torque YAMAHA GRIZZLY 550 2014 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: GRIZZLY 550, Model: YAMAHA GRIZZLY 550 2014Pages: 174, PDF Size: 4.2 MB

Page 122 of 174

8-30

85. Install the oil filler bolt and its gasket, and then

tighten the bolt to the specified torque.

To change the differential gear oil 1. Place the ATV on a level surface.

2. Place an oil pan under the differential gear case to collect the used oil.

3. Remove the differential gear oil filler bolt, the differential gear oil drain bolt and their gasket

to drain the oil from the differential gear case. 4. Install the drain bolt and its new gasket, and

then tighten the bolt to the specified torque.

5. Refill with the recommended differential gear oil to the brim of the filler hole as shown.

NOTICE: Be sure no foreign material en-

ters the differential gear case.

[ECB00411]

Tightening torque: Differential gear oil filler bolt:23 Nm (2.3 m·kgf, 17 ft·lbf)

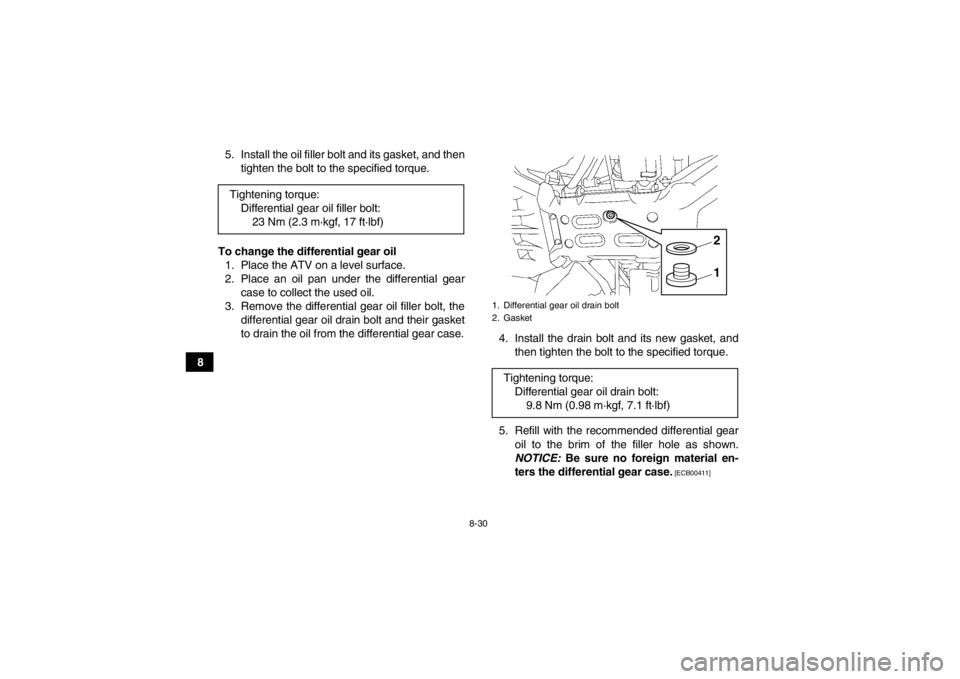

1. Differential gear oil drain bolt

2. GasketTightening torque:Differential gear oil drain bolt:9.8 Nm (0.98 m·kgf, 7.1 ft·lbf)

12

U2LB60E0.book Page 30 Thursday, March 21, 2013 10:20 AM

Page 123 of 174

8-31

8

6. Check the oil filler bolt gasket for damage, and replace it if necessary.

7. Install the oil filler bolt and its gasket, and then tighten the bolt to the specified torque. 8. Check the differential gear case for oil leak-

age. If oil is leaking, check for the cause.

EBU23470Coolant The coolant level should be checked before each

ride. In addition, the coolant must be changed at

the intervals specified in the periodic maintenance

and lubrication chart.EBU27126To check the coolant level1. Place the ATV on a level surface.TIPThe coolant level must be checked on a cold en-

gine since the level varies with engine tempera-

ture.2. Check the coolant level in the coolant reser- voir.TIPThe coolant should be between the minimum and

maximum level marks.

