lock YAMAHA MT-09 2014 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: MT-09, Model: YAMAHA MT-09 2014Pages: 110, PDF Size: 3.21 MB

Page 36 of 110

INSTRUMENT AND CONTROL FUNCTIONS

3-21

3

NOTICE

ECA10702

Use only unleaded g asoline. The use

of lead ed g asoline will cause unre-

pairab le damag e to the catalytic

converter.

EAU57991

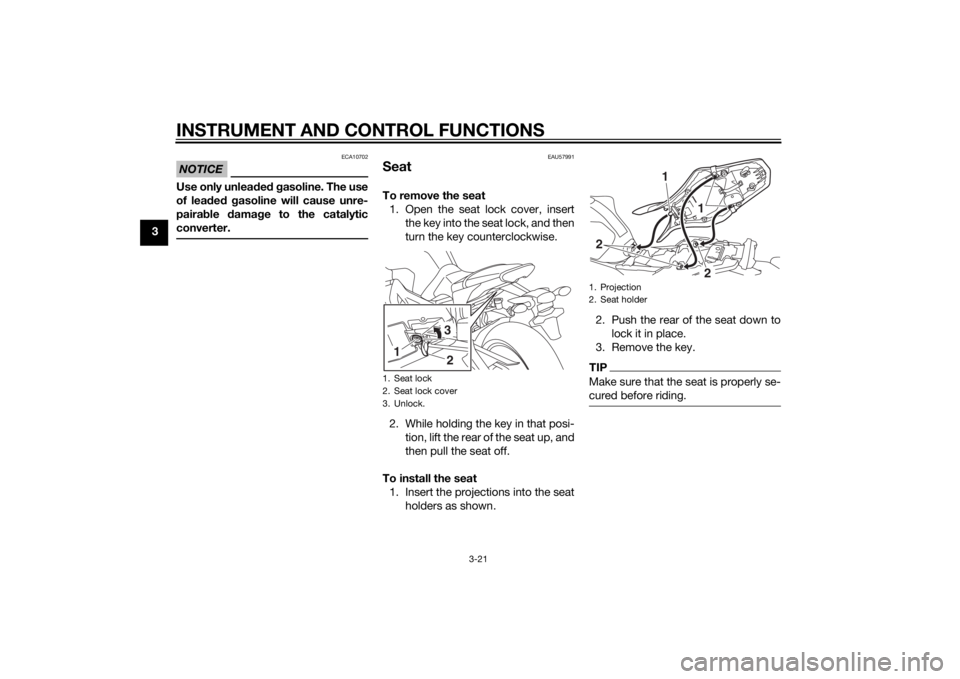

SeatTo remove the seat 1. Open the seat lock cover, insert the key into the seat lock, and then

turn the key counterclockwise.

2. While holding the key in that posi- tion, lift the rear of the seat up, and

then pull the seat off.

To install the seat 1. Insert the projections into the seat holders as shown. 2. Push the rear of the seat down to

lock it in place.

3. Remove the key.

TIPMake sure that the seat is properly se-

cured before riding.

1. Seat lock

2. Seat lock cover

3. Unlock.1

32

1. Projection

2. Seat holder

1

2

21

U1RCELE0.book Page 21 Monday, May 12, 2014 8:51 AM

Page 73 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-22

6

Use only the specifie d b rake flu-

i d ; otherwise, the ru bber seals

may deteriorate, causin g leak-

a g e.

Refill with the same type of

brake flui d. A ddin g a brake flui d

other than DOT 4 may result in a

harmful chemical reaction.

Be careful that water or dust

d oes not enter the brake flui d

reservoir when refillin g. Water

will si gnificantly lower the boil-

in g point of the flui d an d may re-

sult in vapor lock, an d d irt may

clo g the ABS hy draulic unit

valves.

