ABS YAMAHA MT-09 2015 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2015, Model line: MT-09, Model: YAMAHA MT-09 2015Pages: 108, PDF Size: 3.25 MB

Page 70 of 108

PERIODIC MAINTENANCE AND ADJUSTMENT

6-19

6

EAU37914

Checking the brake lever free

playThere should be no free play at the

brake lever end. If there is free play,

have a Yamaha dealer inspect the

brake system.

WARNING

EWA14212

A soft or spon gy feelin g in the b rake

lever can in dicate the presence of

air in the hy draulic system. If there is

air in the hy draulic system, have a

Yamaha dealer blee d the system be-

fore operatin g the vehicle. Air in the

hy draulic system will diminish the b

rakin g performance, which may re-

sult in loss of control and an acci-

d ent.

EAU57070

Brake li ght switchesFor non-ABS mo dels

The brake light, which is activated by

the brake pedal and brake lever,

should come on just before braking

takes effect. If necessary, adjust the

rear brake light switch as follows, but

the front brake light switch should be

adjusted by a Yamaha dealer.

Turn the rear brake light switch adjust-

ing nut while holding the rear brake

light switch in place. To make the

brake light come on earlier, turn the ad-

1. No brake lever free play

1

1. Rear brake light switch

2. Rear brake light switch adjusting nut

1

2

(b)

(a)

U1RCE1E0.book Page 19 Wednesday, May 28, 2014 1:10 PM

Page 71 of 108

PERIODIC MAINTENANCE AND ADJUSTMENT

6-20

6

justing nut in direction (a). To make the

brake light come on later, turn the ad-

justing nut in direction (b).

For ABS mo

dels

The brake light, which is activated by

the brake pedal and brake lever,

should come on just before braking

takes effect. If necessary, have a

Yamaha dealer adjust the brake light switches.

EAU22393

Checkin g the front an d rear

b rake pa dsThe front and rear brake pads must be

checked for wear at the intervals spec-

ified in the periodic maintenance and

lubrication chart.

EAU36891

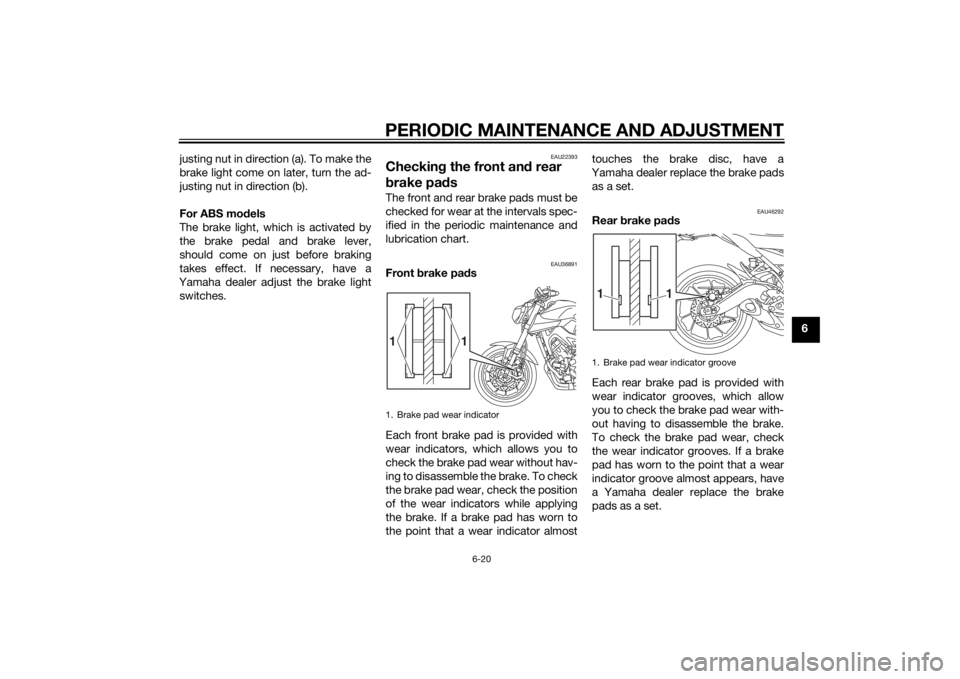

Front brake pad s

Each front brake pad is provided with

wear indicators, which allows you to

check the brake pad wear without hav-

ing to disassemble the brake. To check

the brake pad wear, check the position

of the wear indicators while applying

the brake. If a brake pad has worn to

the point that a wear indicator almost touches the brake disc, have a

Yamaha dealer replace the brake pads

as a set.

