maintenance YAMAHA KODIAK 700 2022 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2022, Model line: KODIAK 700, Model: YAMAHA KODIAK 700 2022Pages: 174, PDF Size: 4.74 MB

Page 100 of 174

9-5

9

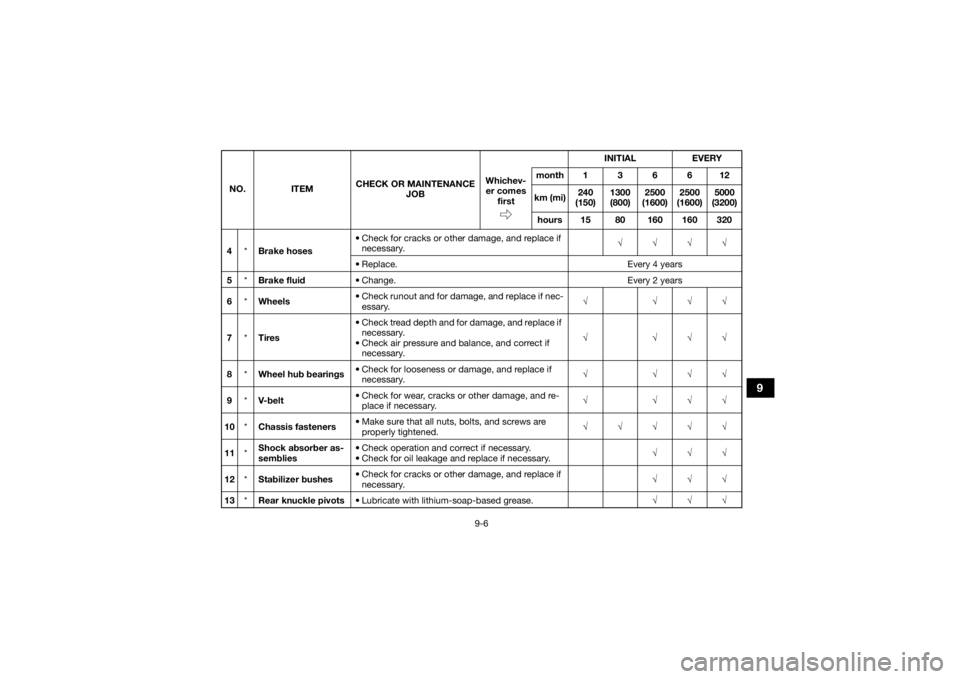

EBU40170Periodic maintenance chart: General maintenance and lubricationTIPFor ATVs not equipped with an odometer or an hour meter, follow the month maintenance intervals in-

stead.

For odometer or hour meter-equipped vehicles, follow the month maintenance interval if the ATV isn’t

ridden for the stated distance or engine operating hours.

Items marked with an asterisk should be performed by a Yamaha dealer as they require special tools,

data and technical skills. NO. ITEM CHECK OR MAINTENANCE

JOB INITIAL

EVERY

Whichev-

er comes first month136612

km (mi) 240

(150) 1300

(800) 2500

(1600) 2500

(1600) 5000

(3200)

hours 15 80 160 160 320

1 Air filter element • Clean and replace if necessary. Every 20–40 hours (more often in wet or

dusty areas)

2 *Front brake • Check operation and correct if necessary.

• Check fluid level and ATV for fluid leakage, and

correct if necessary. √√√√√

• Replace brake pads. Whenever worn to the limit

3 *Rear brake • Check operation and correct if necessary.

• Check brake lever and pedal free play, and adjust

if necessary. √√√√√

• Check brake friction plate wear and replace if necessary. √ √√√

UB5K64E0.book Page 5 Thursday, September 16, 2021 9:00 AM

Page 101 of 174

9-6

9

4*Brake hoses • Check for cracks or other damage, and replace if

necessary. √√√√

• Replace. Every 4 years

5 *Brake fluid • Change. Every 2 years

6 *Wheels • Check runout and for damage, and replace if nec-

essary. √ √√√

7 *Tires • Check tread depth and for damage, and replace if

necessary.

• Check air pressure and balance, and correct if necessary. √ √√√

8 *Wheel hub bearings • Check for looseness or damage, and replace if

necessary. √ √√√

9 *V- b e l t • Check for wear, cracks or other damage, and re-

place if necessary. √ √√√

10 *Chassis fasteners • Make sure that all nuts, bolts, and screws are

properly tightened. √√√√√

11 *Shock absorber as-

semblies • Check operation and correct if necessary.