NOTICE

ECA17641

Brake flui d may d amage painte d

surfaces or plastic parts. Always

clean up spille d flui d imme diately.As the brake pads wear, it is normal for

the brake fluid level to gradually go

down. A low brake fluid level may indi-

cate worn brake pads and/or brake

system leakage; therefore, be sure to

check the brake pads for wear and the

brake system for leakage. If the brake fluid level goes down suddenly, have a

Yamaha dealer check the cause before

further riding.

EAU22733

Chan

gin g the brake flui dHave a Yamaha dealer change the

brake fluid at the intervals specified in

the periodic maintenance and lubrica-

tion chart. In addition, have the oil seals

of the master cylinders and calipers as

well as the brake hoses replaced at the

intervals listed below or whenever they

are damaged or leaking.

Oil seals: Replace every two

years.

Brake hoses: Replace every four

years.

U1RCELE0.book Page 22 Monday, May 12, 2014 8:51 AM

Page 74 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-23

6

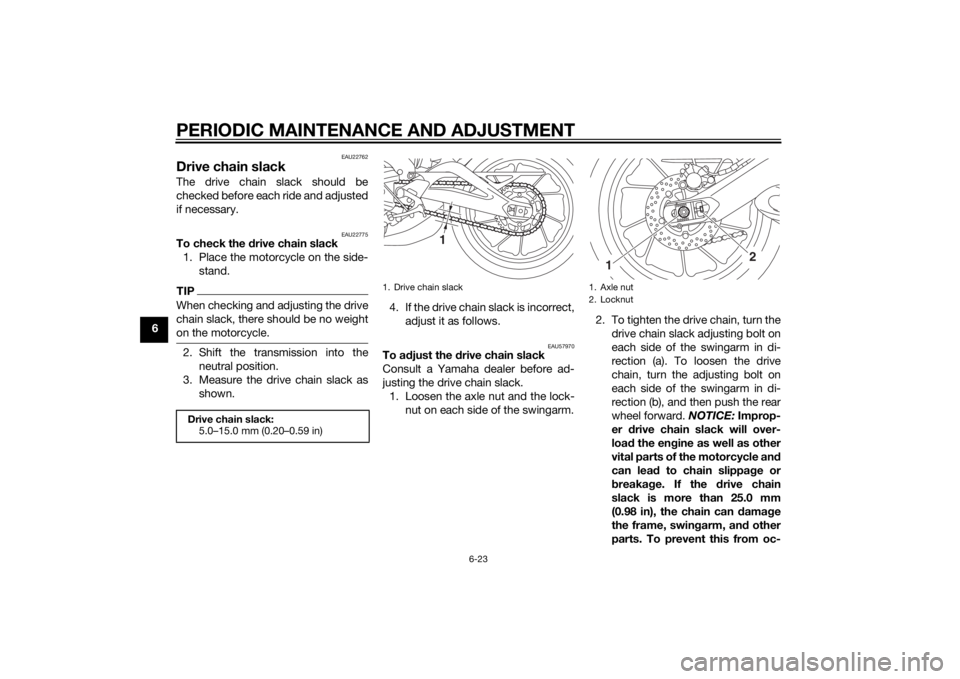

EAU22762

Drive chain slackThe drive chain slack should be

checked before each ride and adjusted

if necessary.

EAU22775

To check the drive chain slack

1. Place the motorcycle on the side- stand.TIPWhen checking and adjusting the drive

chain slack, there should be no weight

on the motorcycle.2. Shift the transmission into theneutral position.

3. Measure the drive chain slack as shown. 4. If the drive chain slack is incorrect,

adjust it as follows.