EAU46292

Rear

brake pa ds

Each rear brake pad is provided with

wear indicator grooves, which allow

you to check the brake pad wear with-

out having to disassemble the brake.

To check the brake pad wear, check

the wear indicator grooves. If a brake

pad has worn to the point that a wear

indicator groove almost appears, have

a Yamaha dealer replace the brake

pads as a set.

1. Brake pad wear indicator

1

1

1. Brake pad wear indicator groove

1

1

U1RCE1E0.book Page 20 Wednesday, May 28, 2014 1:10 PM

Page 72 of 108

PERIODIC MAINTENANCE AND ADJUSTMENT

6-21

6

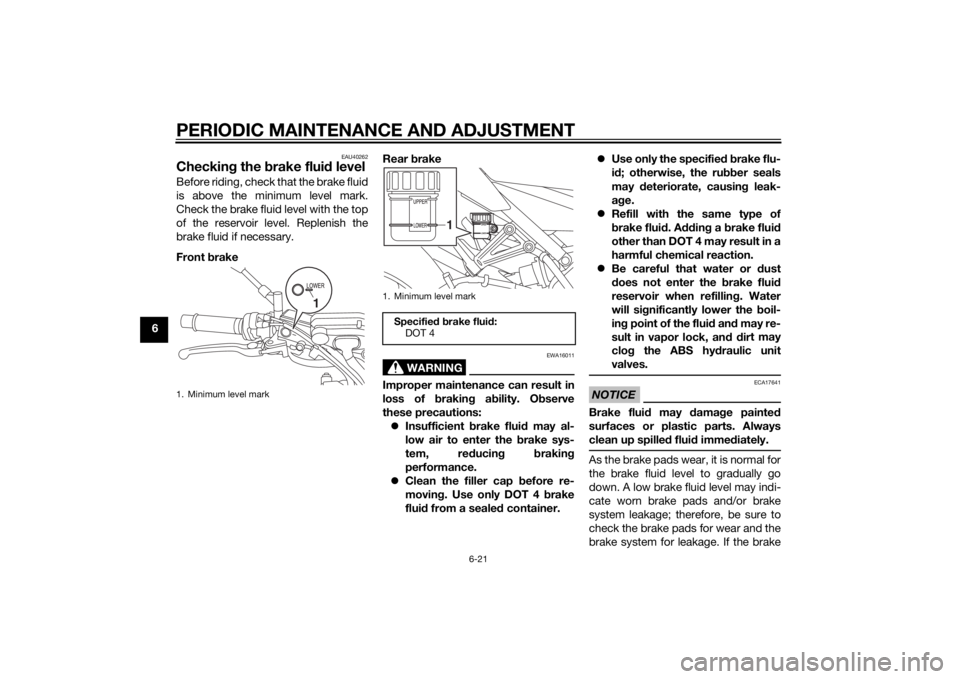

EAU40262

Checking the brake flui d levelBefore riding, check that the brake fluid

is above the minimum level mark.

Check the brake fluid level with the top

of the reservoir level. Replenish the

brake fluid if necessary.

Front brake Rear

brake

WARNING

EWA16011

Improper maintenance can result in

loss of b raking a bility. O bserve

these precautions: Insufficient brake flui d may al-

low air to enter the brake sys-

tem, re ducin g brakin g

performance.

Clean the filler cap before re-

movin g. Use only DOT 4 b rake

flui d from a seale d container.

Use only the specified b rake flu-

i d ; otherwise, the ru bber seals

may deteriorate, causin g leak-

a g e.

Refill with the same type of

brake flui d. A ddin g a brake flui d

other than DOT 4 may result in a

harmful chemical reaction.

Be careful that water or dust

d oes not enter the b rake fluid

reservoir when refillin g. Water

will si gnificantly lower the b oil-

in g point of the flui d an d may re-

sult in vapor lock, an d d ir t may

clo g

the ABS hy draulic unit

valves.

