light YAMAHA MT-09 2014 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: MT-09, Model: YAMAHA MT-09 2014Pages: 110, PDF Size: 3.21 MB

Page 50 of 110

OPERATION AND IMPORTANT RIDING POINTS

5-4

5

EAU58280

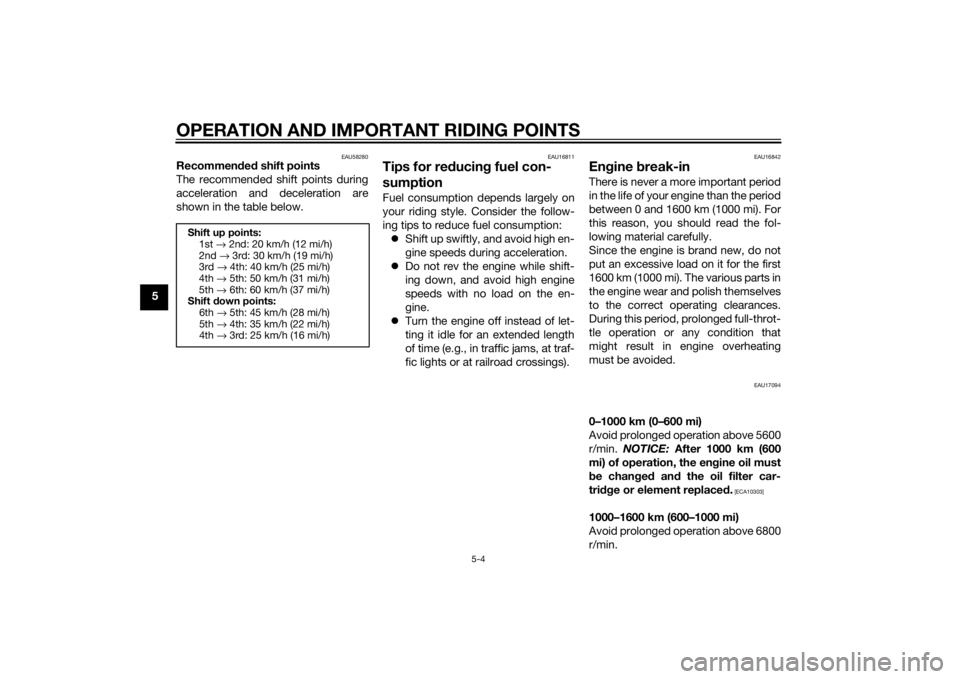

Recommended shift points

The recommended shift points during

acceleration and deceleration are

shown in the table below.

EAU16811

Tips for re ducin g fuel con-

sumptionFuel consumption depends largely on

your riding style. Consider the follow-

ing tips to reduce fuel consumption:

Shift up swiftly, and avoid high en-

gine speeds during acceleration.

Do not rev the engine while shift-

ing down, and avoid high engine

speeds with no load on the en-

gine.

Turn the engine off instead of let-

ting it idle for an extended length

of time (e.g., in traffic jams, at traf-

fic lights or at railroad crossings).

EAU16842

Engine break-inThere is never a more important period

in the life of your engine than the period

between 0 and 1600 km (1000 mi). For

this reason, you should read the fol-

lowing material carefully.

Since the engine is brand new, do not

put an excessive load on it for the first

1600 km (1000 mi). The various parts in

the engine wear and polish themselves

to the correct operating clearances.

During this period, prolonged full-throt-

tle operation or any condition that

might result in engine overheating

must be avoided.

EAU17094

0–1000 km (0–600 mi)

Avoid prolonged operation above 5600

r/min. NOTICE: After 1000 km (600

mi) of operation, the en gine oil must

b e chan ged an d the oil filter car-

tri dge or element replace d.

[ECA10303]

1000–1600 km (600–1000 mi)

Avoid prolonged operation above 6800

r/min.

