warning YAMAHA MT-09 2017 Owner's Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2017, Model line: MT-09, Model: YAMAHA MT-09 2017Pages: 106, PDF Size: 7.05 MB

Page 73 of 106

Periodic maintenance and adjustment7-21

1

2

3

4

5

678

9

10

11

12

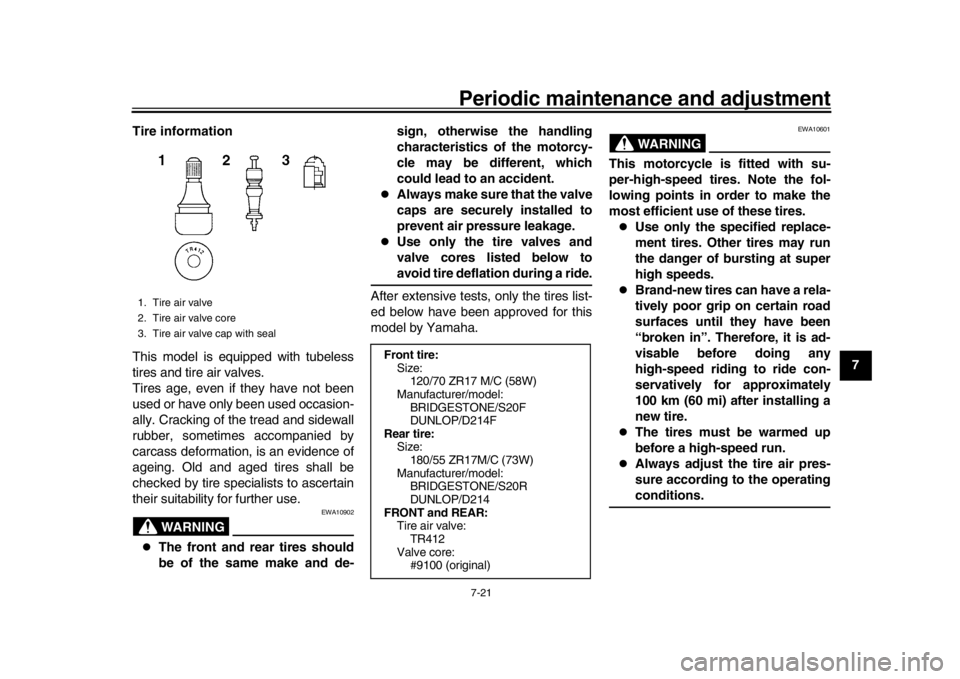

Tire information

This model is equipped with tubeless

tires and tire air valves.

Tires age, even if they have not been

used or have only been used occasion-

ally. Cracking of the tread and sidewall

rubber, sometimes accompanied by

carcass deformation, is an evidence of

ageing. Old and aged tires shall be

checked by tire spec

ialists to ascertain

their suitability for further use.

WARNING

EWA10902

The front and rear tires should

be of the same make and de- sign, otherwise the handling

characteristics of the motorcy-

cle may be different, which

could lead to an accident.

Always make sure that the valve

caps are securely installed to

prevent air pressure leakage.

Use only the tire valves and

valve cores listed below toavoid tire deflation during a ride.

After extensive tests, only the tires list-

ed below have been approved for this

model by Yamaha.

WARNING

EWA10601

This motorcycle is fitted with su-

per-high-speed tires. Note the fol-

lowing points in order to make the

most efficient use of these tires.

Use only the specified replace-

ment tires. Other tires may run

the danger of bursting at super

high speeds.

Brand-new tires can have a rela-

tively poor grip on certain road

surfaces until they have been

“broken in”. Therefore, it is ad-

visable before doing any

high-speed riding to ride con-

servatively for approximately

100 km (60 mi) after installing a

new tire.

The tires must be warmed up

before a high-speed run.

Always adjust the tire air pres-

sure according to the operatingconditions.

