Amp YAMAHA MT-09 2018 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2018, Model line: MT-09, Model: YAMAHA MT-09 2018Pages: 104, PDF Size: 6.97 MB

Page 12 of 104

Safety information

1-5

1

2

3

4

5

6

7

8

9

10

11

12

Check that the fuel cock (if

equipped) is in the off position and

that there are no fuel leaks.

Shift the transmission into gear (for

models with a manual transmis-

sion).

Secure the motorcycle with

tie-downs or suitable straps that

are attached to solid parts of the

motorcycle, such as the frame or

upper front fork triple clamp (and

not, for example, to rubber-mount-

ed handlebars or turn signals, or

parts that could break). Choose

the location for the straps carefully

so the straps will not rub against

painted surfaces during transport.

The suspension should be com-

pressed somewhat by the

tie-downs, if possible, so that the

motorcycle will not bounce exces-

sively during transport.

BS2-9-E1E0_1.book 5 ページ 2018年4月27日 金曜日 午後4時50分

Page 13 of 104

2-1

123

4

5

6

7

8

9

10

11

12

Description

EAU10411

Left view

3

4

5

6

7

8

1, 2

1. Spring preload adjuster (page 4-21)

2. Compression damping force adjuster (page 4-21)

3. Rebound damping force adjuster (page 4-23)

4. Seat (page 4-20)

5. Storage compartment (page 4-21)

6. Spring preload adjuster (page 4-23)

7. Shift pedal (page 4-14)

8. Engine oil drain bolt (page 7-12)

BS2-9-E1E0_1.book 1 ページ 2018年4月27日 金曜日 午後4時50分

Page 14 of 104

Description

2-2

12

3

4

5

6

7

8

9

10

11

12

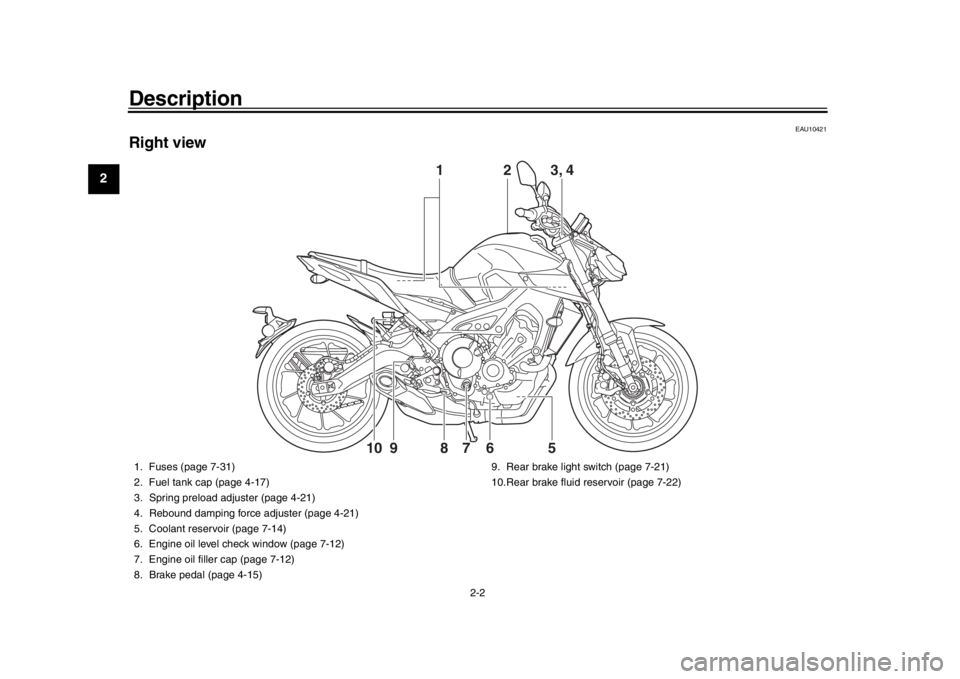

EAU10421

Right view

2

1

6

7

8

9

10

5 3, 4

1. Fuses (page 7-31)

2. Fuel tank cap (page 4-17)

3. Spring preload adjuster (page 4-21)

4. Rebound damping force adjuster (page 4-21)

5. Coolant reservoir (page 7-14)

6. Engine oil level check window (page 7-12)

7. Engine oil filler cap (page 7-12)

8. Brake pedal (page 4-15)

9. Rear brake light switch (page 7-21)

10.Rear brake fluid reservoir (page 7-22)

