engine coolant YAMAHA GRIZZLY 700 2016 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: GRIZZLY 700, Model: YAMAHA GRIZZLY 700 2016Pages: 176, PDF Size: 4.47 MB

Page 128 of 176

8-31

83. If the coolant is at or below the minimum level

mark, remove panels A and C to access the

coolant reservoir. (See page 8-10.)

4. Remove the coolant reservoir cap, add cool- ant or distilled water to the maximum level

mark, install the reservoir cap, and then install

the panels. NOTICE: If coolant is not avail-

able, use distilled water or soft tap water

instead. Do not use hard water or salt wa-

ter since they are harmful to the engine. If

water has been used instead of coolant,

replace it with coolant as soon as possible,

otherwise the cooling system will not be

protected against frost and corrosion. If

water has been added to the coolant, have

a Yamaha dealer check the antifreeze con-

tent of the coolant as soon as possible,

otherwise the effectiveness of the coolant

will be reduced.

[ECB01012]

TIP The radiator fan is automatically switched on or

off according to the coolant temperature in the

radiator.

If the engine overheats, see page 8-66 for fur-

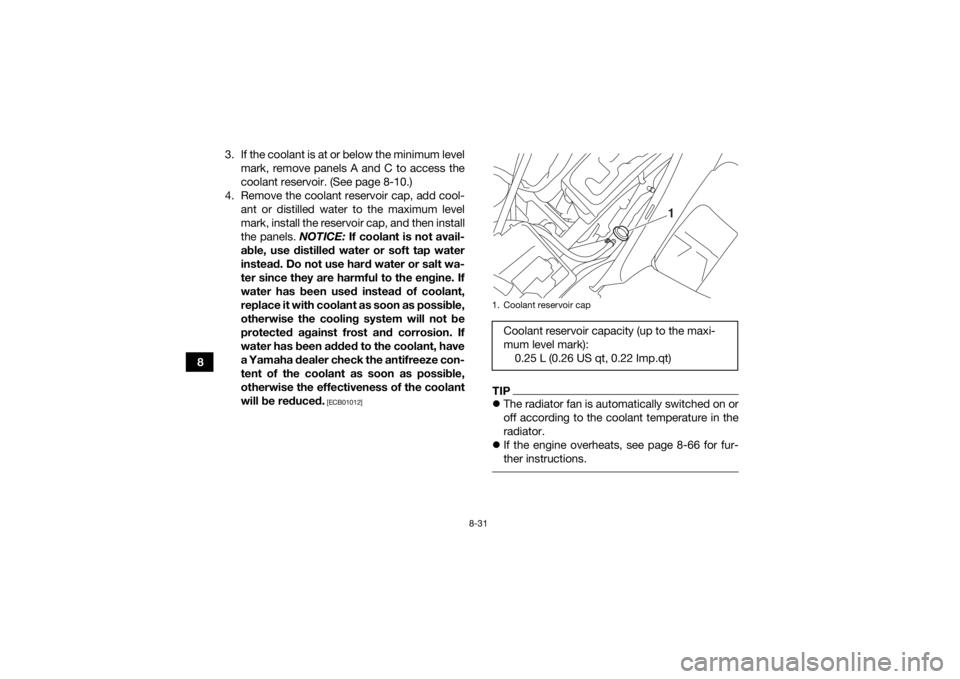

ther instructions. 1. Coolant reservoir capCoolant reservoir capacity (up to the maxi-

mum level mark):

0.25 L (0.26 US qt, 0.22 Imp.qt)

1

U2UD60E0.book Page 31 Tuesday, April 28, 2015 11:55 AM

Page 129 of 176

8-32

8

EBU34211To change the coolant

WARNING

EWB01891Wait for the engine and radiator to cool before

removing the radiator cap. You could be

burned by hot fluid and steam blown out under

pressure. Always place a thick rag over the cap

when opening. Allow any remaining pressure

to escape before completely removing the cap. 1. Park the ATV on a level surface.

