YAMAHA NMAX 150 2017 Workshop Manual

Manufacturer: YAMAHA, Model Year: 2017, Model line: NMAX 150, Model: YAMAHA NMAX 150 2017Pages: 94, PDF Size: 3.7 MB

Page 51 of 94

Periodic maintenance an d a djustment

6-11

6

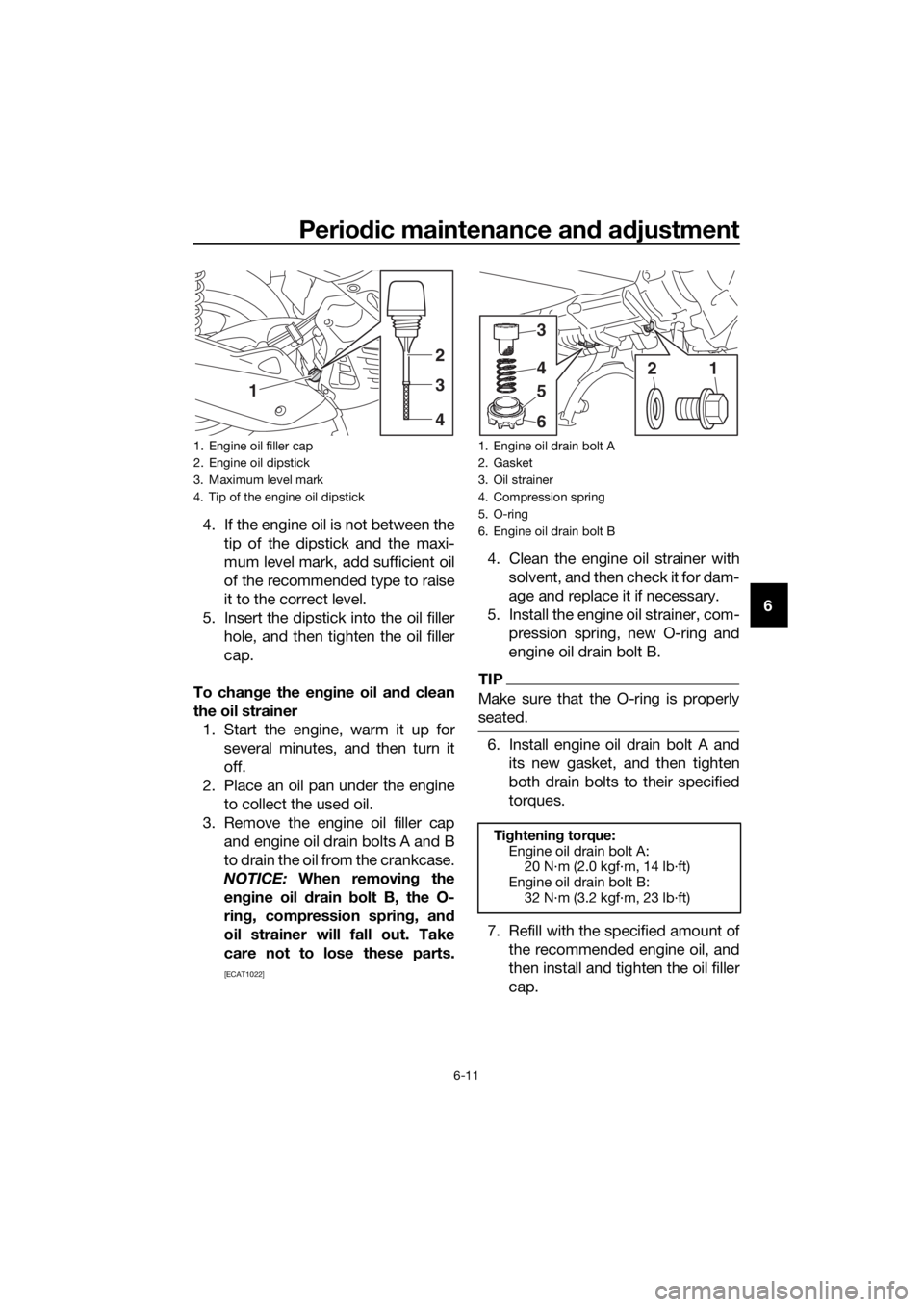

4. If the engine oil is not between the

tip of the dipstick and the maxi-

mum level mark, add sufficient oil

of the recommended type to raise

it to the correct level.

5. Insert the dipstick into the oil filler hole, and then tighten the oil filler

cap.

To chan ge the en gine oil an d clean

the oil strainer 1. Start the engine, warm it up for several minutes, and then turn it

off.

