ABS YAMAHA GRIZZLY 125 2013 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2013, Model line: GRIZZLY 125, Model: YAMAHA GRIZZLY 125 2013Pages: 134, PDF Size: 3.93 MB

Page 77 of 134

8-6

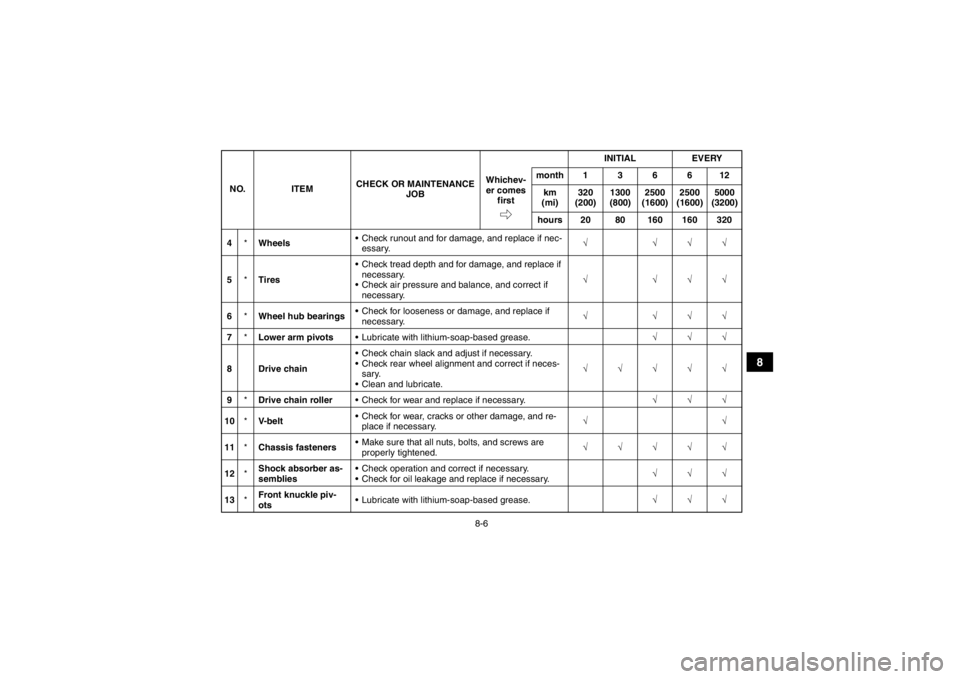

8

4*Wheels Check runout and for damage, and replace if nec-

essary. √ √√√

5 *Tires Check tread depth and for damage, and replace if

necessary.

Check air pressure and balance, and correct if necessary. √ √√√

6 *Wheel hub bearings Check for looseness or damage, and replace if

necessary. √ √√√

7 *Lower arm pivots Lubricate with lithium-soap-based grease. √√√

8 Drive chain Check chain slack and adjust if necessary.

Check rear wheel alignment and correct if neces-

sary.

Clean and lubricate. √√√√√

9 *Drive chain roller Check for wear and replace if necessary. √√√

10 *V- b e l t Check for wear, cracks or other damage, and re-

place if necessary. √√

11 *Chassis fasteners Make sure that all nuts, bolts, and screws are

properly tightened. √√√√√

12 *Shock absorber as-

semblies Check operation and correct if necessary.

Check for oil leakage and replace if necessary.

√√√

13 *Front knuckle piv-

ots Lubricate with lithium-soap-based grease.

√√√

NO. ITEM

CHECK OR MAINTENANCE

JOB INITIAL EVERY

Whichev- er comes first month136612

km

(mi) 320

(200) 1300

(800) 2500

(1600) 2500

(1600) 5000

(3200)

hours 20 80 160 160 320

U1PY61E0.book Page 6 Wednesday, March 14, 2012 5:22 PM

Page 123 of 134

9-1

9

EBU25860

CLEANING AND STORAGE

EBU25902Cleaning Frequent, thorough cleaning of your ATV will not

only enhance its appearance but will improve its

general performance and extend the useful life of

many components.1. Before cleaning the ATV: a. Block off the end of the exhaust pipe toprevent water entry. A plastic bag and

strong rubber band may be used.

b. Make sure the spark plug and all filler caps are properly installed.

2. If the engine case is excessively greasy, apply degreaser with a paint brush. Do not apply de-

greaser to the chain, sprockets or wheel ax-

les.

3. Rinse the dirt and degreaser off with a garden hose. Use only enough pressure to do the job.

WARNING! Wet brakes may have reduced stopping ability, increasing the chance of

an accident. Test the brakes after washing.

Apply the brakes several times at slow

speeds to let friction dry out the linings.

[EWB02311]

NOTICE: Excessive water pressure may cause water seepage and deteriora-

tion of wheel bearings, brakes, transmis-

sion seals and electrical devices. Many

expensive repair bills have resulted from

improper high-pressure detergent applica-

tions such as those available in coin-oper-

ated car washers.

[ECB00711]

4. Once most of the dirt has been hosed off,

wash all surfaces with warm water and mild,

detergent-type soap. An old toothbrush or bot-

tle brush is handy for hard-to-reach places.

5. Rinse the ATV off immediately with clean wa- ter and dry all surfaces with a chamois, clean

towel or soft absorbing cloth.

6. Dry the chain and lubricate it to prevent it from rusting.

7. Clean the seat with a vinyl upholstery cleaner to keep the cover pliable and glossy.

8. Automotive type wax may be applied to all painted and chrome plated surfaces. Avoid

combination cleaner-waxes. Many contain

abrasives which may mar the paint or protec-

tive finish. When finished cleaning, start the

engine and let it idle for several minutes.

U1PY61E0.book Page 1 Wednesday, March 14, 2012 5:22 PM

Page 129 of 134

10-4

10

Spring/shock absorber type:Coil spring/oil damper

Wheel travel: 70 mm (2.8 in)Rear suspension:Type:Swingarm

Spring/shock absorber type: Coil spring/oil damper

Wheel travel:

80 mm (3.1 in)Electrical system:Ignition system:DC CDI

Charging system:

AC magnetoBattery:Model:12N12C-4A-2

Voltage, capacity:

12 V, 12.0 AhHeadlight:Bulb type:Krypton bulbBulb voltage, wattage × quantity:Headlight:

12 V, 30.0/30.0 W × 2

Tail/brake light: 12 V, 5.0/21.0 W × 1

Neutral indicator light:

12 V, 1.7 W × 1 Reverse indicator light:

12 V, 1.7 W × 1

Fuses:Main fuse:

15.0 AEBU30401For Europe only

The figures quoted are emission levels and are not

necessarily safe working levels. Whilst there is a

correlation between the emission and exposure

levels, this cannot be used reliably to determine

whether or not further precautions are required.

Factors that influence the actual level of exposure

of work-force include the characteristics of the

work room, the other sources of noise, etc. i.e. the

number of machines and other adjacent process-

es, and the length of time for which an operator is

exposed to the noise. Also the permissible expo-

sure level can vary from country. This information,

however, will enable the user of the machine to

make a better evaluation of the hazard and risk.

U1PY61E0.book Page 4 Wednesday, March 14, 2012 5:22 PM