ignition YAMAHA GRIZZLY 450 2015 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2015, Model line: GRIZZLY 450, Model: YAMAHA GRIZZLY 450 2015Pages: 170, PDF Size: 3.93 MB

Page 37 of 170

4-7

4

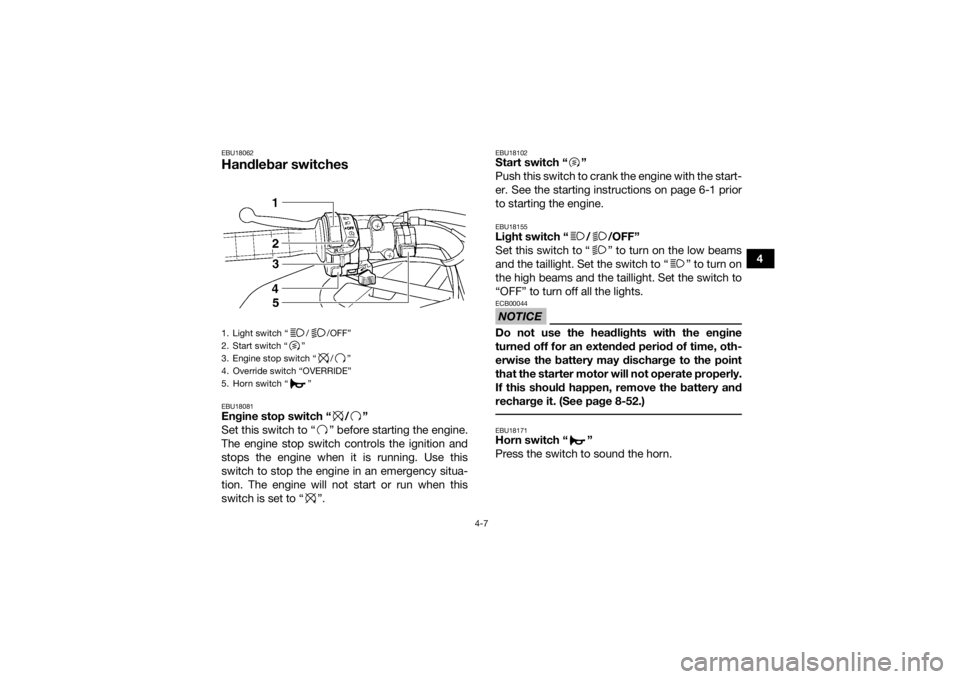

EBU18062Handlebar switchesEBU18081Engine stop switch “ / ”

Set this switch to “ ” before starting the engine.

The engine stop switch controls the ignition and

stops the engine when it is running. Use this

switch to stop the engine in an emergency situa-

tion. The engine will not start or run when this

switch is set to “ ”.

EBU18102Start switch “ ”

Push this switch to crank the engine with the start-

er. See the starting instructions on page 6-1 prior

to starting the engine.EBU18155Light switch “ / /OFF”

Set this switch to “ ” to turn on the low beams

and the taillight. Set the switch to “ ” to turn on

the high beams and the taillight. Set the switch to

“OFF” to turn off all the lights.NOTICEECB00044Do not use the headlights with the engine

turned off for an extended period of time, oth-

erwise the battery may discharge to the point

that the starter motor will not operate properly.

If this should happen, remove the battery and

recharge it. (See page 8-52.) EBU18171Horn switch “ ”

Press the switch to sound the horn.

1. Light switch “ / /OFF”

2. Start switch “ ”

3. Engine stop switch “ / ”

4. Override switch “OVERRIDE”

5. Horn switch “ ”U2LC61E0.book Page 7 Wednesday, February 26, 2014 3:56 PM

Page 46 of 170

4-16

4of sparks, open flames, or other sources of

ignition such as the pilot lights of water heat-

ers and clothes dryers.