EAU57970

To a djust the drive chain slack

Consult a Yamaha dealer before ad-

justing the drive chain slack. 1. Loosen the axle nut and the lock- nut on each side of the swingarm. 2. To tighten the drive chain, turn the

drive chain slack adjusting bolt on

each side of the swingarm in di-

rection (a). To loosen the drive

chain, turn the adjusting bolt on

each side of the swingarm in di-

rection (b), and then push the rear

wheel forward. NOTICE: Improp-

er drive chain slack will over-

loa d the en gine as well as other

vital parts of the motorcycle an d

can lead to chain slippa ge or

b reakag e. If the drive chain

slack is more than 25.0 mm

(0.98 in), the chain can damag e

the frame, swin garm, an d other

parts. To prevent this from oc-

Drive chain slack: 5.0–15.0 mm (0.20–0.59 in)

1. Drive chain slack

1

1. Axle nut

2. Locknut

2

1

U1RCELE0.book Page 23 Monday, May 12, 2014 8:51 AM

Page 75 of 110

![YAMAHA MT-09 2014 User Guide PERIODIC MAINTENANCE AND ADJUSTMENT

6-24

6

currin

g, keep the d rive chain

slack within the specified limits.

[ECA17791]

TIPUsing the alignment marks and notch

on each side of the swingarm, make

sure YAMAHA MT-09 2014 User Guide PERIODIC MAINTENANCE AND ADJUSTMENT

6-24

6

currin

g, keep the d rive chain

slack within the specified limits.

[ECA17791]

TIPUsing the alignment marks and notch

on each side of the swingarm, make

sure](/img/51/50895/w960_50895-74.png)

PERIODIC MAINTENANCE AND ADJUSTMENT

6-24

6

currin

g, keep the d rive chain

slack within the specified limits.

[ECA17791]

TIPUsing the alignment marks and notch

on each side of the swingarm, make

sure that both drive chain pullers are in

the same position for proper wheel

alignment.

3. Tighten the axle nut, then the lock-

nuts to their specified torques.

4. Make sure that the drive chain pullers are in the same position,

the drive chain slack is correct,

and the drive chain moves

smoothly.

EAU23026

Cleanin g an d lu bricatin g the

d rive chainThe drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly wear

out, especially when riding in dusty or

wet areas. Service the drive chain as

follows.NOTICE

ECA10584

The drive chain must b e lubricate d

after washin g the motorcycle, ri din g

in the rain or ri din g in wet areas.1. Clean the drive chain with kero-

sene and a small soft brush.

NOTICE: To prevent d amaging

the O-rin gs, do not clean the

d rive chain with steam cleaners,

hi gh-pressure washers or inap-

propriate solvents.

[ECA11122]

2. Wipe the drive chain dry.

3. Thoroughly lubricate the drive chain with a special O-ring chain

lubricant. NOTICE: Do not use

en gine oil or any other lu bri-

cants for the drive chain, as they

1. Drive chain slack adjusting bolt

(a)(b)

1

1. Notch

2. Alignment marks

3. Drive chain puller

Ti ghtenin g torques:

Axle nut:

150 Nm (15 m·kgf, 108 ft·lbf)

Locknut: 16 Nm (1.6 m·kgf, 12 ft·lbf)

