wheel YAMAHA MT-07 2014 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: MT-07, Model: YAMAHA MT-07 2014Pages: 106, PDF Size: 3.29 MB

Page 67 of 106

PERIODIC MAINTENANCE AND ADJUSTMENT

6-18

6

EAU21963

Cast wheelsTo maximize the performance, durabil-

ity, and safe operation of your vehicle,

note the following points regarding the

specified wheels.ï¬ The wheel rims should be

checked for cracks, bends, warp-

age or other damage before each

ride. If any damage is found, have

a Yamaha dealer replace the

wheel. Do not attempt even the

smallest repair to the wheel. A de-

formed or cracked wheel must be

replaced.

ï¬ The wheel should be balanced

whenever either the tire or wheel

has been changed or replaced. An

unbalanced wheel can result in

poor performance, adverse han-

dling characteristics, and a short-

ened tire life.

EAU33892

Adjusting the clutch lever free

playThe clutch lever free play should mea-

sure 5.0â10.0 mm (0.20â0.39 in) as

shown. Periodically check the clutch

lever free play and, if necessary, adjust

it as follows.

To increase the clutch lever free play,

turn the clutch lever free play adjusting

bolt at the clutch lever in direction (a).

To decrease the clutch lever free play,

turn the adjusting bolt in direction (b).

TIPIf the specified clutch lever free play

cannot be obtained as described

above, proceed as follows.1. Fully turn the adjusting bolt at the

clutch lever in direction (a) to loos-

en the clutch cable.

2. Loosen the locknut at the crank- case.

3. To increase the clutch lever free play, turn the clutch lever free play

adjusting nut in direction (a). To

decrease the clutch lever free

play, turn the adjusting nut in di-

rection (b).

4. Tighten the locknut.

1. Clutch lever free play adjusting bolt

2. Clutch lever free play2

1 (b)(a)

1. Locknut

2. Clutch lever free play adjusting nut

1

2

(a)(b)

U1WSE0E0.book Page 18 Friday, November 22, 2013 8:56 AM

Page 72 of 106

PERIODIC MAINTENANCE AND ADJUSTMENT

6-23

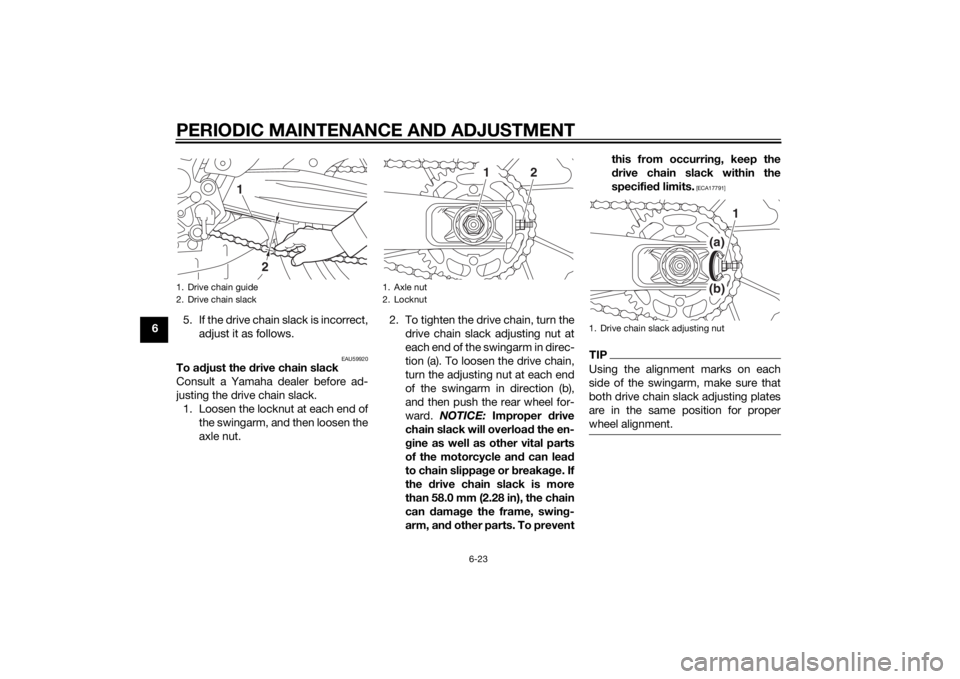

65. If the drive chain slack is incorrect,

adjust it as follows.