BS2-9-E1E0_1.book 2 ページ 2018年4月27日 金曜日 午後4時50分

Page 37 of 104

Instrument and control functions

4-19

1

2

345

6

7

8

9

10

11

12

hol containing ethanol and that contain-

ing methanol. Gasohol containing

ethanol can be used if the ethanol con-

tent does not exceed 10% (E10). Gas-

ohol containing methanol is not

recommended by Yamaha because it

can cause damage to the fuel system

or vehicle performance problems.

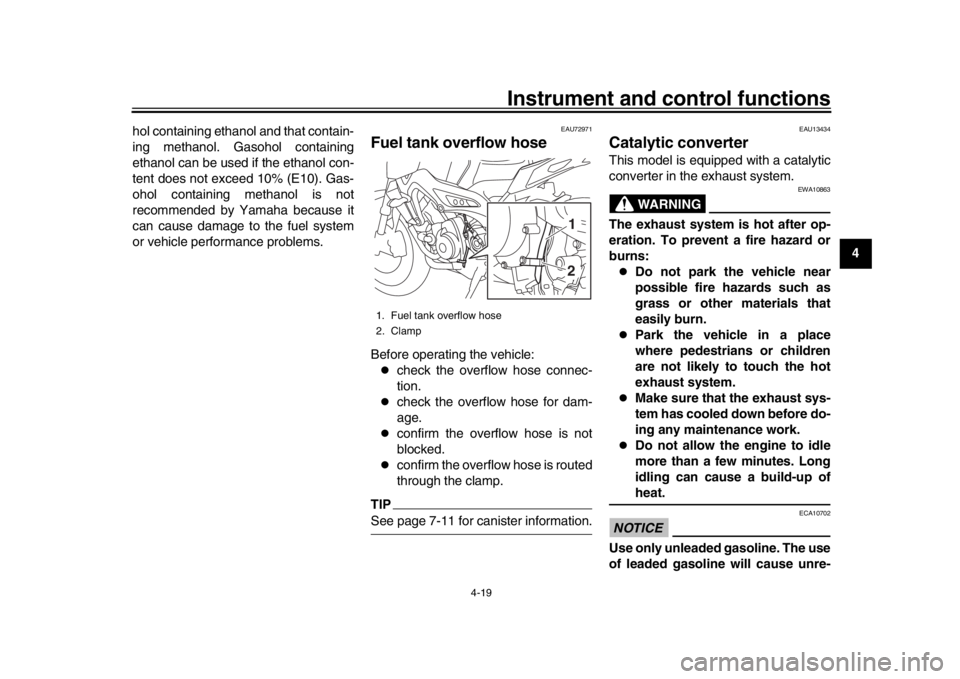

EAU72971

Fuel tank overflow hoseBefore operating the vehicle:

check the overflow hose connec-

tion.

check the overflow hose for dam-

age.

confirm the overflow hose is not

blocked.

confirm the overflow hose is routed

through the clamp.

TIPSee page 7-11 for canister information.

EAU13434

Catalytic converterThis model is equipped with a catalytic

converter in the exhaust system.

WARNING

EWA10863

The exhaust system is hot after op-

eration. To prevent a fire hazard or

burns:

Do not park the vehicle near

possible fire hazards such as

grass or other materials that

easily burn.

Park the vehicle in a place

where pedestrians or children

are not likely to touch the hot

exhaust system.

Make sure that the exhaust sys-

tem has cooled down before do-

ing any maintenance work.

Do not allow the engine to idle

more than a few minutes. Long

idling can cause a build-up ofheat.