3

12

U1RCELE0.book Page 24 Monday, May 12, 2014 8:51 AM

Page 83 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-32

6

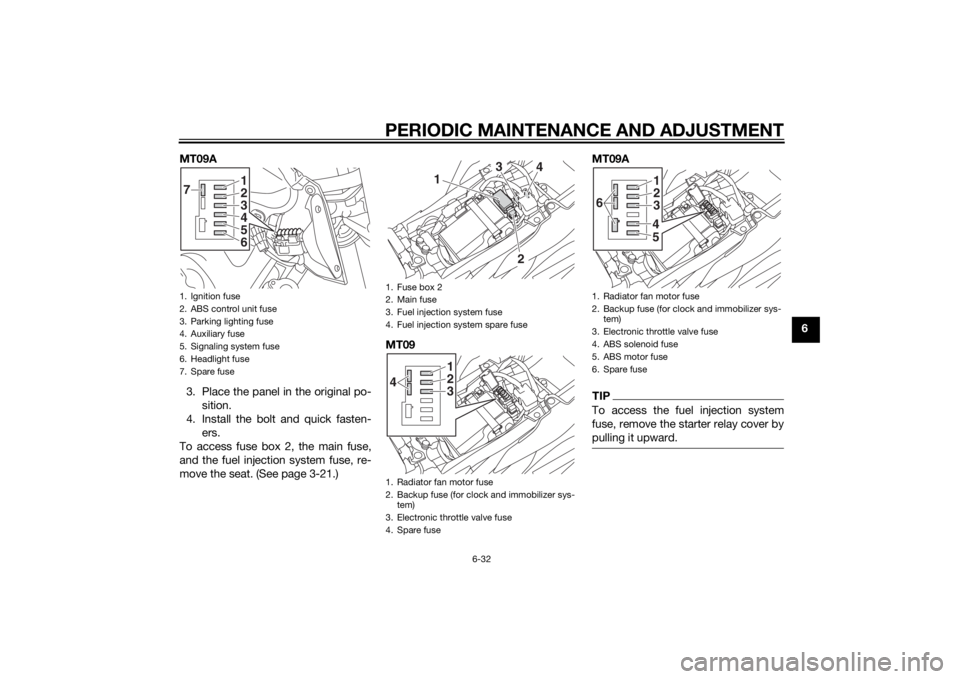

MT09A

3. Place the panel in the original po- sition.

4. Install the bolt and quick fasten- ers.

To access fuse box 2, the main fuse,

and the fuel injection system fuse, re-

move the seat. (See page 3-21.) MT09 MT09A

TIPTo access the fuel injection system

fuse, remove the starter relay cover by

pulling it upward.

1. Ignition fuse

2. ABS control unit fuse

3. Parking lighting fuse

4. Auxiliary fuse

5. Signaling system fuse

6. Headlight fuse

7. Spare fuse

123

7

456

1. Fuse box 2

2. Main fuse

3. Fuel injection system fuse

4. Fuel injection system spare fuse

1. Radiator fan motor fuse

2. Backup fuse (for clock and immobilizer sys-

tem)

3. Electronic throttle valve fuse

4. Spare fuse

2

3

4

1

123

4

1. Radiator fan motor fuse

2. Backup fuse (for clock and immobilizer sys-

tem)