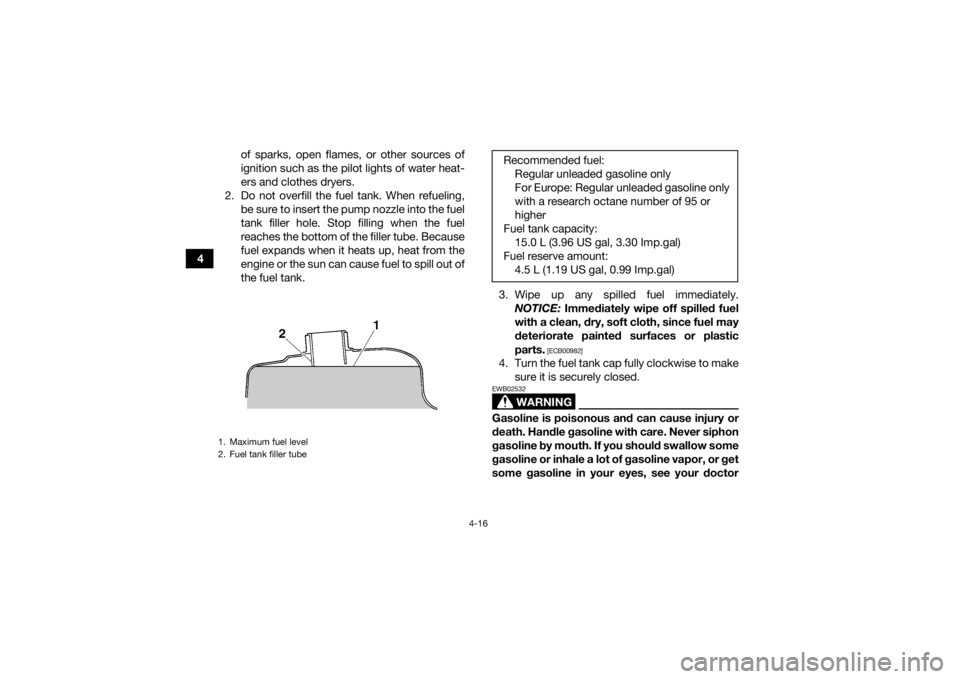

2. Do not overfill the fuel tank. When refueling, be sure to insert the pump nozzle into the fuel

tank filler hole. Stop filling when the fuel

reaches the bottom of the filler tube. Because

fuel expands when it heats up, heat from the

engine or the sun can cause fuel to spill out of

the fuel tank.

3. Wipe up any spilled fuel immediately.NOTICE: Immediately wipe off spilled fuel

with a clean, dry, soft cloth, since fuel may

deteriorate painted surfaces or plastic

parts.

[ECB00982]

4. Turn the fuel tank cap fully clockwise to make sure it is securely closed.

WARNING

EWB02532Gasoline is poisonous and can cause injury or

death. Handle gasoline with care. Never siphon

gasoline by mouth. If you should swallow some

gasoline or inhale a lot of gasoline vapor, or get

some gasoline in your eyes, see your doctor

1. Maximum fuel level

2. Fuel tank filler tube

Recommended fuel:Regular unleaded gasoline only

For Europe: Regular unleaded gasoline only

with a research octane number of 95 or

higher

Fuel tank capacity: 15.0 L (3.96 US gal, 3.30 Imp.gal)

Fuel reserve amount: 4.5 L (1.19 US gal, 0.99 Imp.gal)