Shift up points:

1st → 2nd: 20 km/h (12 mi/h)

2nd → 3rd: 30 km/h (19 mi/h)

3rd → 4th: 40 km/h (25 mi/h)

4th → 5th: 50 km/h (31 mi/h)

5th → 6th: 60 km/h (37 mi/h)

Shift down points:

6th → 5th: 45 km/h (28 mi/h)

5th → 4th: 35 km/h (22 mi/h)

4th → 3rd: 25 km/h (16 mi/h)

U1RCELE0.book Page 4 Monday, May 12, 2014 8:51 AM

Page 57 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-6

6

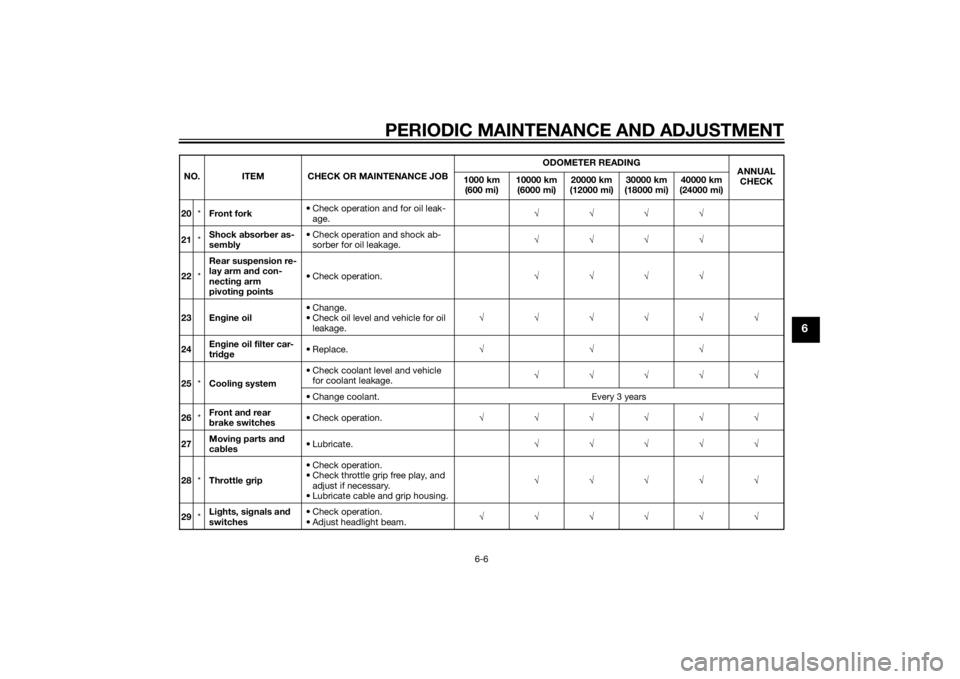

20*Front fork • Check operation and for oil leak-

age. √√√√

21 *Shock a

bsor ber as-

sem bly • Check operation and shock ab-

sorber for oil leakage. √√√√

22 *Rear suspension re-

lay arm an

d con-

nectin g arm

pivotin g points • Check operation.

√√√√

23 En gine oil • Change.

• Check oil level and vehicle for oil

leakage. √√√√√√

24 En

gine oil filter car-

tri dg e •Replace.

√√√

25 *Coolin g system • Check coolant level and vehicle

for coolant leakage. √√√√√

• Change coolant. Every 3 years

26 *Front an

d rear

b rake switches • Check operation.

√√√√√√

27 Movin

g parts an d

ca bles • Lubricate.

√√√√√

28 *Throttle g rip • Check operation.

• Check throttle grip free play, and

adjust if necessary.

• Lubricate cable and grip housing. √√√√√

29 *Li

ghts, si gnals an d

switches • Check operation.

• Adjust headlight beam.

√√√√√√

NO. ITEM CHECK OR MAINTENANCE JOB

OD OMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 10000 km

(6000 mi) 20000 km

(12000 mi) 30000 km

(18000 mi) 40000 km

(24000 mi)

U1RCELE0.book Page 6 Monday, May 12, 2014 8:51 AM

Page 59 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-8

6

EAU19653

Checking the spark plug sThe spark plugs are important engine

components, which should be

checked periodically, preferably by a

Yamaha dealer. Since heat and depos- its will cause any spark plug to slowly

erode, they should be removed and

checked in accordance with the peri-

odic maintenance and lubrication

chart. In addition, the condition of the

spark plugs can reveal the condition of

the engine.

