light YAMAHA MT-25 2016 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: MT-25, Model: YAMAHA MT-25 2016Pages: 96, PDF Size: 5.16 MB

Page 51 of 96

Periodic maintenance and adjustment

6-8

6

EAU19643

Checking the spark plugsThe spark plugs are important engine

components, which should be

checked periodically, preferably by a

Yamaha dealer. Since heat and depos-

its will cause any spark plug to slowly

erode, they should be removed and

checked in accordance with the peri-

odic maintenance and lubrication

chart. In addition, the condition of the

spark plugs can reveal the condition of

the engine.

The porcelain insulator around the

center electrode of each spark plug

should be a medium-to-light tan (the

ideal color when the vehicle is ridden

normally), and all spark plugs installed

in the engine should have the same

color. If any spark plug shows a dis-

tinctly different color, the engine could

be operating improperly. Do not at-

tempt to diagnose such problems

yourself. Instead, have a Yamaha deal-

er check the vehicle.

If a spark plug shows signs of elec-

trode erosion and excessive carbon or

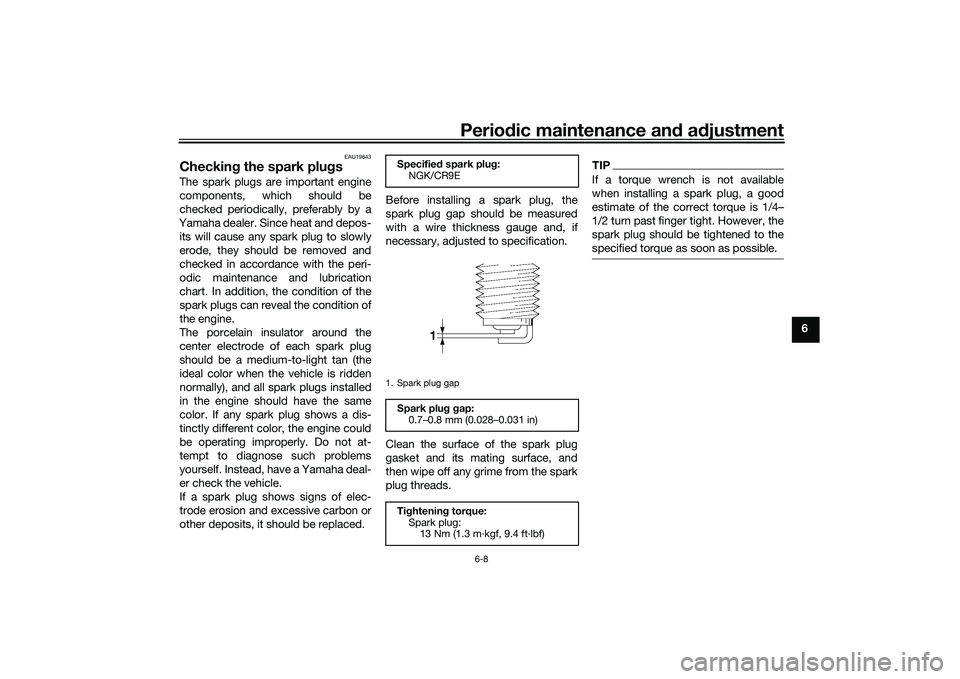

other deposits, it should be replaced.Before installing a spark plug, the

spark plug gap should be measured

with a wire thickness gauge and, if

necessary, adjusted to specification.

Clean the surface of the spark plug

gasket and its mating surface, and

then wipe off any grime from the spark

plug threads.

TIPIf a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is 1/4…

1/2 turn past finger tight. However, the

spark plug should be tightened to the

specified torque as soon as possible.

Specified spark plug:

NGK/CR9E

1. Spark plug gap

Spark plug gap:

0.7–0.8 mm (0.028–0.031 in)

Tightening torque:

Spark plug:

13 Nm (1.3 m·kgf, 9.4 ft·lbf)

UB04E0E0.book Page 8 Wednesday, September 2, 2015 3:51 PM

Page 52 of 96

Periodic maintenance and adjustment

6-9

6

EAUN1150

Engine oil and oil filter car-

tridgeThe engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil filter car-

tridge replaced at the intervals speci-

fied in the periodic maintenance and

lubrication chart.

