torque YAMAHA MT-07 2022 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2022, Model line: MT-07, Model: YAMAHA MT-07 2022Pages: 100, PDF Size: 3.66 MB

Page 52 of 100

Periodic maintenance an d a djustment

6-2

6

EAU85240

Tool kitsThe on–board tool kit is in the location

shown. Also, an additional tool kit was

handed out separately at the time of

vehicle purchase.

The information included in this manual

and the tools provided in the tool kits

are intended to assist you in the perfor-

mance of preventive maintenance and

minor repairs. However, a torque

wrench and other tools are necessary

to perform certain maintenance work

correctly.

TIPIf you do not have the tools or experi-

ence required for a particular job, have

your Yamaha dealer perform it for you.

1. Tool kit

1

UBATE1E0.book Page 2 Thursday, September 2, 2021 10:34 AM

Page 59 of 100

Periodic maintenance an d a djustment

6-9

6

EAU19653

Checkin g the spark plugsThe spark plugs are important engine

components, which should be

checked periodically, preferably by a

Yamaha dealer. Since heat and depos- its will cause any spark plug to slowly

erode, they should be removed and

checked in accordance with the peri-

odic maintenance and lubrication

chart. In addition, the condition of the

spark plugs can reveal the condition of

the engine.

The porcelain insulator around the

center electrode of each spark plug

should be a medium-to-light tan (the

ideal color when the vehicle is ridden

normally), and all spark plugs installed

in the engine should have the same

color. If any spark plug shows a dis-

tinctly different color, the engine could

be operating improperly. Do not at-

tempt to diagnose such problems

yourself. Instead, have a Yamaha deal-

er check the vehicle.

If a spark plug shows signs of elec-

trode erosion and excessive carbon or

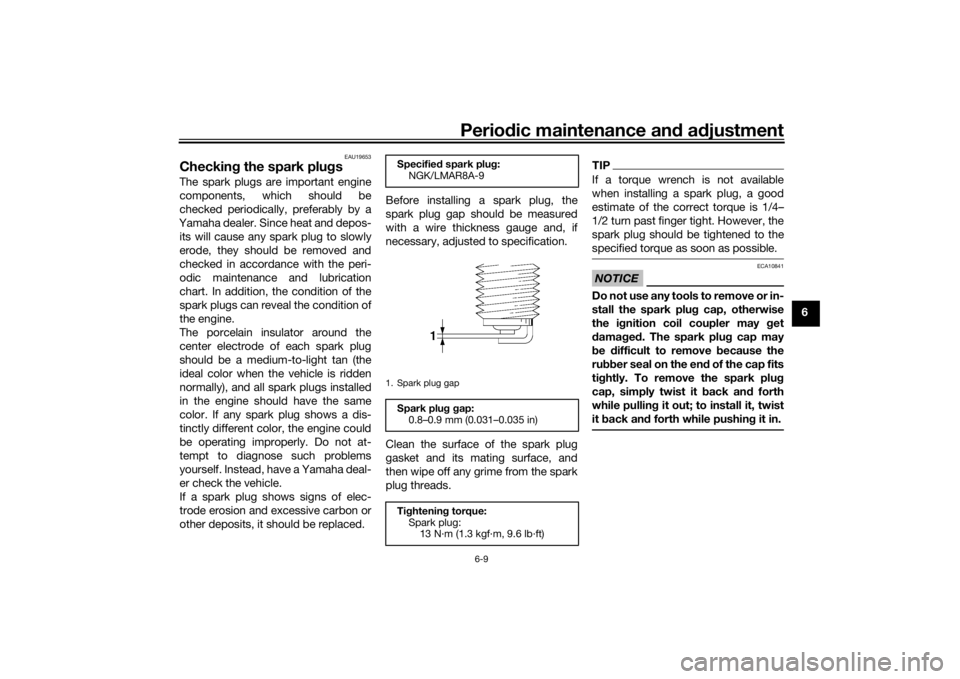

other deposits, it should be replaced. Before installing a spark plug, the

spark plug gap should be measured

with a wire thickness gauge and, if

necessary, adjusted to specification.

Clean the surface of the spark plug

gasket and its mating surface, and

then wipe off any grime from the spark

plug threads.

TIPIf a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is 1/4…

1/2 turn past finger tight. However, the

spark plug should be tightened to the

specified torque as soon as possible.NOTICE

ECA10841

Do not use any tools to remove or in-

stall the spark plu

g cap, otherwise

the i gnition coil coupler may get

d amag ed . The spark plu g cap may

b e difficult to remove because the

ru bber seal on the en d of the cap fits

ti g htly. To remove the spark plu g

cap, simply twist it b ack and forth

while pullin g it out; to install it, twist

it back an d forth while pushin g it in.

