rear wheel YAMAHA MT-09 2018 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2018, Model line: MT-09, Model: YAMAHA MT-09 2018Pages: 104, PDF Size: 6.97 MB

Page 6 of 104

Table of contentsSafety information........................... 1-1

Description ....................................... 2-1

Left view ......................................... 2-1

Right view ....................................... 2-2

Controls and instruments................ 2-3

Special features ............................... 3-1

D-mode (drive mode)...................... 3-1

Traction control system .................. 3-1

Quick shift system ...... .................... 3-3

Instrument and control

functions ........................................... 4-1

Immobilizer system ..... .................... 4-1

Main switch/steering lock................ 4-2

Handlebar switches ........................ 4-4

Indicator lights and warning lights ............................................ 4-5

Multi-function meter unit ................. 4-8

Clutch lever................................... 4-14

Shift pedal..... ............................ .... 4-14

Brake lever ................................... 4-15

Brake pedal .................................. 4-15

ABS .............................................. 4-16

Fuel tank cap ................................ 4-17

Fuel............................................... 4-17

Fuel tank overflow hose................ 4-19

Catalytic converter ........................ 4-19

Seat .............................................. 4-20

Storage compartment ................... 4-21 Adjusting the front fork ................. 4-21

Adjusting the shock absorber

assembly................................... 4-23

Luggage strap holders . ................ 4-25

Auxiliary DC connectors ............... 4-25

Sidestand ..................................... 4-25

Ignition circuit cut- off system ........ 4-26

For your safety – pre-operation

checks .............................................. 5-1

Operation and important riding

points ................................................ 6-1

Starting the engine ......................... 6-1

Shifting ........................................... 6-2

Tips for reducing fuel consumption ............................... 6-3

Engine break-in .............................. 6-3

Parking ........................................... 6-4

Periodic maintenance and

adjustment ....................................... 7-1

Owner’s tool kit............................... 7-2

Periodic maintenance chart for the emission control system ....... 7-3

General maintenance and lubrication chart .......................... 7-5

Removing and installing panels ..... 7-9

Checking the spark plugs ............. 7-10

Canister ........................................ 7-11

Engine oil ..................................... 7-12 Coolant ........................................ 7-14

Air filter element ........................... 7-16

Checking the engine idling

speed............ ............................ 7-16

Checking the throttle grip

free play.................................... 7-16

Valve clearance ........................... 7-17

Tires ............................................. 7-17

Cast wheels ................................. 7-19

Adjusting the clutch lever free play.................................... 7-20

Checking the brake lever free play.................................... 7-20

Brake light switches ..................... 7-21

Checking the front and rear brake pads................................ 7-21

Checking the brake fluid level ...... 7-22

Changing the brake fluid .............. 7-23

Drive chain slack.......................... 7-24

Cleaning and lubricating the

drive chain ................................ 7-25

Checking and lubricating the cables ....................................... 7-26

Checking and lubricating the throttle grip and cable ............... 7-26

Checking and lubricating the brake and shift pedals .............. 7-27

Checking and lubricating the

brake and clutch levers ............ 7-27

Checking and lubricating the sidestand .................................. 7-28BS2-9-E1E0_1.book 1 ページ 2018年4月27日 金曜日 午後4時50分