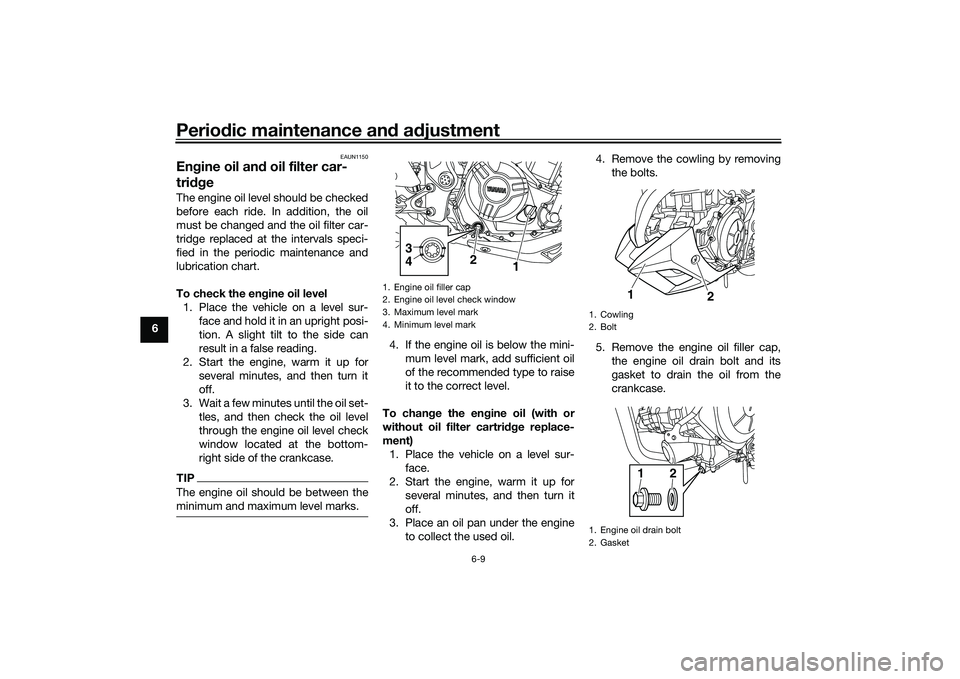

To check the engine oil level

1. Place the vehicle on a level sur-

face and hold it in an upright posi-

tion. A slight tilt to the side can

result in a false reading.

2. Start the engine, warm it up for

several minutes, and then turn it

off.

3. Wait a few minutes until the oil set-

tles, and then check the oil level

through the engine oil level check

window located at the bottom-

right side of the crankcase.TIPThe engine oil should be between the

minimum and maximum level marks.

4. If the engine oil is below the mini-

mum level mark, add sufficient oil

of the recommended type to raise

it to the correct level.

To change the engine oil (with or

without oil filter cartridge replace-

ment)

1. Place the vehicle on a level sur-

face.

2. Start the engine, warm it up for

several minutes, and then turn it

off.

3. Place an oil pan under the engine

to collect the used oil.4. Remove the cowling by removing

the bolts.