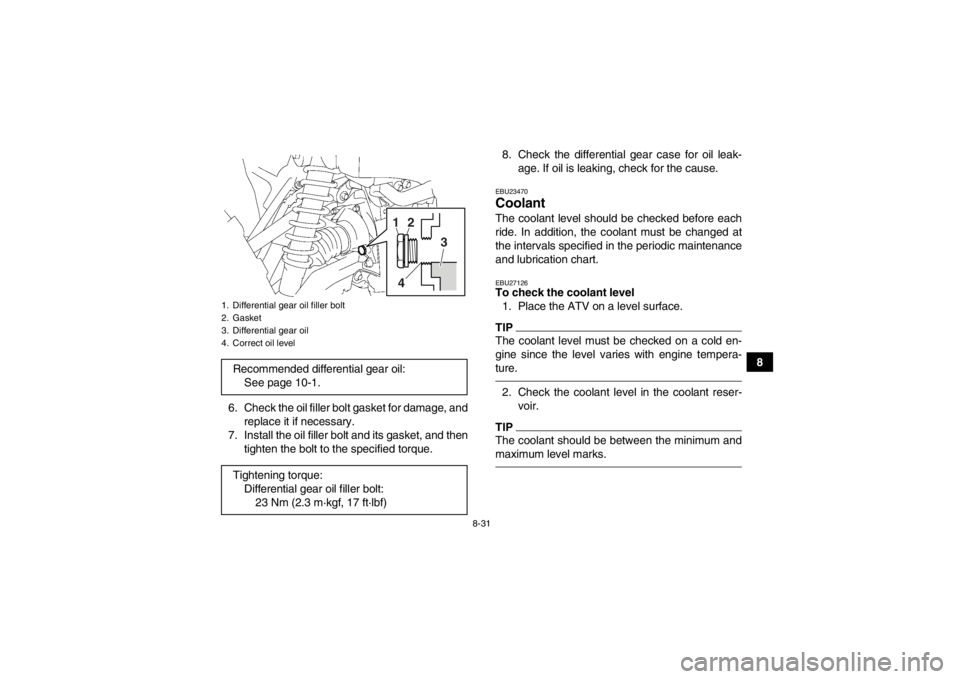

1. Differential gear oil filler bolt

2. Gasket

3. Differential gear oil

4. Correct oil levelRecommended differential gear oil:See page 10-1.

Tightening torque: Differential gear oil filler bolt:23 Nm (2.3 m·kgf, 17 ft·lbf)

1

2

3

4

U2LB60E0.book Page 31 Thursday, March 21, 2013 10:20 AM

Page 127 of 174

8-35

8

9. After draining the coolant, thoroughly flush the

cooling system with clean tap water.

10. Install the coolant drain bolt and its new gas- ket, and then tighten the bolt to the specified

torque.