U2LC61E0.book Page 16 Wednesday, February 26, 2014 3:56 PM

Page 144 of 170

8-52

8

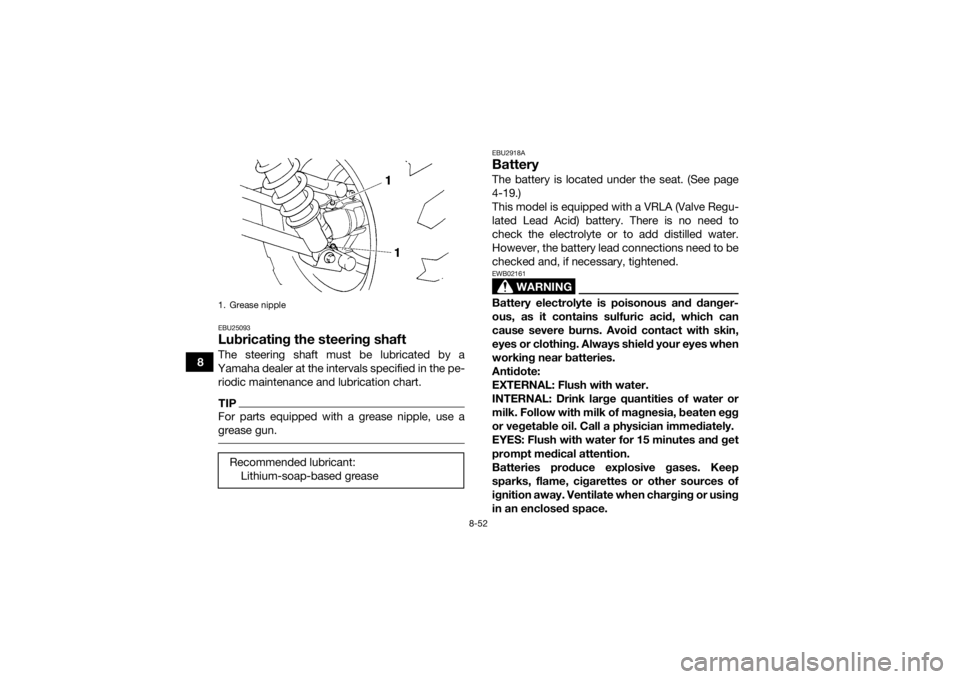

EBU25093Lubricating the steering shaftThe steering shaft must be lubricated by a

Yamaha dealer at the intervals specified in the pe- riodic maintenance and lubrication chart.TIPFor parts equipped with a grease nipple, use a

grease gun.

EBU2918ABatteryThe battery is located under the seat. (See page

4-19.)

This model is equipped with a VRLA (Valve Regu-

lated Lead Acid) battery. There is no need to

check the electrolyte or to add distilled water.

However, the battery lead connections need to be

checked and, if necessary, tightened.

WARNING

EWB02161Battery electrolyte is poisonous and danger-

ous, as it contains sulfuric acid, which can

cause severe burns. Avoid contact with skin,

eyes or clothing. Always shield your eyes when

working near batteries.

Antidote:

EXTERNAL: Flush with water.

INTERNAL: Drink large quantities of water or

milk. Follow with milk of magnesia, beaten egg

or vegetable oil. Call a physician immediately.

EYES: Flush with water for 15 minutes and get

prompt medical attention.

Batteries produce explosive gases. Keep

sparks, flame, cigarettes or other sources of

ignition away. Ventilate when charging or using

in an enclosed space.