NOTICE

ECA10702

Use only unleaded gasoline. The use

of leaded gasoline will cause unre-

1. Fuel tank overflow hose

2. Clamp

21

BS2-9-E1E0_1.book 19 ページ 2018年4月27日 金曜日 午後4時50分

Page 39 of 104

Instrument and control functions

4-21

1

2

345

6

7

8

9

10

11

12

EAU77030

Storage compartmentThe storage compartment is located

under the seat. (See page 4-20.)

When storing documents or other items

in the storage compartment, be sure to

wrap them in a plastic bag so that they

will not get wet. When washing the ve-

hicle, be careful not to let any water en-

ter the storage compartment.

WARNING

EWA15401

Do not exceed the maximum load of174 kg (384 lb) for the vehicle.

EAU76341

Adjusting the front fork

WARNING

EWA14671

Always adjust the spring preload on

both fork legs equally, otherwise

poor handling and loss of stabilitymay result.

Each front fork leg is equipped with a

spring preload adjusting bolt, the right

front fork leg is equipped with a re-

bound damping force adjusting screw

and the left front fork leg with a com-

pression damping force adjusting

screw.NOTICE

ECA10102

To avoid damaging the mechanism,

do not attempt to turn beyond themaximum or minimum settings.

Spring preload

To increase the spring preload and

thereby harden the suspension, turn

the adjusting bolt on each fork leg in di-

rection (a). To decrease the spring pre-

load and thereby soften the

suspension, turn the adjusting bolt on each fork leg in direction (b).

The spring preload setting is deter-

mined by measuring distance A, shown

in the illustration. The shorter distance

A is, the higher the spring preload; the

longer distance A is, the lower the

spring preload.

1. Storage compartment

1

1. Spring preload adjusting bolt

1. Distance A

1

1

(a)

(b)

(a)

(b)

1

BS2-9-E1E0_1.book 21 ページ 2018年4月27日 金曜日 午後4時50分

Page 40 of 104

Instrument and control functions

4-22

1

2

34

5

6

7

8

9

10

11

12 Rebound damping force

The rebound damping force is adjusted

on the right front fork leg only. To in-

crease the rebound damping force and

thereby harden the rebound damping,

turn the adjusting screw in direction (a).

To decrease the rebound damping

force and thereby soften the rebound

damping, turn the adjusting screw in di-

rection (b).

TIPBe sure to perform this adjustment onthe right front fork leg.

Compression damping force

The compression damping force is ad-

justed on the left front fork leg only. To

increase the compression damping

force and thereby harden the compres-

sion damping, turn the adjusting screw

in direction (a). To decrease the com-

pression damping force and therebysoften the compression damping, turn

the adjusting screw in direction (b).

TIPBe sure to perform this adjustment onthe left front fork leg.TIP

Although the total number of clicks

Spring preload setting:

Minimum (soft):Distance A = 19.0 mm (0.75 in)

Standard:

Distance A = 16.0 mm (0.63 in)

Maximum (hard): Distance A = 4.0 mm (0.16 in)

1. Rebound damping force adjusting screwRebound damping setting: Minimum (soft):

11 click(s) in direction (b)*

Standard: 11 click(s) in direction (b)*

Maximum (hard): 0 click(s) in direction (b)*

* With the adjusting knob fully turned in

direction (a)

1

(a)

(b)

1. Compression damping force adjusting

screwCompression damping setting:Minimum (soft):11 click(s) in direction (b)*

Standard: 11 click(s) in direction (b)*

Maximum (hard):

0 click(s) in direction (b)*

* With the adjusting screw fully turned in direction (a)

1

(a) (b)

BS2-9-E1E0_1.book 22 ページ 2018年4月27日 金曜日 午後4時50分

Page 41 of 104

Instrument and control functions

4-23

1

2

345

6

7

8

9

10

11

12

of a damping force adjusting

mechanism may not exactly match

the above specifications due to

small differences in production, the

actual number of clicks always

represents the entire adjusting

range. To obtain a precise adjust-

ment, check the number of clicks

of each damping force adjusting

mechanism and modify the specifi-

cations as necessary.

When turning a damping force ad-

juster in direction (a), the 0 click

position and the 1 click positionmay be the same.