2. Remove panels A, B, C, and D. (See page8-10.)

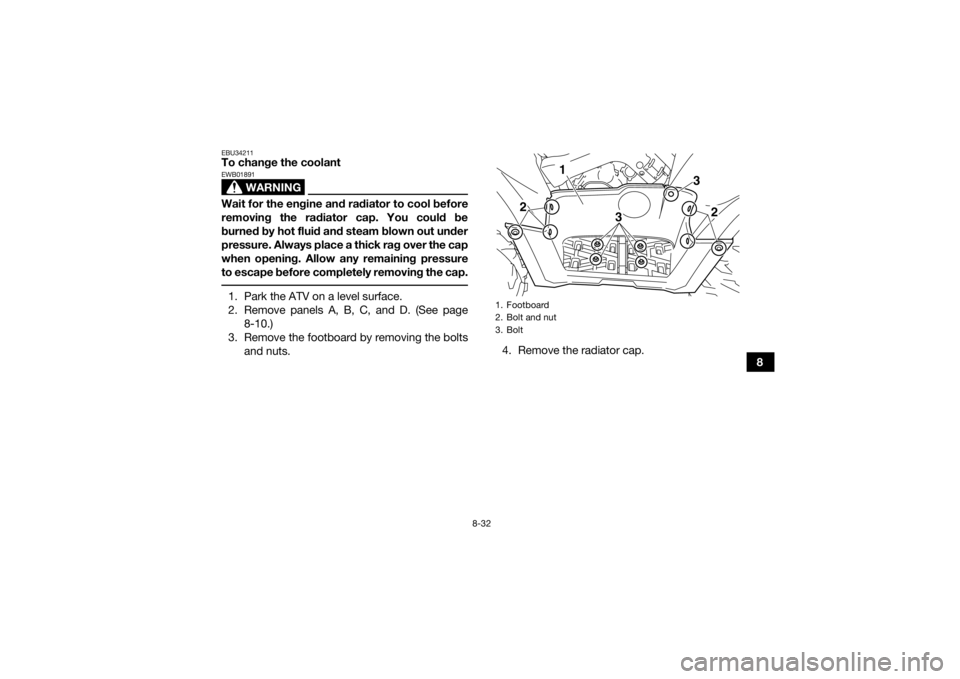

3. Remove the footboard by removing the bolts and nuts. 4. Remove the radiator cap.

1. Footboard

2. Bolt and nut

3. Bolt

3

2

2

3

1

U2UD60E0.book Page 32 Tuesday, April 28, 2015 11:55 AM

Page 130 of 176

8-33

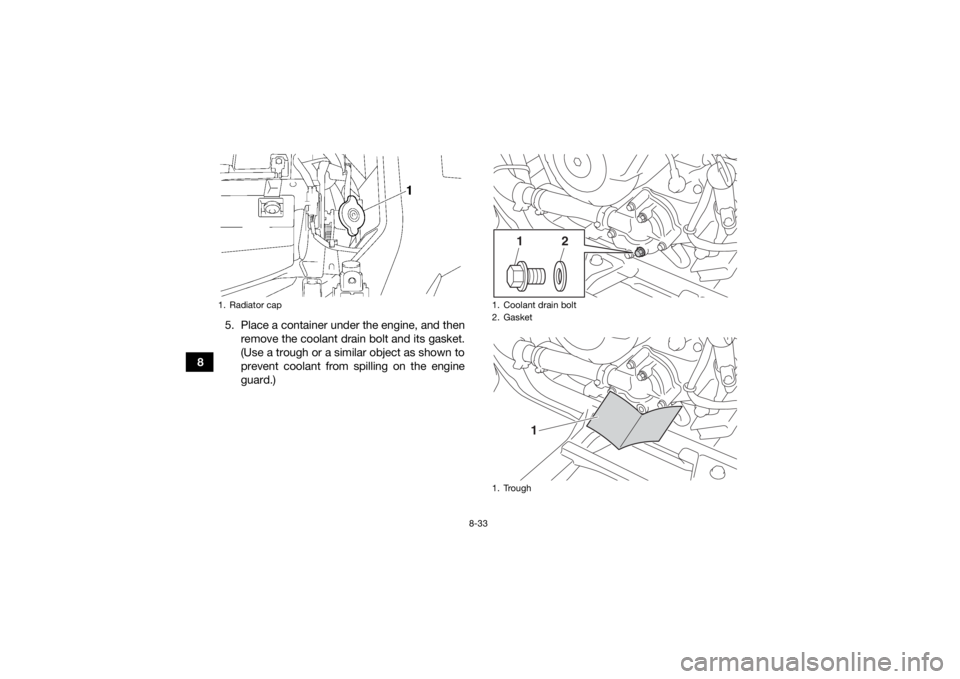

85. Place a container under the engine, and then

remove the coolant drain bolt and its gasket.

