light YAMAHA MT09 TRACER 2016 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: MT09 TRACER, Model: YAMAHA MT09 TRACER 2016Pages: 114, PDF Size: 3.27 MB

Page 38 of 114

Instrument and control functions

3-23

3

EAU54271

Traction control systemThe traction control system helps

maintain traction when accelerating on

slippery surfaces, such as unpaved or

wet roads. If sensors detect that the

rear wheel is starting to slip (uncon-

trolled spinning), the traction control

system assists by regulating engine

power as needed until traction is re-

stored. The “TCS” indicator/warning

light flashes to let the rider know that

traction control has engaged.TIPThe rider may also notice slight chang-

es in engine and exhaust sounds when

the traction control system is engaged.

WARNING

EWA15432

The traction control system is not a

su bstitute for rid ing appropriately

for the con ditions. Traction control

cannot prevent loss of traction d ue

to excessive speed when entering

turns, when acceleratin g har d at a

sharp lean an gle, or while b raking,

an d cannot prevent front wheel slip-

pin g. As with any motorcycle, ap- proach surfaces that may

be

slippery with caution an d avoi d es-

pecially slippery surfaces.

When the key is turned to “ON”, the

traction control system automatically

turns on.

The traction control system can be

turned on or off manually only when

the key is in the “ON” position and the

motorcycle is stopped.TIPTurn the traction control system off to

help free the rear wheel if the motorcy-

cle gets stuck in mud, sand, or other

soft surfaces.NOTICE

ECA16801

Use only the specified tires. (See

pa ge 6-17.) Usin g different sized

tires will prevent the traction control

system from controllin g tire rotation

accurately.

1. Front wheel sensor

2. Front wheel sensor rotor

1. Rear wheel sensor

2. Rear wheel sensor rotor

21

12

U2PPE2E0.book Page 23 Tuesday, June 9, 2015 1:57 PM

Page 39 of 114

Instrument and control functions

3-24

3

Turnin

g on/off the traction control

system

WARNING

EWA15441

Be sure to stop the vehicle before

makin g any settin g chan ges to the

traction control system. Chan gin g

settin gs while ri din g can distract the

operator an d increase the risk of an

acci dent.To turn off the traction control system,

push the “TCS” button on the multi-

function meter unit for at least 2 sec-

onds. The “TCS” indicator/warning

light will come on.

To turn on the traction control system,

push the “TCS” button again. The

“TCS” indicator/warning light will go

off. Resettin

g

The traction control system will be dis-

abled in the following conditions: The rear wheel is rotated with the

centerstand down and the key in

the “ON” position.

Either the front wheel or rear wheel

comes off the ground while riding.

Excessive rear wheel spinning.

If the traction control system has been

disabled, both the “TCS” indica-

tor/warning light and the engine trou-

ble warning light come on. To reset the traction control system

Turn the key to “OFF”. Wait at least 1

second, then turn the key back to

“ON”. The “TCS” indicator/warning

light should go off and the system will

be enabled. The engine trouble warn-

ing light should go off after the motor-

cycle reaches at least 20 km/h (12

mi/h). If the “TCS” indicator/warning

light and/or engine trouble warning

light still remain on after resetting, the

motorcycle may still be ridden; howev-

er, have a Yamaha dealer check the

motorcycle as soon as possible.

1. “TCS” button

2. Traction control system indicator/warning

light “TCS”

12

U2PPE2E0.book Page 24 Tuesday, June 9, 2015 1:57 PM

Page 40 of 114

Instrument and control functions

3-25

3

EAU13075

Fuel tank capTo open the fuel tank cap

Open the fuel tank cap lock cover, in-

sert the key into the lock, and then turn

it 1/4 turn clockwise. The lock will be

released and the fuel tank cap can be

opened.

To close the fuel tank cap

1. Push the fuel tank cap into posi- tion with the key inserted in the

lock.

2. Turn the key counterclockwise to the original position, remove it,

and then close the lock cover.

TIPThe fuel tank cap cannot be closed un-

less the key is in the lock. In addition,

the key cannot be removed if the cap is

not properly closed and locked.

WARNING

EWA11092

Make sure that the fuel tank cap is

properly close d after fillin g fuel.

Leakin g fuel is a fire hazar d.

EAU13222

FuelMake sure there is sufficient gasoline in

the tank.