Page 16 of 104

3-1

1

23

4

5

6

7

8

9

10

11

12

Special features

EAU76422

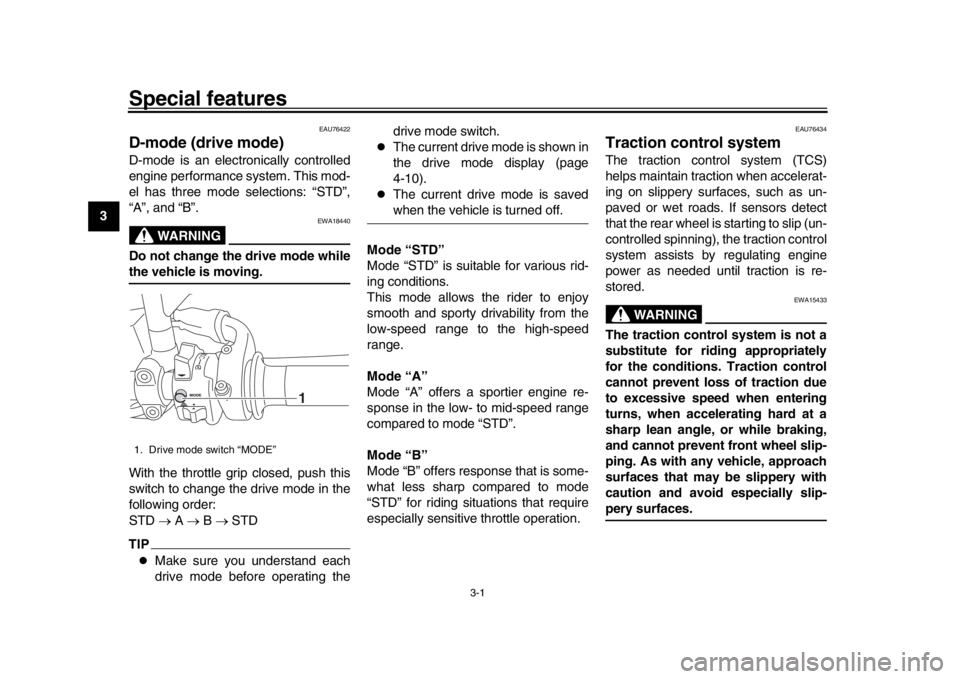

D-mode (drive mode)D-mode is an electronically controlled

engine performance system. This mod-

el has three mode selections: “STD”,

“A”, and “B”.

WARNING

EWA18440

Do not change the drive mode whilethe vehicle is moving.

With the throttle grip closed, push this

switch to change the drive mode in the

following order:

STD A B STDTIP

Make sure you understand each

drive mode before operating the drive mode switch.

The current drive mode is shown in

the drive mode display (page

4-10).

The current drive mode is savedwhen the vehicle is turned off.

Mode “STD”

Mode “STD” is suitable for various rid-

ing conditions.

This mode allows the rider to enjoy

smooth and sporty drivability from the

low-speed range to the high-speed

range.

Mode “A”

Mode “A” offers a sportier engine re-

sponse in the low- to mid-speed range

compared to mode “STD”.

Mode “B”

Mode “B” offers response that is some-

what less sharp compared to mode

“STD” for riding situations that require

especially sensitive throttle operation.

EAU76434

Traction control systemThe traction control system (TCS)

helps maintain traction when accelerat-

ing on slippery surfaces, such as un-

paved or wet roads. If sensors detect

that the rear wheel is starting to slip (un-

controlled spinning), the traction control

system assists by regulating engine

power as needed until traction is re-

stored.

WARNING

EWA15433

The traction control system is not a

substitute for riding appropriately

for the conditions. Traction control

cannot prevent loss of traction due

to excessive speed when entering

turns, when accelerating hard at a

sharp lean angle, or while braking,

and cannot prevent front wheel slip-

ping. As with any vehicle, approach

surfaces that may be slippery with

caution and avoid especially slip-pery surfaces.