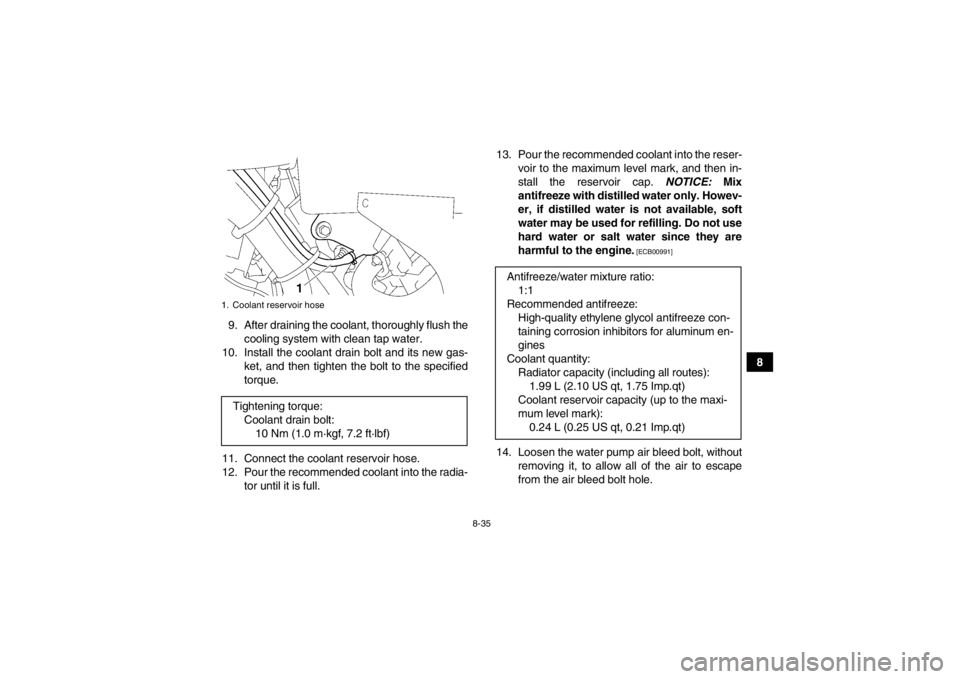

11. Connect the coolant reservoir hose.

12. Pour the recommended coolant into the radia- tor until it is full. 13. Pour the recommended coolant into the reser-

voir to the maximum level mark, and then in-

stall the reservoir cap. NOTICE: Mix

antifreeze with distilled water only. Howev-

er, if distilled water is not available, soft

water may be used for refilling. Do not use

hard water or salt water since they are

harmful to the engine.

[ECB00991]

14. Loosen the water pump air bleed bolt, without removing it, to allow all of the air to escape

from the air bleed bolt hole.

1. Coolant reservoir hoseTightening torque:Coolant drain bolt:10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Antifreeze/water mixture ratio: 1:1

Recommended antifreeze: High-quality ethylene glycol antifreeze con-

taining corrosion inhibitors for aluminum en-

gines

Coolant quantity: Radiator capacity (including all routes):1.99 L (2.10 US qt, 1.75 Imp.qt)

Coolant reservoir capacity (up to the maxi-

mum level mark): 0.24 L (0.25 US qt, 0.21 Imp.qt)