1. Tire air valve

2. Tire air valve core

3. Tire air valve cap with seal

Front tire: Size:

120/70 ZR17 M/C (58W)

Manufacturer/model: BRIDGESTONE/S20F

DUNLOP/D214F

Rear tire: Size:

180/55 ZR17M/C (73W)

Manufacturer/model: BRIDGESTONE/S20R

DUNLOP/D214

FRONT and REAR: Tire air valve:

TR412

Valve core: #9100 (original)

BS2-9-E0.book 21 ページ 2016年9月8日 木曜日 午前11時0分

Page 75 of 106

Periodic maintenance and adjustment7-23

1

2

3

4

5

678

9

10

11

12

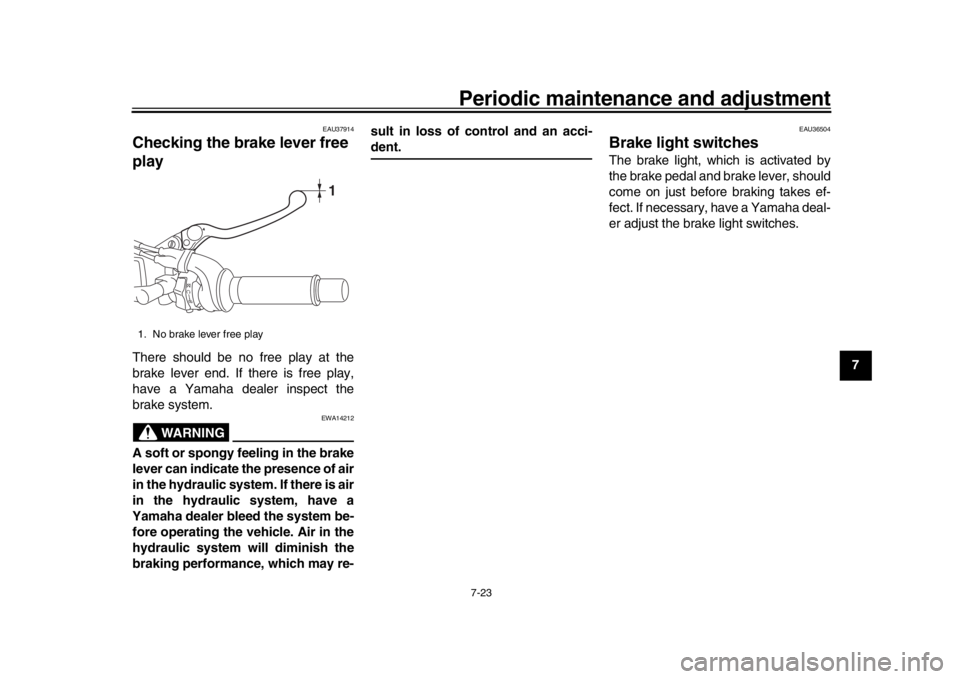

EAU37914

Checking the br ake lever free

playThere should be no free play at the

brake lever end. If there is free play,

have a Yamaha dealer inspect the

brake system.

WARNING

EWA14212

A soft or spongy feeling in the brake

lever can indicate the presence of air

in the hydraulic system. If there is air

in the hydraulic system, have a

Yamaha dealer bleed the system be-

fore operating the vehicle. Air in the

hydraulic system will diminish the

braking performance, which may re- sult in loss of control and an acci-

dent.

EAU36504

Brake light switchesThe brake light, which is activated by

the brake pedal and brake lever, should

come on just before braking takes ef-

fect. If necessary, have a Yamaha deal-

er adjust the brake light switches.