The porcelain insulator around the

center electrode of each spark plug

should be a medium-to-light tan (the

ideal color when the vehicle is ridden

normally), and all spark plugs installed

in the engine should have the same

color. If any spark plug shows a dis-

tinctly different color, the engine could

be operating improperly. Do not at-

tempt to diagnose such problems

yourself. Instead, have a Yamaha deal-

er check the vehicle.

If a spark plug shows signs of elec-

trode erosion and excessive carbon or

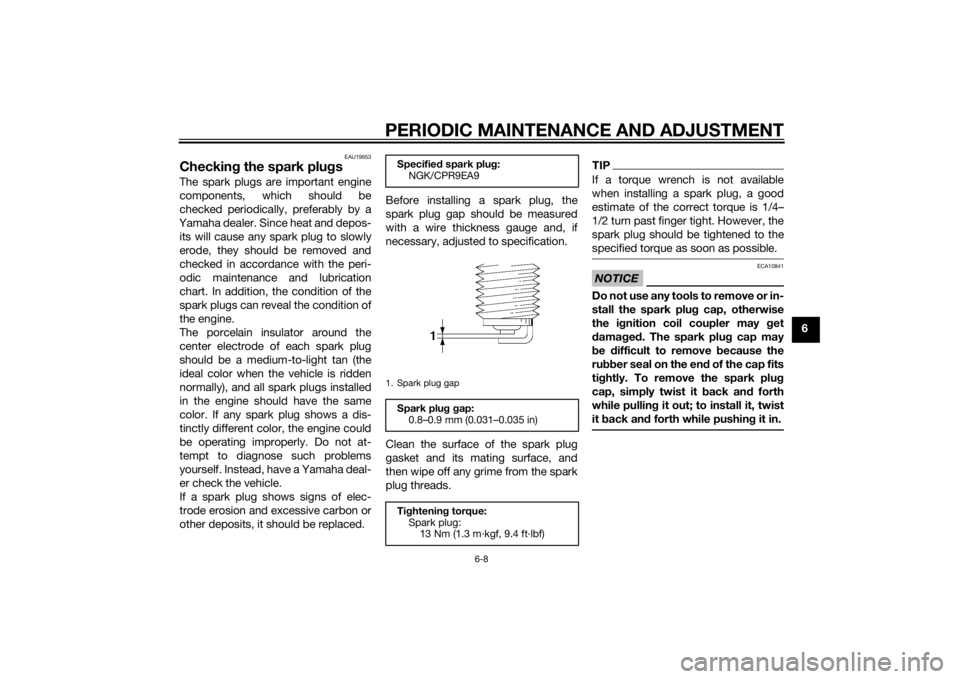

other deposits, it should be replaced. Before installing a spark plug, the

spark plug gap should be measured

with a wire thickness gauge and, if

necessary, adjusted to specification.

Clean the surface of the spark plug

gasket and its mating surface, and

then wipe off any grime from the spark

plug threads.

TIPIf a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is 1/4–

1/2 turn past finger tight. However, the

spark plug should be tightened to the

specified torque as soon as possible.NOTICE

ECA10841

Do not use any tools to remove or in-

stall the spark plu

g cap, otherwise

the i gnition coil coupler may get

d amag ed . The spark plu g cap may

b e difficult to remove because the

ru bber seal on the en d of the cap fits

ti g htly. To remove the spark plu g

cap, simply twist it back an d forth

while pullin g it out; to install it, twist

it back an d forth while pushin g it in.