EAU59920

To a djust the d rive chain slack

Consult a Yamaha dealer before ad-

justing the drive chain slack. 1. Loosen the locknut at each end of the swingarm, and then loosen the

axle nut. 2. To tighten the drive chain, turn the

drive chain slack adjusting nut at

each end of the swingarm in direc-

tion (a). To loosen the drive chain,

turn the adjusting nut at each end

of the swingarm in direction (b),

and then push the rear wheel for-

ward. NOTICE: Improper drive

chain slack will overload the en-

g ine as well as other vital parts

of the motorcycle an d can lead

to chain slippa ge or breakag e. If

the drive chain slack is more

than 58.0 mm (2.28 in), the chain

can damag e the frame, swin g-

arm, an d other parts. To prevent this from occurrin

g, keep the

d rive chain slack within the

specifie d limits.

[ECA17791]

TIPUsing the alignment marks on each

side of the swingarm, make sure that

both drive chain slack adjusting plates

are in the same position for proper

wheel alignment.

1. Drive chain guide

2. Drive chain slack

2

1

1. Axle nut

2. Locknut

2

1

1. Drive chain slack adjusting nut

1

(a)(b)

U1WSE0E0.book Page 23 Wednesday, November 13, 2013 10:28 AM

Page 77 of 106

PERIODIC MAINTENANCE AND ADJUSTMENT

6-28

6

EAU23273

Checking the front forkThe condition and operation of the

front fork must be checked as follows

at the intervals specified in the periodic

maintenance and lubrication chart.

To check the con dition

Check the inner tubes for scratches,

damage and excessive oil leakage.

To check the operation 1. Place the vehicle on a level sur- face and hold it in an upright posi-

tion. WARNING! To avoi d injury,

securely support the vehicle so

there is no dan ger of it fallin g

over.

[EWA10752]

2. While applying the front brake, push down hard on the handle-

bars several times to check if the

front fork compresses and re-

bounds smoothly.

NOTICE

ECA10591

If any damag e is foun d or the front

fork does not operate smoothly,

have a Yamaha d ealer check or re-

pair it.

EAU23284

Checkin g the steerin gWorn or loose steering bearings may

cause danger. Therefore, the operation

of the steering must be checked as fol-

lows at the intervals specified in the

periodic maintenance and lubrication

chart.

1. Place a stand under the engine to raise the front wheel off the

ground. (See page 6-36 for more

information.) WARNING! To

avoi d injury, securely support

the vehicle so there is no dan ger

of it fallin g over.

[EWA10752]

2. Hold the lower ends of the front

fork legs and try to move them for-

ward and backward. If any free

play can be felt, have a Yamaha

dealer check or repair the steer-

ing.

