wheel YAMAHA MT-25 2016 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: MT-25, Model: YAMAHA MT-25 2016Pages: 96, PDF Size: 5.16 MB

Page 76 of 96

Periodic maintenance and adjustment

6-33

65. Insert a new bulb into the socket.

6. Install the socket (together with

the bulb) by pushing it in.

7. Install the rear fender lower panel

by installing the bolts and screws.

8. Install the mudguard by installing

the quick fasteners.

EAU24351

Supporting the motorcycleSince this model is not equipped with a

centerstand, follow these precautions

when removing the front and rear

wheel or performing other mainte-

nance requiring the motorcycle to

stand upright. Check that the motorcy-

cle is in a stable and level position be-

fore starting any maintenance. A

strong wooden box can be placed un-

der the engine for added stability.

To service the front wheel

1. Stabilize the rear of the motorcy-

cle by using a motorcycle stand

or, if an additional motorcycle

stand is not available, by placing a

jack under the frame in front of the

rear wheel.

2. Raise the front wheel off the

ground by using a motorcycle

stand.

To service the rear wheel

Raise the rear wheel off the ground by

using a motorcycle stand or, if a motor-

cycle stand is not available, by placinga jack either under each side of the

frame in front of the rear wheel or under

each side of the swingarm.

UB04E0E0.book Page 33 Wednesday, September 2, 2015 3:51 PM

Page 77 of 96

Periodic maintenance and adjustment

6-34

6

EAU24361

Front wheel

EAUN0670

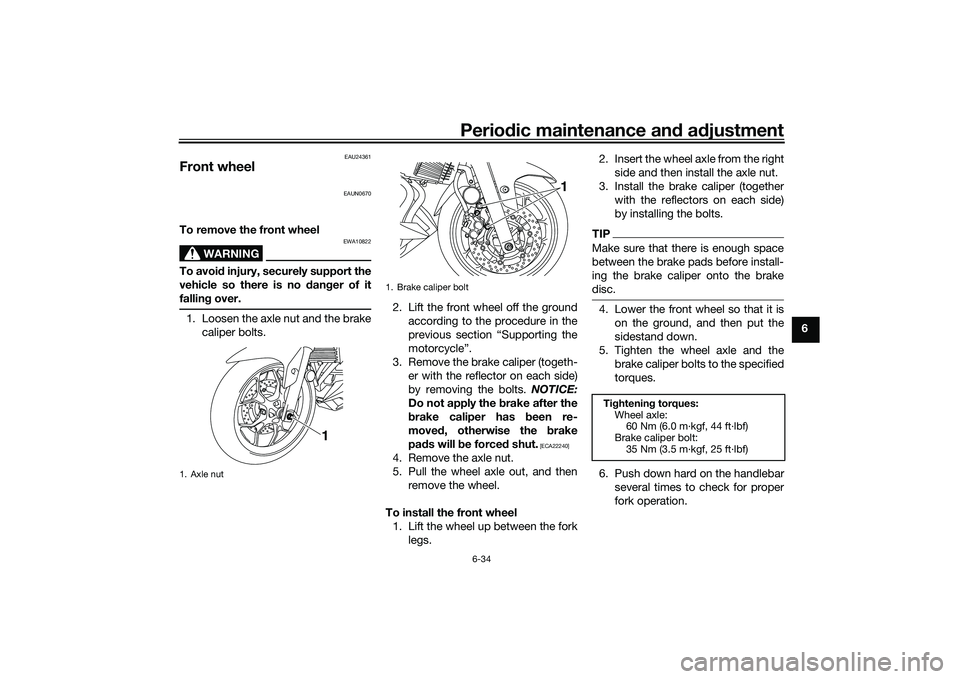

To remove the front wheel

WARNING

EWA10822

To avoid injury, securely support the

vehicle so there is no danger of it

falling over.1. Loosen the axle nut and the brake

caliper bolts.2. Lift the front wheel off the ground

according to the procedure in the

previous section “Supporting the

motorcycle”.

3. Remove the brake caliper (togeth-

er with the reflector on each side)

by removing the bolts. NOTICE:

Do not apply the brake after the

brake caliper has been re-

moved, otherwise the brake

pads will be forced shut.

[ECA22240]

4. Remove the axle nut.

5. Pull the wheel axle out, and then

remove the wheel.

To install the front wheel

1. Lift the wheel up between the fork

legs.2. Insert the wheel axle from the right

side and then install the axle nut.

3. Install the brake caliper (together

with the reflectors on each side)

by installing the bolts.