3. Electronic throttle valve fuse

4. ABS solenoid fuse

5. ABS motor fuse

6. Spare fuse

123

6

45

U1RCELE0.book Page 32 Monday, May 12, 2014 8:51 AM

Page 87 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-36

6

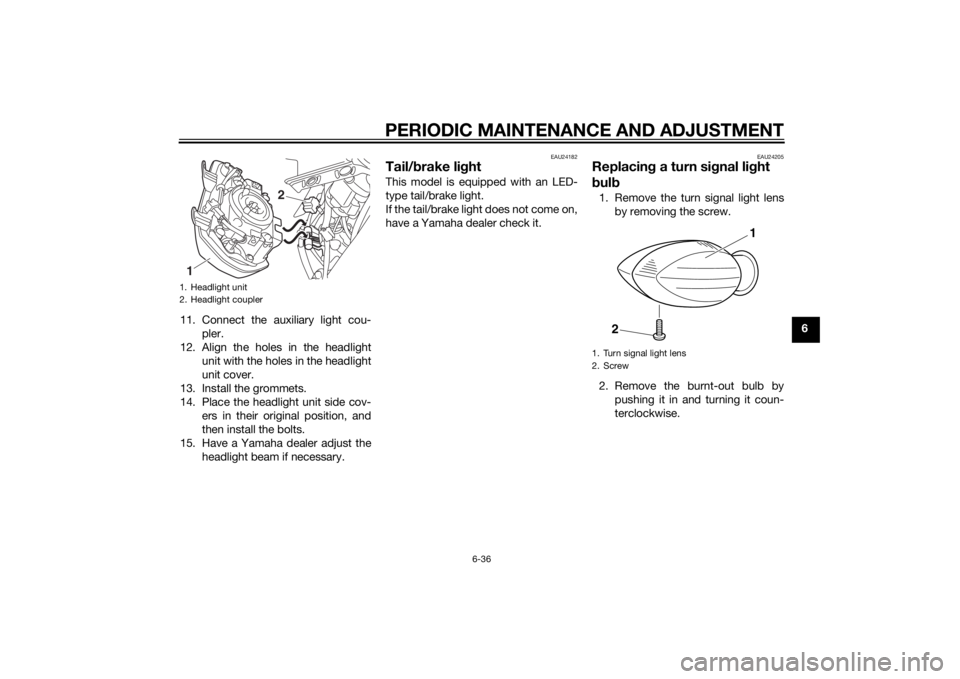

11. Connect the auxiliary light cou-

pler.

12. Align the holes in the headlight unit with the holes in the headlight

unit cover.

13. Install the grommets.

14. Place the headlight unit side cov- ers in their original position, and

then install the bolts.

15. Have a Yamaha dealer adjust the headlight beam if necessary.

EAU24182

Tail/b rake li ghtThis model is equipped with an LED-

type tail/brake light.

If the tail/brake light does not come on,

have a Yamaha dealer check it.

EAU24205

Replacin g a turn sig nal light

b ul b1. Remove the turn signal light lens

by removing the screw.

2. Remove the burnt-out bulb by pushing it in and turning it coun-

terclockwise.

1. Headlight unit

2. Headlight coupler1

2

1. Turn signal light lens

2. Screw

1

2

U1RCELE0.book Page 36 Monday, May 12, 2014 8:51 AM

Page 88 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-37

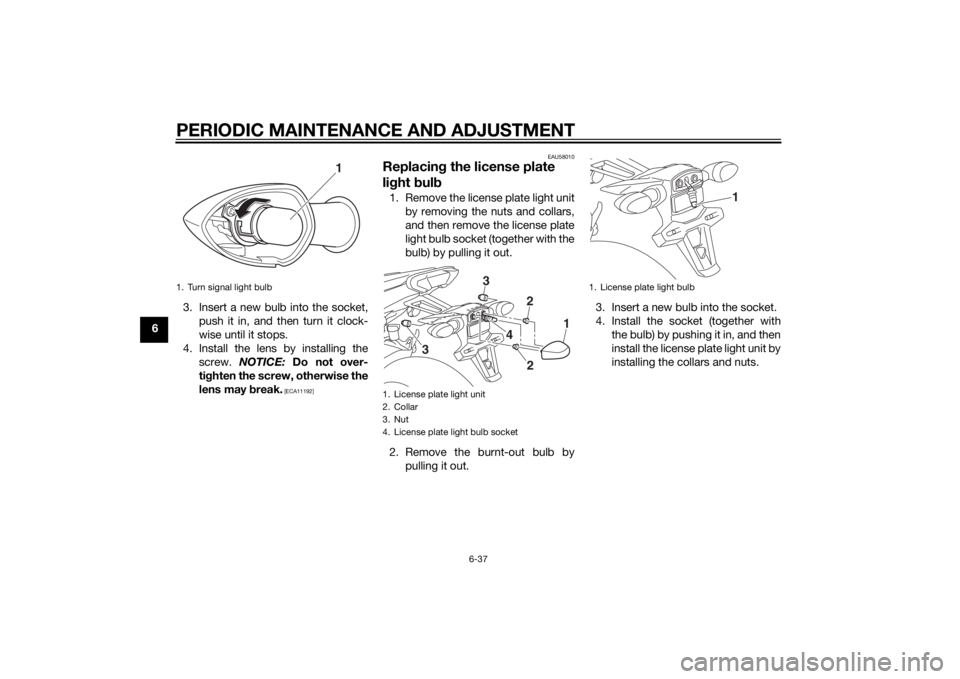

63. Insert a new bulb into the socket,

push it in, and then turn it clock-

wise until it stops.