WARNING

EWA10882

Gasoline an d g asoline vapors are

extremely flammab le. To avoid fires

an d explosions an d to re duce the

risk of injury when refuelin g, follow

these instructions.1. Before refueling, turn off the en- gine and be sure that no one is sit-

ting on the vehicle. Never refuel

while smoking, or while in the vi-

cinity of sparks, open flames, or

other sources of ignition such as

the pilot lights of water heaters

and clothes dryers.

2. Do not overfill the fuel tank. When refueling, be sure to insert the

pump nozzle into the fuel tank filler

hole. Stop filling when the fuel

reaches the bottom of the filler

tube. Because fuel expands when

it heats up, heat from the engine or

the sun can cause fuel to spill out

of the fuel tank.

1. Unlock.

2. Fuel tank cap lock cover

2

1

U2PPE2E0.book Page 25 Tuesday, June 9, 2015 1:57 PM

Page 58 of 114

Operation and important rid ing points

5-1

5

EAU15952

Read the Owner’s Manual carefully to

become familiar with all controls. If

there is a control or function you do not

understand, ask your Yamaha dealer.

WARNING

EWA10272

Failure to familiarize yourself with

the controls can lead to loss of con-

trol, which coul d cause an acci dent

or injury.

EAU48712

TIPThis model is equipped with: a lean angle sensor to stop the en-

gine in case of a turnover. In this

case, the display will indicate error

code 30, but this is not a malfunc-

tion. Turn the key to “OFF” and

then to “ON” to clear the error co-

d e . F ai l in g to do s o wi ll pr e v e nt the

engine from starting even though

the engine will crank when push-

ing the start switch.

an engine auto-stop system. The

engine stops automatically if left

idling for 20 minutes. If the engine

stops, simply push the start

switch to restart the engine.

EAU63090

Startin g the en gineIn order for the ignition circuit cut-off

system to enable starting, one of the

following conditions must be met:

The transmission is in the neutral

position.

The transmission is in gear with

the clutch lever pulled and the

sidestand up.

See page 3-37 for more informa-

tion.

1. Turn the key to “ON” and make sure that the start/engine stop

switch is set to “ ”.

The following warning lights and

indicator lights should come on for

a few seconds, then go off. Oil level warning light

Engine trouble warning light

Traction control system indi-

cator/warning light

Immobilizer system indicator

lightNOTICE

ECA11834

If a warnin g or in dicator li ght does

not come on initially when the key is

turne d to “ON”, or if a warning or in-

U2PPE2E0.book Page 1 Tuesday, June 9, 2015 1:57 PM

Page 59 of 114

Operation and important ri din g points

5-2

5

d

icator li ght remains on, see pa ge

3-4 for the correspon din g warnin g

an d in dicator li ght circuit check.

The ABS warning light should

come on when the key is turned to

“ON”, and then go off after travel-

ing at a speed of 10 km/h (6 mi/h)

or higher.

NOTICE

ECA17682

If the ABS warnin g li ght does not

come on an d then go off as ex-

plaine d a bove, see pa ge 3-4 for the

warnin g li ght circuit check.2. Shift the transmission into the

neutral position. The neutral indi-

cator light should come on. If not,

ask a Yamaha dealer to check the

electrical circuit.

3. Start the engine by pushing the “ ” side of the start/engine

stop switch.

If the engine fails to start, release

the start/engine stop switch, wait

a few seconds, and then try again.

Each starting attempt should be

as short as possible to preserve the battery. Do not crank the en-

gine more than 10 seconds on any

one attempt.

NOTICE

ECA11043

For maximum en

gine life, never ac-

celerate har d when the en gine is

col d!

EAU16673

Shiftin gShifting gears lets you control the

amount of engine power available for

starting off, accelerating, climbing hills,

etc.

The gear positions are shown in the il-

lustration.TIPTo shift the transmission into the neu-

tral position, press the shift pedal down

repeatedly until it reaches the end of its

travel, and then slightly raise it.1. Shift pedal

2. Neutral position

1

N

2 3

4

5

6

1

2

U2PPE2E0.book Page 2 Tuesday, June 9, 2015 1:57 PM

Page 60 of 114

Operation and important rid ing points

5-3

5

NOTICE

ECA10261

Even with the transmission in

the neutral position, do not

coast for lon g period s of time

with the en gine off, an d d o not

tow the motorcycle for lon g d is-

tances. The transmission is

properly lu bricated only when

the en gine is runnin g. Ina de-

quate lu brication may damag e

the transmission.