Specified spark plu g:

NGK/CPR9EA9

1. Spark plug gap

Spark plu g g ap:

0.8–0.9 mm (0.031–0.035 in)

Ti ghtenin g torque:

Spark plug: 13 Nm (1.3 m·kgf, 9.4 ft·lbf)

U1RCELE0.book Page 8 Monday, May 12, 2014 8:51 AM

Page 60 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-9

6

EAU19909

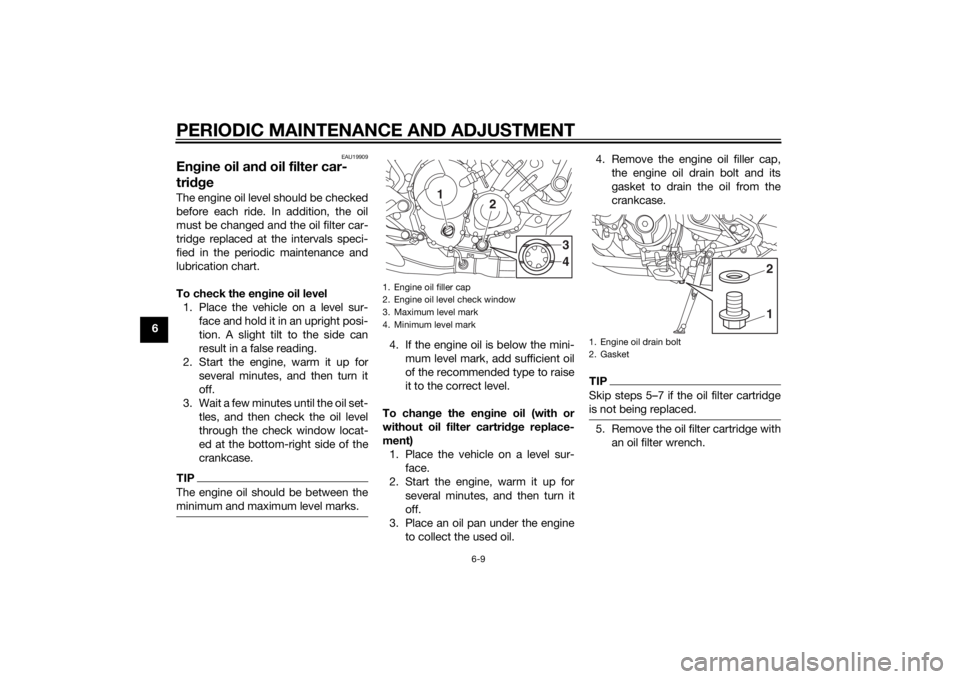

Engine oil an d oil filter car-

tri dgeThe engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil filter car-

tridge replaced at the intervals speci-

fied in the periodic maintenance and

lubrication chart.

To check the en gine oil level

1. Place the vehicle on a level sur- face and hold it in an upright posi-

tion. A slight tilt to the side can

result in a false reading.

2. Start the engine, warm it up for several minutes, and then turn it

off.

3. Wait a few minutes until the oil set- tles, and then check the oil level

through the check window locat-

ed at the bottom-right side of the

crankcase.TIPThe engine oil should be between the

minimum and maximum level marks.

4. If the engine oil is below the mini-mum level mark, add sufficient oil

of the recommended type to raise

it to the correct level.

To chan ge the en gine oil (with or

without oil filter cartri dge replace-

ment) 1. Place the vehicle on a level sur- face.

2. Start the engine, warm it up for several minutes, and then turn it

off.

3. Place an oil pan under the engine to collect the used oil. 4. Remove the engine oil filler cap,

the engine oil drain bolt and its

gasket to drain the oil from the

crankcase.

TIPSkip steps 5–7 if the oil filter cartridge

is not being replaced.5. Remove the oil filter cartridge withan oil filter wrench.

1. Engine oil filler cap

2. Engine oil level check window

3. Maximum level mark

4. Minimum level mark

1

2

34

1. Engine oil drain bolt

2. Gasket

12

U1RCELE0.book Page 9 Monday, May 12, 2014 8:51 AM

Page 62 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-11

6

TIPBe sure to wipe off spilled oil on any

parts after the engine and exhaust sys-

tem have cooled down.NOTICE

ECA11621

In or der to prevent clutch slip-

pa ge (since the en gine oil also

lu bricates the clutch), do not

mix any chemical additives. Do

not use oils with a d iesel speci-

fication of “CD” or oils of a hi gh-

er quality than specifie d. In

a ddition, do not use oils la beled

“ENERGY CONSERVING II” or

hi gher.