Specified spark plu g:

NGK/LMAR8A-9

1. Spark plug gap

Spark plu g g ap:

0.8–0.9 mm (0.031–0.035 in)

Ti ghtenin g torque:

Spark plug: 13 N·m (1.3 kgf·m, 9.6 lb·ft)

UBATE1E0.book Page 9 Thursday, September 2, 2021 10:34 AM

Page 61 of 100

Periodic maintenance an d a djustment

6-11

6

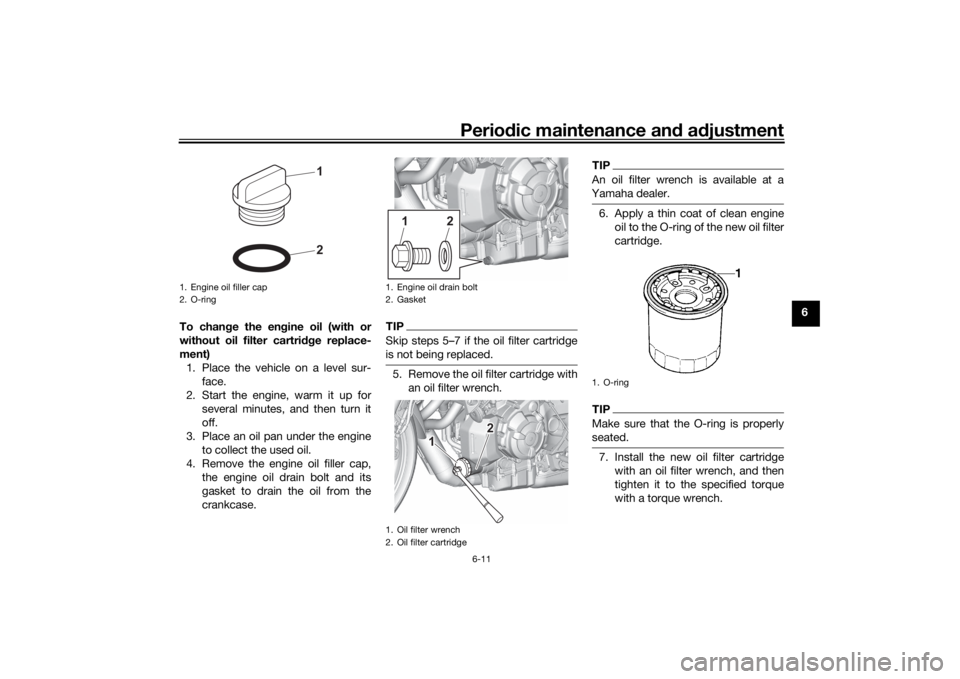

To chan ge the en gine oil (with or

without oil filter cartri dge replace-

ment) 1. Place the vehicle on a level sur- face.

2. Start the engine, warm it up for several minutes, and then turn it

off.

3. Place an oil pan under the engine to collect the used oil.

4. Remove the engine oil filler cap, the engine oil drain bolt and its

gasket to drain the oil from the

crankcase.

TIPSkip steps 5…7 if the oil filter cartridge

is not being replaced.5. Remove the oil filter cartridge withan oil filter wrench.

TIPAn oil filter wrench is available at a

Yamaha dealer.6. Apply a thin coat of clean engineoil to the O-ring of the new oil filter

cartridge.TIPMake sure that the O-ring is properly

seated.7. Install the new oil filter cartridgewith an oil filter wrench, and then

tighten it to the specified torque

with a torque wrench.