(Use a trough or a similar object as shown to

prevent coolant from spilling on the engine

guard.)

1. Radiator cap

1. Coolant drain bolt

2. Gasket

1. Trough

1

2

1

U2UD60E0.book Page 33 Tuesday, April 28, 2015 11:55 AM

Page 131 of 176

8-34

8

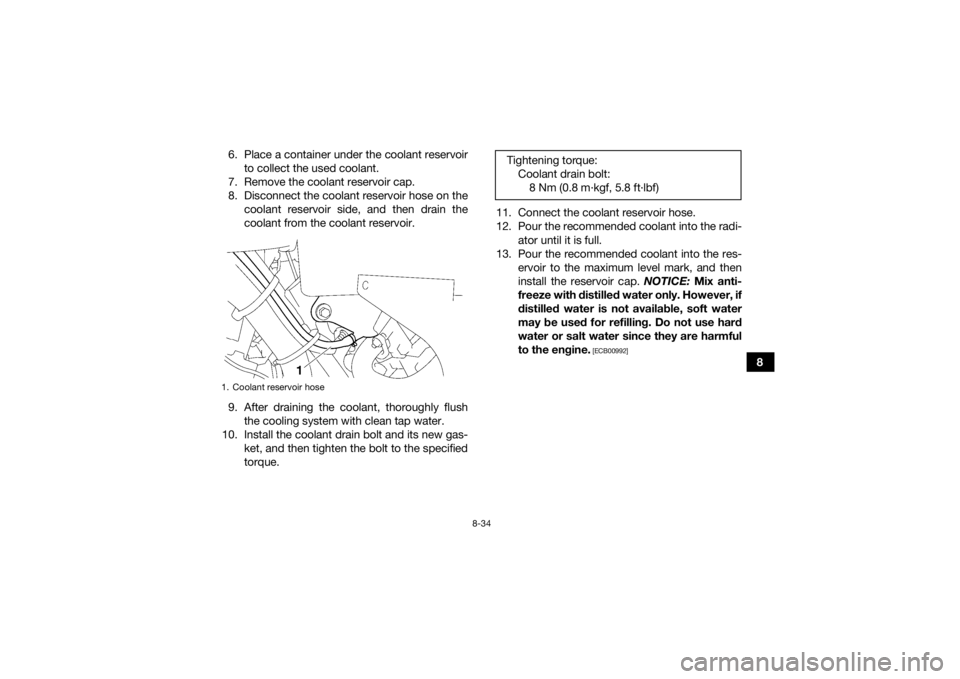

6. Place a container under the coolant reservoir

to collect the used coolant.

7. Remove the coolant reservoir cap.

8. Disconnect the coolant reservoir hose on the coolant reservoir side, and then drain the

coolant from the coolant reservoir.

9. After draining the coolant, thoroughly flush the cooling system with clean tap water.

10. Install the coolant drain bolt and its new gas- ket, and then tighten the bolt to the specified

torque. 11. Connect the coolant reservoir hose.

12. Pour the recommended coolant into the radi-

ator until it is full.

13. Pour the recommended coolant into the res- ervoir to the maximum level mark, and then

install the reservoir cap. NOTICE: Mix anti-

freeze with distilled water only. However, if

distilled water is not available, soft water

may be used for refilling. Do not use hard

water or salt water since they are harmful

to the engine.

[ECB00992]

1. Coolant reservoir hose

Tightening torque: Coolant drain bolt:8 Nm (0.8 m·kgf, 5.8 ft·lbf)