5. Remove the engine oil filler cap,

the engine oil drain bolt and its

gasket to drain the oil from the

crankcase.1. Engine oil filler cap

2. Engine oil level check window

3. Maximum level mark

4. Minimum level mark

3

4

1 2

1. Cowling

2. Bolt

1. Engine oil drain bolt

2. Gasket

1

2

12

UB04E0E0.book Page 9 Wednesday, September 2, 2015 3:51 PM

Page 54 of 96

Periodic maintenance and adjustment

6-11

6

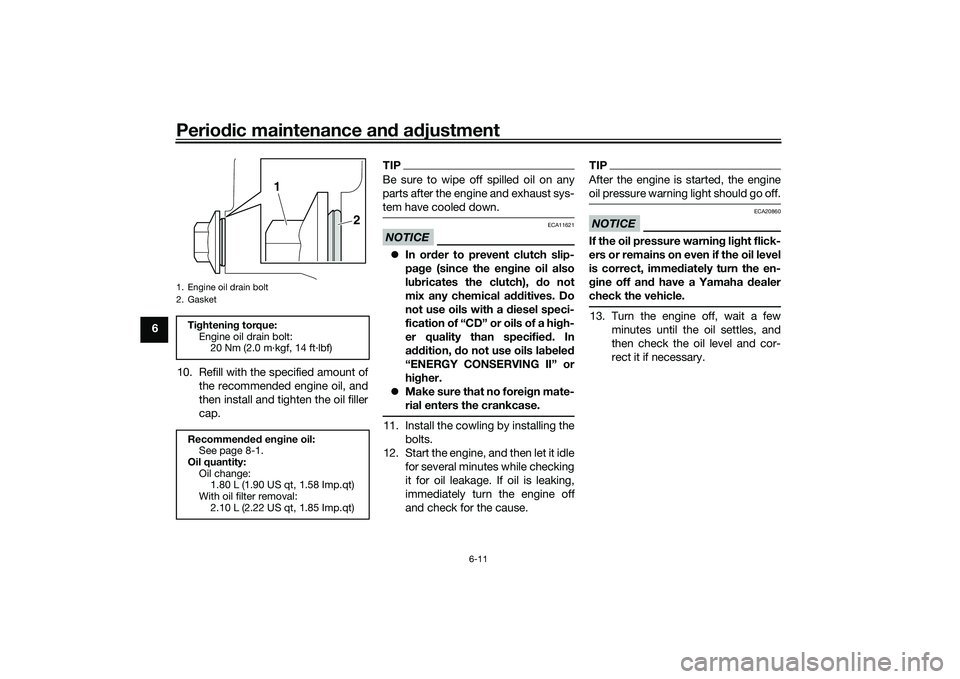

10. Refill with the specified amount of

the recommended engine oil, and

then install and tighten the oil filler

cap.

TIPBe sure to wipe off spilled oil on any

parts after the engine and exhaust sys-

tem have cooled down.NOTICE

ECA11621

In order to prevent clutch slip-

page (since the engine oil also

lubricates the clutch), do not

mix any chemical additives. Do

not use oils with a diesel speci-

fication of “CD” or oils of a high-

er quality than specified. In

addition, do not use oils labeled

“ENERGY CONSERVING II” or

higher.

Make sure that no foreign mate-

rial enters the crankcase.11. Install the cowling by installing the

bolts.

12. Start the engine, and then let it idle

for several minutes while checking

it for oil leakage. If oil is leaking,

immediately turn the engine off

and check for the cause.

TIPAfter the engine is started, the engine

oil pressure warning light should go off.NOTICE

ECA20860

If the oil pressure warning light flick-

ers or remains on even if the oil level

is correct, immediately turn the en-

gine off and have a Yamaha dealer

check the vehicle.13. Turn the engine off, wait a few

minutes until the oil settles, and

then check the oil level and cor-

rect it if necessary.

1. Engine oil drain bolt

2. GasketTightening torque:

Engine oil drain bolt:

20 Nm (2.0 m·kgf, 14 ft·lbf)

Recommended engine oil:

See page 8-1.

Oil quantity:

Oil change:

1.80 L (1.90 US qt, 1.58 Imp.qt)

With oil filter removal:

2.10 L (2.22 US qt, 1.85 Imp.qt)

2

1

UB04E0E0.book Page 11 Wednesday, September 2, 2015 3:51 PM

Page 55 of 96

Periodic maintenance and adjustment

6-12

6

EAU20071

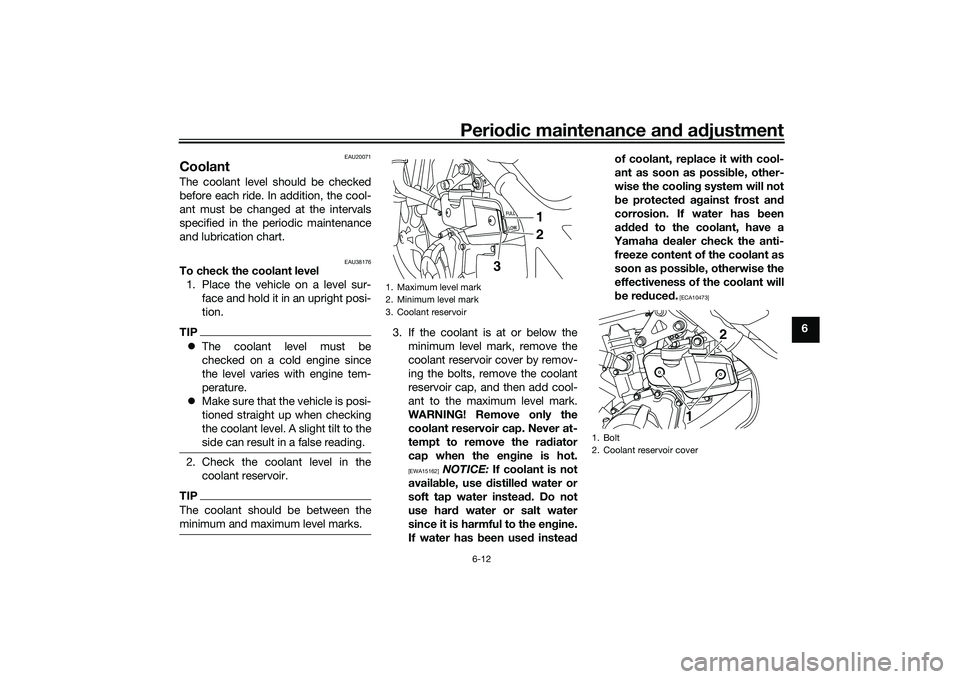

CoolantThe coolant level should be checked

before each ride. In addition, the cool-

ant must be changed at the intervals

specified in the periodic maintenance

and lubrication chart.

EAU38176

To check the coolant level

1. Place the vehicle on a level sur-

face and hold it in an upright posi-

tion.TIPThe coolant level must be

checked on a cold engine since

the level varies with engine tem-

perature.

Make sure that the vehicle is posi-

tioned straight up when checking

the coolant level. A slight tilt to the

side can result in a false reading.2. Check the coolant level in the

coolant reservoir.TIPThe coolant should be between the

minimum and maximum level marks.

3. If the coolant is at or below the

minimum level mark, remove the

coolant reservoir cover by remov-

ing the bolts, remove the coolant

reservoir cap, and then add cool-

ant to the maximum level mark.

WARNING! Remove only the

coolant reservoir cap. Never at-

tempt to remove the radiator

cap when the engine is hot.

[EWA15162]

NOTICE: If coolant is not

available, use distilled water or

soft tap water instead. Do not

use hard water or salt water

since it is harmful to the engine.

If water has been used insteadof coolant, replace it with cool-

ant as soon as possible, other-

wise the cooling system will not

be protected against frost and

corrosion. If water has been

added to the coolant, have a

Yamaha dealer check the anti-

freeze content of the coolant as

soon as possible, otherwise the

effectiveness of the coolant will

be reduced.

[ECA10473]