1. Drive mode switch “MODE”

1

BS2-9-E1E0_1.book 1 ページ 2018年4月27日 金曜日 午後4時50分

Page 17 of 104

Special features

3-2

1

234

5

6

7

8

9

10

11

12

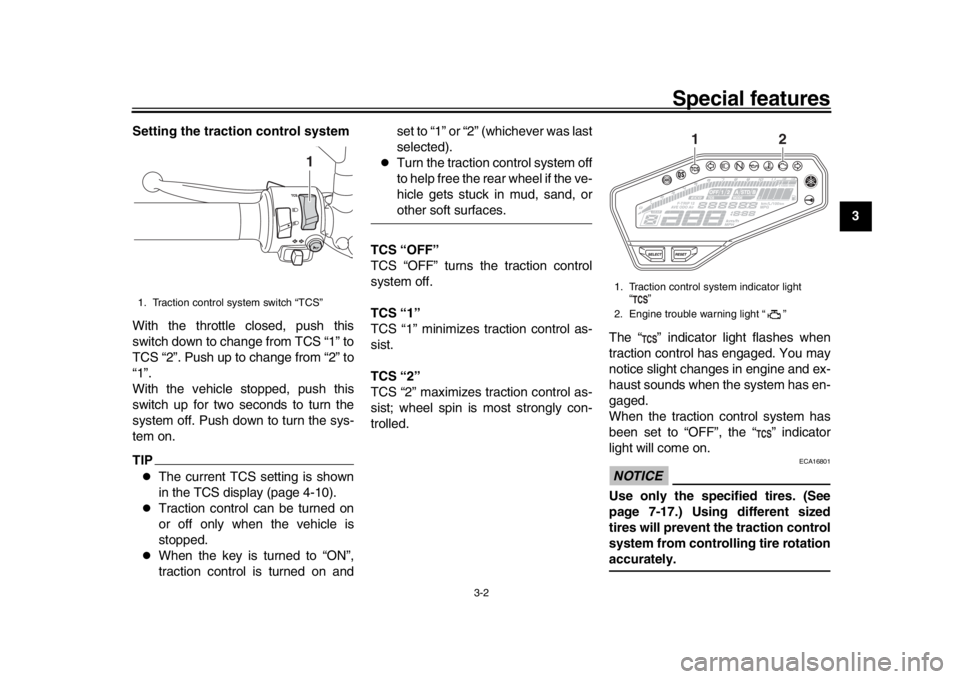

Setting the traction control system

With the throttle closed, push this

switch down to change from TCS “1” to

TCS “2”. Push up to change from “2” to

“1”.

With the vehicle stopped, push this

switch up for two seconds to turn the

system off. Push down to turn the sys-

tem on.

TIP

The current TCS setting is shown

in the TCS display (page 4-10).

Traction control can be turned on

or off only when the vehicle is

stopped.

When the key is turned to “ON”,

traction control is turned on and set to “1” or “2” (whichever was last

selected).

Turn the traction control system off

to help free the rear wheel if the ve-

hicle gets stuck in mud, sand, orother soft surfaces.

TCS “OFF”

TCS “OFF” turns the traction control

system off.

TCS “1”

TCS “1” minimizes traction control as-

sist.

TCS “2”

TCS “2” maximizes traction control as-

sist; wheel spin is most strongly con-

trolled. The “ ” indicator light flashes when

traction control has engaged. You may

notice slight changes in engine and ex-

haust sounds when the system has en-

gaged.

When the traction control system has

been set to “OFF”, the “ ” indicator

light will come on.

NOTICE

ECA16801

Use only the specified tires. (See

page 7-17.) Using different sized

tires will prevent the traction control

system from controlling tire rotationaccurately.

1. Traction control system switch “TCS”

1

1. Traction control system indicator light

“”

2. Engine trouble warning light “ ”

12

BS2-9-E1E0_1.book 2 ページ 2018年4月27日 金曜日 午後4時50分

Page 18 of 104

Special features

3-3

1

23

4

5

6

7

8

9

10

11

12 Resetting the traction control sys-

tem

The traction control system will auto-

matically disable when:

the front wheel or rear wheel

comes off the ground while riding.

excessive rear wheel spin is de-

tected while riding.

either wheel is rotated with the key

turned to “ON” (such as when per-

forming maintenance).

If the traction control system is dis-

abled, both the “ ” indicator light and

the “ ” warning light will come on.

Should this occur, try resetting the sys-

tem as follows. 1. Stop the vehicle and turn the key to “OFF”.

2. Wait a few seconds and then turn the key back to “ON”.

3. The “ ” indicator light should turn off and the system be enabled.

TIPIf the “ ” indicator light remains on af-

ter resetting, the vehicle may still be rid-

den; however, have a Yamaha dealercheck the vehicle as soon as possible.

4. Have a Yamaha dealer check the vehicle and turn off the “ ” warn-

ing light.

EAU76401

Quick shift systemThe quick shift system (QS) allows for

full-throttle, clutch lever-less, electroni-

cally-assisted upshifts. When the shift

switch detects motion in the shift pedal

(page 4-14), engine power and drive

torque are momentarily adjusted to al-

low the upshift to occur.TIP

The quick shift system operates

when traveling at least 20 km/h (12

mi/h) with an engine speed of 2300

r/min or higher, and only when ac-

celerating.

It does not operate when the clutchlever is pulled.