U2UD60E0.book Page 34 Tuesday, April 28, 2015 11:55 AM

Page 132 of 176

8-35

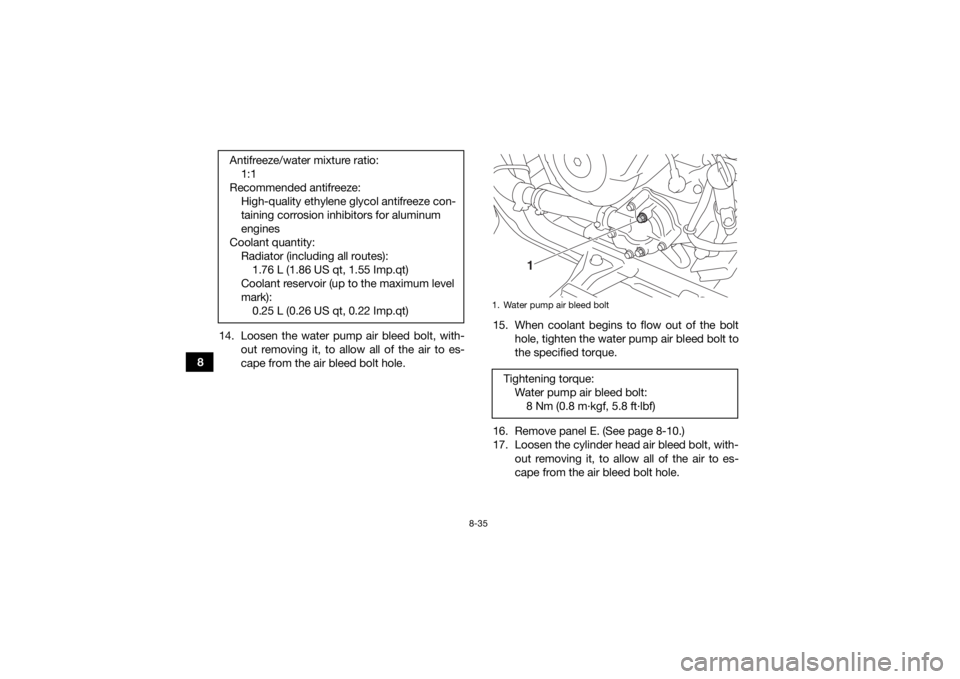

814. Loosen the water pump air bleed bolt, with-

out removing it, to allow all of the air to es-

cape from the air bleed bolt hole. 15. When coolant begins to flow out of the bolt

hole, tighten the water pump air bleed bolt to

the specified torque.

16. Remove panel E. (See page 8-10.)

17. Loosen the cylinder head air bleed bolt, with- out removing it, to allow all of the air to es-

cape from the air bleed bolt hole.

Antifreeze/water mixture ratio:

1:1

Recommended antifreeze: High-quality ethylene glycol antifreeze con-

taining corrosion inhibitors for aluminum

engines

Coolant quantity: Radiator (including all routes):1.76 L (1.86 US qt, 1.55 Imp.qt)

Coolant reservoir (up to the maximum level

mark): 0.25 L (0.26 US qt, 0.22 Imp.qt)