U1WSE0E0.book Page 28 Wednesday, November 13, 2013 10:28 AM

Page 78 of 106

PERIODIC MAINTENANCE AND ADJUSTMENT

6-29

6

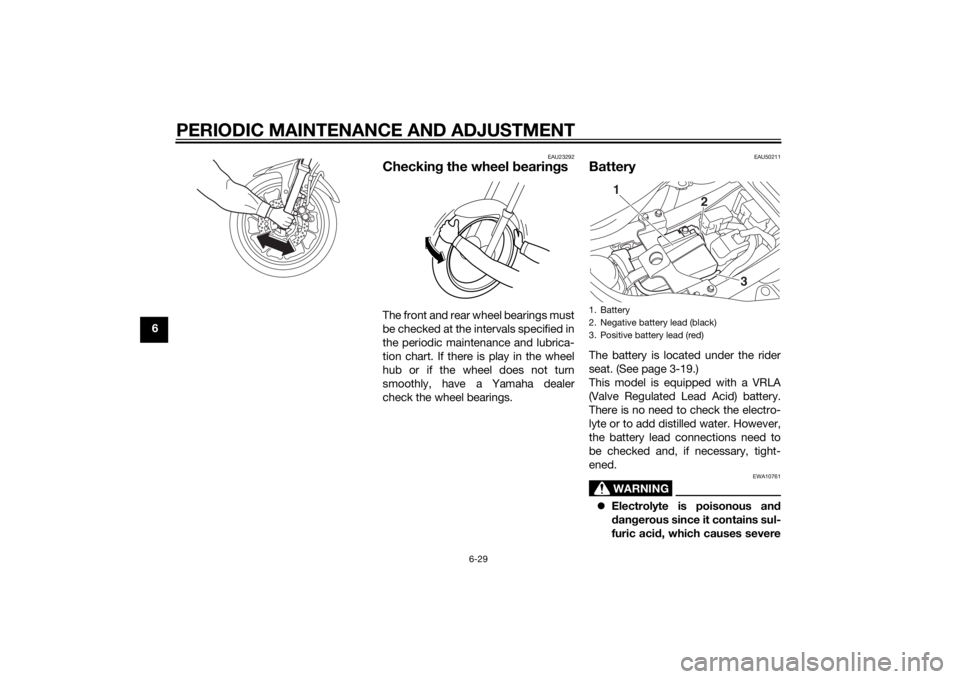

EAU23292

Checking the wheel bearingsThe front and rear wheel bearings must

be checked at the intervals specified in

the periodic maintenance and lubrica-

tion chart. If there is play in the wheel

hub or if the wheel does not turn

smoothly, have a Yamaha dealer

check the wheel bearings.

EAU50211

BatteryThe battery is located under the rider

seat. (See page 3-19.)

This model is equipped with a VRLA

(Valve Regulated Lead Acid) battery.

There is no need to check the electro-

lyte or to add distilled water. However,

the battery lead connections need to

be checked and, if necessary, tight-

ened.

WARNING

EWA10761

ï¬Electrolyte is poisonous and

dangerous since it contains sul-

furic acid, which causes severe1. Battery

2. Negative battery lead (black)

3. Positive battery lead (red)

2

3

1

U1WSERE0.book Page 29 Friday, August 29, 2014 6:18 PM

Page 85 of 106

PERIODIC MAINTENANCE AND ADJUSTMENT

6-36

6

EAU46405

Replacing the auxiliary li ght

b ul bIf the auxiliary light bulb burns out, re-

place it as follows.

1. Remove the headlight unit. (See page 6-32.)

2. Remove the auxiliary light bulb socket (together with the bulb) by

turning it counterclockwise.

3. Remove the burnt-out bulb by pulling it out of the socket. 4. Insert a new bulb into the socket.

5. Install the socket (together with

the bulb) by turning it clockwise.

6. Install the headlight unit.

EAU24351

Supportin g the motorcycleSince this model is not equipped with a

centerstand, follow these precautions

when removing the front and rear

wheel or performing other mainte-

nance requiring the motorcycle to

stand upright. Check that the motorcy-

cle is in a stable and level position be-

fore starting any maintenance. A

strong wooden box can be placed un-

der the engine for added stability.

To service the front wheel

1. Stabilize the rear of the motorcy- cle by using a motorcycle stand

or, if an additional motorcycle

stand is not available, by placing a

jack under the frame in front of the

rear wheel.

2. Raise the front wheel off the ground by using a motorcycle

stand.

To service the rear wheel

Raise the rear wheel off the ground by

using a motorcycle stand or, if a motor-

cycle stand is not available, by placing

1. Auxiliary light bulb socket

1

1. Auxiliary light bulb

1

U1WSE0E0.book Page 36 Wednesday, November 13, 2013 10:28 AM

Page 86 of 106

PERIODIC MAINTENANCE AND ADJUSTMENT

6-37

6a jack either under each side of the

frame in front of the rear wheel or under

each side of the swingarm.