1. Maximum level mark

2. Minimum level mark

3. Coolant reservoir

1

2

3

1. Bolt

2. Coolant reservoir cover

2

1

UB04E0E0.book Page 12 Wednesday, September 2, 2015 3:51 PM

Page 62 of 96

Periodic maintenance and adjustment

6-19

6

EAU22274

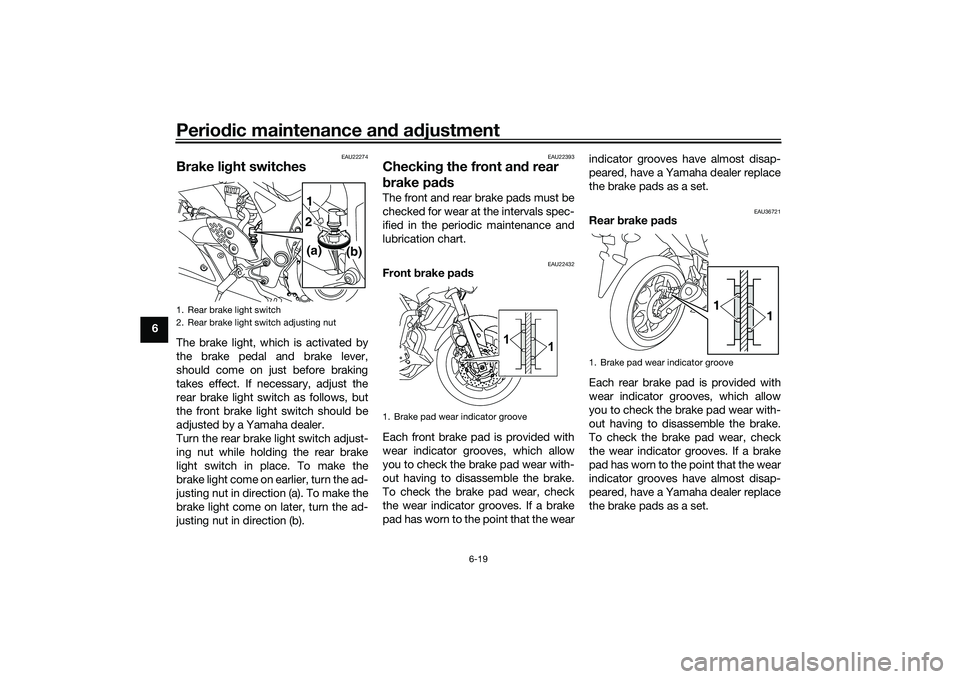

Brake light switchesThe brake light, which is activated by

the brake pedal and brake lever,

should come on just before braking

takes effect. If necessary, adjust the

rear brake light switch as follows, but

the front brake light switch should be

adjusted by a Yamaha dealer.

Turn the rear brake light switch adjust-

ing nut while holding the rear brake

light switch in place. To make the

brake light come on earlier, turn the ad-

justing nut in direction (a). To make the

brake light come on later, turn the ad-

justing nut in direction (b).

EAU22393

Checking the front and rear

brake padsThe front and rear brake pads must be

checked for wear at the intervals spec-

ified in the periodic maintenance and

lubrication chart.

EAU22432

Front brake pads

Each front brake pad is provided with

wear indicator grooves, which allow

you to check the brake pad wear with-

out having to disassemble the brake.

To check the brake pad wear, check

the wear indicator grooves. If a brake

pad has worn to the point that the wearindicator grooves have almost disap-

peared, have a Yamaha dealer replace

the brake pads as a set.

EAU36721

Rear brake pads

Each rear brake pad is provided with

wear indicator grooves, which allow

you to check the brake pad wear with-

out having to disassemble the brake.

To check the brake pad wear, check

the wear indicator grooves. If a brake

pad has worn to the point that the wear

indicator grooves have almost disap-

peared, have a Yamaha dealer replace

the brake pads as a set.

1. Rear brake light switch

2. Rear brake light switch adjusting nut

(a)

(b)1

2

1. Brake pad wear indicator groove

1 1

1. Brake pad wear indicator groove

1

1

UB04E0E0.book Page 19 Wednesday, September 2, 2015 3:51 PM

Page 73 of 96

Periodic maintenance and adjustment

6-30

6

If a fuse is blown, replace it as follows.1. Turn the key to “ ” and turn off

the electrical circuit in question.

2. Remove the blown fuse, and then

install a new fuse of the specified

amperage. WARNING! Do not

use a fuse of a higher amperage

rating than recommended to

avoid causing extensive dam-

age to the electrical system and

possibly a fire.

[EWA15132]

3. Turn the key to “ ” and turn on

the electrical circuit in question to

check if the device operates.

4. If the fuse immediately blows

again, have a Yamaha dealer

check the electrical system.