TIPMake sure that there is enough space

between the brake pads before install-

ing the brake caliper onto the brake

disc.4. Lower the front wheel so that it is

on the ground, and then put the

sidestand down.

5. Tighten the wheel axle and the

brake caliper bolts to the specified

torques.

6. Push down hard on the handlebar

several times to check for proper

fork operation.

1. Axle nut

1

1. Brake caliper bolt

1

Tightening torques:

Wheel axle:

60 Nm (6.0 m·kgf, 44 ft·lbf)

Brake caliper bolt:

35 Nm (3.5 m·kgf, 25 ft·lbf)

UB04E0E0.book Page 34 Wednesday, September 2, 2015 3:51 PM

Page 78 of 96

Periodic maintenance and adjustment

6-35

6

EAU25081

Rear wheel

EAU62612

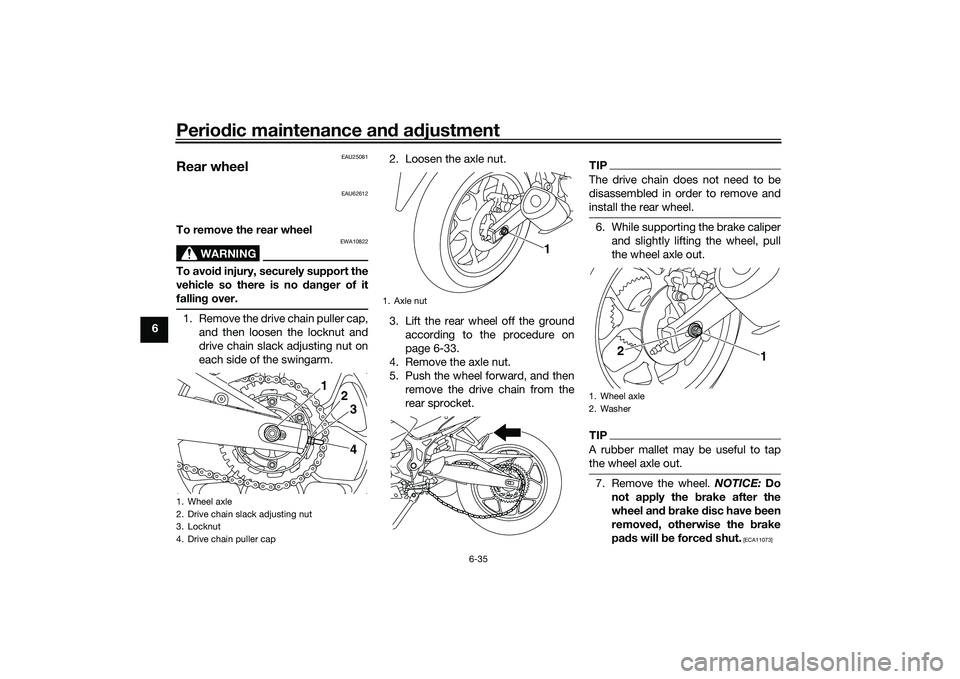

To remove the rear wheel

WARNING

EWA10822

To avoid injury, securely support the

vehicle so there is no danger of it

falling over.1. Remove the drive chain puller cap,

and then loosen the locknut and

drive chain slack adjusting nut on

each side of the swingarm.2. Loosen the axle nut.

3. Lift the rear wheel off the ground

according to the procedure on

page 6-33.

4. Remove the axle nut.

5. Push the wheel forward, and then

remove the drive chain from the

rear sprocket.

TIPThe drive chain does not need to be

disassembled in order to remove and

install the rear wheel.6. While supporting the brake caliper

and slightly lifting the wheel, pull

the wheel axle out.TIPA rubber mallet may be useful to tap

the wheel axle out.7. Remove the wheel. NOTICE: Do

not apply the brake after the

wheel and brake disc have been

removed, otherwise the brake

pads will be forced shut.

[ECA11073]

1. Wheel axle

2. Drive chain slack adjusting nut

3. Locknut

4. Drive chain puller cap

342

1

1. Axle nut

1

1. Wheel axle

2. Washer

1 2

UB04E0E0.book Page 35 Wednesday, September 2, 2015 3:51 PM

Page 79 of 96

Periodic maintenance and adjustment

6-36

6 To install the rear wheel

1. Install the wheel and the brake cal-

iper bracket by inserting the wheel

axle from the left-hand side.

TIPMake sure that the slot in the

brake caliper bracket is fit over the

retainer on the swingarm.

Make sure that there is enough

space between the brake pads

before installing the wheel.2. Install the drive chain onto the rear

sprocket.