4. Install the lens by installing the screw. NOTICE: Do not over-

ti g hten the screw, otherwise the

lens may break.

[ECA11192] EAU58010

Replacin

g the license plate

li g ht bul b1. Remove the license plate light unit

by removing the nuts and collars,

and then remove the license plate

light bulb socket (together with the

bulb) by pulling it out.

2. Remove the burnt-out bulb by pulling it out. 3. Insert a new bulb into the socket.

4. Install the socket (together with

the bulb) by pushing it in, and then

install the license plate light unit by

installing the collars and nuts.

1. Turn signal light bulb

1

1. License plate light unit

2. Collar

3. Nut

4. License plate light bulb socket

1

22

4

3

3

1. License plate light bulb

1

U1RCELE0.book Page 37 Monday, May 12, 2014 8:51 AM

Page 89 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-38

6

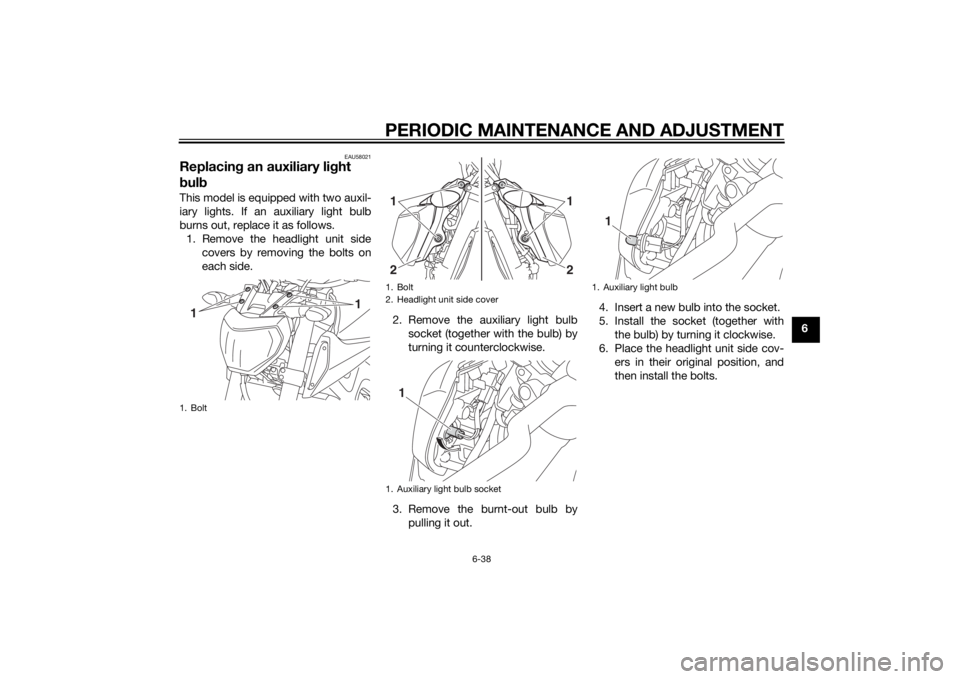

EAU58021

Replacing an auxiliary li ght

b ul bThis model is equipped with two auxil-

iary lights. If an auxiliary light bulb

burns out, replace it as follows.

1. Remove the headlight unit side covers by removing the bolts on

each side.

2. Remove the auxiliary light bulbsocket (together with the bulb) by

turning it counterclockwise.

3. Remove the burnt-out bulb by pulling it out. 4. Insert a new bulb into the socket.

5. Install the socket (together with

the bulb) by turning it clockwise.