NOTICE

ECA17641

Brake flui d may damag e painted

surfaces or plastic parts. Always

clean up spille d flui d imme diately.As the brake pads wear, it is normal for

the brake fluid level to gradually go

down. A low brake fluid level may indi-

cate worn brake pads and/or brake

system leakage; therefore, be sure to

check the brake pads for wear and the

brake system for leakage. If the brake

1. Minimum level mark

1

1. Minimum level markSpecifie d b rake flui d:

DOT 4

1

U1RCE1E0.book Page 21 Wednesday, May 28, 2014 1:10 PM

Page 82 of 108

PERIODIC MAINTENANCE AND ADJUSTMENT

6-31

6MT09 MT09A

3. Place the panel in the original po-sition.

4. Install the bolt and quick fasten- ers.

To access fuse box 2, the main fuse,

and the fuel injection system fuse, re-

move the seat. (See page 3-21.)

1. Fuse box 1

1

1. Ignition fuse

2. Parking lighting fuse

3. Auxiliary fuse

4. Signaling system fuse

5. Headlight fuse

6. Spare fuse

12

6

345

1. Ignition fuse

2. ABS control unit fuse

3. Parking lighting fuse

4. Auxiliary fuse

5. Signaling system fuse

6. Headlight fuse

7. Spare fuse

123

7

456

U1RCE1E0.book Page 31 Wednesday, May 28, 2014 1:10 PM

Page 83 of 108

PERIODIC MAINTENANCE AND ADJUSTMENT

6-32

6

MT09 MT09A

TIPTo access the fuel injection system

fuse, remove the starter relay cover by

pulling it upward.

If a fuse is blown, replace it as follows.

1. Turn the key to “OFF” and turn off the electrical circuit in question.

2. Remove the blown fuse, and then install a new fuse of the specified

amperage. WARNING! Do not

use a fuse of a hi gher ampera ge

ratin g than recommen ded to

avoi d causin g extensive dam-

a g e to the electrical system an d

possi bly a fire.

[EWA15132]

1. Fuse box 2

2. Main fuse

3. Fuel injection system fuse

4. Fuel injection system spare fuse

1. Radiator fan motor fuse

2. Backup fuse (for clock and immobilizer sys-

tem)

3. Electronic throttle valve fuse

4. Spare fuse

2

3

4

1

123

4

1. Radiator fan motor fuse

2. Backup fuse (for clock and immobilizer sys-

tem)