1. Engine oil filler cap

2. O-ring

21

1. Engine oil drain bolt

2. Gasket

1. Oil filter wrench

2. Oil filter cartridge

2

1

1 1 1 2 2

1. O-ring

UBATE1E0.book Page 11 Thursday, September 2, 2021 10:34 AM

Page 62 of 100

Periodic maintenance an d a djustment

6-12

6

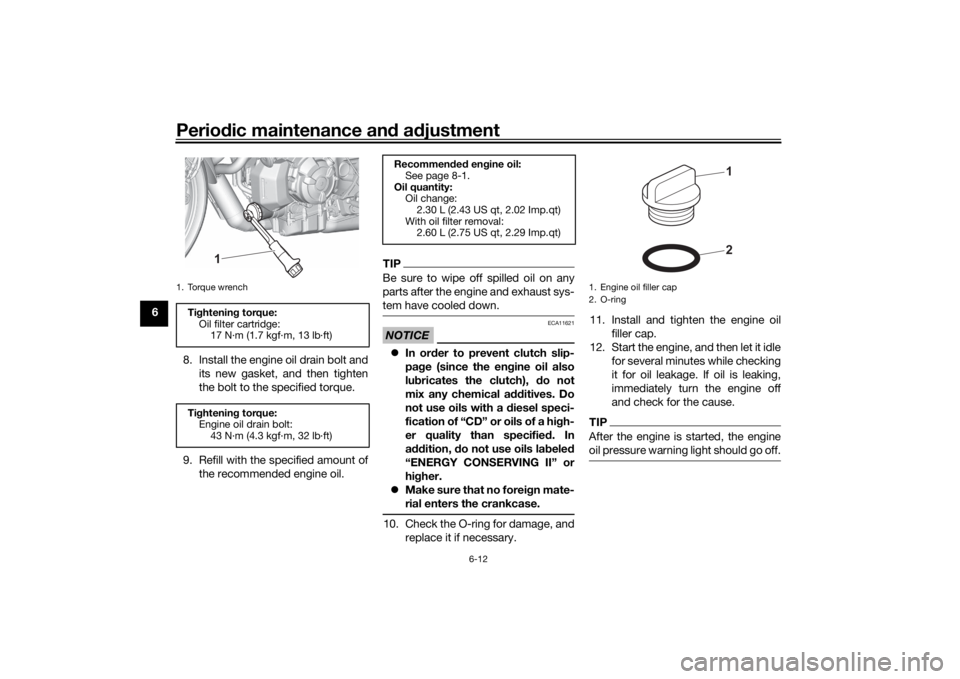

8. Install the engine oil drain bolt andits new gasket, and then tighten

the bolt to the specified torque.

9. Refill with the specified amount of the recommended engine oil.

TIPBe sure to wipe off spilled oil on any

parts after the engine and exhaust sys-

tem have cooled down.NOTICE

ECA11621

In or der to prevent clutch slip-

pa ge (since the en gine oil also

lu bricates the clutch), do not

mix any chemical additives. Do

not use oils with a diesel speci-

fication of “CD” or oils of a hi gh-

er quality than specifie d. In

a ddition, do not use oils la beled

“ENERGY CONSERVING II” or

hi gher.

Make sure that no forei gn mate-

rial enters the crankcase.10. Check the O-ring for damage, and replace it if necessary. 11. Install and tighten the engine oil

filler cap.

12. Start the engine, and then let it idle for several minutes while checking

it for oil leakage. If oil is leaking,

immediately turn the engine off

and check for the cause.

TIPAfter the engine is started, the engine

oil pressure warning light should go off.

1. Torque wrenchTightenin g torque:

Oil filter cartridge: 17 N·m (1.7 kgf·m, 13 lb·ft)

Ti ghtenin g torque:

Engine oil drain bolt:

43 N·m (4.3 kgf·m, 32 lb·ft)

1

Recommen ded en gine oil:

See page 8-1.

Oil quantity: Oil change:

2.30 L (2.43 US qt, 2.02 Imp.qt)

With oil filter removal: 2.60 L (2.75 US qt, 2.29 Imp.qt)

1. Engine oil filler cap

2. O-ring

21

UBATE1E0.book Page 12 Thursday, September 2, 2021 10:34 AM

Page 74 of 100

Periodic maintenance an d a djustment

6-24

6

EAU59921

To a djust the d rive chain slack

Consult a Yamaha dealer before ad-

justing the drive chain slack. 1. Loosen the locknut at each end of the swingarm, and then loosen the

axle nut.

2. To tighten the drive chain, turn the drive chain slack adjusting nut at

each end of the swingarm in direc-

tion (a). To loosen the drive chain,

turn the adjusting nut at each end

of the swingarm in direction (b),

and then push the rear wheel for-

ward.

TIPUsing the alignment marks on each

side of the swingarm, make sure that

both drive chain slack adjusting plates

are in the same position for proper

wheel alignment.

3. Tighten the axle nut, and thentighten the locknuts to the speci-

fied torques.

4. Make sure that the drive chain slack adjusting plates are in the

same position, the drive chain

slack is correct, and the drive

chain moves smoothly.

1. Axle nut

2. Locknut

1 1 1 2 2

1. Drive chain slack adjusting nut

1. Alignment marks

2. Drive chain slack adjusting plate

1 1 1

(a) (a) (a)

(b) (b) (b)

111

22

Ti ghtenin g torques:

Axle nut: 105 N·m (10.5 kgf·m, 77 lb·ft)

Locknut:

16 N·m (1.6 kgf·m, 12 lb·ft)

UBATE1E0.book Page 24 Thursday, September 2, 2021 10:34 AM