wheel YAMAHA MT-07 2017 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2017, Model line: MT-07, Model: YAMAHA MT-07 2017Pages: 102, PDF Size: 3.09 MB

Page 74 of 102

Periodic maintenance an d a djustment

6-25

6

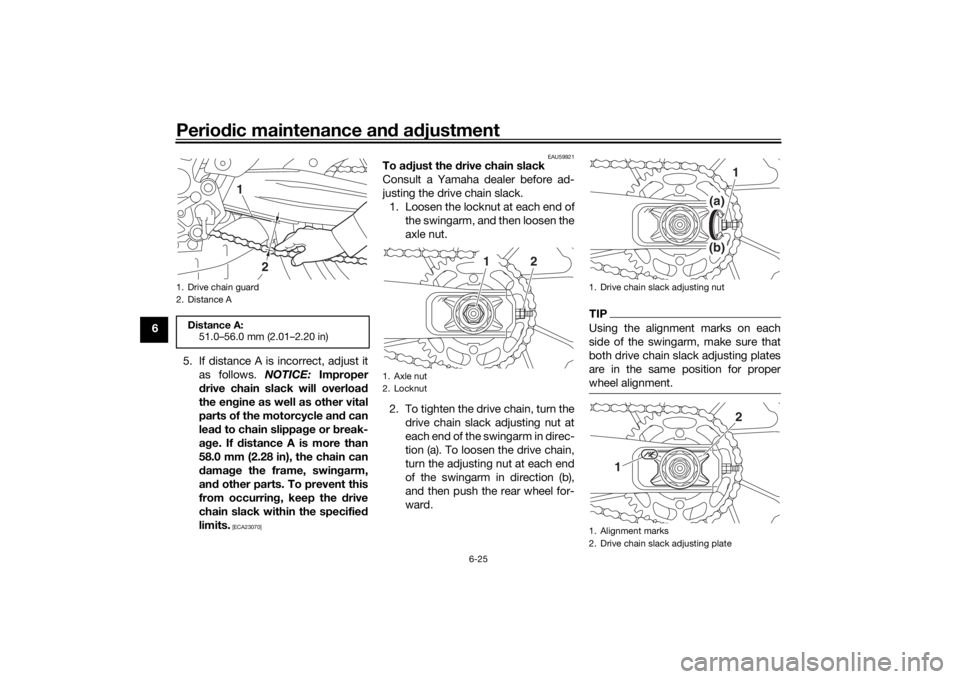

5. If distance A is incorrect, adjust itas follows. NOTICE: Improper

d rive chain slack will overload

the en gine as well as other vital

parts of the motorcycle an d can

lea d to chain slippag e or break-

a g e. If distance A is more than

58.0 mm (2.28 in), the chain can

d amag e the frame, swin garm,

an d other parts. To prevent this

from occurrin g, keep the drive

chain slack within the specifie d

limits.

[ECA23070] EAU59921

To a

djust the drive chain slack

Consult a Yamaha dealer before ad-

justing the drive chain slack. 1. Loosen the locknut at each end of the swingarm, and then loosen the

axle nut.

2. To tighten the drive chain, turn the drive chain slack adjusting nut at

each end of the swingarm in direc-

tion (a). To loosen the drive chain,

turn the adjusting nut at each end

of the swingarm in direction (b),

and then push the rear wheel for-

ward.

TIPUsing the alignment marks on each

side of the swingarm, make sure that

both drive chain slack adjusting plates

are in the same position for proper

wheel alignment.