3. Electronic throttle valve fuse

4. ABS solenoid fuse

5. ABS motor fuse

6. Spare fuse

123

6

45

1. Starter relay cover

2. Fuel injection system fuse

3. Fuel injection system spare fuse

1

2

3

U1RCE1E0.book Page 32 Wednesday, May 28, 2014 1:10 PM

Page 84 of 108

PERIODIC MAINTENANCE AND ADJUSTMENT

6-33

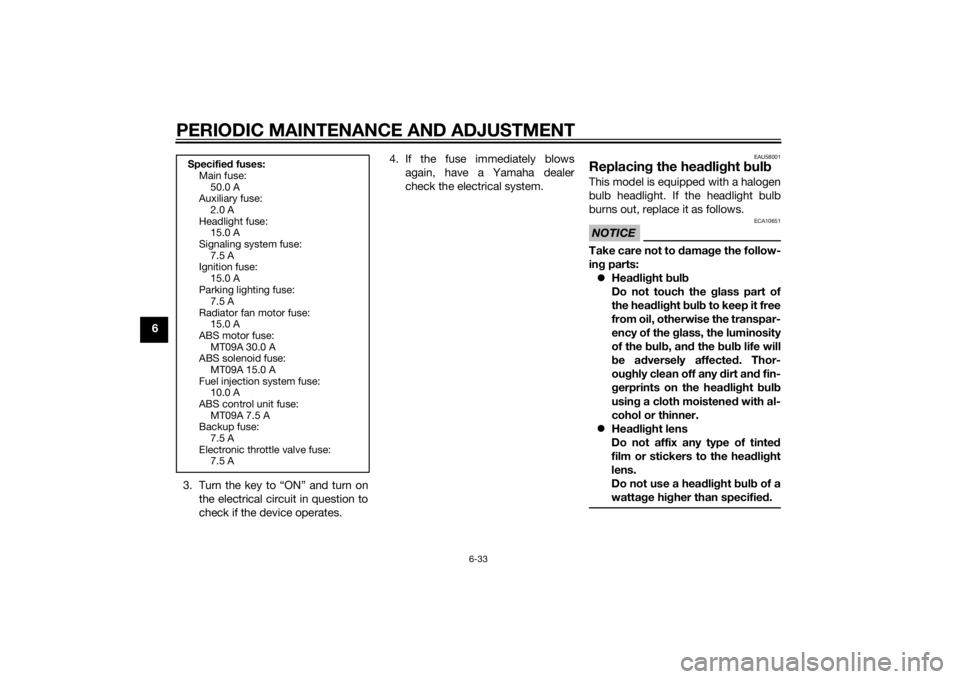

63. Turn the key to “ON” and turn onthe electrical circuit in question to

check if the device operates. 4. If the fuse immediately blows

again, have a Yamaha dealer

check the electrical system.

EAU58001

Replacin g the hea dlig ht bul bThis model is equipped with a halogen

bulb headlight. If the headlight bulb

burns out, replace it as follows.NOTICE

ECA10651

Take care not to damag e the follow-

in g parts:

Hea dlig ht bul b

Do not touch the glass part of

the hea dlig ht bul b to keep it free

from oil, otherwise the transpar-

ency of the glass, the luminosity

of the b ulb, an d the b ulb life will

b e ad versely affecte d. Thor-

ou ghly clean off any d irt and fin-

g erprints on the hea dlig ht bul b

usin g a cloth moistene d with al-

cohol or thinner.

Hea dlig ht lens

Do not affix any type of tinte d

film or stickers to the hea dlig ht

lens.

Do not use a hea dlig ht bul b of a

wattag e higher than specifie d.

Specifie d fuses:

Main fuse:

50.0 A

Auxiliary fuse:

2.0 A

Headlight fuse: 15.0 A

Signaling system fuse: 7.5 A

Ignition fuse:

15.0 A

Parking lighting fuse: 7.5 A

Radiator fan motor fuse: 15.0 A

ABS motor fuse:

MT09A 30.0 A

ABS solenoid fuse: MT09A 15.0 A

Fuel injection system fuse: 10.0 A

ABS control unit fuse:

MT09A 7.5 A

Backup fuse: 7.5 A

Electronic throttle valve fuse: 7.5 A

U1RCE1E0.book Page 33 Wednesday, May 28, 2014 1:10 PM

Page 90 of 108

PERIODIC MAINTENANCE AND ADJUSTMENT

6-39

6a jack either under each side of the

frame in front of the rear wheel or under

each side of the swingarm.