• Check for oil leakage and replace if necessary.

√√√

12 *Stabilizer bushes • Check for cracks or other damage, and replace if

necessary. √√√

13 *Rear knuckle pivots • Lubricate with lithium-soap-based grease. √√√

NO.

ITEM CHECK OR MAINTENANCE

JOB INITIAL

EVERY

Whichev- er comes first month136612

km (mi) 240

(150) 1300

(800) 2500

(1600) 2500

(1600) 5000

(3200)

hours 15 80 160 160 320

UB5K64E0.book Page 6 Thursday, September 16, 2021 9:00 AM

Page 102 of 174

9-7

9

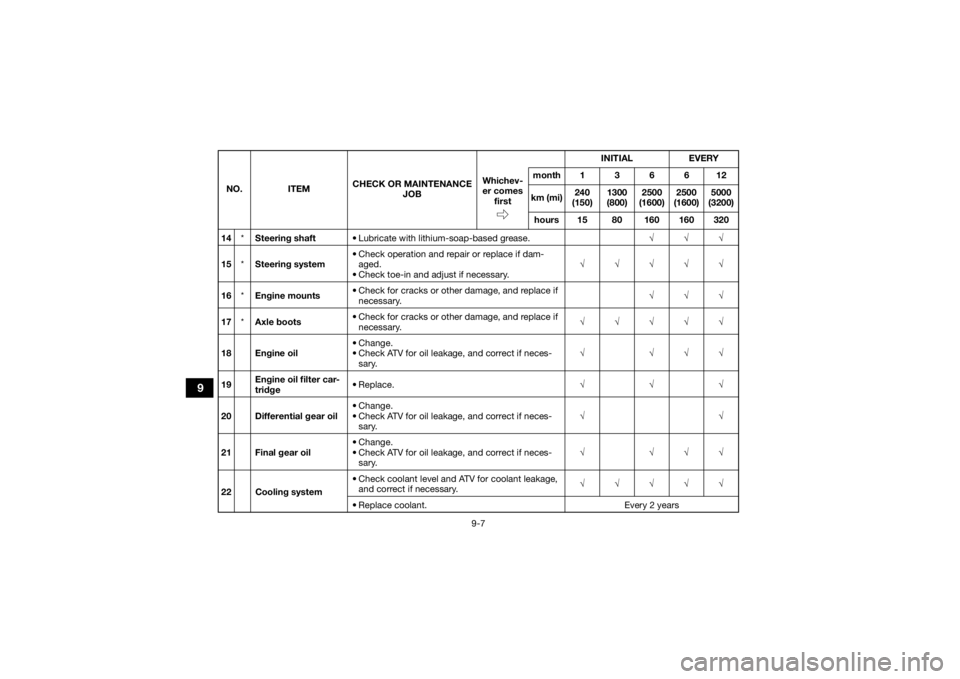

14*Steering shaft • Lubricate with lithium-soap-based grease. √√√

15 *Steering system • Check operation and repair or replace if dam-

aged.

• Check toe-in and adjust if necessary. √√√√√

16 *Engine mounts • Check for cracks or other damage, and replace if

necessary. √√√

17 *Axle boots • Check for cracks or other damage, and replace if

necessary. √√√√√

18 Engine oil • Change.

• Check ATV for oil leakage, and correct if neces-

sary. √ √√√

19 Engine oil filter car-

tridge • Replace.

√√√

20 Differential gear oil • Change.

• Check ATV for oil leakage, and correct if neces-

sary. √√

21 Final gear oil • Change.

• Check ATV for oil leakage, and correct if neces-

sary. √ √√√

22 Cooling system • Check coolant level and ATV for coolant leakage,

and correct if necessary. √√√√√

• Replace coolant. Every 2 years

NO.

ITEM CHECK OR MAINTENANCE

JOB INITIAL

EVERY

Whichev-

er comes first month136612

km (mi) 240

(150) 1300

(800) 2500

(1600) 2500

(1600) 5000

(3200)