Always use the clutch while

chan gin g g ears to avoi d d am-

a g in g the en gine, transmission,

an d d rive train, which are not

d esi gne d to withstan d the

shock of force d shifting .

EAU16682

To start out an d accelerate

1. Pull the clutch lever to disengage the clutch.

2. Shift the transmission into first gear. The neutral indicator light

should go out.

3. Open the throttle gradually, and at the same time, release the clutch

lever slowly. 4. At the recommended shift points

shown in the following table, close

the throttle, and at the same time,

quickly pull the clutch lever in.

5. Shift the transmission into second gear. (Make sure not to shift the

transmission into the neutral posi-

tion.)

6. Open the throttle part way and gradually release the clutch lever.

7. Follow the same procedure when shifting to the next higher gear.

TIPWhen shifting gears in normal operat-

ing conditions, use the recommended

shift points.

EAU58270

To decelerate

1. Release the throttle and apply both the front and the rear brakes

smoothly to slow the motorcycle.

2. At the recommended shift points shown in the following table, shift

to a lower gear.

3. When the motorcycle reaches 25 km/h (16 mi/h), the engine is about

to stall or runs roughly, pull the clutch lever in, use the brakes to

slow the motorcycle, and continue

to downshift as necessary.

4. Once the motorcycle has stopped, the transmission can be

shifted into the neutral position.

The neutral indicator light should

come on and then the clutch lever

can be released.

WARNING

EWA17380

Improper brakin g can cause

loss of control or traction. Al-

ways use b oth brakes an d apply

them smoothly.

Make sure that the motorcycle

and the en gine have sufficiently

slowe d b efore shiftin g to a low-

er gear. En gag in g a lower gear

when the vehicle or en gine

speed is too hi gh coul d make

the rear wheel lose traction or

the en gine to over-rev. This

coul d cause loss of control, an

acci dent an d injury. It coul d also

cause en gine or drive train dam-

a g e.

U2PPE2E0.book Page 3 Tuesday, June 9, 2015 1:57 PM

Page 61 of 114

Operation and important ri din g points

5-4

5

EAU64150

Recommen ded shift points

The recommended shift points during

acceleration and deceleration are

shown in the table below.

EAU16811

Tips for re ducin g fuel con-

sumptionFuel consumption depends largely on

your riding style. Consider the follow-

ing tips to reduce fuel consumption:

Shift up swiftly, and avoid high en-

gine speeds during acceleration.

Do not rev the engine while shift-

ing down, and avoid high engine

speeds with no load on the en-

gine.

Turn the engine off instead of let-

ting it idle for an extended length

of time (e.g., in traffic jams, at traf-

fic lights or at railroad crossings).

EAU16842

Engine break-inThere is never a more important period

in the life of your engine than the period

between 0 and 1600 km (1000 mi). For

this reason, you should read the fol-

lowing material carefully.

Since the engine is brand new, do not

put an excessive load on it for the first

1600 km (1000 mi). The various parts in

the engine wear and polish themselves

to the correct operating clearances.

During this period, prolonged full-throt-

tle operation or any condition that

might result in engine overheating

must be avoided.

EAU63170

0–1000 km (0–600 mi)

Avoid prolonged operation above 5600

r/min. NOTICE: After 1000 km (600

mi) of operation, the en gine oil must

b e chan ged an d the oil filter car-

tri dge or element replace d.

[ECA10303]

1000–1600 km (600–1000 mi)

Avoid prolonged operation above 6800

r/min.

Shift up points:

1st → 2nd: 20 km/h (12 mph)

2nd → 3rd: 30 km/h (19 mph)

3rd → 4th: 40 km/h (25 mph)

4th → 5th: 50 km/h (31 mph)

5th → 6th: 60 km/h (37 mph)

Shift down points:

6th → 5th: 45 km/h (28 mph)

5th → 4th: 35 km/h (22 mph)

4th → 3rd: 25 km/h (16 mph)