EAU44792

Front wheel (for non-ABS

mo

dels)

WARNING

EWA14841

For the ABS mo del, have a Yamaha

d ealer remove an d install the wheel.

EAU59931

To remove the front wheel

WARNING

EWA10822

To avoi d injury, securely support the

vehicle so there is no dan ger of it

fallin g over.1. Loosen the front wheel axle pinch

bolt, then the wheel axle and the

brake caliper bolts. 2. Lift the front wheel off the ground

according to the procedure in the

previous section âSupporting the

motorcycleâ.

3. Remove the brake hose holder on the left side by removing the bolt.

1. Front wheel axle pinch bolt

2. Wheel axle

3. Brake caliper bolt23

1

U1WSE0E0.book Page 37 Wednesday, November 13, 2013 10:28 AM

Page 87 of 106

PERIODIC MAINTENANCE AND ADJUSTMENT

6-38

6

4. Remove the brake caliper on each side by removing the bolts.

NOTICE: Do not apply the brake

after the brake calipers have

b een removed , otherwise the

b rake pad s will be force d shut.

[ECA11052]

5. Pull the wheel axle out, and then

remove the wheel.

To install the front wheel 1. Lift the wheel up between the fork legs.

2. Insert the wheel axle from the right side. 3. Lower the front wheel so that it is

on the ground, and then put the

sidestand down.

4. Install the brake calipers by install- ing the bolts.

TIPMake sure that there is enough space

between the brake pads before install-

ing the brake calipers onto the brake

discs.5. Install the brake hose holder by in-stalling the bolt.

6. Tighten the brake caliper bolts and the brake hose holder bolt to the

specified torques.

7. Tighten the wheel axle, and then the wheel axle pinch bolt to the

specified torques. 8. Push down hard on the handlebar

several times to check for proper

fork operation.

1. Brake hose holder

2. Bolt

3. Brake caliper

4. Brake caliper bolt4

321

Tightenin g torques:

Brake caliper bolt: 40 Nm (4.0 m·kgf, 29 ft·lbf)

Brake hose holder bolt:

7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Tightenin g torques:

Wheel axle:

65 Nm (6.5 m·kgf, 47 ft·lbf)

Front wheel axle pinch bolt:

23 Nm (2.3 m·kgf, 17 ft·lbf)

U1WSE0E0.book Page 38 Wednesday, November 13, 2013 10:28 AM

Page 88 of 106

PERIODIC MAINTENANCE AND ADJUSTMENT

6-39

6

EAU44802

Rear wheel (for non-ABS

models)

WARNING

EWA14841

For the ABS mo del, have a Yamaha

d ealer remove an d install the wheel.

EAU59940

To remove the rear wheel

WARNING

EWA10822

To avoi d injury, securely support the

vehicle so there is no dan ger of it

fallin g over.1. Loosen the locknut and drive

chain slack adjusting nut on each

side of the swingarm.

2. Loosen the axle nut. 3. Lift the rear wheel off the ground

according to the procedure on

page 6-36.

4. Remove the axle nut and the drive chain slack adjusting plate.

5. Push the wheel forward, and then remove the drive chain from the

rear sprocket.

TIPï¬If the drive chain is difficult to re-

move, remove the wheel axle first,

and then lift the wheel upward

enough to remove the drive chain

from the rear sprocket.

ï¬ The drive chain does not need to

be disassembled in order to re-

move and install the rear wheel.6. While supporting the brake caliper

and slightly lifting the wheel, pull

the wheel axle out and remove the

drive chain slack adjusting plate.