1. Grease nippleRecommended lubricant: Lithium-soap-based grease

U2LC61E0.book Page 52 Wednesday, February 26, 2014 3:56 PM

Page 147 of 170

8-55

8

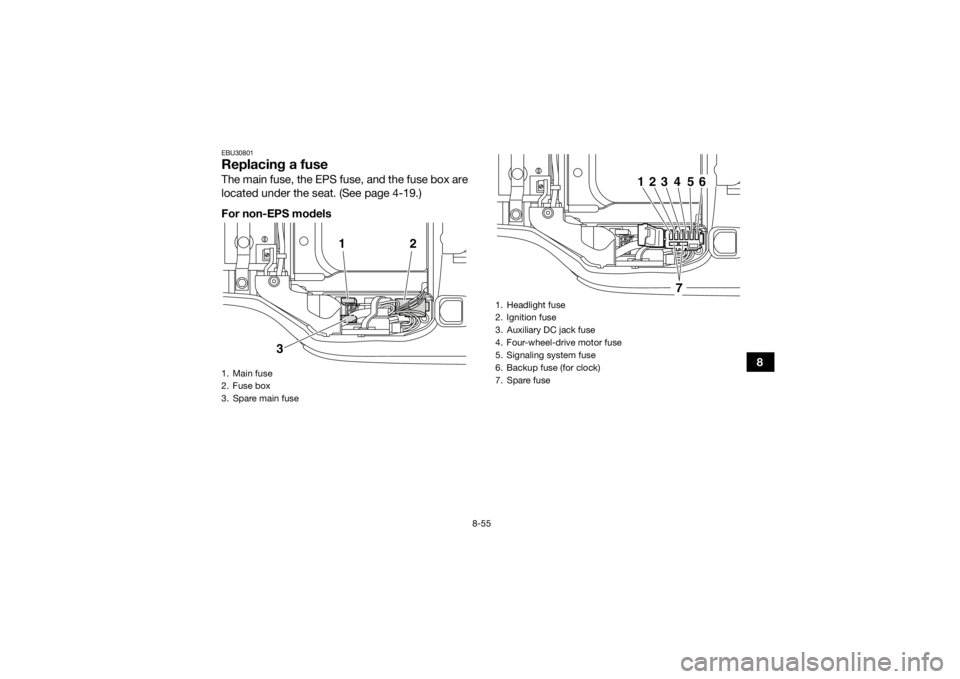

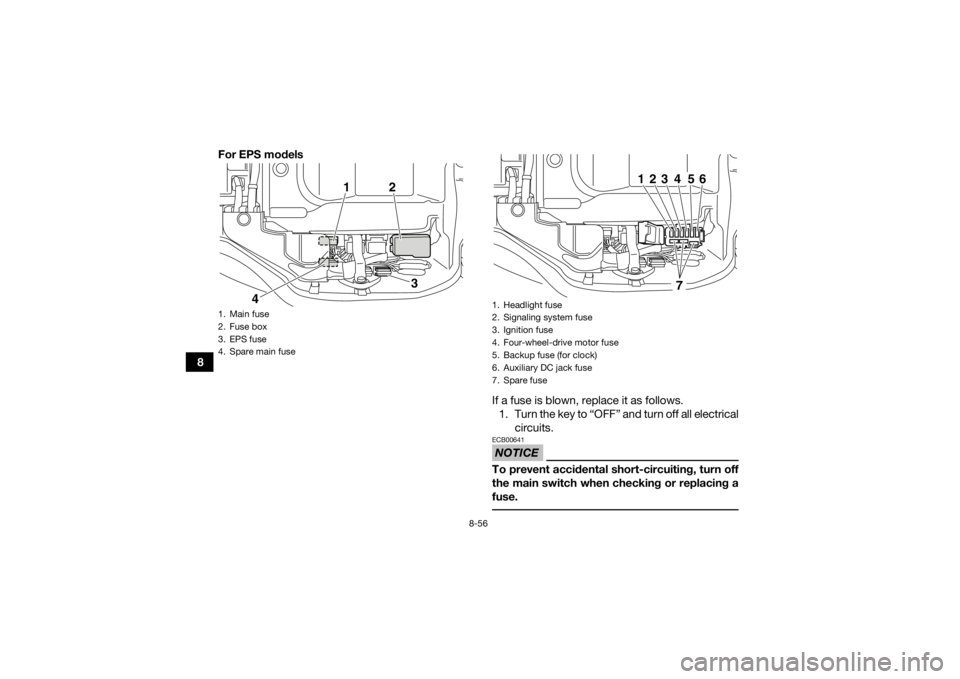

EBU30801Replacing a fuseThe main fuse, the EPS fuse, and the fuse box are

located under the seat. (See page 4-19.)

For non-EPS models1. Main fuse

2. Fuse box

3. Spare main fuse

1

2

3

1. Headlight fuse

2. Ignition fuse

3. Auxiliary DC jack fuse

4. Four-wheel-drive motor fuse

5. Signaling system fuse

6. Backup fuse (for clock)

7. Spare fuse

1

2

3

4

5

6

7

U2LC61E0.book Page 55 Wednesday, February 26, 2014 3:56 PM

Page 148 of 170

8-56

8For EPS models

If a fuse is blown, replace it as follows.1. Turn the key to “OFF” and turn off all electrical circuits.

NOTICEECB00641To prevent accidental short-circuiting, turn off

the main switch when checking or replacing a

fuse.