1. No brake lever free play

1

BS2-9-E0.book 23 ページ 2016年9月8日 木曜日 午前11時0分

Page 77 of 106

Periodic maintenance and adjustment7-25

1

2

3

4

5

678

9

10

11

12

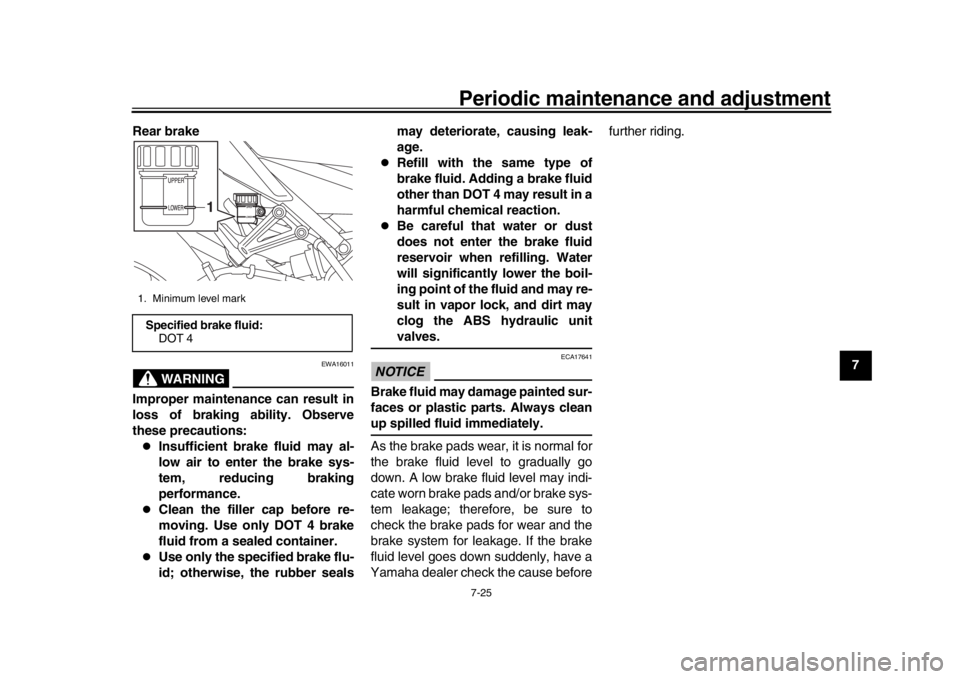

Rear brake

WARNING

EWA16011

Improper maintenance can result in

loss of braking ability. Observe

these precautions:

Insufficient brake fluid may al-

low air to enter the brake sys-

tem, reducing braking

performance.

Clean the filler cap before re-

moving. Use only DOT 4 brake

fluid from a sealed container.

Use only the specified brake flu-

id; otherwise, the rubber seals may deteriorate, causing leak-

age.

Refill with the same type of

brake fluid. Adding a brake fluid

other than DOT 4 may result in a

harmful chemical reaction.

Be careful that water or dust

does not enter the brake fluid

reservoir when refilling. Water

will significantly lower the boil-

ing point of the fluid and may re-

sult in vapor lock, and dirt may

clog the ABS hydraulic unitvalves.

NOTICE

ECA17641

Brake fluid may damage painted sur-

faces or plastic parts. Always cleanup spilled fluid immediately.

As the brake pads wear, it is normal for

the brake fluid level to gradually go

down. A low brake fluid level may indi-

cate worn brake pads and/or brake sys-

tem leakage; therefore, be sure to

check the brake pads for wear and the

brake system for leakage. If the brake

fluid level goes down suddenly, have a

Yamaha dealer check the cause before

further riding.

1. Minimum level markSpecified brake fluid:

DOT 4

1

BS2-9-E0.book 25 ページ 2016年9月8日 木曜日 午前11時0分

Page 80 of 106

Periodic maintenance and adjustment

7-28

1

2

3

4

5

67

8

9

10

11

12

EAU23026

Cleaning and l ubricating the

drive chainThe drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly wear

out, especially when riding in dusty or

wet areas. Service the drive chain as

follows.NOTICE

ECA10584

The drive chain must be lubricated

after washing the motorcycle, ridingin the rain or riding in wet areas.