U2LB60E0.book Page 35 Thursday, March 21, 2013 10:20 AM

Page 128 of 174

8-36

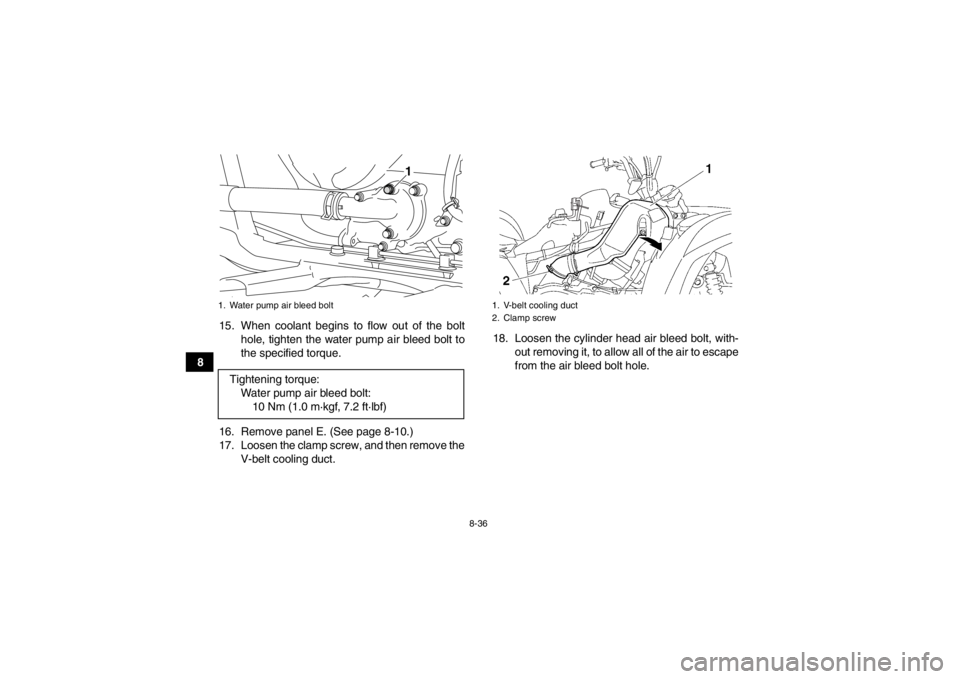

815. When coolant begins to flow out of the bolt

hole, tighten the water pump air bleed bolt to

the specified torque.

16. Remove panel E. (See page 8-10.)

17. Loosen the clamp screw, and then remove the V-belt cooling duct. 18. Loosen the cylinder head air bleed bolt, with-

out removing it, to allow all of the air to escape

from the air bleed bolt hole.

1. Water pump air bleed boltTightening torque:Water pump air bleed bolt:10 Nm (1.0 m·kgf, 7.2 ft·lbf)

1

1. V-belt cooling duct

2. Clamp screw

U2LB60E0.book Page 36 Thursday, March 21, 2013 10:20 AM

Page 129 of 174

8-37

8

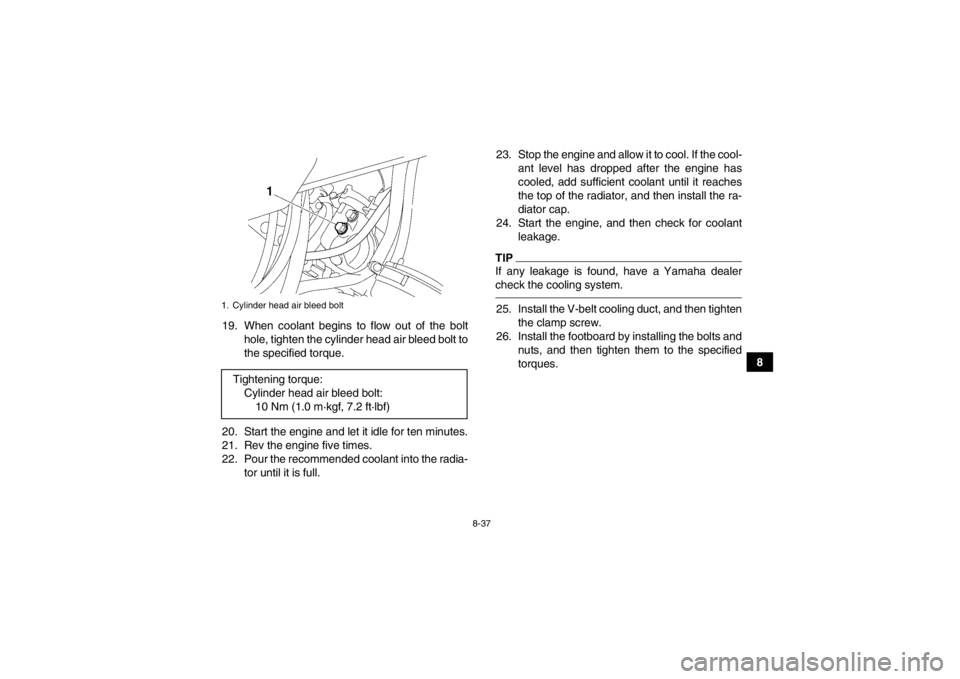

19. When coolant begins to flow out of the bolt

hole, tighten the cylinder head air bleed bolt to

the specified torque.