1. Main fuse

2. Fuse box

3. EPS fuse

4. Spare main fuse

12

3

4

1. Headlight fuse

2. Signaling system fuse

3. Ignition fuse

4. Four-wheel-drive motor fuse

5. Backup fuse (for clock)

6. Auxiliary DC jack fuse

7. Spare fuse

1

2

3

4

5

6

7

U2LC61E0.book Page 56 Wednesday, February 26, 2014 3:56 PM

Page 149 of 170

8-57

8

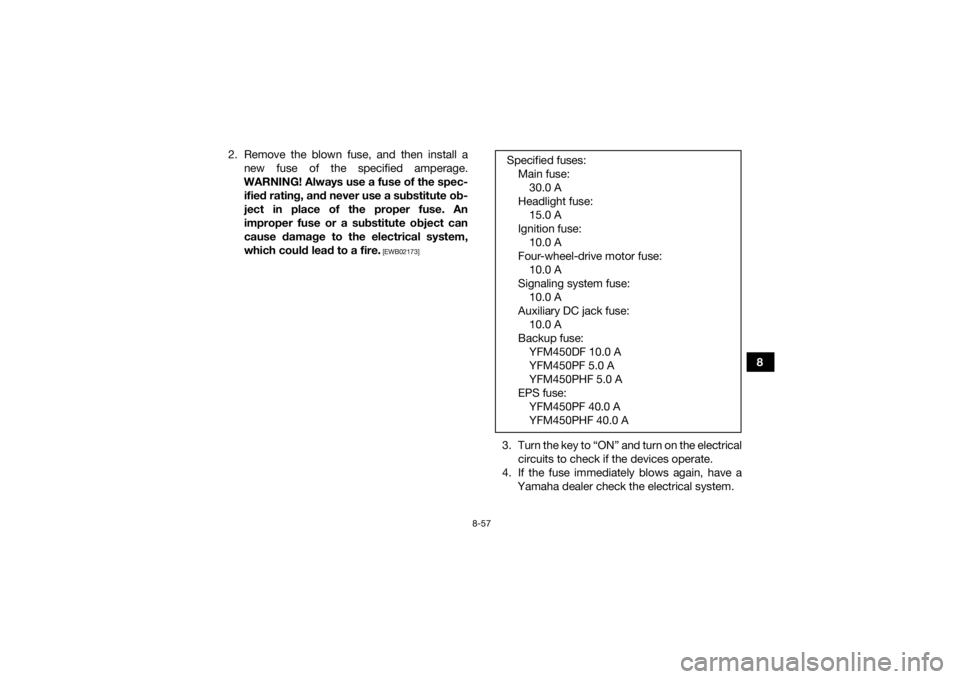

2. Remove the blown fuse, and then install a

new fuse of the specified amperage.

WARNING! Always use a fuse of the spec- ified rating, and never use a substitute ob-

ject in place of the proper fuse. An

improper fuse or a substitute object can

cause damage to the electrical system,

which could lead to a fire.

[EWB02173]

3. Turn the key to “ON” and turn on the electrical circuits to check if the devices operate.

4. If the fuse immediately blows again, have a Yamaha dealer check the electrical system.

Specified fuses:

Main fuse:30.0 A

Headlight fuse: 15.0 A

Ignition fuse: 10.0 A

Four-wheel-drive motor fuse: 10.0 A

Signaling system fuse: 10.0 A

Auxiliary DC jack fuse: 10.0 A

Backup fuse: YFM450DF 10.0 A

YFM450PF 5.0 A

YFM450PHF 5.0 A

EPS fuse: YFM450PF 40.0 A

YFM450PHF 40.0 A

U2LC61E0.book Page 57 Wednesday, February 26, 2014 3:56 PM

Page 155 of 170

8-63

8

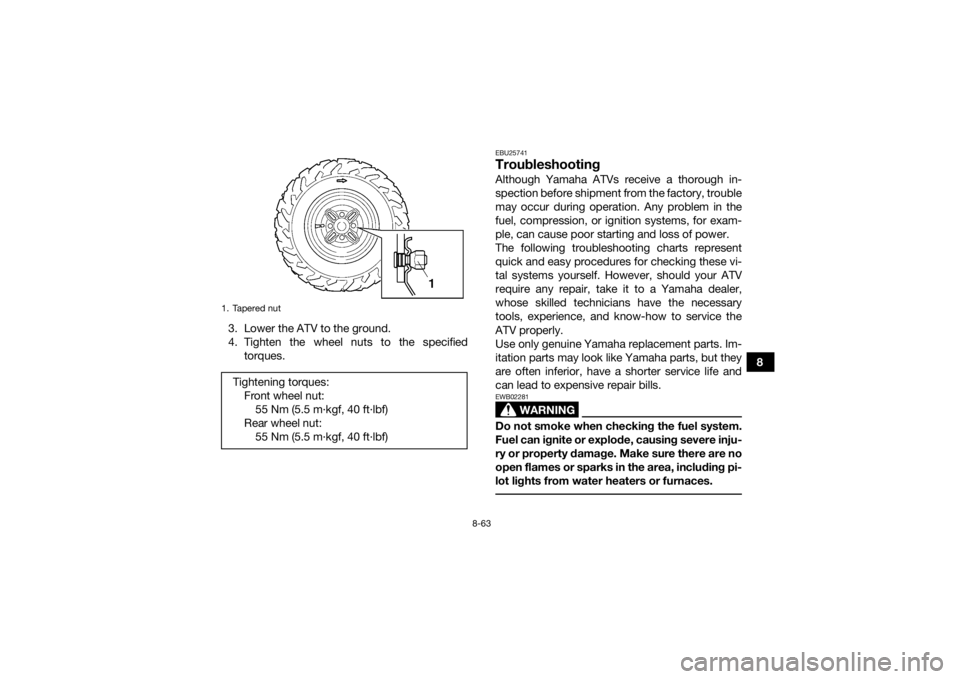

3. Lower the ATV to the ground.

4. Tighten the wheel nuts to the specified

torques.

EBU25741TroubleshootingAlthough Yamaha ATVs receive a thorough in-

spection before shipment from the factory, trouble

may occur during operation. Any problem in the

fuel, compression, or ignition systems, for exam-

ple, can cause poor starting and loss of power.

The following troubleshooting charts represent

quick and easy procedures for checking these vi-

tal systems yourself. However, should your ATV

require any repair, take it to a Yamaha dealer,

whose skilled technicians have the necessary

tools, experience, and know-how to service the

ATV properly.

Use only genuine Yamaha replacement parts. Im-

itation parts may look like Yamaha parts, but they

are often inferior, have a shorter service life and

can lead to expensive repair bills.

WARNING

EWB02281Do not smoke when checking the fuel system.

Fuel can ignite or explode, causing severe inju-

ry or property damage. Make sure there are no

open flames or sparks in the area, including pi-

lot lights from water heaters or furnaces.

1. Tapered nutTightening torques:Front wheel nut:55 Nm (5.5 m·kgf, 40 ft·lbf)

Rear wheel nut: 55 Nm (5.5 m·kgf, 40 ft·lbf)

U2LC61E0.book Page 63 Wednesday, February 26, 2014 3:56 PM

Page 156 of 170

8-64

8

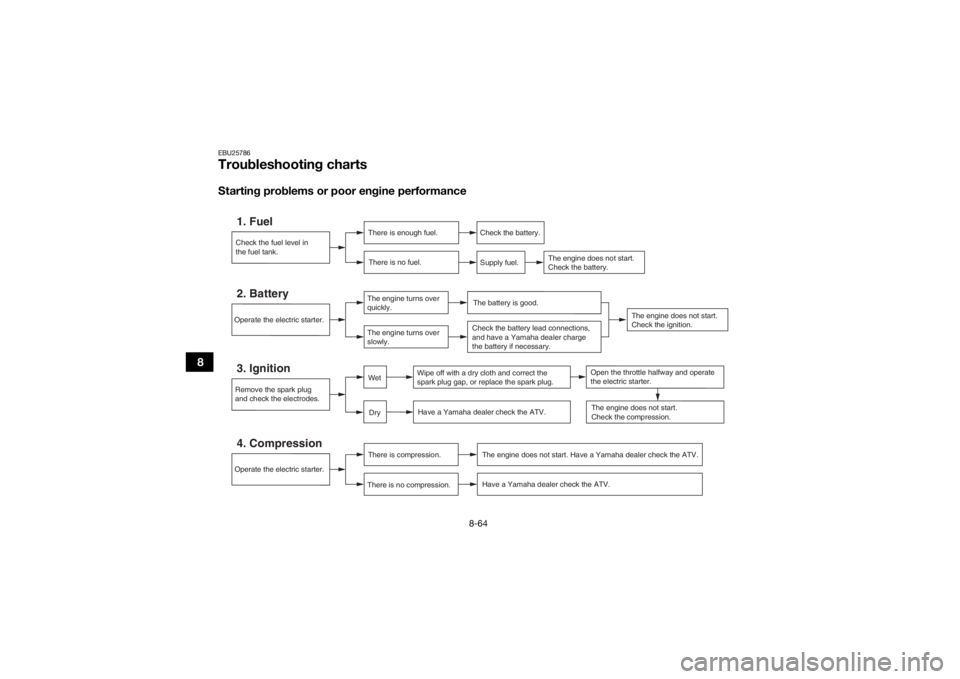

EBU25786Troubleshooting chartsStarting problems or poor engine performance

Check the fuel level in

the fuel tank.1. Fuel

There is enough fuel.There is no fuel.