Make sure that no forei gn mate-

rial enters the crankcase.

10. Start the engine, and then let it idle for several minutes while checking

it for oil leakage. If oil is leaking,

immediately turn the engine off

and check for the cause.TIPAfter the engine is started, the engine

oil level warning light should go off if

the oil level is sufficient.NOTICE

ECA10402

If the oil level warnin g lig ht flickers

or remains on even if the oil level is

correct, immed iately turn the en gine

off an d have a Yamaha d ealer check

the vehicle.11. Turn the engine off, wait a few minutes until the oil settles, and

then check the oil level and cor-

rect it if necessary.

EAU20071

CoolantThe coolant level should be checked

before each ride. In addition, the cool-

ant must be changed at the intervals

specified in the periodic maintenance

and lubrication chart.

EAU20093

To check the coolant level1. Place the vehicle on a level sur- face and hold it in an upright posi-

tion.TIPThe coolant level must be

checked on a cold engine since

the level varies with engine tem-

perature.

Make sure that the vehicle is posi-

tioned straight up when checking

the coolant level. A slight tilt to the

side can result in a false reading.2. Check the coolant level in the

coolant reservoir.TIPThe coolant should be between the

minimum and maximum level marks.

Recommen ded en gine oil:

See page 8-1.

Oil quantity: Without oil filter cartridge replace-

ment:2.40 L (2.54 US qt, 2.11 Imp.qt)

With oil filter cartridge replacement:

2.70 L (2.85 US qt, 2.38 Imp.qt)

U1RCELE0.book Page 11 Monday, May 12, 2014 8:51 AM

Page 71 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-20

6

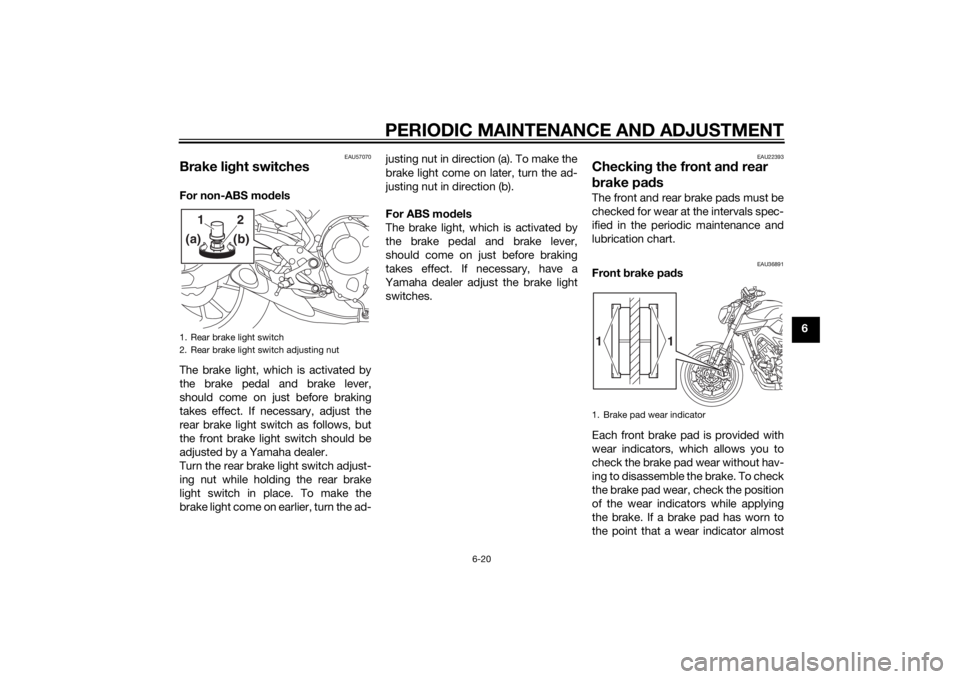

EAU57070

Brake light switchesFor non-ABS mo dels

The brake light, which is activated by

the brake pedal and brake lever,

should come on just before braking

takes effect. If necessary, adjust the

rear brake light switch as follows, but

the front brake light switch should be

adjusted by a Yamaha dealer.