20. Start the engine and let it idle for ten minutes.

21. Rev the engine five times.

22. Pour the recommended coolant into the radia- tor until it is full. 23. Stop the engine and allow it to cool. If the cool-

ant level has dropped after the engine has

cooled, add sufficient coolant until it reaches

the top of the radiator, and then install the ra-

diator cap.

24. Start the engine, and then check for coolant leakage.

TIPIf any leakage is found, have a Yamaha dealer

check the cooling system.25. Install the V-belt cooling duct, and then tightenthe clamp screw.

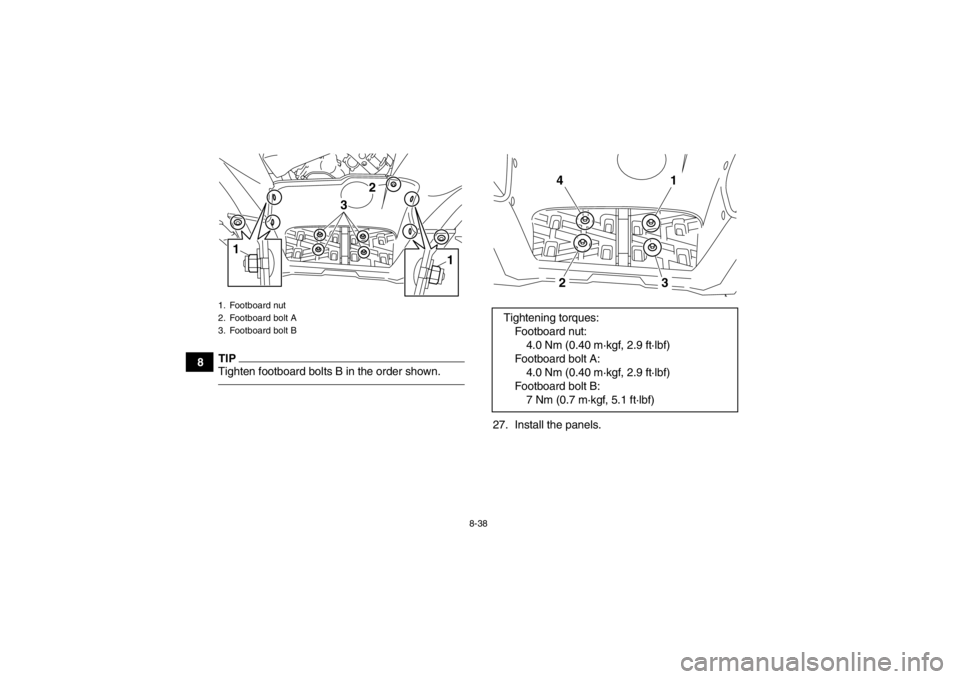

26. Install the footboard by installing the bolts and nuts, and then tighten them to the specified

torques.

1. Cylinder head air bleed boltTightening torque:Cylinder head air bleed bolt:10 Nm (1.0 m·kgf, 7.2 ft·lbf)

U2LB60E0.book Page 37 Thursday, March 21, 2013 10:20 AM

Page 130 of 174

8-38

8

TIPTighten footboard bolts B in the order shown.

27. Install the panels.

1. Footboard nut

2. Footboard bolt A

3. Footboard bolt B

3

1

2

1

Tightening torques:Footboard nut:4.0 Nm (0.40 m·kgf, 2.9 ft·lbf)

Footboard bolt A: 4.0 Nm (0.40 m·kgf, 2.9 ft·lbf)