1. Water pump air bleed boltTightening torque:Water pump air bleed bolt:8 Nm (0.8 m·kgf, 5.8 ft·lbf)

1

U2UD60E0.book Page 35 Tuesday, April 28, 2015 11:55 AM

Page 133 of 176

8-36

8

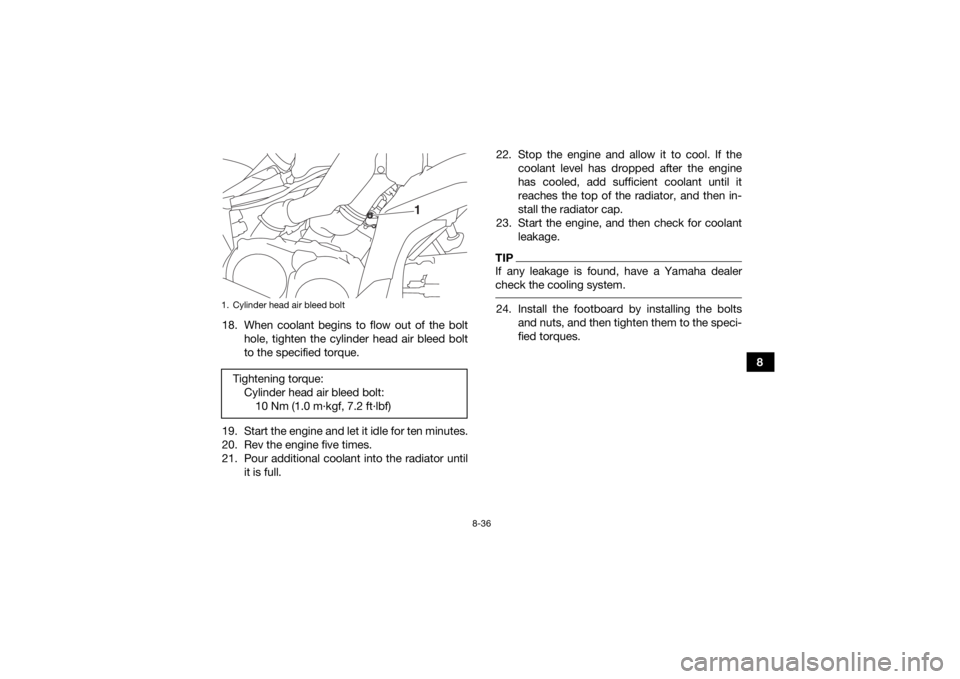

18. When coolant begins to flow out of the bolt

hole, tighten the cylinder head air bleed bolt

to the specified torque.

19. Start the engine and let it idle for ten minutes.

20. Rev the engine five times.

21. Pour additional coolant into the radiator until it is full. 22. Stop the engine and allow it to cool. If the

coolant level has dropped after the engine

has cooled, add sufficient coolant until it

reaches the top of the radiator, and then in-

stall the radiator cap.

23. Start the engine, and then check for coolant leakage.

TIPIf any leakage is found, have a Yamaha dealer

check the cooling system. 24. Install the footboard by installing the boltsand nuts, and then tighten them to the speci-

fied torques.

1. Cylinder head air bleed boltTightening torque:Cylinder head air bleed bolt:10 Nm (1.0 m·kgf, 7.2 ft·lbf)

1

U2UD60E0.book Page 36 Tuesday, April 28, 2015 11:55 AM

Page 163 of 176

8-66

8

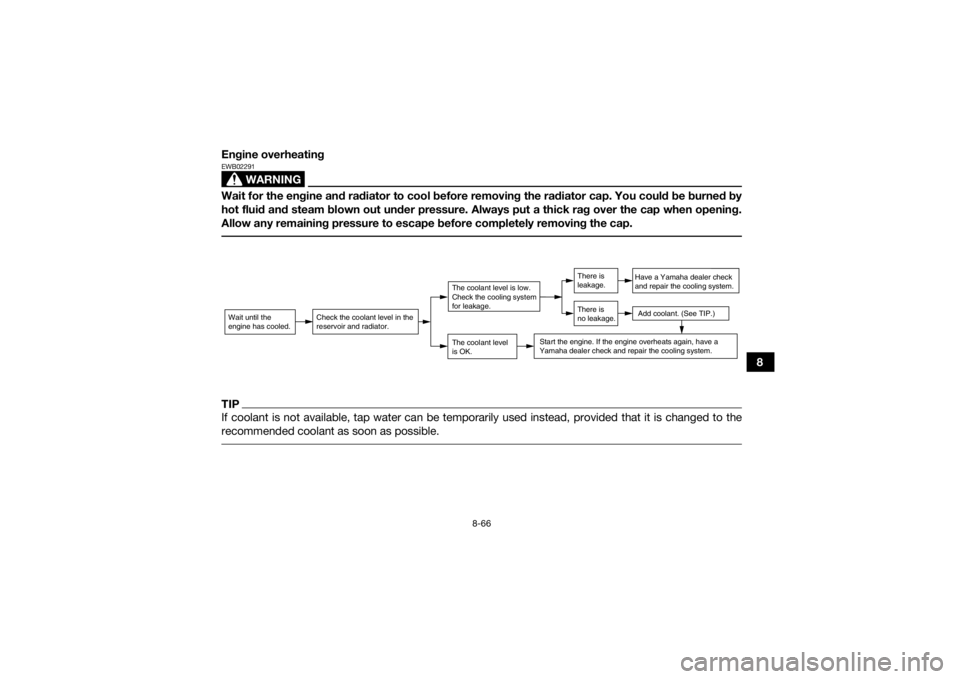

Engine overheating

WARNING

EWB02291Wait for the engine and radiator to cool before removing the radiator cap. You could be burned by

hot fluid and steam blown out under pressure. Always put a thick rag over the cap when opening.

Allow any remaining pressure to escape before completely removing the cap. TIPIf coolant is not available, tap water can be temporarily used instead, provided that it is changed to the

recommended coolant as soon as possible. Wait until the

engine has cooled.