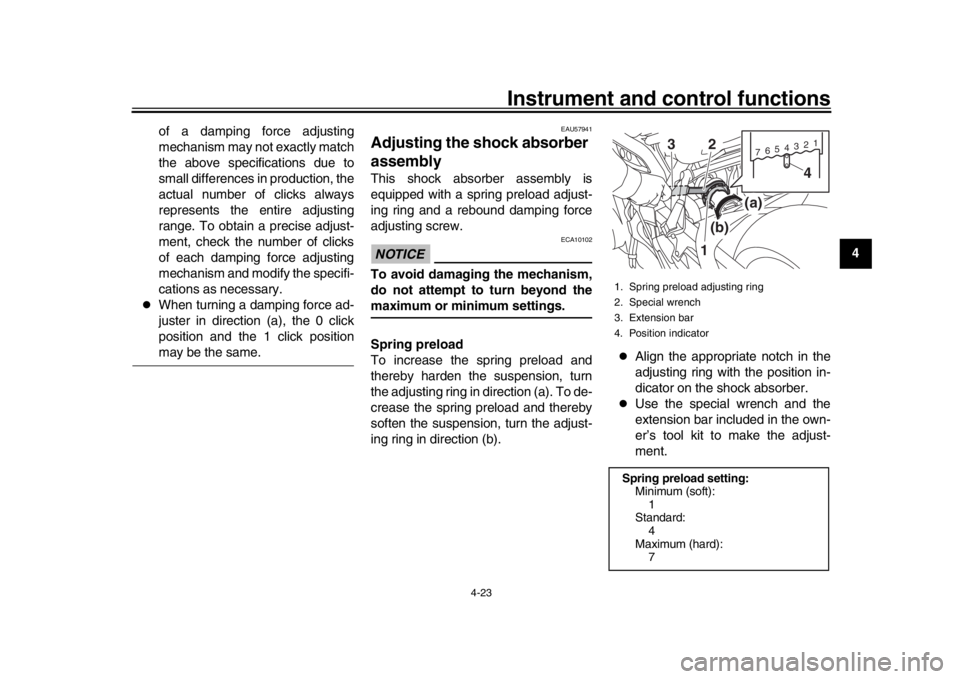

EAU57941

Adjusting the shock absorber

assemblyThis shock absorber assembly is

equipped with a spring preload adjust-

ing ring and a rebound damping force

adjusting screw.NOTICE

ECA10102

To avoid damaging the mechanism,

do not attempt to turn beyond themaximum or minimum settings.

Spring preload

To increase the spring preload and

thereby harden the suspension, turn

the adjusting ring in direction (a). To de-

crease the spring preload and thereby

soften the suspension, turn the adjust-

ing ring in direction (b).

Align the appropriate notch in the

adjusting ring with the position in-

dicator on the shock absorber.

Use the special wrench and the

extension bar included in the own-

er’s tool kit to make the adjust-

ment.

1. Spring preload adjusting ring

2. Special wrench

3. Extension bar

4. Position indicatorSpring preload setting:

Minimum (soft):1

Standard:

4

Maximum (hard): 7

7654321

1(b) (a)