1. Drive chain slack adjusting plate

2. Drive chain slack adjusting nut

3. Locknut

4. Axle nut

1

2

3

4

U1WSE0E0.book Page 39 Wednesday, November 13, 2013 10:28 AM

Page 89 of 106

PERIODIC MAINTENANCE AND ADJUSTMENT

6-40

6

TIPA rubber mallet may be useful to tap

the wheel axle out.7. Remove the wheel. NOTICE: Do

not apply the b rake after the

wheel an d b rake disc have been

remove d, otherwise the brake

pa ds will b e forced shut.

[ECA11073]

To install the rear wheel

1. Install the wheel, the brake caliper bracket, and the drive chain slack

adjusting plate by inserting the

wheel axle from the right-hand

side.

TIPï¬Make sure that the slot in the

brake caliper bracket is fit over the

retainer on the swingarm.

ï¬ Make sure that there is enough

space between the brake pads

before installing the wheel.

ï¬ Make sure that the arrow mark on

each chain puller is pointing up-

ward.

2. Install the drive chain onto the rear

sprocket.

3. Install the drive chain slack adjust- ing plate and the axle nut.

4. Lower the rear wheel so that it is on the ground, and then put the

sidestand down.

5. Adjust the drive chain slack. (See page 6-22.)

6. Tighten the axle nut, and then tighten the locknuts to the speci-

fied torques.

1. Brake caliper

2. Drive chain slack adjusting plate

3. Wheel axle

13

2

1. Brake caliper bracket

2. Slot

3. Retainer

1

2

3

1. Drive chain puller

2. Arrow mark

2

1

U1WSE0E0.book Page 40 Wednesday, November 13, 2013 10:28 AM

Page 93 of 106

MOTORCYCLE CARE AND STORAGE7-1

7

EAU37834

Matte color cautionNOTICE

ECA15193

Some models are equipped with

matte colored finished parts. Be

sure to consult a Yamaha dealer for

a d vice on what prod ucts to use be-

fore cleanin g the vehicle. Usin g a

b rush, harsh chemical pro ducts or

cleanin g compoun ds when cleanin g

these parts will scratch or damag e

their surface. Wax also shoul d not

b e applie d to any matte colored fin-

ishe d parts.

EAU26015

CareWhile the open design of a motorcycle

reveals the attractiveness of the tech-

nology, it also makes it more vulnera-

ble. Rust and corrosion can develop

even if high-quality components are

used. A rusty exhaust pipe may go un-

noticed on a car, however, it detracts

from the overall appearance of a mo-

torcycle. Frequent and proper care

does not only comply with the terms of

the warranty, but it will also keep your

motorcycle looking good, extend its

life and optimize its performance.

Before cleanin g

1. Cover the muffler outlet with a plastic bag after the engine has

cooled down.

2. Make sure that all caps and cov- ers as well as all electrical cou-

plers and connectors, including

the spark plug caps, are tightly in-

stalled.

3. Remove extremely stubborn dirt, like oil burnt onto the crankcase,

with a degreasing agent and a

brush, but never apply such prod- ucts onto seals, gaskets, sprock-

ets, the drive chain and wheel

axles. Always rinse the dirt and

degreaser off with water.

Cleanin g

NOTICE

ECA10773

ï¬Avoi d usin g stron g aci dic wheel

cleaners, especially on spoked

wheels. If such pro ducts are

use d on har d-to-remove dirt, do

not leave the cleaner on the af-

fected area any lon ger than in-

structed . Also, thorou ghly rinse

the area off with water, immed i-

ately dry it, an d then apply a cor-

rosion protection spray.

ï¬ Improper cleanin g can d amage

plastic parts (such as cowlin gs,

panels, win dshiel ds, hea dlig ht

lenses, meter lenses, etc.) an d

the mufflers. Use only a soft,

clean cloth or spon ge with wa-

ter to clean plastic. However, if

the plastic parts cannot be thor-

ou ghly cleaned with water, di-

lute d mil d d eter gent with water

may be used . Be sure to rinse

U1WSE0E0.book Page 1 Wednesday, November 13, 2013 10:28 AM