1. Drive chain guard

2. Distance ADistance A:51.0–56.0 mm (2.01–2.20 in)

2

1

1. Axle nut

2. Locknut

2

1

1. Drive chain slack adjusting nut

1. Alignment marks

2. Drive chain slack adjusting plate

1

(a)(b)

2

1

UBU2E0E0.book Page 25 Friday, September 9, 2016 9:23 AM

Page 79 of 102

Periodic maintenance an d a djustment

6-30

6

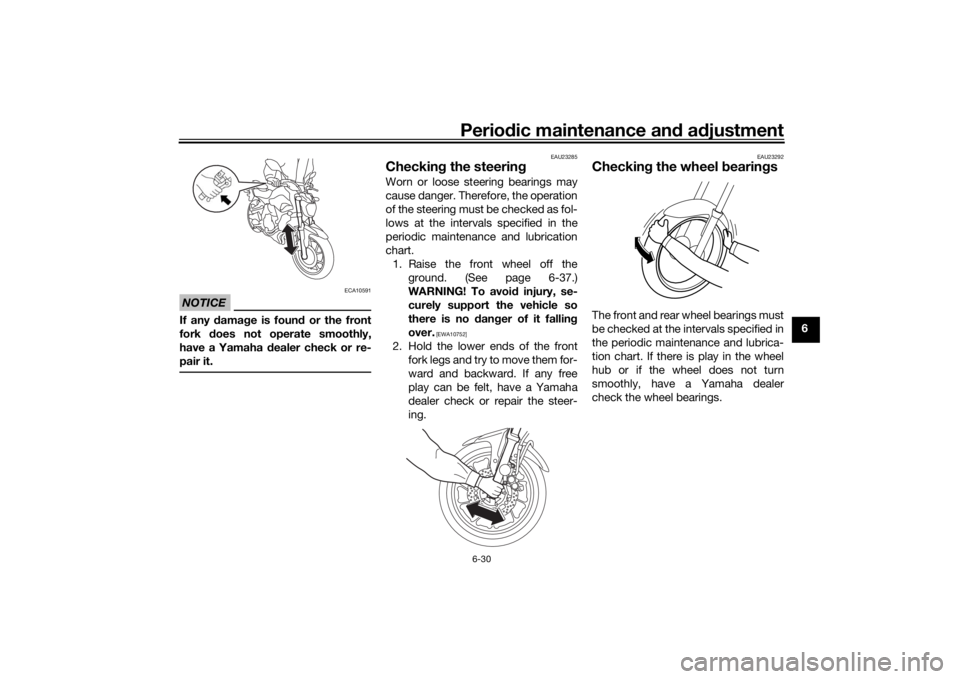

NOTICE

ECA10591

If any damag e is foun d or the front

fork does not operate smoothly,

have a Yamaha d ealer check or re-

pair it.

EAU23285

Checkin g the steerin gWorn or loose steering bearings may

cause danger. Therefore, the operation

of the steering must be checked as fol-

lows at the intervals specified in the

periodic maintenance and lubrication

chart.

1. Raise the front wheel off the ground. (See page 6-37.)

WARNING! To avoi d injury, se-

curely support the vehicle so

there is no dan ger of it fallin g

over.

[EWA10752]

2. Hold the lower ends of the front fork legs and try to move them for-

ward and backward. If any free

play can be felt, have a Yamaha

dealer check or repair the steer-

ing.

EAU23292

Checkin g the wheel bearin gsThe front and rear wheel bearings must

be checked at the intervals specified in

the periodic maintenance and lubrica-

tion chart. If there is play in the wheel

hub or if the wheel does not turn

smoothly, have a Yamaha dealer

check the wheel bearings.