BS2-9-E1E0_1.book 3 ページ 2018年4月27日 金曜日 午後4時50分

Page 34 of 104

Instrument and control functions

4-16

1

2

34

5

6

7

8

9

10

11

12

EAU63040

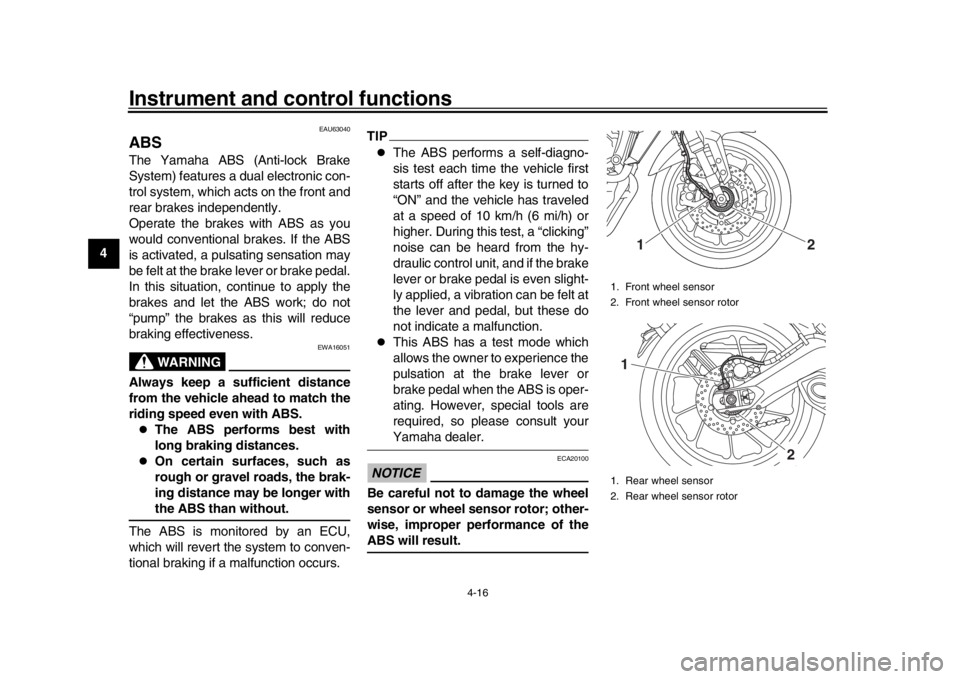

ABSThe Yamaha ABS (Anti-lock Brake

System) features a dual electronic con-

trol system, which acts on the front and

rear brakes independently.

Operate the brakes with ABS as you

would conventional brakes. If the ABS

is activated, a pulsating sensation may

be felt at the brake lever or brake pedal.

In this situation, continue to apply the

brakes and let the ABS work; do not

“pump” the brakes as this will reduce

braking effectiveness.

WARNING

EWA16051

Always keep a sufficient distance

from the vehicle ahead to match the

riding speed even with ABS.

The ABS performs best with

long braking distances.

On certain surfaces, such as

rough or gravel roads, the brak-

ing distance may be longer withthe ABS than without.

The ABS is monitored by an ECU,

which will revert the system to conven-

tional braking if a malfunction occurs.

TIP

The ABS performs a self-diagno-

sis test each time the vehicle first

starts off after the key is turned to

“ON” and the vehicle has traveled

at a speed of 10 km/h (6 mi/h) or

higher. During this test, a “clicking”

noise can be heard from the hy-

draulic control unit, and if the brake

lever or brake pedal is even slight-

ly applied, a vibration can be felt at

the lever and pedal, but these do

not indicate a malfunction.

This ABS has a test mode which

allows the owner to experience the

pulsation at the brake lever or

brake pedal when the ABS is oper-

ating. However, special tools are

required, so please consult yourYamaha dealer.

NOTICE

ECA20100

Be careful not to damage the wheel

sensor or wheel sensor rotor; other-

wise, improper performance of theABS will result.

