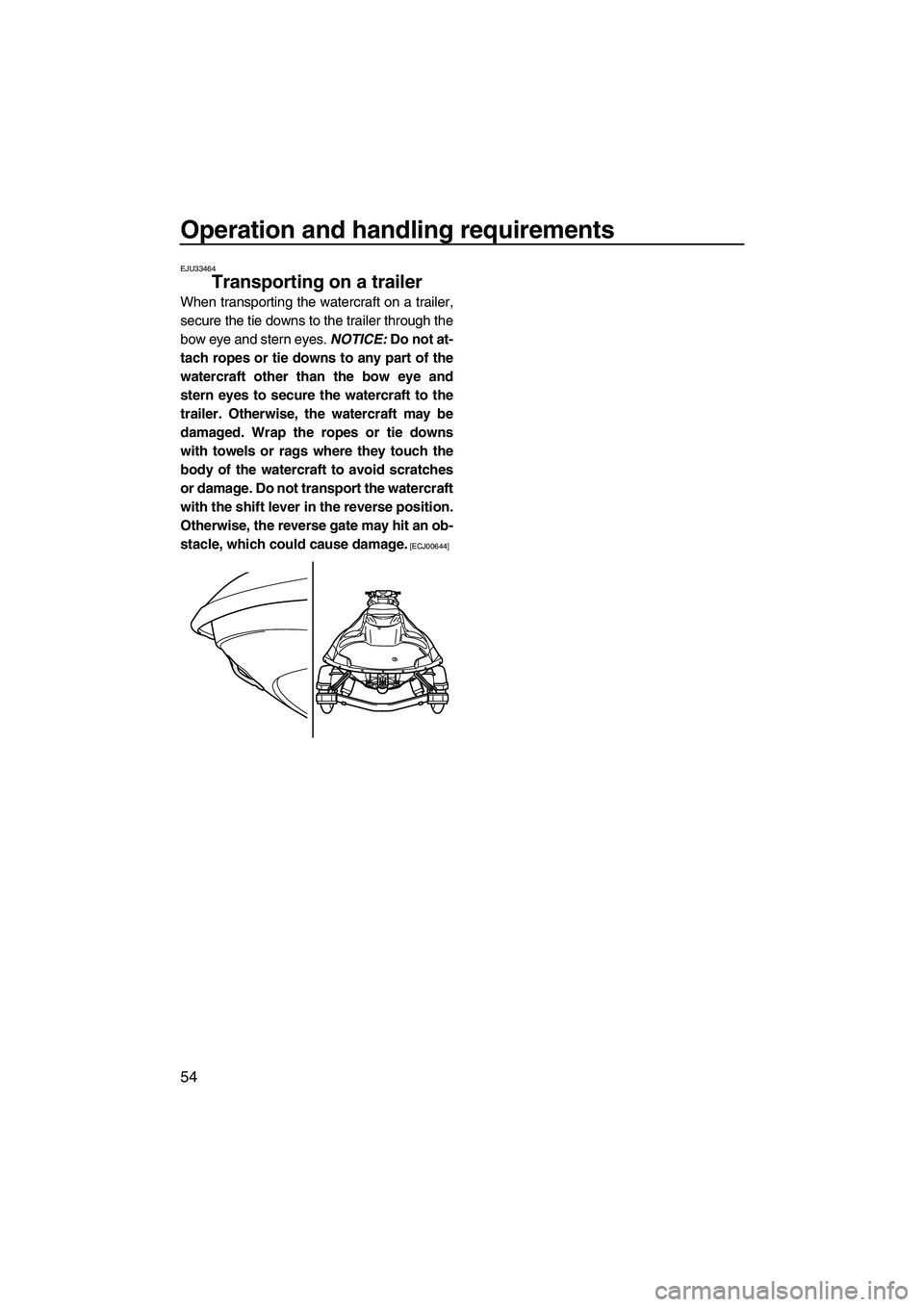

EJU33464

Transporting on a trailer

When transporting the watercraft on a trailer,

secure the tie downs to the trailer through the

bow eye and stern eyes. NOTICE: Do not at-

tach ropes or tie downs to any part of the

watercraft other than the bow eye and

stern eyes to secure the watercraft to the

trailer. Otherwise, the watercraft may be

damaged. Wrap the ropes or tie downs

with towels or rags where they touch the

body of the watercraft to avoid scratches

or damage. Do not transport the watercraft

with the shift lever in the reverse position.

Otherwise, the reverse gate may hit an ob-

stacle, which could cause damage.

[ECJ00644]

UF2C74E0.book Page 54 Friday, August 3, 2012 2:34 PM

Page 62 of 106

Pre-operation checks

56

EJU31981

WARNING

EWJ00411

Failure to inspect or maintain the watercraft properly increases the possibility of an ac-

cident or damage to the watercraft. Do not operate the watercraft if you find any prob-

lem. If a problem cannot be corrected by the procedures provided in this manual, have

the watercraft inspected by a Yamaha dealer.