hours 15 80 160 160 320UB5K64E0.book Page 7 Thursday, September 16, 2021 9:00 AM

Page 103 of 174

9-8

9

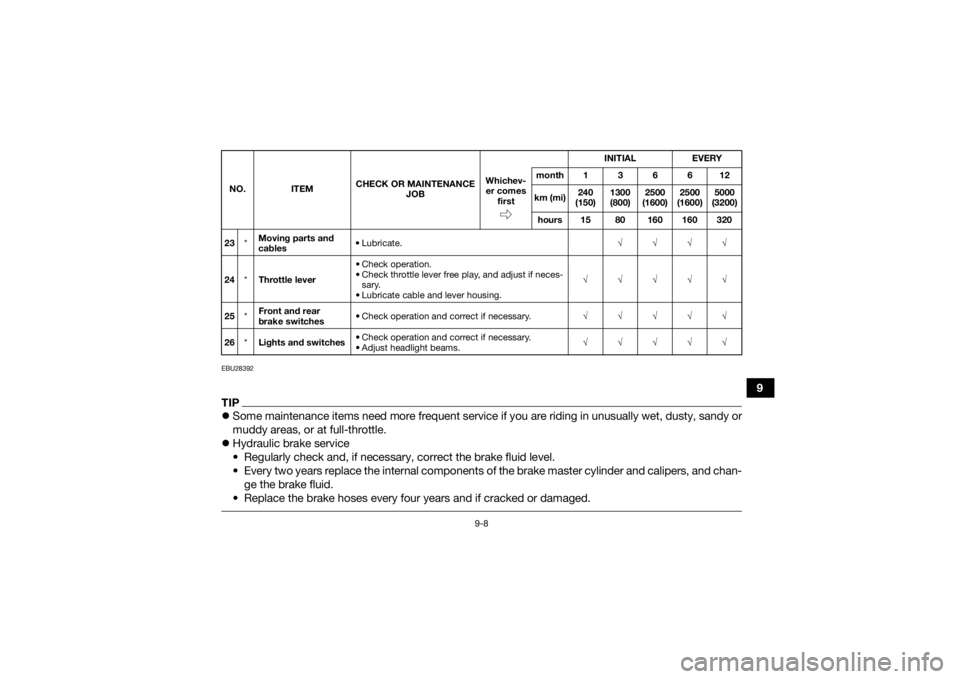

EBU28392TIPSome maintenance items need more frequent service if you are riding in unusually wet, dusty, sandy or

muddy areas, or at full-throttle.

Hydraulic brake service

• Regularly check and, if necessary, correct the brake fluid level.

• Every two years replace the internal components of the brake master cylinder and calipers, and chan-

ge the brake fluid.

• Replace the brake hoses every four years and if cracked or damaged. 23 *Moving parts and

cables •Lubricate.

√√√√

24 *Throttle lever • Check operation.

• Check throttle lever free play, and adjust if neces-

sary.

• Lubricate cable and lever housing. √√√√√

25 *Front and rear

brake switches • Check operation and correct if necessary.

√√√√√

26 *Lights and switches • Check operation and correct if necessary.

• Adjust headlight beams. √√√√√

NO. ITEM

CHECK OR MAINTENANCE

JOB INITIAL EVERY

Whichev- er comes first month136612

km (mi) 240

(150) 1300

(800) 2500

(1600) 2500

(1600) 5000

(3200)