UBU2E0E0.book Page 30 Friday, September 9, 2016 9:23 AM

Page 86 of 102

Periodic maintenance an d a djustment

6-37

6

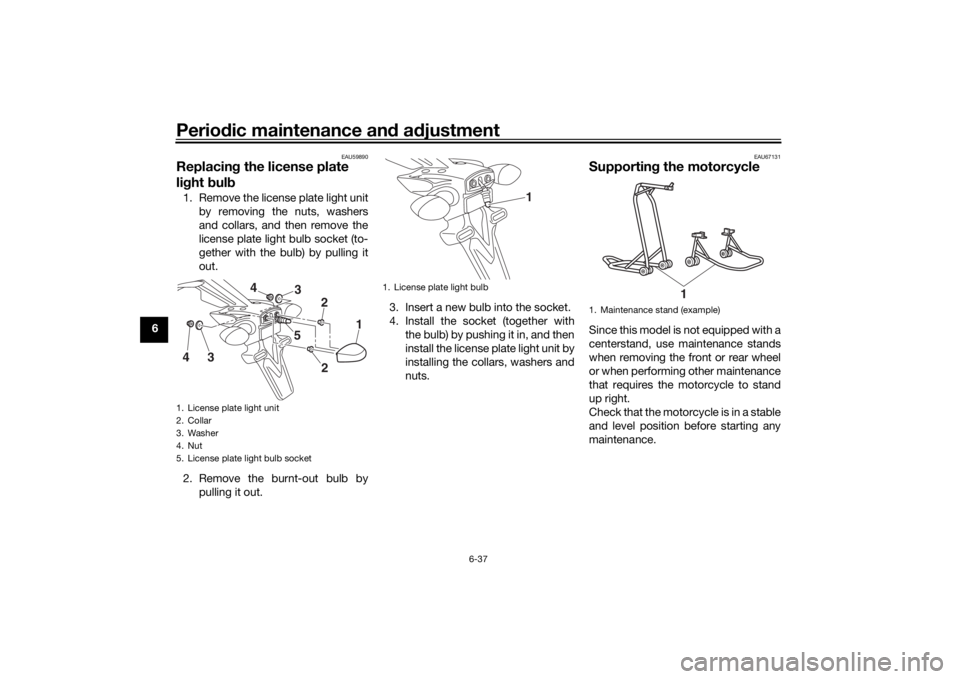

EAU59890

Replacin g the license plate

li g ht bul b1. Remove the license plate light unit

by removing the nuts, washers

and collars, and then remove the

license plate light bulb socket (to-

gether with the bulb) by pulling it

out.

2. Remove the burnt-out bulb by pulling it out. 3. Insert a new bulb into the socket.

4. Install the socket (together with

the bulb) by pushing it in, and then

install the license plate light unit by

installing the collars, washers and

nuts.

EAU67131

Supportin g the motorcycleSince this model is not equipped with a

centerstand, use maintenance stands

when removing the front or rear wheel

or when performing other maintenance

that requires the motorcycle to stand

up right.

Check that the motorcycle is in a stable

and level position before starting any

maintenance.

1. License plate light unit

2. Collar

3. Washer

4. Nut

5. License plate light bulb socket

1

22

53

4

3

4

1. License plate light bulb

1

1. Maintenance stand (example)

1

UBU2E0E0.book Page 37 Friday, September 9, 2016 9:23 AM

Page 90 of 102

Motorcycle care and stora ge

7-1

7

EAU37834

Matte color cautionNOTICE

ECA15193

Some mo dels are equipped with

matte colore d finishe d parts. Be

sure to consult a Yamaha d ealer for

a d vice on what prod ucts to use be-

fore cleanin g the vehicle. Usin g a

b rush, harsh chemical prod ucts or

cleanin g compoun ds when cleanin g

these parts will scratch or damag e

their surface. Wax also shoul d not

b e applied to any matte colore d fin-

ishe d parts.

EAU26015

CareWhile the open design of a motorcycle

reveals the attractiveness of the tech-

nology, it also makes it more vulnera-

ble. Rust and corrosion can develop

even if high-quality components are

used. A rusty exhaust pipe may go un-

noticed on a car, however, it detracts

from the overall appearance of a mo-

torcycle. Frequent and proper care

does not only comply with the terms of

the warranty, but it will also keep your

motorcycle looking good, extend its

life and optimize its performance.

Before cleanin g

1. Cover the muffler outlet with a plastic bag after the engine has

cooled down.