Check the battery.

Supply fuel.

The engine does not start.

Check the battery.

The engine does not start.

Check the ignition.

Operate the electric starter.4. Compression

There is compression.

There is no compression.

The engine does not start. Have a Yamaha dealer check the ATV.Have a Yamaha dealer check the ATV.

Remove the spark plug

and check the electrodes.3. Ignition

Wipe off with a dry cloth and correct the

spark plug gap, or replace the spark plug. Have a Yamaha dealer check the ATV.

The engine does not start.

Check the compression.

Operate the electric starter.2. Battery

The engine turns over

quickly.

The engine turns over

slowly.

The battery is good.Check the battery lead connections,

and have a Yamaha dealer charge

the battery if necessary.

DryWet

Open the throttle halfway and operate

the electric starter.

U2LC61E0.book Page 64 Wednesday, February 26, 2014 3:56 PM

Page 164 of 170

10-4

10

Rear:22.0 kPa (0.220 kgf/cm², 3.2 psi)

Front wheel:Wheel type:

Panel wheel

Rim size: 12 x 6.0ATRear wheel:Wheel type:

Panel wheel

Rim size: 12 x 7.5ATFront brake:Type:

Disc brake

Operation: Right hand operation

Specified brake fluid: DOT 4Rear brake:Type:Wet multiple disc brake

Operation: Left hand and right foot operationFront suspension:Type:Double wishbone

Spring/shock absorber type: Coil spring/oil damper

Wheel travel:

160 mm (6.3 in)

Rear suspension:Type:Double wishbone

Spring/shock absorber type:

Coil spring/oil damper

Wheel travel: 180 mm (7.1 in)Electrical system:Ignition system:

DC CDI

Charging system: AC magnetoBattery:Model:

YTX20L-BS

Voltage, capacity: 12 V, 18.0 AhHeadlight:Bulb type:

Krypton bulbBulb voltage, wattage × quantity:Headlight:

12 V, 30.0/30.0 W × 2

Tail/brake light:

12 V, 5.0/21.0 W × 1

Meter lighting: EL (Electroluminescent)

Neutral indicator light: LED

Reverse indicator light:

LED

U2LC61E0.book Page 4 Wednesday, February 26, 2014 3:56 PM

Page 165 of 170

10-5

10

Coolant temperature warning light:LED

Park indicator light: LED

On-Command four-wheel-drive/differential gear lock

indicator: LCD

High-range indicator light:

LED

Low-range indicator light: LED

Differential gear lock indicator light: LED

EPS warning light:

YFM450PF 12 V, 1.7 W

YFM450PHF 12 V, 1.7 WFuses:Main fuse:30.0 A

EPS fuse: YFM450PF 40.0 A

YFM450PHF 40.0 A

Headlight fuse: 15.0 A

Signaling system fuse:

10.0 A

Ignition fuse: 10.0 A

Auxiliary DC jack fuse: 10.0 A Backup fuse:

YFM450DF 10.0 A

YFM450PF 5.0 A

YFM450PHF 5.0 A

Four-wheel-drive motor fuse:

10.0 A

EBU30402For Europe only

The figures quoted are emission levels and are not

necessarily safe working levels. Whilst there is a

correlation between the emission and exposure

levels, this cannot be used reliably to determine

whether or not further precautions are required.

Factors that influence the actual level of exposure

of work-force include the characteristics of the

work room, the other sources of noise, etc. i.e. the

number of machines and other adjacent process-

es, and the length of time for which an operator is

exposed to the noise. Also the permissible expo-

sure level can vary from country. This information,

however, will enable the user of the machine to

make a better evaluation of the hazard and risk.

U2LC61E0.book Page 5 Wednesday, February 26, 2014 3:56 PM