Turn the rear brake light switch adjust-

ing nut while holding the rear brake

light switch in place. To make the

brake light come on earlier, turn the ad- justing nut in direction (a). To make the

brake light come on later, turn the ad-

justing nut in direction (b).

For ABS mo

dels

The brake light, which is activated by

the brake pedal and brake lever,

should come on just before braking

takes effect. If necessary, have a

Yamaha dealer adjust the brake light

switches.

EAU22393

Checkin g the front an d rear

b rake pa dsThe front and rear brake pads must be

checked for wear at the intervals spec-

ified in the periodic maintenance and

lubrication chart.

EAU36891

Front brake pad s

Each front brake pad is provided with

wear indicators, which allows you to

check the brake pad wear without hav-

ing to disassemble the brake. To check

the brake pad wear, check the position

of the wear indicators while applying

the brake. If a brake pad has worn to

the point that a wear indicator almost

1. Rear brake light switch

2. Rear brake light switch adjusting nut

1

2

(b)

(a)

1. Brake pad wear indicator

1

1

U1RCELE0.book Page 20 Monday, May 12, 2014 8:51 AM

Page 82 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-31

6

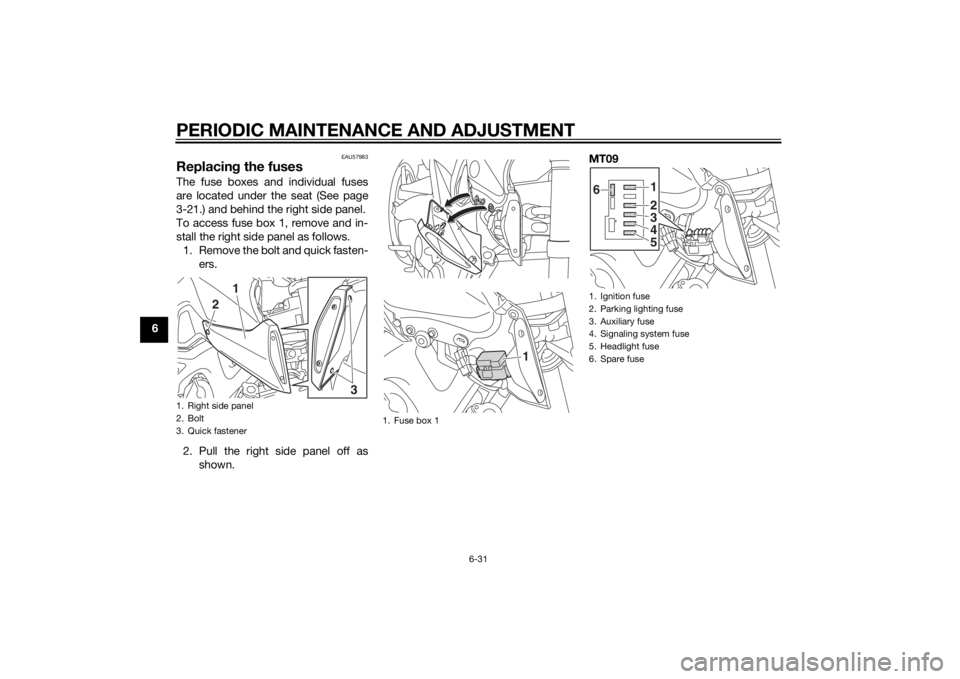

EAU57983

Replacing the fusesThe fuse boxes and individual fuses

are located under the seat (See page

3-21.) and behind the right side panel.

To access fuse box 1, remove and in-

stall the right side panel as follows.