1. Clean the drive chain with kero- sene and a small soft brush.

NOTICE: To prevent damaging

the O-rings, do not clean the

drive chain with steam cleaners,

high-pressure washers or inap-

propriate solvents.

[ECA11122]

2. Wipe the drive chain dry.

3. Thoroughly lubricate the drive chain with a special O-ring chain

lubricant. NOTICE: Do not use

engine oil or any other lubri-

cants for the drive chain, as they may contain substances that

could damage the O-rings.

[ECA11112]

EAU23098

Checking and lubricating the

cablesThe operation of all control cables and

the condition of the cables should be

checked before each ride, and the ca-

bles and cable ends should be lubricat-

ed if necessary. If a cable is damaged

or does not move smoothly, have a

Yamaha dealer check or replace it.

WARNING! Damage to the outer

housing of cables may result in in-

ternal rusting and cause interfer-

ence with cable movement. Replace

damaged cables as soon as possi-

ble to prevent unsafe condi-

tions.

[EWA10712]

Recommended lubricant:

Yamaha cable lubricant or other suit-

able cable lubricant

BS2-9-E0.book 28 ページ 2016年9月8日 木曜日 午前11時0分

Page 82 of 106

Periodic maintenance and adjustment

7-30

1

2

3

4

5

67

8

9

10

11

12

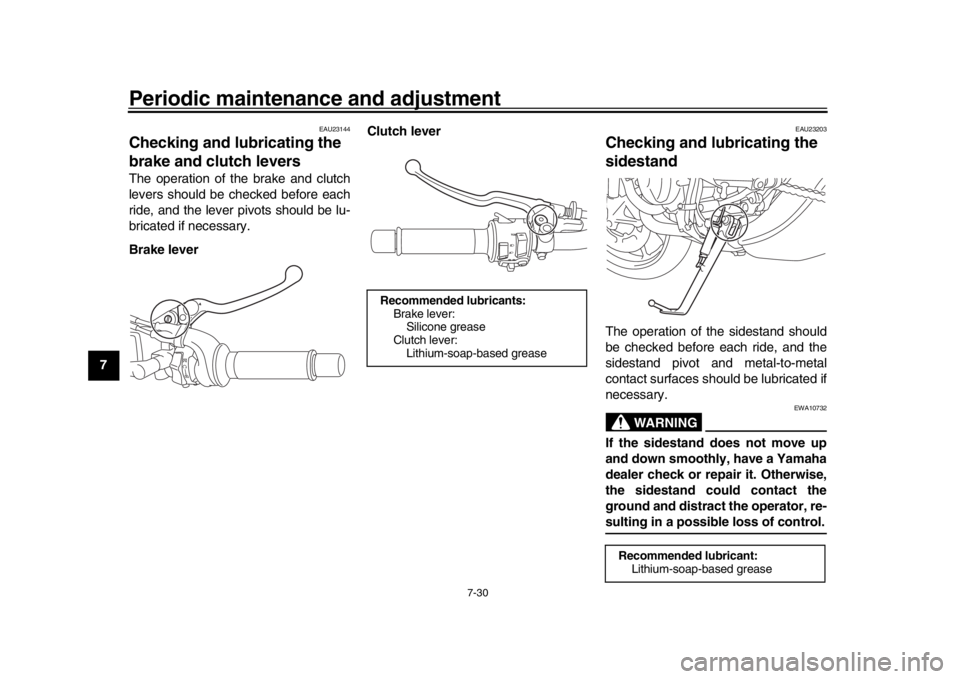

EAU23144

Checking and lubricating the

brake and clutch leversThe operation of the brake and clutch

levers should be checked before each

ride, and the lever pivots should be lu-

bricated if necessary.

Brake lever Clutch lever

EAU23203

Checking and lubricating the

sidestandThe operation of the sidestand should

be checked before each ride, and the

sidestand pivot and metal-to-metal

contact surfaces should be lubricated if

necessary.