1. Front wheel sensor

2. Front wheel sensor rotor

1. Rear wheel sensor

2. Rear wheel sensor rotor

1

2

1

2

BS2-9-E1E0_1.book 16 ページ 2018年4月27日 金曜日 午後4時50分

Page 47 of 104

For your safety – pre-operation checks

5-2

1

2

3

456

7

8

9

10

11

12

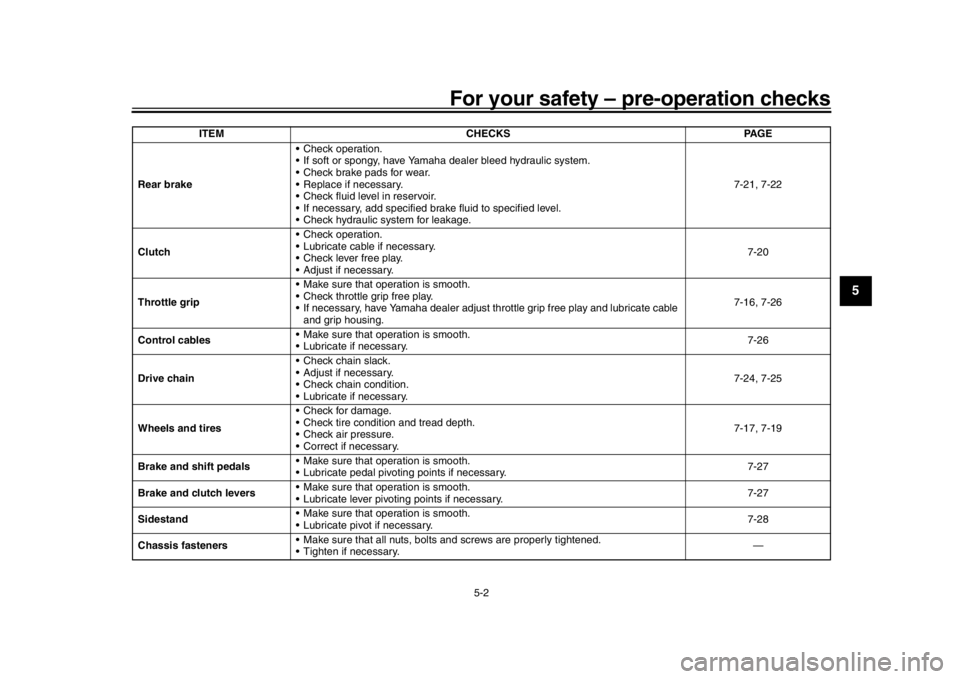

Rear brake Check operation.

If soft or spongy, have Yamaha dealer bleed hydraulic system.

Check brake pads for wear.

Replace if necessary.

Check fluid level in reservoir.

If necessary, add specified brake fluid to specified level.

Check hydraulic system for leakage. 7-21, 7-22

Clutch Check operation.

Lubricate cable if necessary.

Check lever free play.

Adjust if necessary. 7-20

Throttle grip Make sure that operation is smooth.

Check throttle grip free play.

If necessary, have Yamaha dealer adjust th

rottle grip free play and lubricate cable

and grip housing. 7-16, 7-26

Control cables Make sure that operation is smooth.

Lubricate if necessary. 7-26

Drive chain Check chain slack.

Adjust if necessary.

Check chain condition.

Lubricate if necessary. 7-24, 7-25

Wheels and tires Check for damage.

Check tire condition and tread depth.

Check air pressure.

Correct if necessary. 7-17, 7-19

Brake and shift pedals Make sure that operation is smooth.

Lubricate pedal pivoting points if necessary. 7-27

Brake and clutch levers Make sure that operation is smooth.

Lubricate lever pivoting points if necessary. 7-27

Sidestand Make sure that operation is smooth.

Lubricate pivot if necessary. 7-28

Chassis fasteners Make sure that all nuts, bolts and screws are properly tightened.