4

2

3

BS2-9-E1E0_1.book 23 ページ 2018年4月27日 金曜日 午後4時50分

Page 42 of 104

Instrument and control functions

4-24

1

2

34

5

6

7

8

9

10

11

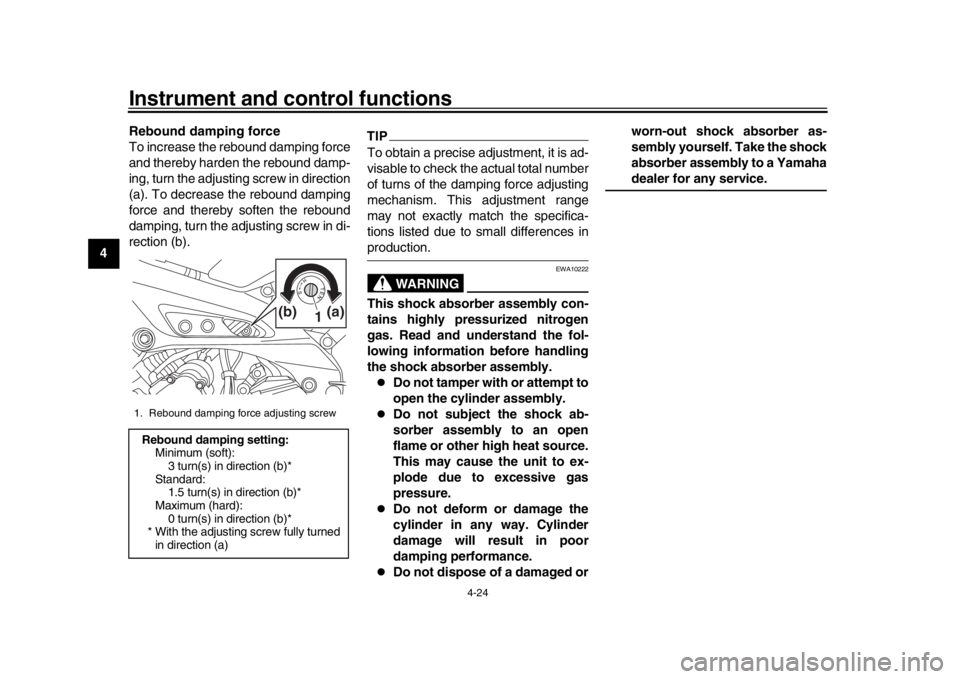

12 Rebound damping force

To increase the rebound damping force

and thereby harden the rebound damp-

ing, turn the adjusting screw in direction

(a). To decrease the rebound damping

force and thereby soften the rebound

damping, turn the adjusting screw in di-

rection (b).

TIPTo obtain a precise adjustment, it is ad-

visable to check the actual total number

of turns of the damping force adjusting

mechanism. This adjustment range

may not exactly match the specifica-

tions listed due to small differences inproduction.

WARNING

EWA10222

This shock absorber assembly con-

tains highly pressurized nitrogen

gas. Read and understand the fol-

lowing information before handling

the shock absorber assembly.

Do not tamper with or attempt to

open the cylinder assembly.

Do not subject the shock ab-

sorber assembly to an open

flame or other high heat source.

This may cause the unit to ex-

plode due to excessive gas

pressure.

Do not deform or damage the

cylinder in any way. Cylinder

damage will result in poor

damping performance.

Do not dispose of a damaged or worn-out shock absorber as-

sembly yourself. Take the shock

absorber assembly to a Yamaha

dealer for any service.

1. Rebound damping force adjusting screwRebound damping setting:

Minimum (soft):

3 turn(s) in direction (b)*

Standard: 1.5 turn(s) in direction (b)*

Maximum (hard): 0 turn(s) in direction (b)*

* With the adjusting screw fully turned

in direction (a)

1 (a)(b)