1. Remove the bolt and quick fasten- ers.

2. Pull the right side panel off as shown. MT091. Right side panel

2. Bolt

3. Quick fastener

1

3

2

1. Fuse box 1

1

1. Ignition fuse

2. Parking lighting fuse

3. Auxiliary fuse

4. Signaling system fuse

5. Headlight fuse

6. Spare fuse

12

6

345

U1RCELE0.book Page 31 Monday, May 12, 2014 8:51 AM

Page 83 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-32

6

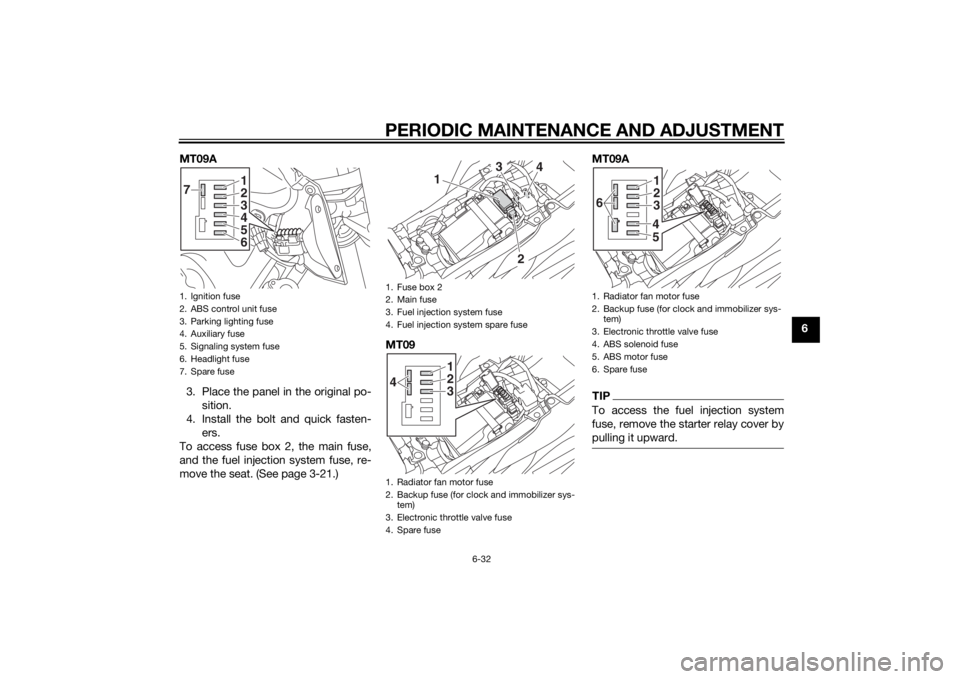

MT09A

3. Place the panel in the original po- sition.

4. Install the bolt and quick fasten- ers.

To access fuse box 2, the main fuse,

and the fuel injection system fuse, re-

move the seat. (See page 3-21.) MT09 MT09A

TIPTo access the fuel injection system

fuse, remove the starter relay cover by

pulling it upward.

1. Ignition fuse

2. ABS control unit fuse

3. Parking lighting fuse

4. Auxiliary fuse

5. Signaling system fuse

6. Headlight fuse

7. Spare fuse

123

7

456

1. Fuse box 2

2. Main fuse

3. Fuel injection system fuse

4. Fuel injection system spare fuse

1. Radiator fan motor fuse

2. Backup fuse (for clock and immobilizer sys-

tem)

3. Electronic throttle valve fuse

4. Spare fuse

2

3

4

1

123

4

1. Radiator fan motor fuse

2. Backup fuse (for clock and immobilizer sys-

tem)