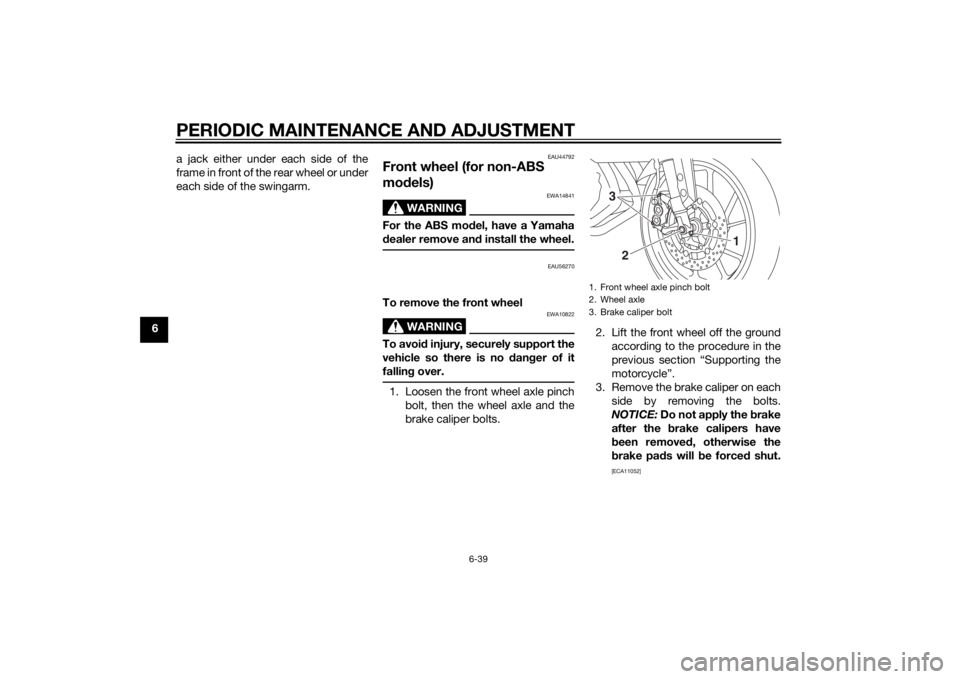

EAU44792

Front wheel (for non-ABS

mo

dels)

WARNING

EWA14841

For the ABS mo del, have a Yamaha

d ealer remove an d install the wheel.

EAU56270

To remove the front wheel

WARNING

EWA10822

To avoi d injury, securely support the

vehicle so there is no dan ger of it

fallin g over.1. Loosen the front wheel axle pinch

bolt, then the wheel axle and the

brake caliper bolts. 2. Lift the front wheel off the ground

according to the procedure in the

previous section “Supporting the

motorcycle”.

3. Remove the brake caliper on each side by removing the bolts.

NOTICE: Do not apply the b rake

after the brake calipers have

b een removed , otherwise the

b rake pa ds will b e forced shut.

[ECA11052]

1. Front wheel axle pinch bolt

2. Wheel axle

3. Brake caliper bolt

3

2

1

U1RCE1E0.book Page 39 Wednesday, May 28, 2014 1:10 PM

Page 91 of 108

PERIODIC MAINTENANCE AND ADJUSTMENT

6-40

6

4. Pull the wheel axle out, and then

remove the wheel.

To install the front wheel 1. Lift the wheel up between the fork legs.

2. Insert the wheel axle.

3. Install the brake calipers by install- ing the bolts.

TIPMake sure that there is enough space

between the brake pads before install-

ing the brake calipers onto the brake

discs.

4. Lower the front wheel so that it ison the ground, and then put the

sidestand down.

5. Tighten the wheel axle, the front wheel axle pinch bolt and the

brake caliper bolts to the specified

torques.

6. Push down hard on the handlebar several times to check for proper

fork operation.

EAU44802

Rear wheel (for non-ABS

mo dels)

WARNING

EWA14841

For the ABS mo del, have a Yamaha

d ealer remove an d install the wheel.

EAU56701

To remove the rear wheel

WARNING

EWA10822

To avoi d injury, securely support the

vehicle so there is no dan ger of it

fallin g over.1. Loosen the axle nut.