Tighten if necessary. —

ITEM CHECKS PAGE

BS2-9-E1E0_1.book 2 ページ 2018年4月27日 金曜日 午後4時50分

Page 57 of 104

Periodic maintenance and adjustment

7-5

1

2

3

4

5

678

9

10

11

12

EAU71351

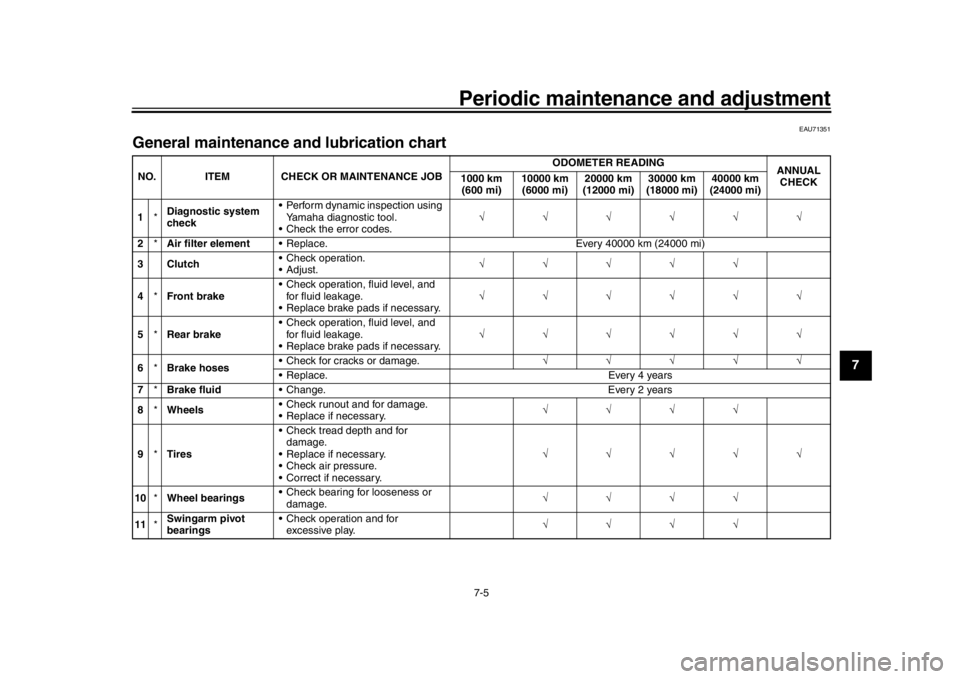

General maintenance an d lubrication chartNO. ITEM CHECK OR MAINTENANCE JOB ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 10000 km

(6000 mi) 20000 km

(12000 mi) 30000 km

(18000 mi) 40000 km

(24000 mi)

1 *Diagnostic system

check Perform dynamic inspection using

Yamaha diagnostic tool.

Check the error codes.

2 *Air filter element Replace. Every 40000 km (24000 mi)

3Clutch Check operation.

Adjust.

4 *Front brake Check operation, fluid level, and

for fluid leakage.

Replace brake pads if necessary.

5 *Rear brake Check operation, fluid level, and

for fluid leakage.

Replace brake pads if necessary.

6 *Brake hoses Check for cracks or damage.

Replace. Every 4 years

7 *Brake fluid Change. Every 2 years

8 *Wheels Check runout and for damage.

Replace if necessary.

9 *Tires Check tread depth and for

damage.

Replace if necessary.

Check air pressure.

Correct if necessary.

10 *Wheel bearings Check bearing for looseness or

damage.

11 *Swingarm pivot

bearings Check operation and for

excessive play.