WARNING

EWA10732

If the sidestand does not move up

and down smoothly, have a Yamaha

dealer check or repair it. Otherwise,

the sidestand could contact the

ground and distract the operator, re-sulting in a possible loss of control.

Recommended lubricants:

Brake lever:Silicone grease

Clutch lever: Lithium-soap-based grease

Recommended lubricant: Lithium-soap-based grease

BS2-9-E0.book 30 ページ 2016年9月8日 木曜日 午前11時0分

Page 83 of 106

Periodic maintenance and adjustment7-31

1

2

3

4

5

678

9

10

11

12

EAUM1653

Lubricating the swingarm

pivotsThe swingarm pivots must be lubricat-

ed by a Yamaha dealer at the intervals

specified in the periodic maintenance

and lubrication chart.

EAU23273

Checking the front forkThe condition and operation of the front

fork must be checked as follows at the

intervals specified in the periodic main-

tenance and lubrication chart.

To check the condition

Check the inner tubes for scratches,

damage and excessive oil leakage.

To check the operation 1. Place the vehicle on a level sur- face and hold it in an upright posi-

tion. WARNING! To avoid injury,

securely support the vehicle so

there is no danger of it falling

over.

[EWA10752]

2. While applying the front brake, push down hard on the handlebars

several times to check if the front

fork compresses and rebounds

smoothly.

NOTICE

ECA10591

If any damage is found or the front

fork does not operate smoothly,

have a Yamaha dealer check or re-pair it.

Recommended lubricant:Lithium-soap-based grease

BS2-9-E0.book 31 ページ 2016年9月8日 木曜日 午前11時0分

Page 84 of 106

Periodic maintenance and adjustment

7-32

1

2

3

4

5

67

8

9

10

11

12

EAU23285

Checking the steeringWorn or loose steering bearings may

cause danger. Therefore, the operation

of the steering must be checked as fol-

lows at the intervals specified in the pe-

riodic maintenance and lubrication

chart. 1. Raise the front wheel off the ground. (See page 7-37.)

WARNING! To avoid injury, se-

curely support the vehicle so

there is no danger of it falling

over.

[EWA10752]

2. Hold the lower ends of the frontfork legs and try to move them for-

ward and backward. If any free

play can be felt, have a Yamaha

dealer check or repair the steering.

EAU23292

Checking the w heel bearingsThe front and rear wheel bearings must

be checked at the intervals specified in

the periodic maintenance and lubrica-

tion chart. If there is play in the wheel

hub or if the wheel does not turn

smoothly, have a Yamaha dealer check

the wheel bearings.