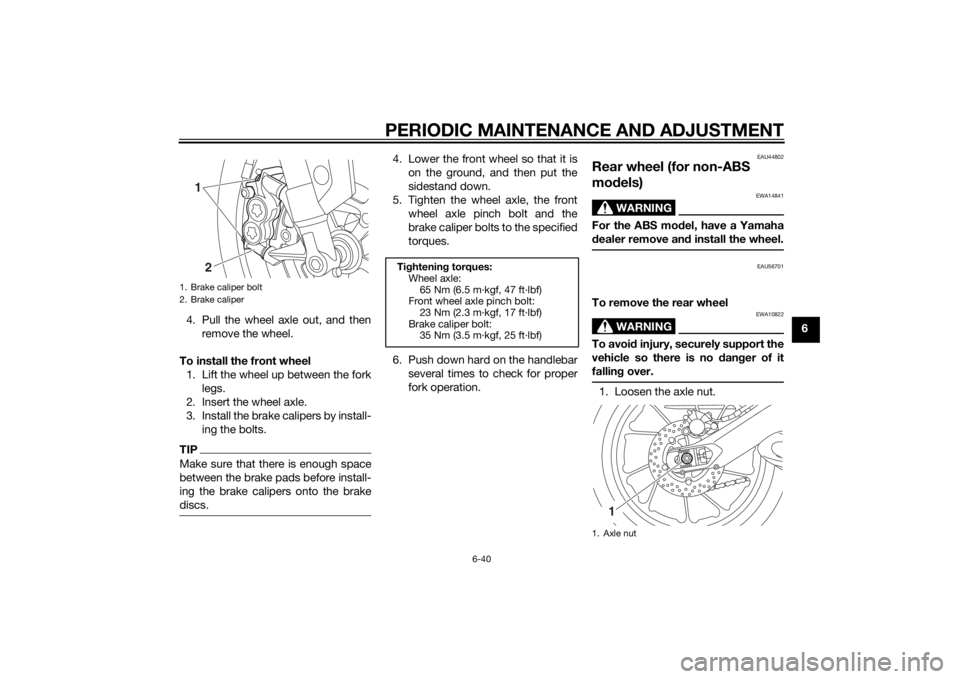

1. Brake caliper bolt

2. Brake caliper

12

Ti ghtenin g torques:

Wheel axle: 65 Nm (6.5 m·kgf, 47 ft·lbf)

Front wheel axle pinch bolt:

23 Nm (2.3 m·kgf, 17 ft·lbf)

Brake caliper bolt: 35 Nm (3.5 m·kgf, 25 ft·lbf)

1. Axle nut

1

U1RCE1E0.book Page 40 Wednesday, May 28, 2014 1:10 PM

Page 97 of 108

MOTORCYCLE CARE AND STORAGE7-2

7

off any

deter gent resi due usin g

plenty of water, as it is harmful

to plastic parts.

Do not use any harsh chemical

prod ucts on plastic parts. Be

sure to avoi d usin g cloths or

spon ges which have b een in

contact with stron g or a brasive

cleanin g prod ucts, solvent or

thinner, fuel ( gasoline), rust re-

movers or inhi bitors, brake flui d,

antifreeze or electrolyte.

Do not use hi gh-pressure wash-

ers or steam-jet cleaners since

they cause water seepag e and

d eterioration in the followin g ar-

eas: seals (of wheel an d swin g-

arm bearin gs, fork an d b rakes),

electric components (couplers,

connectors, instruments,

switches an d li ghts), breather

hoses an d vents.

For motorcycles equippe d with

a win dshiel d: Do not use stron g

cleaners or har d spon ges as

they will cause dullin g or

sc r

atchin g. Some cleanin g

compoun ds for plastic may

leave scratches on the win d- shiel

d. Test the pro duct on a

small hi dden part of the win d-

shiel d to make sure that it does

not leave any marks. If the win d-

shiel d is scratche d, use a quality

plastic polishin g compoun d af-

ter washing .

After normal useRemove dirt with warm water, a mild

detergent, and a soft, clean sponge,

and then rinse thoroughly with clean

water. Use a toothbrush or bottlebrush

for hard-to-reach areas. Stubborn dirt

and insects will come off more easily if

the area is covered with a wet cloth for

a few minutes before cleaning.

After riding in the rain, near the sea oron salt-sprayed roadsSince sea salt or salt sprayed on roads

during winter are extremely corrosive

in combination with water, carry out

the following steps after each ride in

the rain, near the sea or on salt-

sprayed roads.

TIPSalt sprayed on roads in the winter

may remain well into spring.1. Clean the motorcycle with cold

water and a mild detergent, after

the engine has cooled down.

NOTICE: Do not use warm wa-

ter since it increases the corro-

sive action of the salt.

[ECA10792]

2. Apply a corrosion protection spray on all metal, including chrome-

and nickel-plated, surfaces to pre-

vent corrosion.

After cleanin g

1. Dry the motorcycle with a chamois or an absorbing cloth.

2. Immediately dry the drive chain and lubricate it to prevent it from

rusting.

3. Use a chrome polish to shine chrome, aluminum and stainless-

steel parts, including the exhaust

system. (Even the thermally in-

duced discoloring of stainless-

steel exhaust systems can be re-

moved through polishing.)