2. Make sure that all caps and cov- ers as well as all electrical cou-

plers and connectors, including

the spark plug caps, are tightly in-

stalled.

3. Remove extremely stubborn dirt, like oil burnt onto the crankcase,

with a degreasing agent and a

brush, but never apply such prod- ucts onto seals, gaskets, sprock-

ets, the drive chain and wheel

axles. Always rinse the dirt and

degreaser off with water.

Cleanin g

NOTICE

ECA10773

Avoi d using strong aci dic wheel

cleaners, especially on spoke d

wheels. If such prod ucts are

use d on har d-to-remove dirt, do

not leave the cleaner on the af-

fected area any lon ger than in-

structed . Also, thorou ghly rinse

the area off with water, imme di-

ately dry it, an d then apply a cor-

rosion protection spray.

Improper cleanin g can d amage

plastic parts (such as cowlin gs,

panels, win dshiel ds, hea dlig ht

lenses, meter lenses, etc.) an d

the mufflers. Use only a soft,

clean cloth or spon ge with wa-

ter to clean plastic. However, if

the plastic parts cannot b e thor-

ou ghly cleaned with water, di-

lute d mil d d eter gent with water

may be used . Be sure to rinse

UBU2E0E0.book Page 1 Friday, September 9, 2016 9:23 AM

Page 91 of 102

Motorcycle care and stora ge

7-2

7

off any

deter gent resi due usin g

plenty of water, as it is harmful

to plastic parts.

Do not use any harsh chemical

prod ucts on plastic parts. Be

sure to avoi d usin g cloths or

spon ges which have b een in

contact with stron g or a brasive

cleanin g prod ucts, solvent or

thinner, fuel ( gasoline), rust re-

movers or inhi bitors, brake flui d,

antifreeze or electrolyte.

Do not use hi gh-pressure wash-

ers or steam-jet cleaners since

they cause water seepag e and

d eterioration in the followin g ar-

eas: seals (of wheel an d swin g-

arm bearin gs, fork an d b rakes),

electric components (couplers,

connectors, instruments,

switches an d li ghts), breather

hoses an d vents.

For motorcycles equippe d with

a win dshiel d: Do not use stron g

cleaners or har d spon ges as

they will cause dullin g or

sc r

atchin g. Some cleanin g

compoun ds for plastic may

leave scratches on the win d- shiel

d. Test the pro duct on a

small hi dden part of the win d-

shiel d to make sure that it does

not leave any marks. If the win d-

shiel d is scratche d, use a quality

plastic polishin g compoun d af-

ter washing .

After normal useRemove dirt with warm water, a mild

detergent, and a soft, clean sponge,

and then rinse thoroughly with clean

water. Use a toothbrush or bottlebrush

for hard-to-reach areas. Stubborn dirt

and insects will come off more easily if

the area is covered with a wet cloth for

a few minutes before cleaning.

After riding in the rain, near the sea oron salt-sprayed roadsSince sea salt or salt sprayed on roads

during winter are extremely corrosive

in combination with water, carry out

the following steps after each ride in

the rain, near the sea or on salt-

sprayed roads.

TIPSalt sprayed on roads in the winter

may remain well into spring.1. Clean the motorcycle with cold

water and a mild detergent, after

the engine has cooled down.

NOTICE: Do not use warm wa-

ter since it increases the corro-

sive action of the salt.

[ECA10792]

2. Apply a corrosion protection spray on all metal, including chrome-

and nickel-plated, surfaces to pre-

vent corrosion.

After cleanin g

1. Dry the motorcycle with a chamois or an absorbing cloth.

2. Immediately dry the drive chain and lubricate it to prevent it from

rusting.

3. Use a chrome polish to shine chrome, aluminum and stainless-

steel parts, including the exhaust

system. (Even the thermally in-

duced discoloring of stainless-

steel exhaust systems can be re-

moved through polishing.)