Check the coolant level in the

reservoir and radiator.

The coolant level

is OK.The coolant level is low.

Check the cooling system

for leakage.

Have a Yamaha dealer check

and repair the cooling system.Add coolant. (See TIP.)

Start the engine. If the engine overheats again, have a

Yamaha dealer check and repair the cooling system.

There is

leakage.

There is

no leakage.

U2UD60E0.book Page 66 Tuesday, April 28, 2015 11:55 AM

Page 168 of 176

10-2

10

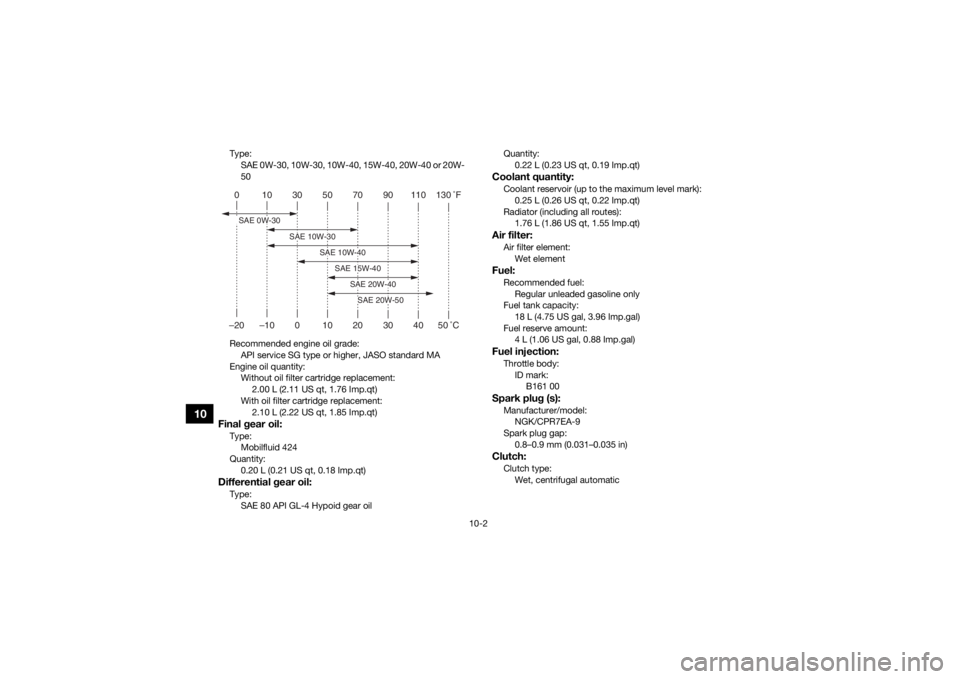

Type:SAE 0W-30, 10W-30, 10W-40, 15W-40, 20W-40 or 20W-

50

Recommended engine oil grade: API service SG type or higher, JASO standard MA

Engine oil quantity: Without oil filter cartridge replacement: 2.00 L (2.11 US qt, 1.76 Imp.qt)

With oil filter cartridge replacement: 2.10 L (2.22 US qt, 1.85 Imp.qt)Final gear oil:Type:Mobilfluid 424

Quantity: 0.20 L (0.21 US qt, 0.18 Imp.qt)Differential gear oil:Type:SAE 80 API GL-4 Hypoid gear oil Quantity:

0.22 L (0.23 US qt, 0.19 Imp.qt)

Coolant quantity:Coolant reservoir (up to the maximum level mark):

0.25 L (0.26 US qt, 0.22 Imp.qt)

Radiator (including all routes): 1.76 L (1.86 US qt, 1.55 Imp.qt)Air filter:Air filter element:

Wet elementFuel:Recommended fuel:Regular unleaded gasoline only

Fuel tank capacity:

18 L (4.75 US gal, 3.96 Imp.gal)

Fuel reserve amount: 4 L (1.06 US gal, 0.88 Imp.gal)Fuel injection:Throttle body:

ID mark: B161 00Spark plug (s):Manufacturer/model:NGK/CPR7EA-9

Spark plug gap: 0.8–0.9 mm (0.031–0.035 in)Clutch:Clutch type:Wet, centrifugal automatic