3. Install the axle nut.4. Lower the rear wheel so that it is

on the ground, and then put the

sidestand down.

5. Adjust the drive chain slack. (See

page 6-21.)

6. Tighten the axle nut, and then

tighten the locknuts to the speci-

fied torques.

7. Install the drive chain puller caps.

EAU25872

TroubleshootingAlthough Yamaha motorcycles receive

a thorough inspection before shipment

from the factory, trouble may occur

during operation. Any problem in the

fuel, compression, or ignition systems,

for example, can cause poor starting

and loss of power.

The following troubleshooting charts

represent quick and easy procedures

for checking these vital systems your-

self. However, should your motorcycle

require any repair, take it to a Yamaha

dealer, whose skilled technicians have

the necessary tools, experience, and

know-how to service the motorcycle

properly.

Use only genuine Yamaha replace-

ment parts. Imitation parts may look

like Yamaha parts, but they are often

inferior, have a shorter service life and

can lead to expensive repair bills.

WARNING

EWA15142

When checking the fuel system, do

not smoke, and make sure there are

no open flames or sparks in the ar-

ea, including pilot lights from water

1. Retainer

2. Slot

1

2

Tightening torques:

Axle nut:

57 Nm (5.7 m·kgf, 41 ft·lbf)

Locknut:

16 Nm (1.6 m·kgf, 12 ft·lbf)

UB04E0E0.book Page 36 Wednesday, September 2, 2015 3:51 PM

Page 83 of 96

Motorcycle care and storage

7-1

7

EAU37834

Matte color cautionNOTICE

ECA15193

Some models are equipped with

matte colored finished parts. Be

sure to consult a Yamaha dealer for

advice on what products to use be-

fore cleaning the vehicle. Using a

brush, harsh chemical products or

cleaning compounds when cleaning

these parts will scratch or damage

their surface. Wax also should not

be applied to any matte colored fin-

ished parts.

EAU54661

CareWhile the open design of a motorcycle

reveals the attractiveness of the tech-

nology, it also makes it more vulnera-

ble. Rust and corrosion can develop

even if high-quality components are

used. A rusty exhaust pipe may go un-

noticed on a car, however, it detracts

from the overall appearance of a mo-

torcycle. Frequent and proper care

does not only comply with the terms of

the warranty, but it will also keep your

motorcycle looking good, extend its

life and optimize its performance.

Before cleaning

1. Cover the muffler outlet with a

plastic bag after the engine has

cooled down.

2. Make sure that all caps and cov-

ers as well as all electrical cou-

plers and connectors, including

the spark plug caps, are tightly in-

stalled.

3. Remove extremely stubborn dirt,

like oil burnt onto the crankcase,

with a degreasing agent and a

brush, but never apply such prod-ucts onto seals, gaskets, sprock-

ets, the drive chain and wheel

axles. Always rinse the dirt and

degreaser off with water.

Cleaning

NOTICE

ECA10773

Avoid using strong acidic wheel

cleaners, especially on spoked

wheels. If such products are

used on hard-to-remove dirt, do

not leave the cleaner on the af-

fected area any longer than in-

structed. Also, thoroughly rinse

the area off with water, immedi-

ately dry it, and then apply a cor-

rosion protection spray.

Improper cleaning can damage

plastic parts (such as cowlings,

panels, windshields, headlight

lenses, meter lenses, etc.) and

the mufflers. Use only a soft,

clean cloth or sponge with wa-

ter to clean plastic. However, if

the plastic parts cannot be thor-

oughly cleaned with water, di-

luted mild detergent with water

may be used. Be sure to rinse

UB04E0E0.book Page 1 Wednesday, September 2, 2015 3:51 PM

Page 84 of 96

Motorcycle care and storage

7-2

7off any detergent residue using

plenty of water, as it is harmful

to plastic parts.

Do not use any harsh chemical

products on plastic parts. Be

sure to avoid using cloths or

sponges which have been in

contact with strong or abrasive

cleaning products, solvent or

thinner, fuel (gasoline), rust re-

movers or inhibitors, brake fluid,

antifreeze or electrolyte.

Do not use high-pressure wash-

ers or steam-jet cleaners since

they cause water seepage and

deterioration in the following ar-

eas: seals (of wheel and swing-

arm bearings, fork and brakes),

electric components (couplers,

connectors, instruments,

switches and lights), breather

hoses and vents.

For motorcycles equipped with

a windshield: Do not use strong

cleaners or hard sponges as

they will cause dulling

or

scratching. Some cleaning

compounds for plastic may

leave scratches on the wind-shield. Test the product on a

small hidden part of the wind-

shield to make sure that it does

not leave any marks. If the wind-

shield is scratched, use a quality

plastic polishing compound af-

ter washing.