6. Place the headlight unit side cov- ers in their original position, and

then install the bolts.1. Bolt

1

1

1. Bolt

2. Headlight unit side cover

1. Auxiliary light bulb socket1

1

2

2

1

1. Auxiliary light bulb

1

U1RCELE0.book Page 38 Monday, May 12, 2014 8:51 AM

Page 92 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-41

6

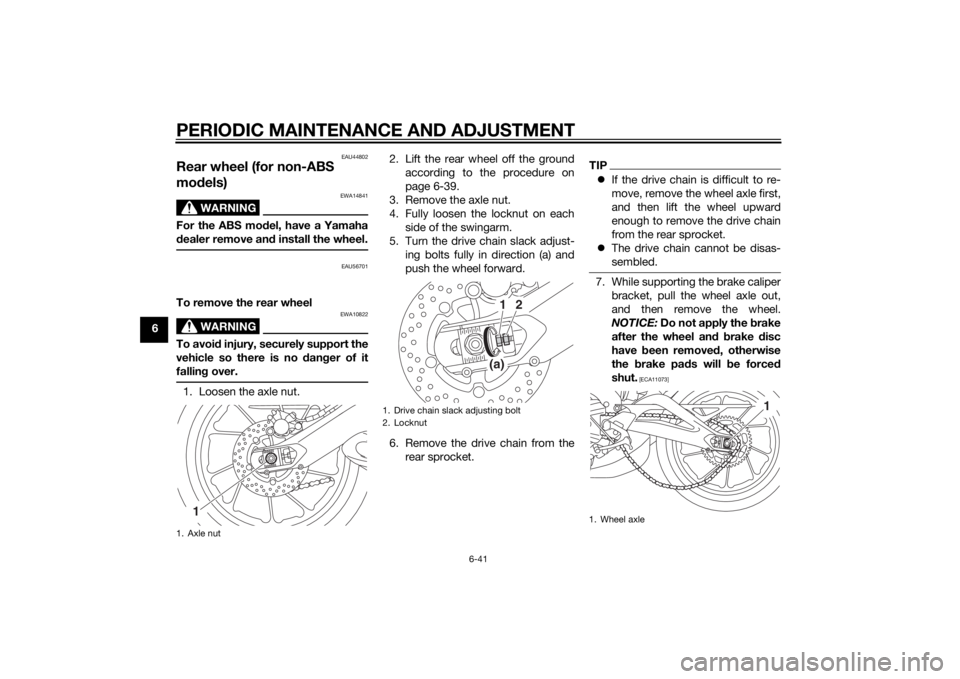

EAU44802

Rear wheel (for non-ABS

models)

WARNING

EWA14841

For the ABS mo del, have a Yamaha

d ealer remove an d install the wheel.

EAU56701

To remove the rear wheel

WARNING

EWA10822

To avoi d injury, securely support the

vehicle so there is no dan ger of it

fallin g over.1. Loosen the axle nut. 2. Lift the rear wheel off the ground

according to the procedure on

page 6-39.

3. Remove the axle nut.

4. Fully loosen the locknut on each side of the swingarm.

5. Turn the drive chain slack adjust- ing bolts fully in direction (a) and

push the wheel forward.

6. Remove the drive chain from the rear sprocket.

TIPIf the drive chain is difficult to re-

move, remove the wheel axle first,

and then lift the wheel upward

enough to remove the drive chain

from the rear sprocket.

The drive chain cannot be disas-

sembled.7. While supporting the brake caliper

bracket, pull the wheel axle out,

and then remove the wheel.

NOTICE: Do not apply the b rake

after the wheel an d b rake disc

have been removed , otherwise

the brake pa ds will be forced

shut.