U2PPE2E0.book Page 4 Tuesday, June 9, 2015 1:57 PM

Page 68 of 114

Periodic maintenance an d a djustment

6-6

6

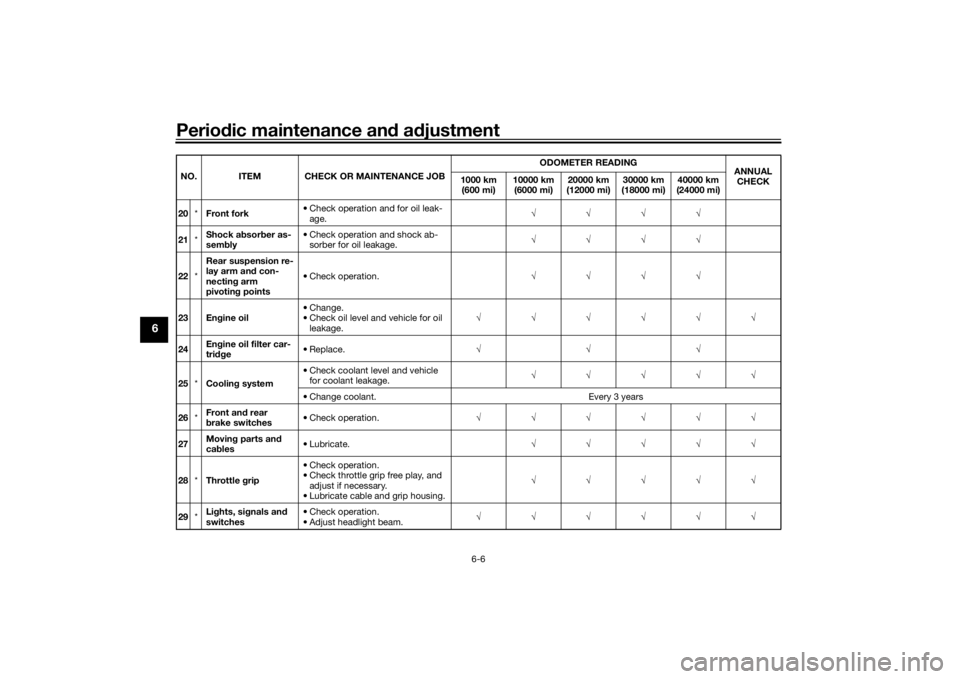

20 *Front fork • Check operation and for oil leak-

age. √√√√

21 *Shock a

bsor ber as-

sem bly • Check operation and shock ab-

sorber for oil leakage. √√√√

22 *Rear suspension re-

lay arm an

d con-

nectin g arm

pivotin g points • Check operation.

√√√√

23 En gine oil • Change.

• Check oil level and vehicle for oil

leakage. √√√√√√

24 En

gine oil filter car-

tri dge • Replace.

√√√

25 *Coolin g system • Check coolant level and vehicle

for coolant leakage. √√√√√

• Change coolant. Every 3 years

26 *Front an

d rear

b rake switches • Check operation.

√√√√√√

27 Movin

g parts an d

cab les • Lubricate.

√√√√√

28 *Throttle grip • Check operation.

• Check throttle grip free play, and

adjust if necessary.

• Lubricate cable and grip housing. √√√√√

29 *Li

ghts, si gnals an d

switches • Check operation.

• Adjust headlight beam.

√√√√√√

NO. ITEM CHECK OR MAINTENANCE JOB

OD

OM ETER READING

ANNUAL

CHECK

1000 km

(600 mi) 10000 km

(6000 mi) 20000 km

(12000 mi) 30000 km

(18000 mi) 40000 km

(24000 mi)