Footboard bolt B: 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

4

1

2

3

U2LB60E0.book Page 38 Thursday, March 21, 2013 10:20 AM

Page 135 of 174

8-43

8

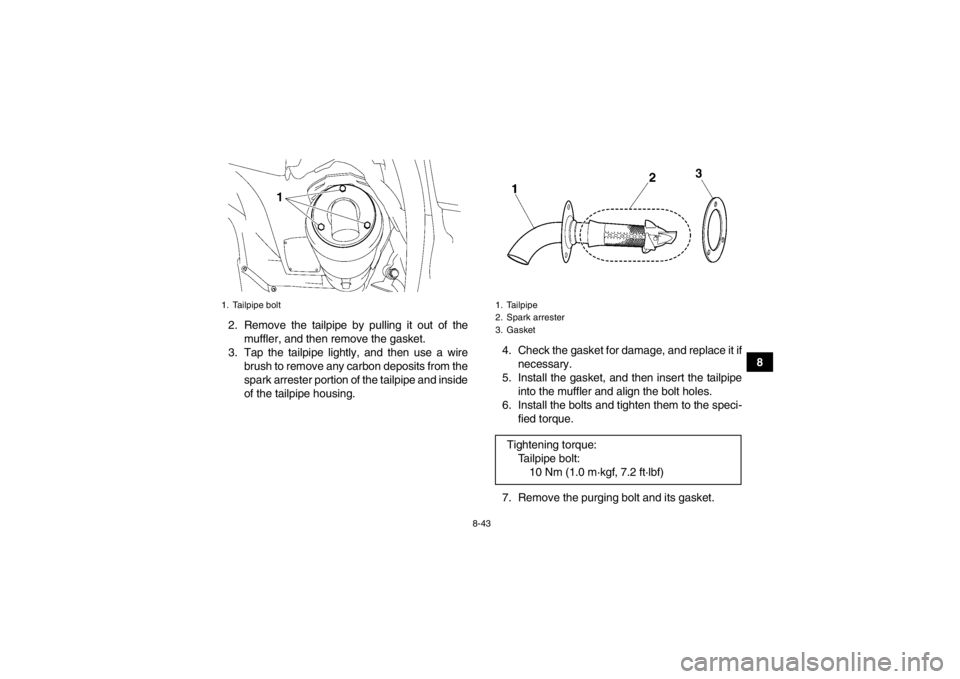

2. Remove the tailpipe by pulling it out of the

muffler, and then remove the gasket.

3. Tap the tailpipe lightly, and then use a wire brush to remove any carbon deposits from the

spark arrester portion of the tailpipe and inside

of the tailpipe housing. 4. Check the gasket for damage, and replace it if

necessary.