[ECA11073]

1. Axle nut

1

1. Drive chain slack adjusting bolt

2. Locknut

(a)1

2

1. Wheel axle

1

U1RCELE0.book Page 41 Monday, May 12, 2014 8:51 AM

Page 93 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-42

6

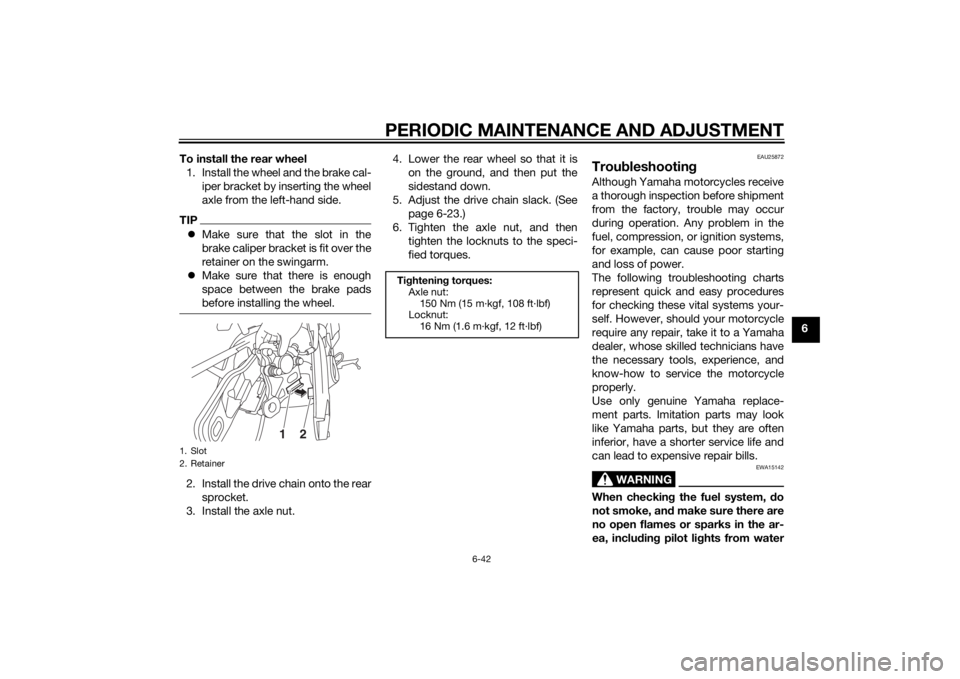

To install the rear wheel

1. Install the wheel and the brake cal- iper bracket by inserting the wheel

axle from the left-hand side.

TIPMake sure that the slot in the

brake caliper bracket is fit over the

retainer on the swingarm.

Make sure that there is enough

space between the brake pads

before installing the wheel.2. Install the drive chain onto the rear

sprocket.

3. Install the axle nut. 4. Lower the rear wheel so that it is

on the ground, and then put the

sidestand down.

5. Adjust the drive chain slack. (See page 6-23.)

6. Tighten the axle nut, and then tighten the locknuts to the speci-

fied torques.

EAU25872

Trou bleshootin gAlthough Yamaha motorcycles receive

a thorough inspection before shipment

from the factory, trouble may occur

during operation. Any problem in the

fuel, compression, or ignition systems,

for example, can cause poor starting

and loss of power.

The following troubleshooting charts

represent quick and easy procedures

for checking these vital systems your-

self. However, should your motorcycle

require any repair, take it to a Yamaha

dealer, whose skilled technicians have

the necessary tools, experience, and

know-how to service the motorcycle

properly.

Use only genuine Yamaha replace-

ment parts. Imitation parts may look

like Yamaha parts, but they are often

inferior, have a shorter service life and

can lead to expensive repair bills.

WARNING

EWA15142

When checkin g the fuel system, d o

not smoke, an d make sure there are

no open flames or sparks in the ar-

ea, inclu din g pilot li ghts from water

1. Slot

2. Retainer

2

1

Ti ghtenin g torques:

Axle nut: 150 Nm (15 m·kgf, 108 ft·lbf)

Locknut:

16 Nm (1.6 m·kgf, 12 ft·lbf)

U1RCELE0.book Page 42 Monday, May 12, 2014 8:51 AM