U2PPE2E0.book Page 6 Tuesday, June 9, 2015 1:57 PM

Page 70 of 114

Periodic maintenance an d a djustment

6-8

6

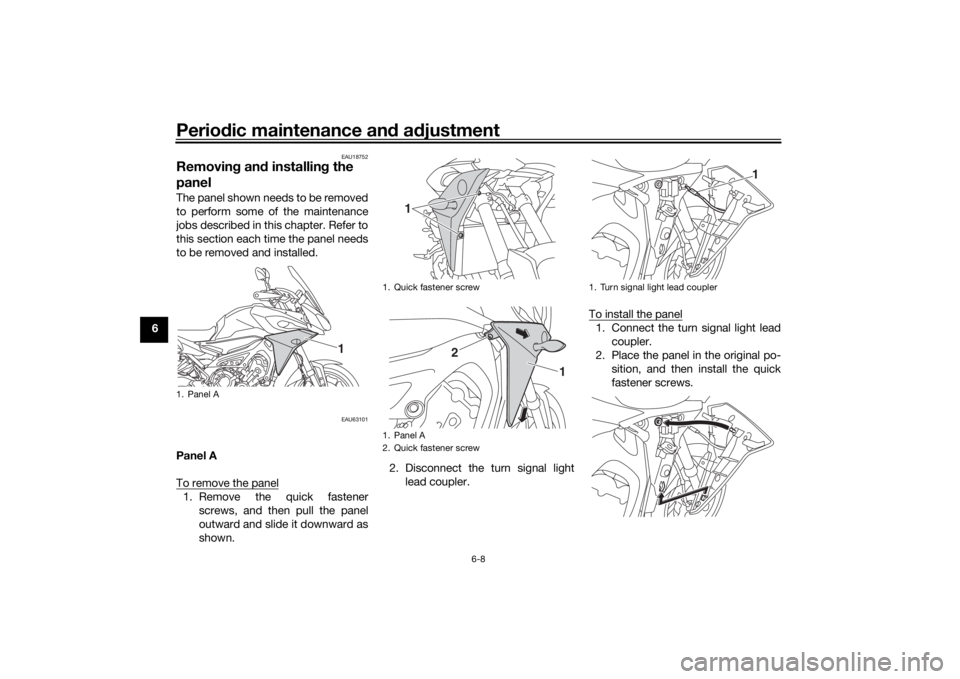

EAU18752

Removin g an d installin g the

panelThe panel shown needs to be removed

to perform some of the maintenance

jobs described in this chapter. Refer to

this section each time the panel needs

to be removed and installed.

EAU63101

Panel A

To remove the panel1. Remove the quick fastener

screws, and then pull the panel

outward and slide it downward as

shown. 2. Disconnect the turn signal light

lead coupler. To install the panel

1. Connect the turn signal light lead

coupler.

2. Place the panel in the original po- sition, and then install the quick

fastener screws.

1. Panel A

1

1. Quick fastener screw

1. Panel A

2. Quick fastener screw

1

1

2

1. Turn signal light lead coupler

1

U2PPE2E0.book Page 8 Tuesday, June 9, 2015 1:57 PM

Page 71 of 114

Periodic maintenance an d a djustment

6-9

6

EAU19653

Checkin g the spark plugsThe spark plugs are important engine

components, which should be

checked periodically, preferably by a

Yamaha dealer. Since heat and depos- its will cause any spark plug to slowly

erode, they should be removed and

checked in accordance with the peri-

odic maintenance and lubrication

chart. In addition, the condition of the

spark plugs can reveal the condition of

the engine.

The porcelain insulator around the

center electrode of each spark plug

should be a medium-to-light tan (the

ideal color when the vehicle is ridden

normally), and all spark plugs installed

in the engine should have the same

color. If any spark plug shows a dis-

tinctly different color, the engine could

be operating improperly. Do not at-

tempt to diagnose such problems

yourself. Instead, have a Yamaha deal-

er check the vehicle.

If a spark plug shows signs of elec-

trode erosion and excessive carbon or

other deposits, it should be replaced. Before installing a spark plug, the

spark plug gap should be measured

with a wire thickness gauge and, if

necessary, adjusted to specification.

Clean the surface of the spark plug

gasket and its mating surface, and

then wipe off any grime from the spark

plug threads.

TIPIf a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is 1/4–

1/2 turn past finger tight. However, the

spark plug should be tightened to the

specified torque as soon as possible.NOTICE

ECA10841

Do not use any tools to remove or in-

stall the spark plu

g cap, otherwise

the i gnition coil coupler may get

d amag ed . The spark plu g cap may

b e difficult to remove because the

ru bber seal on the en d of the cap fits

ti g htly. To remove the spark plu g

cap, simply twist it b ack and forth

while pullin g it out; to install it, twist

it back an d forth while pushin g it in.

Specified spark plu g:

NGK/CPR9EA9

1. Spark plug gap

Spark plu g g ap:

0.8–0.9 mm (0.031–0.035 in)

Ti ghtenin g torque:

Spark plug: 13 Nm (1.3 m·kgf, 9.4 ft·lbf)

U2PPE2E0.book Page 9 Tuesday, June 9, 2015 1:57 PM