5. Install the gasket, and then insert the tailpipe into the muffler and align the bolt holes.

6. Install the bolts and tighten them to the speci- fied torque.

7. Remove the purging bolt and its gasket.

1. Tailpipe bolt

1. Tailpipe

2. Spark arrester

3. GasketTightening torque: Tailpipe bolt:10 Nm (1.0 m·kgf, 7.2 ft·lbf)

U2LB60E0.book Page 43 Thursday, March 21, 2013 10:20 AM

Page 136 of 174

8-44

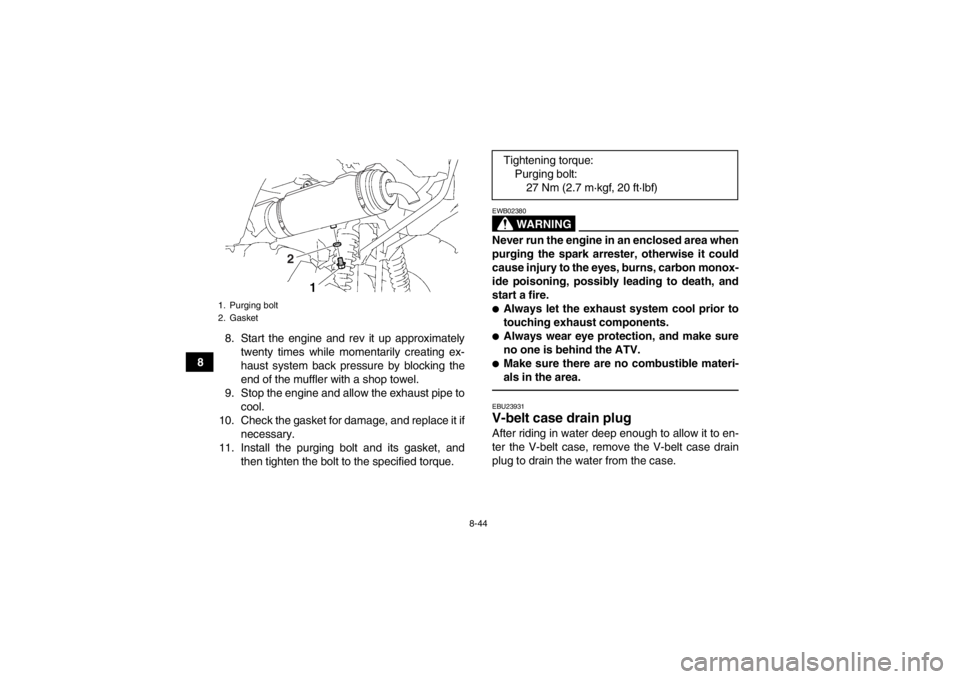

88. Start the engine and rev it up approximately

twenty times while momentarily creating ex-

haust system back pressure by blocking the

end of the muffler with a shop towel.

9. Stop the engine and allow the exhaust pipe to cool.

10. Check the gasket for damage, and replace it if necessary.

11. Install the purging bolt and its gasket, and then tighten the bolt to the specified torque.

WARNING

EWB02380Never run the engine in an enclosed area when

purging the spark arrester, otherwise it could

cause injury to the eyes, burns, carbon monox-

ide poisoning, possibly leading to death, and

start a fire.●Always let the exhaust system cool prior to

touching exhaust components.●Always wear eye protection, and make sure

no one is behind the ATV.●Make sure there are no combustible materi-

als in the area.EBU23931V-belt case drain plug After riding in water deep enough to allow it to en-

ter the V-belt case, remove the V-belt case drain

plug to drain the water from the case.

1. Purging bolt

2. Gasket

2

Tightening torque:Purging bolt:27 Nm (2.7 m·kgf, 20 ft·lbf)

U2LB60E0.book Page 44 Thursday, March 21, 2013 10:20 AM

Page 151 of 174

8-59

8

4. Install the front carrier by installing the bolts

and tightening them to the specified torques.

5. Install the panel.

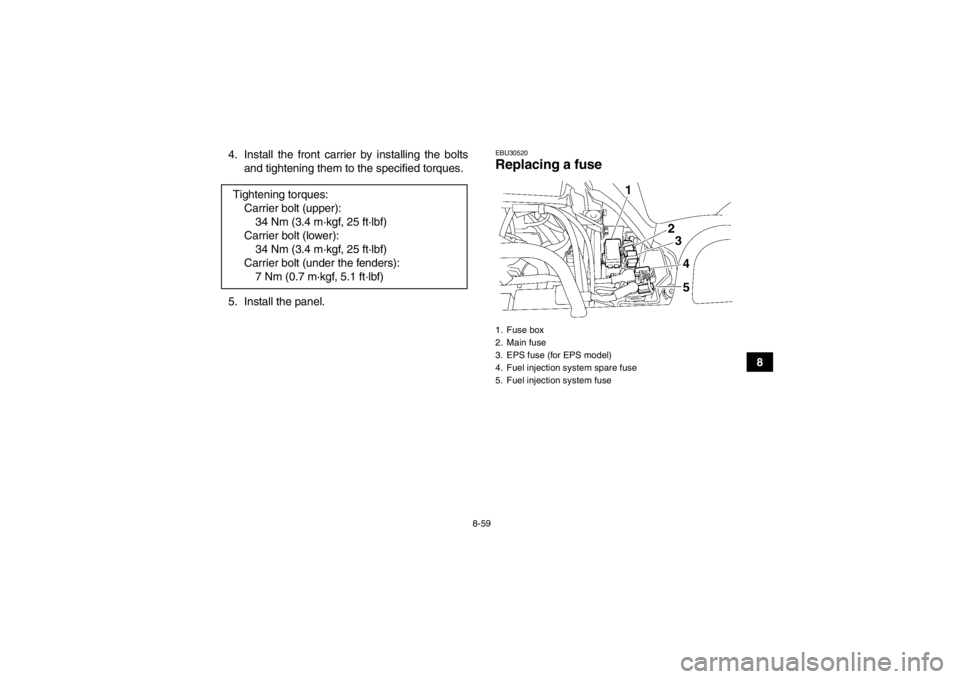

EBU30520Replacing a fuse

Tightening torques: Carrier bolt (upper):34 Nm (3.4 m·kgf, 25 ft·lbf)