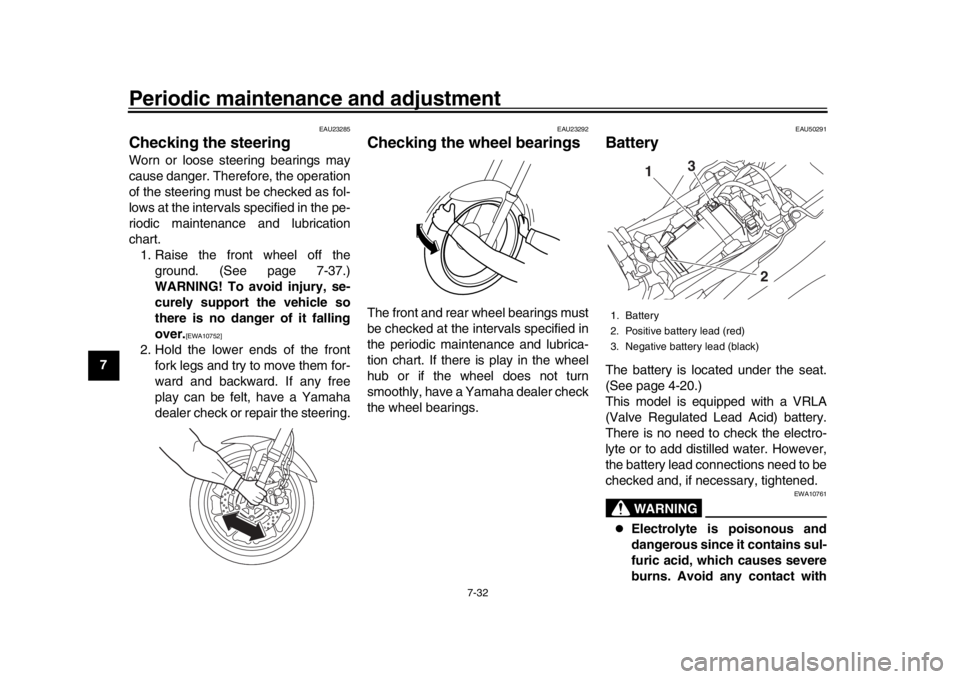

EAU50291

BatteryThe battery is located under the seat.

(See page 4-20.)

This model is equipped with a VRLA

(Valve Regulated Lead Acid) battery.

There is no need to check the electro-

lyte or to add distilled water. However,

the battery lead connections need to be

checked and, if necessary, tightened.

WARNING

EWA10761

Electrolyte is poisonous and

dangerous since it contains sul-

furic acid, which causes severe

burns. Avoid any contact with

1. Battery

2. Positive battery lead (red)

3. Negative battery lead (black)

2

3

1

BS2-9-E0.book 32 ページ 2016年9月8日 木曜日 午前11時0分

Page 87 of 106

Periodic maintenance and adjustment7-35

1

2

3

4

5

678

9

10

11

12

TIPTo access the fuel injection system

fuse, remove the starter relay cover bypulling it upward. If a fuse is blown, replace it as follows.

1. Turn the key to “OFF” and turn off the electrical circuit in question.

2. Remove the blown fuse, and then install a new fuse of the specified

amperage. WARNING! Do not

use a fuse of a higher amperage

rating than recommended to

avoid causing extensive dam-

age to the electrical system and

possibly a fire.

[EWA15132]

3. Turn the key to “ON” and turn on the electrical circuit in question to

1. Radiator fan motor fuse

2. Backup fuse

3. Electronic throttle valve fuse

4. Terminal fuse 1

5. ABS solenoid fuse

6. ABS motor fuse

7. Spare fuse

1234

7

56

1. Starter relay cover

2. Fuel injection system fuse

3. Fuel injection system spare fuse

1

2

3

Specified fuses:Main fuse:50.0 A

Auxiliary fuse 1:

2.0 A

Terminal fuse 1: 2.0 A

Grip warmer fuse: 5.0 A

Headlight fuse:

10.0 A

Signaling system fuse: 7.5 A

Ignition fuse: 15.0 A

Parking lighting fuse:

7.5 A

Radiator fan motor fuse: 15.0 A

ABS motor fuse: 30.0 A

ABS solenoid fuse:

15.0 A

Fuel injection system fuse: 10.0 A

ABS control unit fuse: 7.5 A

Backup fuse: 7.5 A

Electronic throttle valve fuse: 7.5 A

BS2-9-E0.book 35 ページ 2016年9月8日 木曜日 午前11時0分

Page 90 of 106

Periodic maintenance and adjustment

7-38

1

2

3

4

5

67

8

9

10

11

12

EAU25872

TroubleshootingAlthough Yamaha motorcycles receive

a thorough inspection before shipment

from the factory, trouble may occur dur-

ing operation. Any problem in the fuel,

compression, or ignition systems, for

example, can cause poor starting and

loss of power.

The following troubleshooting charts

represent quick and easy procedures

for checking these vital systems your-

self. However, should your motorcycle

require any repair, take it to a Yamaha

dealer, whose skilled technicians have

the necessary tools, experience, and

know-how to service the motorcycle

properly.