UBU2E0E0.book Page 2 Friday, September 9, 2016 9:23 AM

Page 93 of 102

Motorcycle care and stora ge

7-4

7

2. Fill up the fuel tank and add fuel

stabilizer (if available) to prevent

the fuel tank from rusting and the

fuel from deteriorating.

3. Perform the following steps to protect the cylinders, piston rings,

etc. from corrosion.a. Remove the spark plug caps and spark plugs.

b. Pour a teaspoonful of engine oil into each spark plug bore.

c. Install the spark plug caps onto the spark plugs, and then pla-

ce the spark plugs on the cylin-

der head so that the electrodes

are grounded. (This will limit

sparking during the next step.)

d. Turn the engine over several times with the starter. (This will

coat the cylinder walls with oil.)

WARNING! To prevent dam-

a g e or injury from sparkin g,

make sure to groun d the

spark plu g electro des while

turning the en gine over.

[EWA10952]

e. Remove the spark plug caps

from the spark plugs, and then

install the spark plugs and the

spark plug caps.

4. Lubricate all control cables and the pivoting points of all levers and

pedals as well as of the side-

stand/centerstand.

5. Check and, if necessary, correct the tire air pressure, and then lift

the motorcycle so that both of its

wheels are off the ground. Alterna-

tively, turn the wheels a little every

month in order to prevent the tires

from becoming degraded in one

spot.

6. Cover the muffler outlet with a plastic bag to prevent moisture

from entering it.

7. Remove the battery and fully char- ge it. Store it in a cool, dry place

and charge it once a month. Do

not store the battery in an exces-

sively cold or warm place [less

than 0 °C (30 °F) or more than 30

°C (90 °F)]. For more information

on storing the battery, see page

6-31.

TIPMake any necessary repairs before

storing the motorcycle.