BS2-9-E1E0_1.book 24 ページ 2018年4月27日 金曜日 午後4時50分

Page 85 of 104

Periodic maintenance and adjustment7-33

1

2

3

4

5

678

9

10

11

12

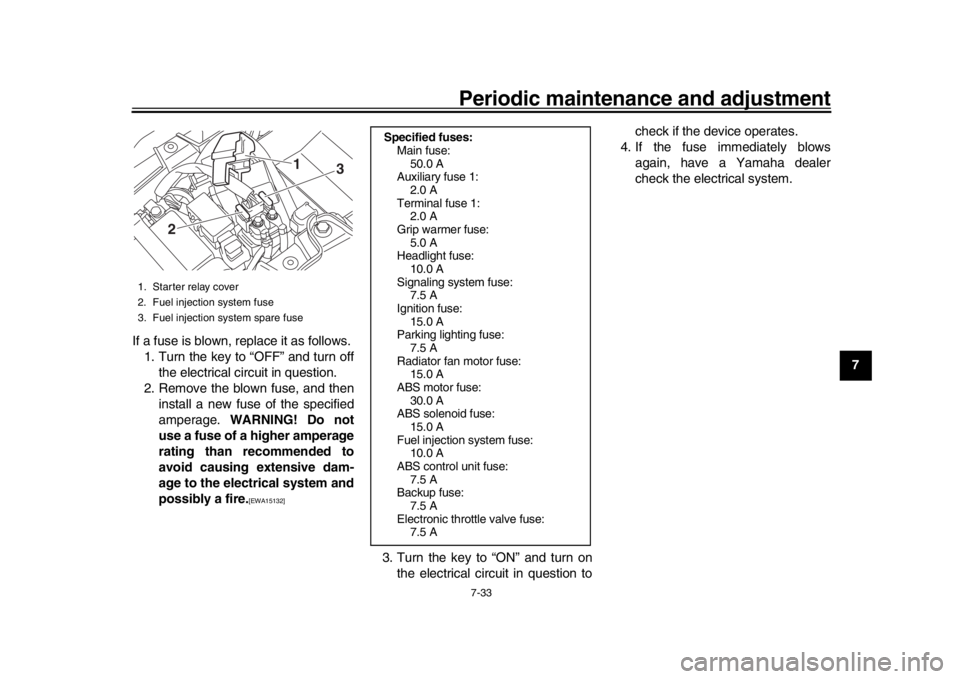

If a fuse is blown, replace it as follows.

1. Turn the key to “OFF” and turn off the electrical circuit in question.

2. Remove the blown fuse, and then install a new fuse of the specified

amperage. WARNING! Do not

use a fuse of a higher amperage

rating than recommended to

avoid causing extensive dam-

age to the electrical system and

possibly a fire.

[EWA15132]

3. Turn the key to “ON” and turn on the electrical circuit in question to check if the device operates.

4. If the fuse immediately blows again, have a Yamaha dealer

check the electrical system.

1. Starter relay cover

2. Fuel injection system fuse

3. Fuel injection system spare fuse

1

2

3

Specified fuses:Main fuse:50.0 A

Auxiliary fuse 1:

2.0 A

Terminal fuse 1: 2.0 A

Grip warmer fuse: 5.0 A

Headlight fuse:

10.0 A

Signaling system fuse: 7.5 A

Ignition fuse: 15.0 A

Parking lighting fuse:

7.5 A

Radiator fan motor fuse: 15.0 A

ABS motor fuse: 30.0 A

ABS solenoid fuse:

15.0 A

Fuel injection system fuse: 10.0 A

ABS control unit fuse: 7.5 A

Backup fuse: 7.5 A

Electronic throttle valve fuse: 7.5 A

BS2-9-E1E0_1.book 33 ページ 2018年4月27日 金曜日 午後4時50分

Page 87 of 104

Periodic maintenance and adjustment7-35

1

2

3

4

5

678

9

10

11

12

3. Insert a new bulb into the socket,

push it in, and then turn it clock-

wise until it stops.

4. Install the lens by installing the screw. NOTICE: Do not over-

tighten the screw, otherwise the

lens may break.

[ECA11192] EAU67131

Supporting the motorcycleSince this model is not equipped with a

centerstand, use maintenance stands

when removing the front or rear wheel

or when performing other maintenance

that requires the motorcycle to stand up

right.

Check that the motorcycle is in a stable

and level position before starting any

maintenance.

EAU25872

TroubleshootingAlthough Yamaha motorcycles receive

a thorough inspection before shipment

from the factory, trouble may occur dur-

ing operation. Any problem in the fuel,

compression, or ignition systems, for

example, can cause poor starting and

loss of power.

The following troubleshooting charts

represent quick and easy procedures

for checking these vital systems your-

self. However, should your motorcycle

require any repair, take it to a Yamaha

dealer, whose skilled technicians have

the necessary tools, experience, and

know-how to service the motorcycle

properly.

Use only genuine Yamaha replace-

ment parts. Imitation parts may look like

Yamaha parts, but they are often inferi-

or, have a shorter service life and can

lead to expensive repair bills.

WARNING

EWA15142

When checking the fuel system, do

not smoke, and make sure there are

no open flames or sparks in the ar-

ea, including pilot lights from water

1. Turn signal light bulb

1

1. Maintenance stand (example)

1

BS2-9-E1E0_1.book 35 ページ 2018年4月27日 金曜日 午後4時50分