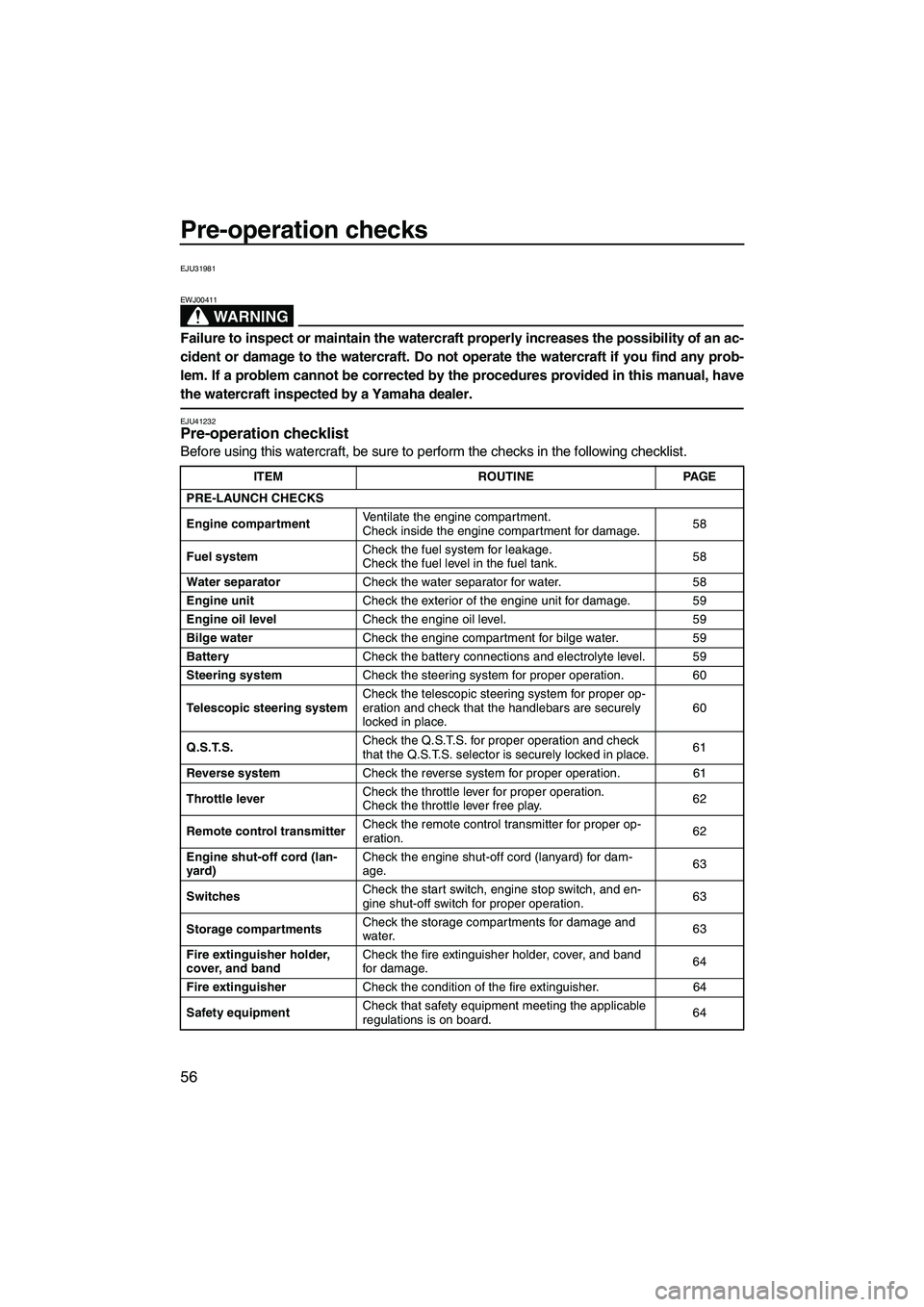

EJU41232Pre-operation checklist

Before using this watercraft, be sure to perform the checks in the following checklist.

ITEM ROUTINEPAGE

PRE-LAUNCH CHECKS

Engine compartment Ventilate the engine compartment.

Check inside the engine compartment for damage.

58

Fuel system Check the fuel system for leakage.

Check the fuel level in the fuel tank.

58

Water separator Check the water separator for water. 58

Engine unit Check the exterior of the engine unit for damage. 59

Engine oil level Check the engine oil level. 59

Bilge water Check the engine compartment for bilge water. 59

Battery Check the battery connections and electrolyte level. 59

Steering system Check the steering system for proper operation. 60

Telescopic steering system Check the telescopic steering system for proper op-

eration and check that the handlebars are securely

locked in place. 60

Q.S.T.S. Check the Q.S.T.S. for proper operation and check

that the Q.S.T.S. selector is securely locked in place.

61

Reverse system Check the reverse system for proper operation. 61

Throttle lever Check the throttle lever for proper operation.

Check the throttle lever free play.

62

Remote control transmitter Check the remote control transmitter for proper op-

eration.

62

Engine shut-off cord (lan-

yard) Check the engine shut-off cord (lanyard) for dam-

age.

63

Switches Check the start switch, engine stop switch, and en-

gine shut-off switch for proper operation.

63

Storage compartments Check the storage compartments for damage and

water.