BS2-9-E1E0_1.book 5 ページ 2018年4月27日 金曜日 午後4時50分

Page 70 of 104

Periodic maintenance and adjustment

7-18

1

2

3

4

5

67

8

9

10

11

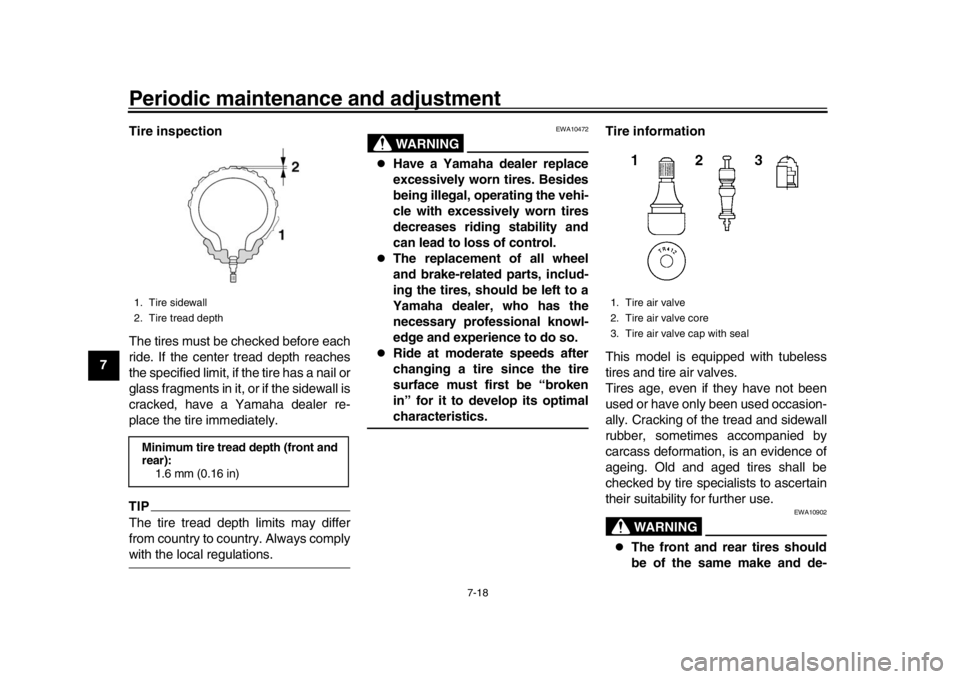

12 Tire inspection

The tires must be checked before each

ride. If the center tread depth reaches

the specified limit, if the tire has a nail or

glass fragments in it, or if the sidewall is

cracked, have a Yamaha dealer re-

place the tire immediately.

TIPThe tire tread depth limits may differ

from country to country. Always complywith the local regulations.

WARNING

EWA10472

Have a Yamaha dealer replace

excessively worn tires. Besides

being illegal, operating the vehi-

cle with excessively worn tires

decreases riding stability and

can lead to loss of control.

The replacement of all wheel

and brake-related parts, includ-

ing the tires, should be left to a

Yamaha dealer, who has the

necessary professional knowl-

edge and experience to do so.

Ride at moderate speeds after

changing a tire since the tire

surface must first be “broken

in” for it to develop its optimalcharacteristics.

Tire information

This model is equipped with tubeless

tires and tire air valves.

Tires age, even if they have not been

used or have only been used occasion-

ally. Cracking of the tread and sidewall

rubber, sometimes accompanied by

carcass deformation, is an evidence of

ageing. Old and aged tires shall be

checked by tire specialists to ascertain

their suitability for further use.

WARNING

EWA10902

The front and rear tires should

be of the same make and de-

1. Tire sidewall

2. Tire tread depthMinimum tire tread depth (front and

rear):

1.6 mm (0.16 in)

1. Tire air valve

2. Tire air valve core

3. Tire air valve cap with seal

BS2-9-E1E0_1.book 18 ページ 2018年4月27日 金曜日 午後4時50分

Page 71 of 104

Periodic maintenance and adjustment7-19

1

2

3

4

5

678

9

10

11

12

sign, otherwise the handling

characteristics of the motorcy-

cle may be different, which

could lead to an accident.

Always make sure that the valve

caps are securely installed to

prevent air pressure leakage.

Use only the tire valves and

valve cores listed below toavoid tire deflation during a ride.

After extensive tests, only the tires list-

ed below have been approved for this

model by Yamaha.

WARNING

EWA10601

This motorcycle is fitted with su-

per-high-speed tires. Note the fol-

lowing points in order to make the

most efficient use of these tires.

Use only the specified replace-

ment tires. Other tires may run

the danger of bursting at super

high speeds.

Brand-new tires can have a rela-

tively poor grip on certain road

surfaces until they have been

“broken in”. Therefore, it is ad-

visable before doing any

high-speed riding to ride con-

servatively for approximately

100 km (60 mi) after installing a

new tire.

The tires must be warmed up

before a high-speed run.

Always adjust the tire air pres-

sure according to the operatingconditions.

EAU21963

Cast wheelsTo maximize the performance, durabil-

ity, and safe operation of your vehicle,

note the following points regarding the

specified wheels.

The wheel rims should be checked

for cracks, bends, warpage or oth-

er damage before each ride. If any

damage is found, have a Yamaha

dealer replace the wheel. Do not

attempt even the smallest repair to

the wheel. A deformed or cracked

wheel must be replaced.

The wheel should be balanced

whenever either the tire or wheel

has been changed or replaced. An

unbalanced wheel can result in

poor performance, adverse han-

dling characteristics, and a short-

ened tire life.