Carrier bolt (lower): 34 Nm (3.4 m·kgf, 25 ft·lbf)

Carrier bolt (under the fenders): 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

1. Fuse box

2. Main fuse

3. EPS fuse (for EPS model)

4. Fuel injection system spare fuse

5. Fuel injection system fuse

U2LB60E0.book Page 59 Thursday, March 21, 2013 10:20 AM

Page 157 of 174

8-65

8

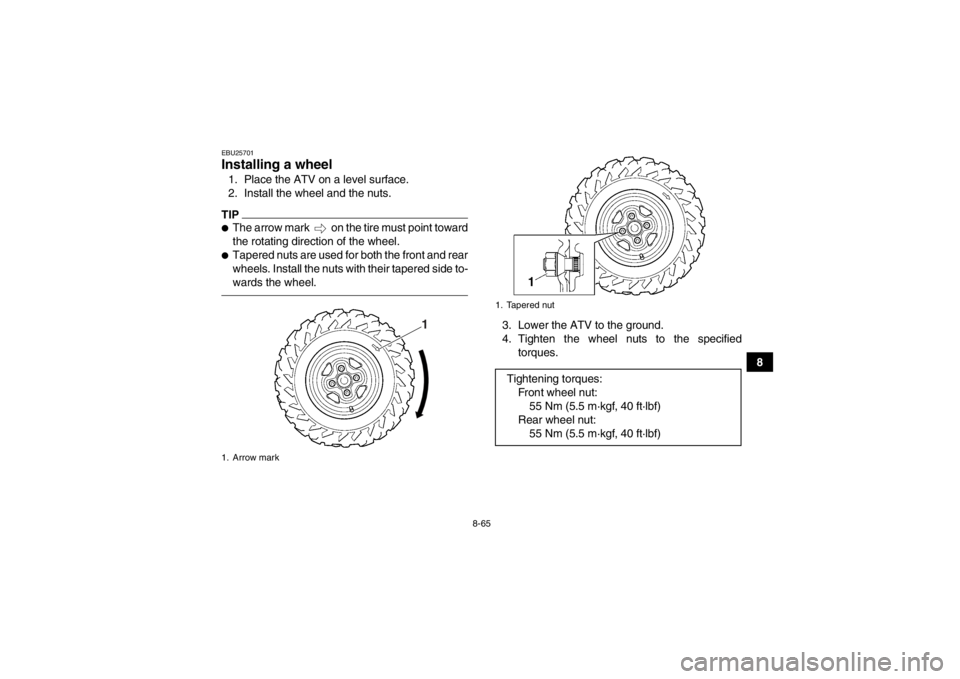

EBU25701Installing a wheel 1. Place the ATV on a level surface.

2. Install the wheel and the nuts.TIP●The arrow mark on the tire must point toward

the rotating direction of the wheel.●Tapered nuts are used for both the front and rear

wheels. Install the nuts with their tapered side to-

wards the wheel.

3. Lower the ATV to the ground.

4. Tighten the wheel nuts to the specifiedtorques.

1. Arrow mark

1

1. Tapered nutTightening torques:Front wheel nut:55 Nm (5.5 m·kgf, 40 ft·lbf)

Rear wheel nut: 55 Nm (5.5 m·kgf, 40 ft·lbf)

U2LB60E0.book Page 65 Thursday, March 21, 2013 10:20 AM