EAU68470

Replacing the headlight bulbThis model is equipped with halogen

bulb headlight. If a headlight bulb

burns out, have a Yamaha dealer re-

place it and, if necessary, adjust the

headlight beam.NOTICE

ECA17871

Headlight lens:

Do not affix any type of tinted film or

stickers to the headlight lens.

Do not use a headlight bulb of a

wattage higher than specified.

1. Fuse box

1. Ignition fuse

2. Signaling system fuse

3. Backup fuse (for clock)

4. Headlight fuse

5. Radiator fan motor fuse

6. Spare fuse

16

12345

Specified fuses:

Main fuse:

30.0 A

Headlight fuse:

15.0 A

Signaling system fuse:

7.5 A

Ignition fuse:

15.0 A

Radiator fan motor fuse:

7.5 A

Backup fuse:

7.5 A

UB04E0E0.book Page 30 Wednesday, September 2, 2015 3:51 PM

Page 74 of 96

Periodic maintenance and adjustment

6-31

6

EAU44941

Auxiliary lightThis model is equipped with an LED-

type auxiliary light.

If the auxiliary light does not come on,

have a Yamaha dealer check it.

EAU24182

Tail/brake lightThis model is equipped with an LED-

type tail/brake light.

If the tail/brake light does not come on,

have a Yamaha dealer check it.

EAU62590

Replacing a turn signal light

bulb1. Remove the turn signal light lens

by removing the screw.

2. Remove the turn signal light bulb

socket (together with the bulb) by

turning it counterclockwise.

1. Auxiliary light

1 1

1. Turn signal light lens

2. Screw

1

2

UB04E0E0.book Page 31 Wednesday, September 2, 2015 3:51 PM

Page 75 of 96

Periodic maintenance and adjustment

6-32

6 3. Remove the burnt-out bulb by

pulling it out.

4. Insert a new bulb into the socket.

5. Install the socket (together with

the bulb) by turning it clockwise.

6. Install the turn signal light lens by

installing the screw. NOTICE: Do

not overtighten the screw, oth-

erwise the lens may break.

[ECA11192]EAU62670

Replacing the license plate

light bulb1. Remove the mudguard by remov-

ing the quick fasteners.

2. Remove the rear fender lower

panel by removing the bolts and

screws.3. Remove the license plate light

bulb socket (together with the

bulb) by pulling it out.

4. Remove the burnt-out bulb by

pulling it out.