UBU2E0E0.book Page 4 Friday, September 9, 2016 9:23 AM

Page 94 of 102

Specifications

8-1

8

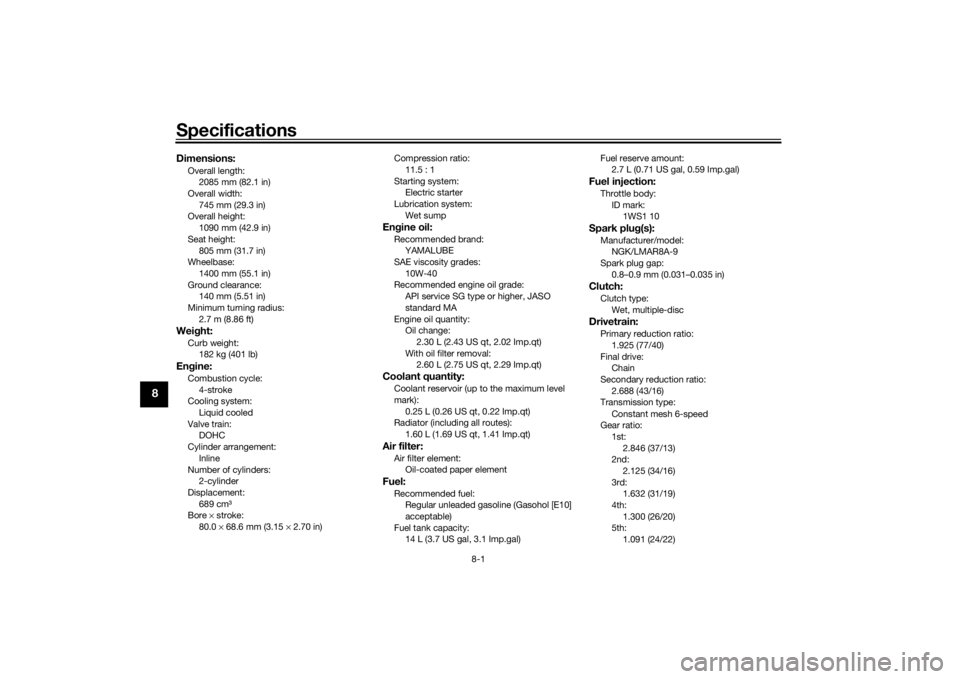

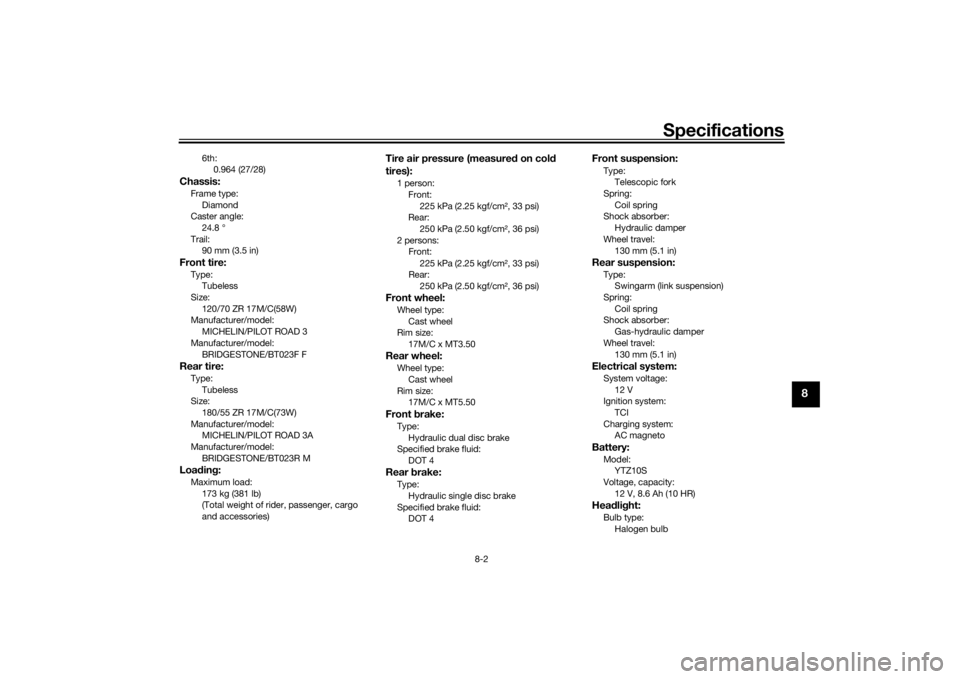

Dimensions:Overall length:2085 mm (82.1 in)

Overall width:

745 mm (29.3 in)

Overall height: 1090 mm (42.9 in)

Seat height: 805 mm (31.7 in)

Wheelbase:

1400 mm (55.1 in)

Ground clearance: 140 mm (5.51 in)

Minimum turning radius: 2.7 m (8.86 ft)Wei ght:Curb weight:

182 kg (401 lb)Engine:Combustion cycle:

4-stroke

Cooling system: Liquid cooled

Valve train: DOHC

Cylinder arrangement:

Inline

Number of cylinders: 2-cylinder

Displacement: 689 cm³

Bore × stroke:

80.0 × 68.6 mm (3.15 × 2.70 in) Compression ratio:

11.5 : 1

Starting system: Electric starter

Lubrication system:

Wet sump

Engine oil:Recommended brand:

YAMALUBE

SAE viscosity grades:

10W-40

Recommended engine oil grade: API service SG type or higher, JASO

standard MA

Engine oil quantity: Oil change:

2.30 L (2.43 US qt, 2.02 Imp.qt)

With oil filter removal: 2.60 L (2.75 US qt, 2.29 Imp.qt)Coolant quantity:Coolant reservoir (up to the maximum level

mark):0.25 L (0.26 US qt, 0.22 Imp.qt)

Radiator (including all routes):