hours 15 80 160 160 320UB5K64E0.book Page 8 Thursday, September 16, 2021 9:00 AM

Page 104 of 174

9-9

9

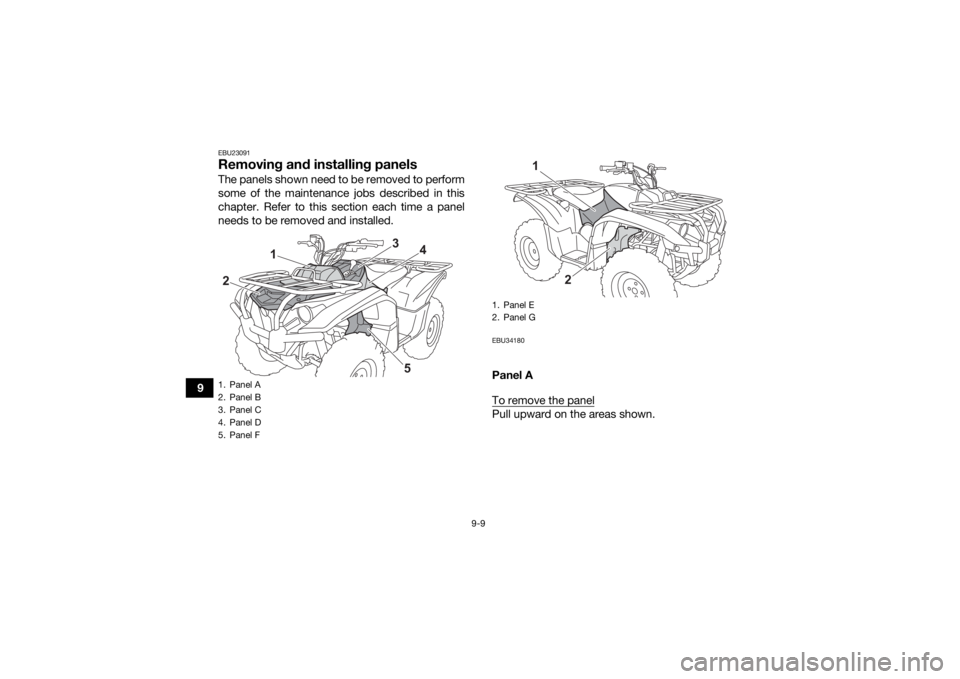

EBU23091Removing and installing panelsThe panels shown need to be removed to perform

some of the maintenance jobs described in this

chapter. Refer to this section each time a panel

needs to be removed and installed.

EBU34180Panel A

To remove the panelPull upward on the areas shown.

1. Panel A

2. Panel B

3. Panel C

4. Panel D

5. Panel F2

1

3

4

5

1. Panel b

2. Panel d

2

1

UB5K64E0.book Page 9 Thursday, September 16, 2021 9:00 AM

Page 112 of 174

9-17

9

EBU38133Checking the spark plugThe spark plug is an important engine component,

which is easy to check. Since heat and deposits

will cause any spark plug to slowly erode, the

spark plug should be removed and checked in ac-

cordance with the periodic maintenance chart. In

addition, the condition of the spark plug can reveal

the condition of the engine.

To remove the spark plug1. Remove panels A, C, and E. (See page 9-9.)

2. Remove the spark plug cap. 3. Remove the spark plug with a spark plug

wrench as shown.

Tightening torques:

Panel bolt:4.0 N·m (0.40 kgf·m, 3.0 lb·ft)

Footboard nut: 4.0 N·m (0.40 kgf·m, 3.0 lb·ft)

1. Spark plug cap

1. Spark plug wrench

11

UB5K64E0.book Page 17 Thursday, September 16, 2021 9:00 AM

Page 114 of 174

9-19

9

TIPIf a torque wrench is not available when installing

the spark plug, a good estimate of the correct

torque is 1/4–1/2 turn past finger tight. However,

the spark plug should be tightened to the speci-

fied torque as soon as possible. 3. Install the spark plug cap.

4. Install the panels.EBU2746DEngine oil and oil filter cartridgeThe engine oil level should be checked before

each ride. In addition, the oil must be changed and

the oil filter cartridge replaced at the intervals

specified in the periodic maintenance chart.

To check the engine oil level1. Park the ATV on a level surface.

2. Check the engine oil level on a cold engine.

TIPIf the engine was started before checking the oil

level, warm up the engine, and then wait at least

10 minutes until the oil settles for an accurate

reading. 3. Remove the access cover by turning it coun- terclockwise.

4. Remove the engine oil dipstick, and then wipe it off with a clean rag.

Tightening torque:

Spark plug:13 N

Page 119 of 174

9-24

9

Yamaha’s experience gained over many years of

research and development into oil since the

1960’s helps make Yamalube the best choice for

your Yamaha engine.

EBU27309Final gear oilThe final gear case must be checked for oil leak-

age before each ride. If any leakage is found, have

a Yamaha dealer check and repair the ATV. In ad-

dition, the final gear oil level must be checked and

the oil changed as follows at the intervals speci-

fied in the periodic maintenance chart.

To check the final gear oil level 1. Park the ATV on a level surface. 2. Remove the final gear oil level check bolt and

its gasket, and then check the oil level in the

final gear case. The oil level should be at the

brim of the check hole.

3. If the oil is below the brim of the check hole, remove the final gear oil filler bolt and its gas-

ket, and then add sufficient oil of the recom-

mended type to raise it to the correct level.

1. Final gear oil

2. Gasket

3. Final gear oil level check bolt

4. Correct oil level

1

243

UB5K64E0.book Page 24 Thursday, September 16, 2021 9:00 AM

Page 121 of 174

![YAMAHA KODIAK 700 2022 User Guide 9-26

9

5. Refill with the recommended final gear oil to

the brim of the check hole as shown.

NOTICE: Be sure no foreign material en-

ters the final gear case.

[ECB00422]

6. Check the oil level check YAMAHA KODIAK 700 2022 User Guide 9-26

9

5. Refill with the recommended final gear oil to

the brim of the check hole as shown.