63

Fire extinguisher holder,

cover, and band Check the fire extinguisher holder, cover, and band

for damage.

64

Fire extinguisher Check the condition of the fire extinguisher. 64

Safety equipment Check that safety equipment meeting the applicable

regulations is on board.

64

UF2C74E0.book Page 56 Friday, August 3, 2012 2:34 PM

Page 63 of 106

Pre-operation checks

57

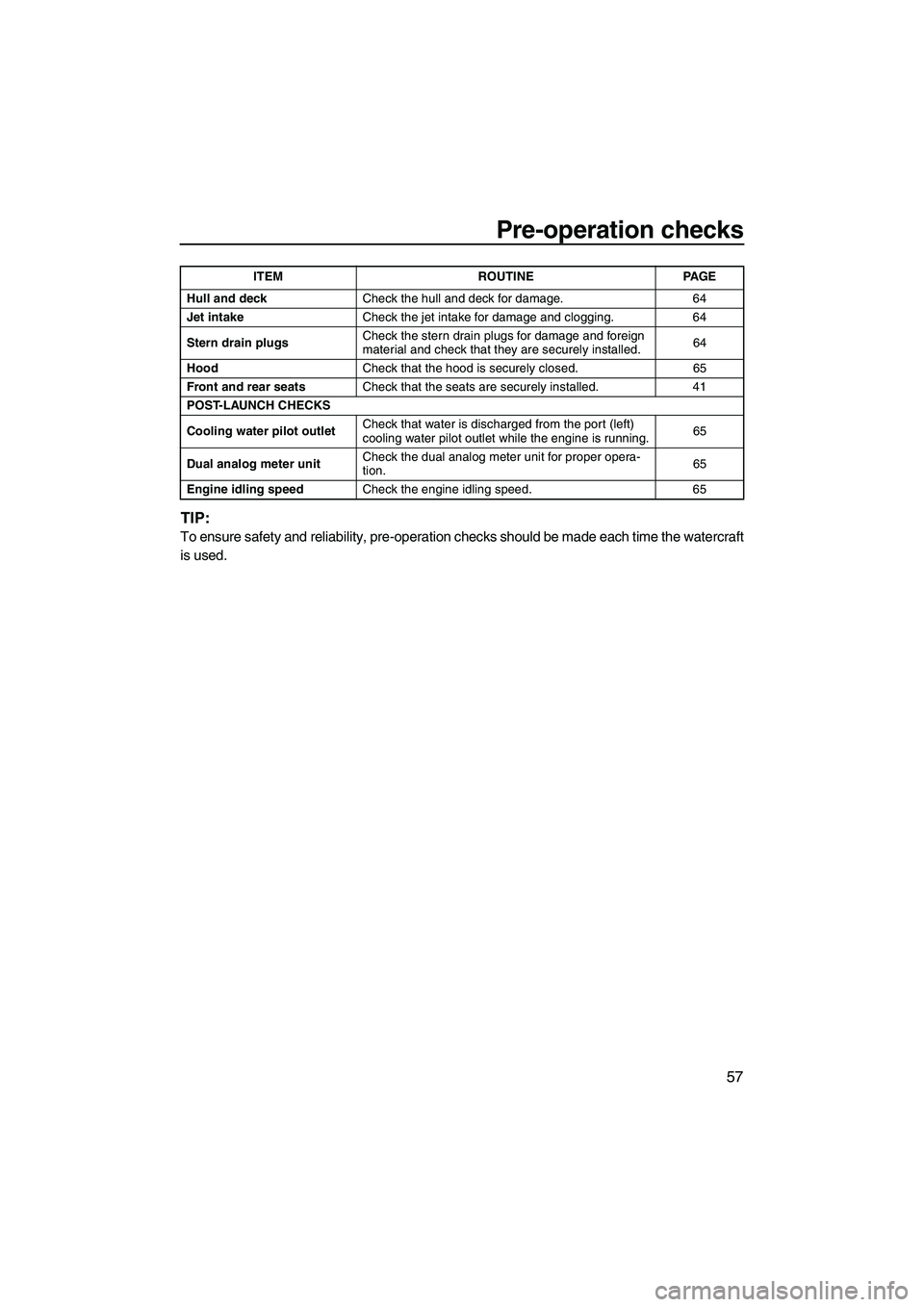

TIP:

To ensure safety and reliability, pre-operation checks should be made each time the watercraft

is used.

Hull and deck Check the hull and deck for damage. 64

Jet intake Check the jet intake for damage and clogging. 64

Stern drain plugs Check the stern drain plugs for damage and foreign

material and check that they are securely installed.

64

Hood Check that the hood is securely closed. 65

Front and rear seats Check that the seats are securely installed. 41

POST-LAUNCH CHECKS

Cooling water pilot outlet Check that water is discharged from the port (left)

cooling water pilot outlet while the engine is running.

65

Dual analog meter unit Check the dual analog meter unit for proper opera-

tion.

65

Engine idling speed Check the engine idling speed. 65

ITEM ROUTINE PAGE

UF2C74E0.book Page 57 Friday, August 3, 2012 2:34 PM