1.60 L (1.69 US qt, 1.41 Imp.qt)Air filter:Air filter element:Oil-coated paper elementFuel:Recommended fuel:Regular unleaded gasoline (Gasohol [E10]

acceptable)

Fuel tank capacity: 14 L (3.7 US gal, 3.1 Imp.gal) Fuel reserve amount:

2.7 L (0.71 US gal, 0.59 Imp.gal)

Fuel injection:Throttle body:

ID mark: 1WS1 10Spark plu g(s):Manufacturer/model:

NGK/LMAR8A-9

Spark plug gap: 0.8–0.9 mm (0.031–0.035 in)Clutch:Clutch type:Wet, multiple-discDrivetrain:Primary reduction ratio:

1.925 (77/40)

Final drive: Chain

Secondary reduction ratio: 2.688 (43/16)

Transmission type:

Constant mesh 6-speed

Gear ratio: 1st:

2.846 (37/13)

2nd: 2.125 (34/16)

3rd: 1.632 (31/19)

4th:

1.300 (26/20)

5th: 1.091 (24/22)

UBU2E0E0.book Page 1 Friday, September 9, 2016 9:23 AM

Page 95 of 102

Specifications

8-2

8

6th:0.964 (27/28)

Chassis:Frame type:

Diamond

Caster angle: 24.8 °

Trail: 90 mm (3.5 in)Front tire:Type:Tubeless

Size: 120/70 ZR 17M/C(58W)

Manufacturer/model:

MICHELIN/PILOT ROAD 3

Manufacturer/model: BRIDGESTONE/BT023F FRear tire:Type:

Tubeless

Size: 180/55 ZR 17M/C(73W)

Manufacturer/model: MICHELIN/PILOT ROAD 3A

Manufacturer/model:

BRIDGESTONE/BT023R MLoa din g:Maximum load:

173 kg (381 lb)

(Total weight of rider, passenger, cargo

and accessories)

Tire air pressure (measure d on col d

tires):1 person:

Front:225 kPa (2.25 kgf/cm², 33 psi)

Rear:

250 kPa (2.50 kgf/cm², 36 psi)

2 persons: Front:

225 kPa (2.25 kgf/cm², 33 psi)

Rear: 250 kPa (2.50 kgf/cm², 36 psi)Front wheel:Wheel type:

Cast wheel

Rim size: 17M/C x MT3.50Rear wheel:Wheel type:

Cast wheel

Rim size: 17M/C x MT5.50Front brake:Type:

Hydraulic dual disc brake

Specified brake fluid: DOT 4Rear brake:Type:

Hydraulic single disc brake

Specified brake fluid: DOT 4

Front suspension:Type:Telescopic fork

Spring:

Coil spring

Shock absorber: Hydraulic damper

Wheel travel: 130 mm (5.1 in)Rear suspension:Type:Swingarm (link suspension)

Spring: Coil spring

Shock absorber:

Gas-hydraulic damper

Wheel travel: 130 mm (5.1 in)Electrical system:System voltage:

12 V

Ignition system: TCI

Charging system: AC magnetoBattery:Model:YTZ10S

Voltage, capacity: 12 V, 8.6 Ah (10 HR)Hea dlig ht:Bulb type:

Halogen bulb

UBU2E0E0.book Page 2 Friday, September 9, 2016 9:23 AM

Page 100 of 102

Index

10-2

10

Tires ...................................................... 6-18

Tool kit .................................................... 6-2

Troubleshooting .................................... 6-38

Troubleshooting charts ......................... 6-39

Turn signal indicator lights ...................... 3-4

Turn signal light bulb, replacing............ 6-36

Turn signal switch ................................. 3-13VValve clearance..................................... 6-17

Vehicle identification number ................. 9-1WWheel bearings, checking..................... 6-30

Wheels .................................................. 6-20

UBU2E0E0.book Page 2 Friday, September 9, 2016 9:23 AM