Front tire: Size:

120/70 ZR17 M/C (58W)

Manufacturer/model: BRIDGESTONE/S20F

DUNLOP/D214F

Rear tire: Size:

180/55 ZR17M/C (73W)

Manufacturer/model: BRIDGESTONE/S20R

DUNLOP/D214

FRONT and REAR: Tire air valve:

TR412

Valve core: #9100 (original)

BS2-9-E1E0_1.book 19 ページ 2018年4月27日 金曜日 午後4時50分

Page 76 of 104

Periodic maintenance and adjustment

7-24

1

2

3

4

5

67

8

9

10

11

12

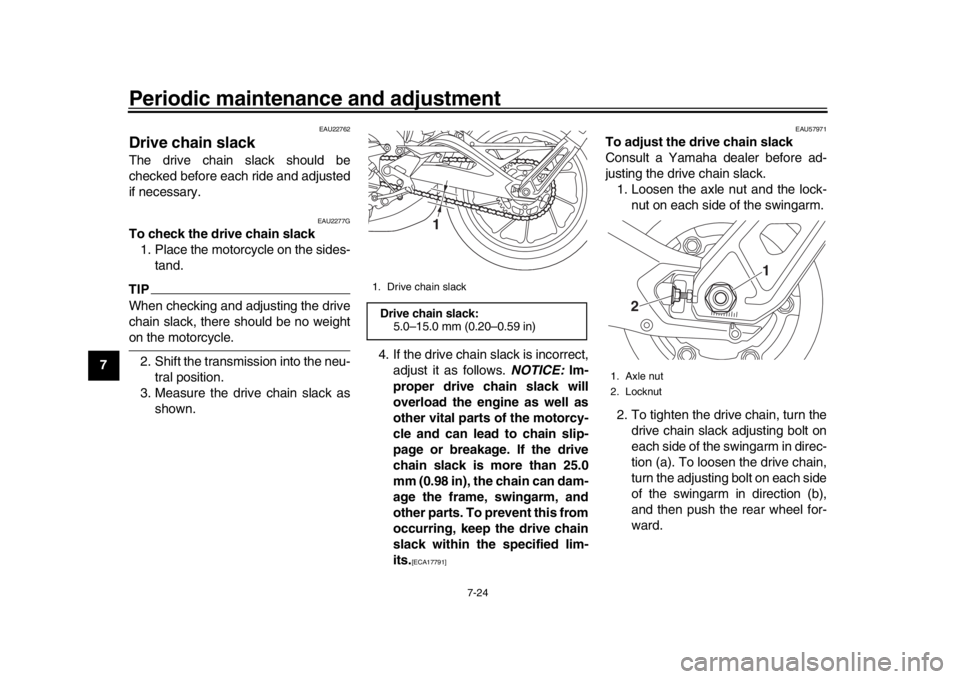

EAU22762

Drive chain slackThe drive chain slack should be

checked before each ride and adjusted

if necessary.

EAU2277G

To check the drive chain slack 1. Place the motorcycle on the sides- tand.TIPWhen checking and adjusting the drive

chain slack, there should be no weighton the motorcycle.

2. Shift the transmission into the neu- tral position.

3. Measure the drive chain slack as shown. 4. If the drive chain slack is incorrect,

adjust it as follows. NOTICE: Im-

proper drive chain slack will

overload the engine as well as

other vital parts of the motorcy-

cle and can lead to chain slip-

page or breakage. If the drive

chain slack is more than 25.0

mm (0.98 in), the chain can dam-

age the frame, swingarm, and

other parts. To prevent this from

occurring, keep the drive chain

slack within the specified lim-

its.

[ECA17791] EAU57971

To adjust the drive chain slack

Consult a Yamaha dealer before ad-

justing the drive chain slack.

1. Loosen the axle nut and the lock- nut on each side of the swingarm.

2. To tighten the drive chain, turn the drive chain slack adjusting bolt on

each side of the swingarm in direc-

tion (a). To loosen the drive chain,

turn the adjusting bolt on each side

of the swingarm in direction (b),

and then push the rear wheel for-

ward.

1. Drive chain slackDrive chain slack:5.0–15.0 mm (0.20–0.59 in)

1

1. Axle nut

2. Locknut

1

2

BS2-9-E1E0_1.book 24 ページ 2018年4月27日 金曜日 午後4時50分