Use only genuine Yamaha replace-

ment parts. Imitation parts may look like

Yamaha parts, but they are often inferi-

or, have a shorter service life and can

lead to expensive repair bills.

WARNING

EWA15142

When checking the fuel system, do

not smoke, and make sure there are

no open flames or sparks in the ar-

ea, including pilot lights from water heaters or furnaces. Gasoline or

gasoline vapors can ignite or ex-

plode, causing severe injury or

property damage.

BS2-9-E0.book 38 ページ 2016年9月8日 木曜日 午前11時0分

Page 92 of 106

Periodic maintenance and adjustment

7-40

1

2

3

4

5

67

8

9

10

11

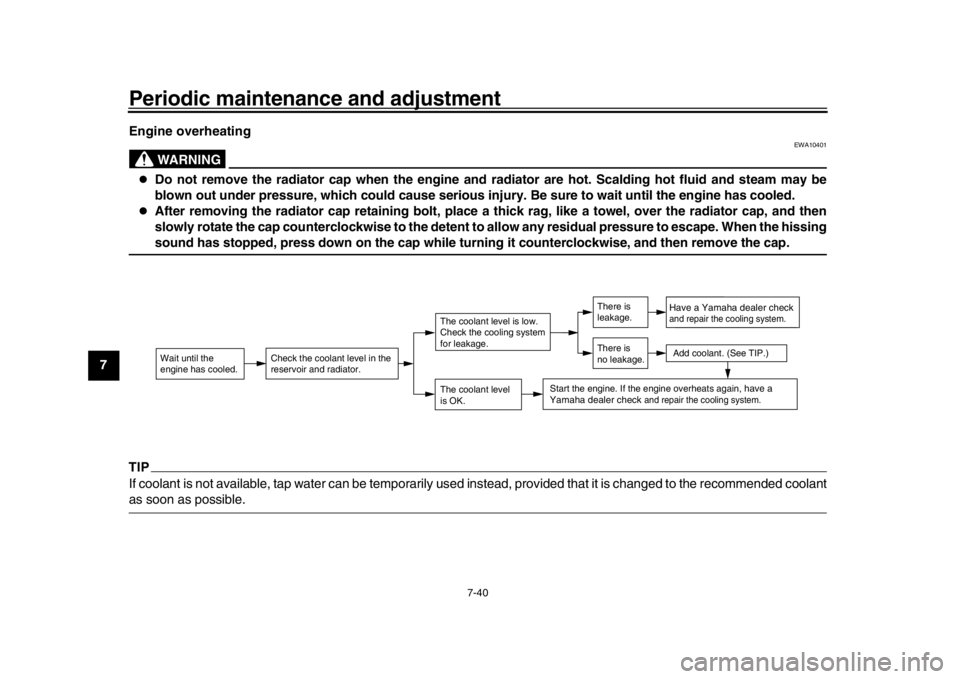

12 Engine overheating

WARNING

EWA10401

Do not remove the radiator cap when the engine and radiator are hot. Scalding hot fluid and steam may be

blown out under pressure, which could cause serious injury. Be sure to wait until the engine has cooled.

After removing the radiator cap retaining bolt, place a thick rag, like a towel, over the radiator cap, and then

slowly rotate the cap counterclockwise to the detent to allow any residual pressure to escape. When the hissingsound has stopped, press down on the cap while turning it counterclockwise, and then remove the cap.

TIPIf coolant is not available, tap water can be temporarily us

ed instead, provided that it is changed to the recommended coolantas soon as possible.

Wait until the

engine has cooled.

Check the coolant level in the

reservoir and radiator.

The coolant level

is OK.The coolant level is low.

Check the cooling system

for leakage.

Have a Yamaha dealer checkand repair the cooling system.Add coolant. (See TIP.)

Start the engine. If the engine overheats again,

have a

Yamaha dealer check

and repair the cooling system.

There is

leakage.

There is

no leakage.

BS2-9-E0.book 40 ページ 2016年9月8日 木曜日 午前11時0分