U1RCE1E0.book Page 2 Wednesday, May 28, 2014 1:10 PM

Page 101 of 108

SPECIFICATIONS

8-2

8

2nd:2.000 (38/19)

3rd: 1.619 (34/21)

4th:

1.381 (29/21)

5th: 1.190 (25/21)

6th: 1.037 (28/27)

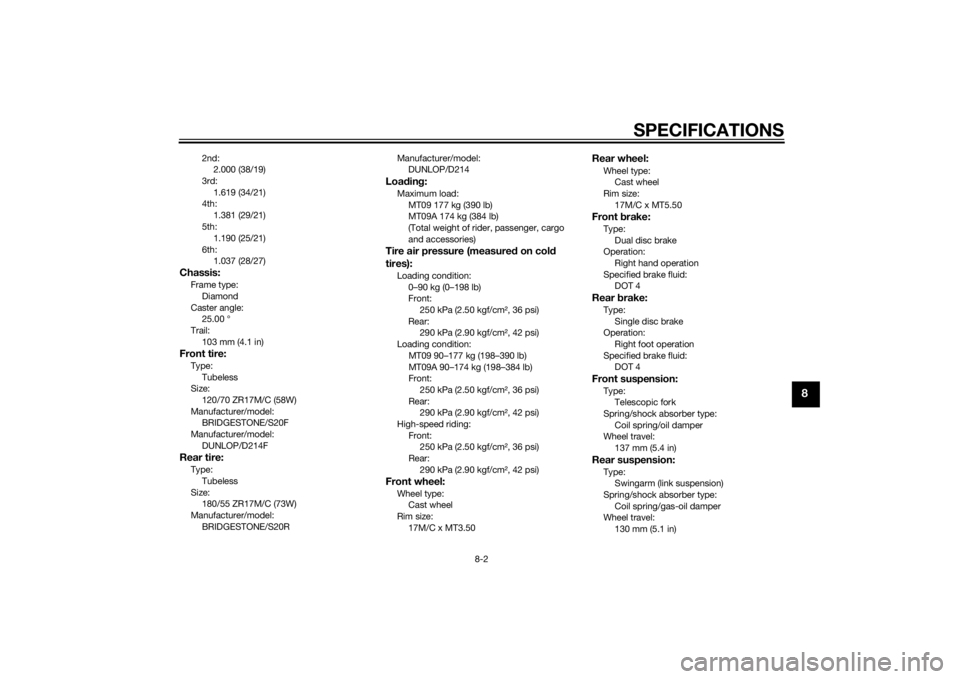

Chassis:Frame type:Diamond

Caster angle: 25.00 °

Trail:

103 mm (4.1 in)Front tire:Type:Tubeless

Size:

120/70 ZR17M/C (58W)

Manufacturer/model: BRIDGESTONE/S20F

Manufacturer/model: DUNLOP/D214FRear tire:Type: Tubeless

Size: 180/55 ZR17M/C (73W)

Manufacturer/model:

BRIDGESTONE/S20R Manufacturer/model:

DUNLOP/D214

Loa din g:Maximum load:

MT09 177 kg (390 lb)

MT09A 174 kg (384 lb)

(Total weight of rider, passenger, cargo

and accessories)Tire air pressure (measure d on col d

tires):Loading condition:

0–90 kg (0–198 lb)

Front:250 kPa (2.50 kgf/cm², 36 psi)

Rear: 290 kPa (2.90 kgf/cm², 42 psi)

Loading condition:

MT09 90–177 kg (198–390 lb)

MT09A 90–174 kg (198–384 lb)

Front:250 kPa (2.50 kgf/cm², 36 psi)

Rear: 290 kPa (2.90 kgf/cm², 42 psi)

High-speed riding: Front:250 kPa (2.50 kgf/cm², 36 psi)

Rear: 290 kPa (2.90 kgf/cm², 42 psi)Front wheel:Wheel type:Cast wheel

Rim size: 17M/C x MT3.50

Rear wheel:Wheel type:Cast wheel

Rim size:

17M/C x MT5.50Front brake:Type:

Dual disc brake

Operation:

Right hand operation

Specified brake fluid: DOT 4Rear brake:Type:

Single disc brake

Operation: Right foot operation

Specified brake fluid: DOT 4Front suspension:Type:Telescopic fork

Spring/shock absorber type: Coil spring/oil damper

Wheel travel:

137 mm (5.4 in)Rear suspension:Type:Swingarm (link suspension)

Spring/shock absorber type:

Coil spring/gas-oil damper

Wheel travel: 130 mm (5.1 in)

U1RCE1E0.book Page 2 Wednesday, May 28, 2014 1:10 PM