After normal useRemove dirt with warm water, a mild

detergent, and a soft, clean sponge,

and then rinse thoroughly with clean

water. Use a toothbrush or bottlebrush

for hard-to-reach areas. Stubborn dirt

and insects will come off more easily if

the area is covered with a wet cloth for

a few minutes before cleaning.

After riding in the rain, near the sea oron salt-sprayed roadsSince sea salt or salt sprayed on roads

during winter are extremely corrosive

in combination with water, carry out

the following steps after each ride in

the rain, near the sea or on salt-

sprayed roads.

TIPSalt sprayed on roads in the winter

may remain well into spring.1. Clean the motorcycle with cold

water and a mild detergent, after

the engine has cooled down.

NOTICE: Do not use warm wa-

ter since it increases the corro-

sive action of the salt.

[ECA10792]

2. Apply a corrosion protection spray

on all metal, including chrome-

and nickel-plated, surfaces to pre-

vent corrosion.

Cleaning the windshieldAvoid using any alkaline or strong acid

cleaner, gasoline, brake fluid, or any

other solvent. Clean the windshield

with a cloth or sponge dampened with

a mild detergent, and then wash it off

thoroughly with water. For additional

cleaning, use Yamaha Windshield

Cleaner or another high-quality wind-

shield cleaner. Some cleaning com-

pounds for plastics may leave

scratches on the windshield. Before

using such cleaners, test an area of the

UB04E0E0.book Page 2 Wednesday, September 2, 2015 3:51 PM

Page 86 of 96

Motorcycle care and storage

7-4

7

EAU26183

StorageShort-term

Always store your motorcycle in a cool,

dry place and, if necessary, protect it

against dust with a porous cover. Be

sure the engine and the exhaust sys-

tem are cool before covering the mo-

torcycle.NOTICE

ECA10811

Storing the motorcycle in a

poorly ventilated room or cover-

ing it with a tarp, while it is still

wet, will allow water and humid-

ity to seep in and cause rust.

To prevent corrosion, avoid

damp cellars, stables (because

of the presence of ammonia)

and areas where strong chemi-

cals are stored.Long-term

Before storing your motorcycle for sev-

eral months:

1. Follow all the instructions in the

“Care” section of this chapter.2. Fill up the fuel tank and add fuel

stabilizer (if available) to prevent

the fuel tank from rusting and the

fuel from deteriorating.

3. Perform the following steps to

protect the cylinders, piston rings,

etc. from corrosion.

a. Remove the spark plug caps

and spark plugs.

b. Pour a teaspoonful of engine

oil into each spark plug bore.

c. Install the spark plug caps onto

the spark plugs, and then

place the spark plugs on the

cylinder head so that the elec-

trodes are grounded. (This will

limit sparking during the next

step.)

d. Turn the engine over several

times with the starter. (This will

coat the cylinder walls with oil.)

WARNING! To prevent dam-

age or injury from sparking,

make sure to ground the

spark plug electrodes while

turning the engine over.

[EWA10952]

e. Remove the spark plug caps

from the spark plugs, and then

install the spark plugs and the

spark plug caps.

4. Lubricate all control cables and

the pivoting points of all levers and

pedals as well as of the side-

stand/centerstand.

5. Check and, if necessary, correct

the tire air pressure, and then lift

the motorcycle so that both of its

wheels are off the ground. Alterna-

tively, turn the wheels a little every

month in order to prevent the tires

from becoming degraded in one

spot.

6. Cover the muffler outlet with a

plastic bag to prevent moisture

from entering it.

7. Remove the battery and fully

charge it. Store it in a cool, dry

place and charge it once a month.

Do not store the battery in an ex-

cessively cold or warm place [less

than 0 °C (30 °F) or more than 30

°C (90 °F)]. For more information

on storing the battery, see page

6-28.