1. Turn signal light bulb socket

1

1. Mudguard

2. Quick fastener

1

2

1. Bolt

2. Screw

3. Rear fender lower panel

1. License plate light bulb

2. License plate light bulb socket

3

2

1

2

2 121

UB04E0E0.book Page 32 Wednesday, September 2, 2015 3:51 PM

Page 78 of 96

Periodic maintenance and adjustment

6-35

6

EAU25081

Rear wheel

EAU62612

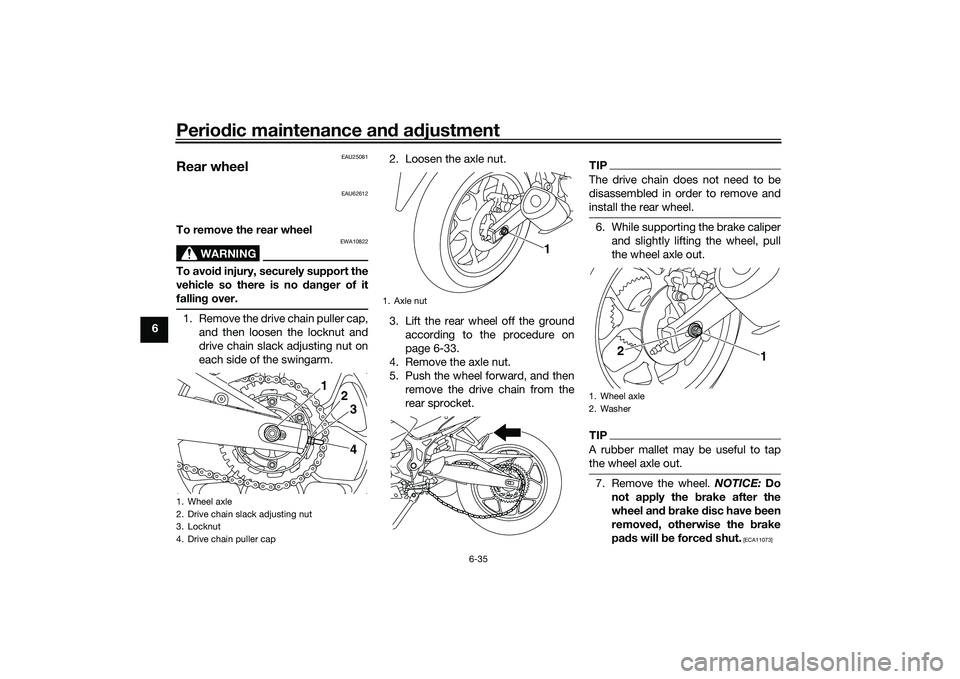

To remove the rear wheel

WARNING

EWA10822

To avoid injury, securely support the

vehicle so there is no danger of it

falling over.1. Remove the drive chain puller cap,

and then loosen the locknut and

drive chain slack adjusting nut on

each side of the swingarm.2. Loosen the axle nut.

3. Lift the rear wheel off the ground

according to the procedure on

page 6-33.

4. Remove the axle nut.

5. Push the wheel forward, and then

remove the drive chain from the

rear sprocket.

TIPThe drive chain does not need to be

disassembled in order to remove and

install the rear wheel.6. While supporting the brake caliper

and slightly lifting the wheel, pull

the wheel axle out.TIPA rubber mallet may be useful to tap

the wheel axle out.7. Remove the wheel. NOTICE: Do

not apply the brake after the

wheel and brake disc have been

removed, otherwise the brake

pads will be forced shut.

[ECA11073]

1. Wheel axle

2. Drive chain slack adjusting nut

3. Locknut

4. Drive chain puller cap

342

1

1. Axle nut

1

1. Wheel axle

2. Washer

1 2

UB04E0E0.book Page 35 Wednesday, September 2, 2015 3:51 PM

Page 79 of 96

Periodic maintenance and adjustment

6-36

6 To install the rear wheel

1. Install the wheel and the brake cal-

iper bracket by inserting the wheel

axle from the left-hand side.

TIPMake sure that the slot in the

brake caliper bracket is fit over the

retainer on the swingarm.

Make sure that there is enough

space between the brake pads

before installing the wheel.2. Install the drive chain onto the rear

sprocket.

3. Install the axle nut.4. Lower the rear wheel so that it is

on the ground, and then put the

sidestand down.

5. Adjust the drive chain slack. (See

page 6-21.)

6. Tighten the axle nut, and then

tighten the locknuts to the speci-

fied torques.

7. Install the drive chain puller caps.

EAU25872

TroubleshootingAlthough Yamaha motorcycles receive

a thorough inspection before shipment

from the factory, trouble may occur

during operation. Any problem in the

fuel, compression, or ignition systems,

for example, can cause poor starting

and loss of power.

The following troubleshooting charts

represent quick and easy procedures

for checking these vital systems your-

self. However, should your motorcycle

require any repair, take it to a Yamaha

dealer, whose skilled technicians have

the necessary tools, experience, and

know-how to service the motorcycle

properly.

Use only genuine Yamaha replace-

ment parts. Imitation parts may look

like Yamaha parts, but they are often

inferior, have a shorter service life and

can lead to expensive repair bills.

WARNING

EWA15142

When checking the fuel system, do

not smoke, and make sure there are

no open flames or sparks in the ar-

ea, including pilot lights from water

1. Retainer

2. Slot

1

2

Tightening torques:

Axle nut:

57 Nm (5.7 m·kgf, 41 ft·lbf)

Locknut:

16 Nm (1.6 m·kgf, 12 ft·lbf)

UB04E0E0.book Page 36 Wednesday, September 2, 2015 3:51 PM