0 10 30 50 70 90 110 130 �F

–20 –10 0 10 20 30 40 50 �CSAE 0W-30

SAE 10W-30

SAE 10W-40

SAE 15W-40

SAE 20W-40SAE 20W-50

U2UD60E0.book Page 2 Tuesday, April 28, 2015 11:55 AM

Page 171 of 176

10-5

10

Coolant temperature warning light:LED

EPS warning light: LED (YFM70GPHG, YFM70GPLG, YFM70GPSG,

YFM70GPXG)

Park indicator light: LED

Engine trouble warning light:

LED

High-range indicator light: LED

Low-range indicator light: LED

Differential gear lock indicator light:

LEDFuses:Main fuse:40.0 A

Fuel injection system fuse:

15.0 A

EPS fuse: 40.0 A (YFM70GPHG, YFM70GPLG, YFM70GPSG,

YFM70GPXG)

Headlight fuse: 10.0 A

Signaling system fuse: 10.0 A

Ignition fuse:

10.0 A

Auxiliary DC jack fuse: 10.0 A Four-wheel-drive motor fuse:

10.0 A

Radiator fan motor fuse: 20.0 A

EBU30402For Europe only

The figures quoted are emission levels and are not

necessarily safe working levels. Whilst there is a

correlation between the emission and exposure

levels, this cannot be used reliably to determine

whether or not further precautions are required.

Factors that influence the actual level of exposure

of work-force include the characteristics of the

work room, the other sources of noise, etc. i.e. the

number of machines and other adjacent process-

es, and the length of time for which an operator is

exposed to the noise. Also the permissible expo-

sure level can vary from country. This information,

however, will enable the user of the machine to

make a better evaluation of the hazard and risk.

U2UD60E0.book Page 5 Tuesday, April 28, 2015 11:55 AM

Page 174 of 176

12-1

12

INDEX

AAccessories and loading ................................................ 6-6

Accessories, auxiliary jack ........................................... 4-24

Air filter element, cleaning ............................................ 8-38

Axle boots .................................................................... 8-49BBattery .......................................................................... 8-54

Brake fluid, changing ...................................................8-46

Brake fluid level, checking ........................................... 8-45

Brake lever, front .......................................................... 4-14

Brake levers, checking and lubricating ........................ 8-50

Brake pads, checking the front and rear ..................... 8-44

Brake pedal and rear brake lever ................................. 4-14

Brake pedal, checking and lubricating ........................ 8-51

Brake pedal free play, adjusting .................................. 8-47

Brakes .......................................................................... 8-43

Brakes, front and rear .................................................... 5-3CCables, checking and lubricating ................................. 8-50

Carrier, front ................................................................. 4-22

Carrier, rear .................................................................. 4-22

Chassis fasteners ........................................................... 5-6

Cleaning ......................................................................... 9-1

Coolant ................................................................. 5-3, 8-30

Coolant temperature warning light ................................. 4-3DDifferential gear oil ............................................... 5-3, 8-28

Drive select lever .......................................................... 4-15

Drive select lever and driving in reverse ........................ 6-2Drive select lever safety system cable, adjusting ........ 8-43

EEngine break-in .............................................................. 6-4

Engine oil ....................................................................... 5-3

Engine oil and oil filter cartridge .................................. 8-21

Engine stop switch ......................................................... 4-8

Engine trouble warning light .......................................... 4-3

EPS warning light (for EPS model) ................................. 4-4FFinal gear oil ......................................................... 5-3, 8-25

Four-wheel-drive/differential gear lock indicator ........... 4-4

Front and rear brake lever free play, checking ............ 8-46

Fuel ...................................................................... 4-16, 5-3

Fuel tank cap ............................................................... 4-15

Fuses, replacing ........................................................... 8-57HHandlebar switches ....................................................... 4-7

Headlight beam, adjusting ........................................... 8-61

Headlight bulb, replacing ............................................. 8-59

High-range indicator light .............................................. 4-2

Horn switch .................................................................... 4-8IIdentification numbers ................................................. 11-1

Indicator lights and warning lights ................................. 4-2

Instruments, lights and switches ................................... 5-7LLabel locations ............................................................... 1-1

Light switch .................................................................... 4-8

Low-range indicator light ............................................... 4-2

U2UD60E0.book Page 1 Tuesday, April 28, 2015 11:55 AM