3. Electronic throttle valve fuse

4. ABS solenoid fuse

5. ABS motor fuse

6. Spare fuse

123

6

45

U1RCELE0.book Page 32 Monday, May 12, 2014 8:51 AM

Page 84 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-33

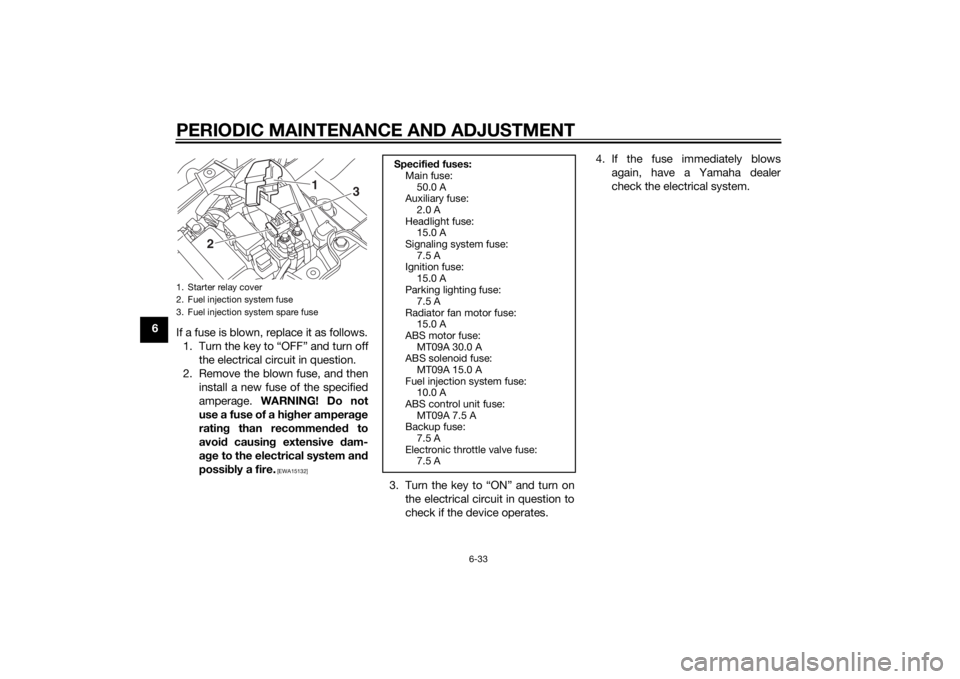

6If a fuse is blown, replace it as follows.

1. Turn the key to “OFF” and turn off the electrical circuit in question.

2. Remove the blown fuse, and then install a new fuse of the specified

amperage. WARNING! Do not

use a fuse of a hi gher ampera ge

ratin g than recommen ded to

avoi d causin g extensive d am-

a g e to the electrical system an d

possi bly a fire.

[EWA15132]

3. Turn the key to “ON” and turn on

the electrical circuit in question to

check if the device operates. 4. If the fuse immediately blows

again, have a Yamaha dealer

check the electrical system.

1. Starter relay cover

2. Fuel injection system fuse

3. Fuel injection system spare fuse

1

2

3

Specifie d fuses:

Main fuse:

50.0 A

Auxiliary fuse:

2.0 A

Headlight fuse: 15.0 A

Signaling system fuse: 7.5 A

Ignition fuse:

15.0 A

Parking lighting fuse: 7.5 A

Radiator fan motor fuse: 15.0 A

ABS motor fuse:

MT09A 30.0 A

ABS solenoid fuse: MT09A 15.0 A

Fuel injection system fuse: 10.0 A

ABS control unit fuse:

MT09A 7.5 A

Backup fuse: 7.5 A

Electronic throttle valve fuse: 7.5 A

U1RCELE0.book Page 33 Monday, May 12, 2014 8:51 AM

Page 85 of 110

PERIODIC MAINTENANCE AND ADJUSTMENT

6-34

6

EAU58001

Replacing the hea dlig ht bul bThis model is equipped with a halogen

bulb headlight. If the headlight bulb

burns out, replace it as follows.NOTICE

ECA10651

Take care not to damag e the follow-

in g parts:

Hea dlig ht bul b

Do not touch the glass part of

the hea dlig ht bul b to keep it free

from oil, otherwise the transpar-

ency of the g lass, the luminosity

of the b ulb, an d the b ulb life will

b e ad versely affected . Thor-

ou ghly clean off any d irt and fin-

g erprints on the head light bul b

using a cloth moistene d with al-

cohol or thinner.

Hea dlig ht lens

Do not affix any type of tinted

film or stickers to the head light

lens.

Do not use a hea dlig ht bul b of a

watta ge hi gher than specified .

1. Remove the headlight unit side

covers by removing the bolts on

each side. 2. Pull up the headlight unit cover to

separate it from the headlight unit.

3. Remove the grommets.1. Do not touch the glass part of the bulb.

1. Bolt

1

1

1. Bolt

2. Headlight unit side cover

1. Headlight unit cover1

1

2

21

U1RCELE0.book Page 34 Monday, May 12, 2014 8:51 AM