UB04E0E0.book Page 4 Wednesday, September 2, 2015 3:51 PM

Page 88 of 96

Specifications

8-1

8

Dimensions:Overall length:

2090 mm (82.3 in)

Overall width:

745 mm (29.3 in)

Overall height:

1035 mm (40.7 in)

Seat height:

780 mm (30.7 in)

Wheelbase:

1380 mm (54.3 in)

Ground clearance:

160 mm (6.30 in)

Minimum turning radius:

2.7 m (8.86 ft)Weight:Curb weight:

165 kg (364 lb)Engine:Combustion cycle:

4-stroke

Cooling system:

Liquid cooled

Valve train:

DOHC

Cylinder arrangement:

Inline

Number of cylinders:

2-cylinder

Displacement:

250 cm3

Bore × stroke:

60.0 × 44.1 mm (2.36 × 1.74 in)Compression ratio:

11.6 : 1

Starting system:

Electric starter

Lubrication system:

Wet sump

Engine oil:Recommended brand:

YAMALUBE

SAE viscosity grades:

10W-40

Recommended engine oil grade:

API service SG type or higher, JASO

standard MA

Engine oil quantity:

Oil change:

1.80 L (1.90 US qt, 1.58 Imp.qt)

With oil filter removal:

2.10 L (2.22 US qt, 1.85 Imp.qt)Coolant quantity:Coolant reservoir (up to the maximum level

mark):

0.25 L (0.26 US qt, 0.22 Imp.qt)

Radiator (including all routes):

0.96 L (1.01 US qt, 0.84 Imp.qt)Air filter:Air filter element:

Oil-coated paper elementFuel:Recommended fuel:

Regular unleaded gasoline (Gasohol [E10]

acceptable)

Fuel tank capacity:

14 L (3.7 US gal, 3.1 Imp.gal)Fuel reserve amount:

3.0 L (0.79 US gal, 0.66 Imp.gal)

Fuel injection:Throttle body:

ID mark:

1WD1 00Spark plug(s):Manufacturer/model:

NGK/CR9E

Spark plug gap:

0.7–0.8 mm (0.028–0.031 in)Clutch:Clutch type:

Wet, multiple-discDrivetrain:Primary reduction ratio:

3.043 (70/23)

Final drive:

Chain

Secondary reduction ratio:

3.071 (43/14)

Transmission type:

Constant mesh 6-speed

Gear ratio:

1st:

2.667 (40/15)

2nd:

1.882 (32/17)

3rd:

1.455 (32/22)

4th:

1.200 (30/25)

5th:

1.037 (28/27)

UB04E0E0.book Page 1 Wednesday, September 2, 2015 3:51 PM

Page 89 of 96

Specifications

8-2

8

6th:

0.920 (23/25)

Chassis:Frame type:

Diamond

Caster angle:

25.0 °

Trail:

95 mm (3.7 in)Front tire:Type:

Tubeless

Size:

110/70-17M/C (54S)

Manufacturer/model:

IRC/RX-01FRear tire:Type:

Tubeless

Size:

140/70-17M/C (66S)

Manufacturer/model:

IRC/RX-01RLoading:Maximum load:

160 kg (353 lb)

(Total weight of rider, passenger, cargo

and accessories)Tire air pressure (measured on cold

tires):1 person:

Front:

200 kPa (2.00 kgf/cm2, 29 psi)Rear:

225 kPa (2.25 kgf/cm2, 33 psi)

2 persons:

Front:

200 kPa (2.00 kgf/cm2, 29 psi)

Rear:

225 kPa (2.25 kgf/cm2, 33 psi)

Front wheel:Wheel type:

Cast wheel

Rim size:

17M/C x MT2.75Rear wheel:Wheel type:

Cast wheel

Rim size:

17M/C x MT4.00Front brake:Type:

Hydraulic single disc brake

Specified brake fluid:

DOT 4Rear brake:Type:

Hydraulic single disc brake

Specified brake fluid:

DOT 4Front suspension:Type:

Telescopic fork

Spring:

Coil spring

Shock absorber:

Hydraulic damperWheel travel:

130 mm (5.1 in)

Rear suspension:Type:

Swingarm

Spring:

Coil spring

Shock absorber:

Hydraulic damper

Wheel travel:

125 mm (4.9 in)Electrical system:System voltage:

12 V

Ignition system:

TCI

Charging system:

AC magnetoBattery:Model:

GTZ8V

Voltage, capacity:

12 V, 7.0 Ah (10 HR)Headlight:Bulb type:

Halogen bulbBulb wattage × quantity:Headlight:

H4, 60.0 W/55.0 W x 1

Brake/tail light:

LED

Front turn signal light:

10.0 W × 2

UB04E0E0.book Page 2 Wednesday, September 2, 2015 3:51 PM

Page 94 of 96

Index

10-2

10

Turn signal light bulb, replacing............ 6-31

Turn signal switch ................................. 3-11VValve clearance..................................... 6-15

Vehicle identification number ................. 9-1WWheel bearings, checking..................... 6-27

Wheel (front).......................................... 6-34

Wheel (rear) ........................................... 6-35

Wheels .................................................. 6-17

UB04E0E0.book Page 2 Wednesday, September 2, 2015 3:51 PM