NOTICE: Be sure no foreign material en-

ters the final gear case.

[ECB00422]

6. Check the oil level check](/img/51/50551/w960_50551-120.png)

9-26

9

5. Refill with the recommended final gear oil to

the brim of the check hole as shown.

NOTICE: Be sure no foreign material en-

ters the final gear case.

[ECB00422]

6. Check the oil level check bolt gasket and the oil filler bolt gasket for damage, and replace

them if necessary.

7. Install the oil level check bolt, the oil filler bolt and their gasket, and then tighten the bolts to

the specified torques.

8. Check the final gear case for oil leakage. If oil is leaking, check for the cause.EBU23429Differential gear oilThe differential gear case must be checked for oil

leakage before each ride. If any leakage is found,

have a Yamaha dealer check and repair the ATV.

In addition, the differential gear oil level must be

checked and the oil changed as follows at the in-

tervals specified in the periodic maintenance

chart.

Tightening torque:

Final gear oil drain bolt:23 N·m (2.3 kgf·m, 17 lb·ft)

1. Final gear oil

2. Gasket

3. Final gear oil level check bolt

4. Correct oil levelRecommended final gear oil: See page 11-1.

1

243

Tightening torquesWFinal gear oil level check bolt:10 N

Page 123 of 174

9-28

9

4. Install the drain bolt and its new gasket, and

then tighten the bolt to the specified torque.

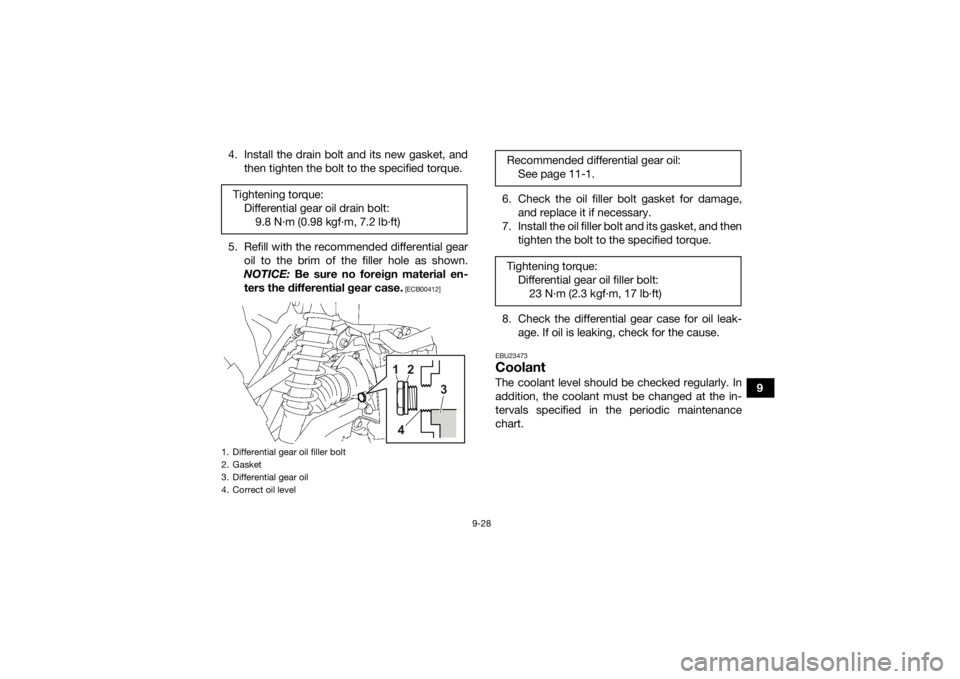

5. Refill with the recommended differential gear oil to the brim of the filler hole as shown.

NOTICE: Be sure no foreign material en-

ters the differential gear case.

[ECB00412]

6. Check the oil filler bolt gasket for damage, and replace it if necessary.

7. Install the oil filler bolt and its gasket, and then tighten the bolt to the specified torque.

8. Check the differential gear case for oil leak- age. If oil is leaking, check for the cause.EBU23473CoolantThe coolant level should be checked regularly. In

addition, the coolant must be changed at the in-

tervals specified in the periodic maintenance

chart.

Tightening torque:

Differential gear oil drain bolt:9.8 N·m (0.98 kgf·m, 7.2 lb·ft)

1. Differential gear oil filler bolt

2. Gasket

3. Differential gear oil

4. Correct oil level

1

2

3

4

Recommended differential gear oil: See page 11-1.

Tightening torque: Differential gear oil filler bolt:23 N