2. Place an oil pan under the engine to collect the used oil.

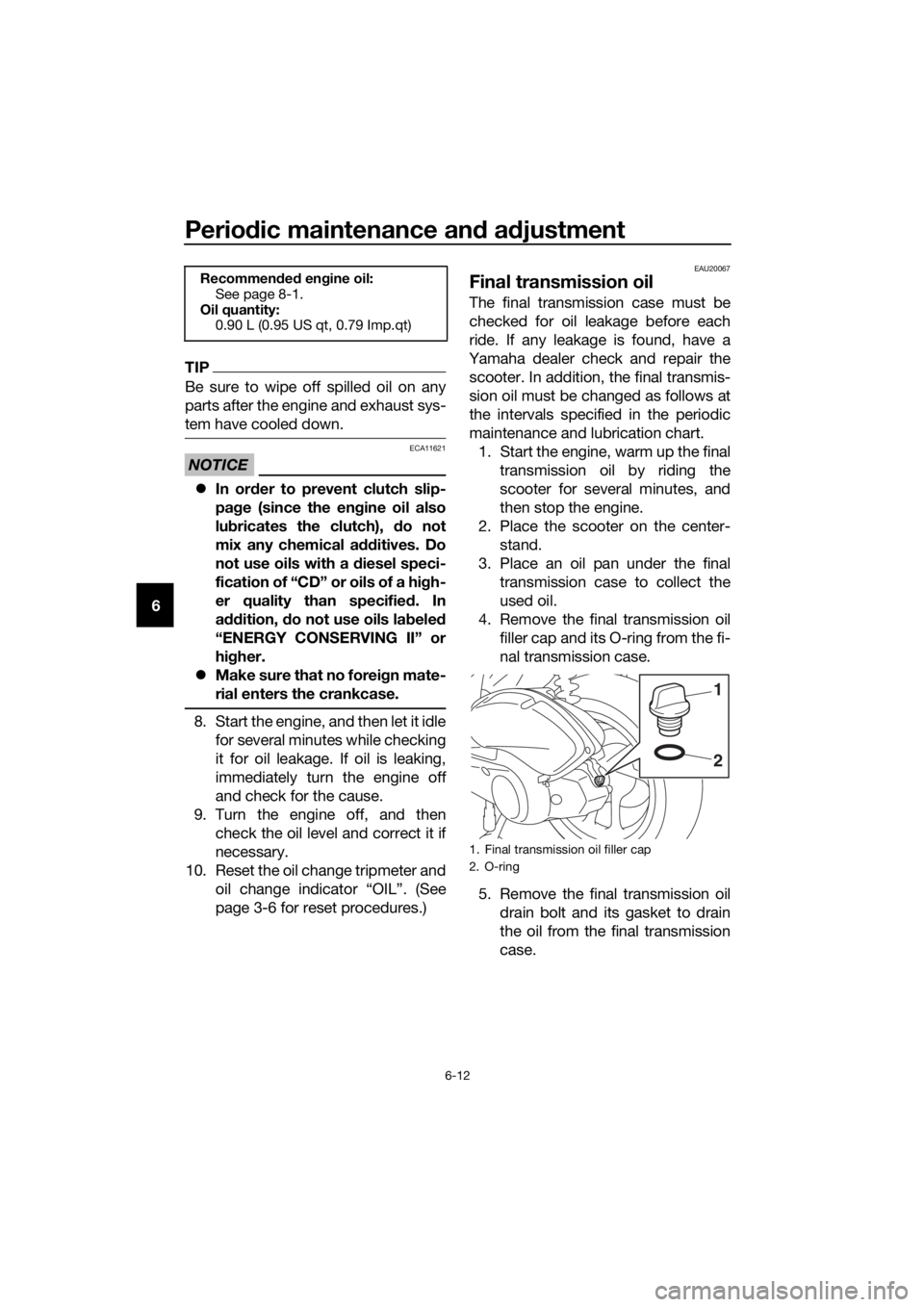

3. Remove the engine oil filler cap and engine oil drain bolts A and B

to drain the oil from the crankcase.

NOTICE: When removin g the

en gine oil d rain bolt B, the O-

rin g, compression sprin g, an d

oil strainer will fall out. Take

care not to lose these parts.

[ECAT1022]

4. Clean the engine oil strainer with solvent, and then check it for dam-

age and replace it if necessary.

5. Install the engine oil strainer, com- pression spring, new O-ring and

engine oil drain bolt B.

TIP

Make sure that the O-ring is properly

seated.

6. Install engine oil drain bolt A andits new gasket, and then tighten

both drain bolts to their specified

torques.

7. Refill with the specified amount of the recommended engine oil, and

then install and tighten the oil filler

cap.

1. Engine oil filler cap

2. Engine oil dipstick

3. Maximum level mark

4. Tip of the engine oil dipstick

1

2

3

4

1. Engine oil drain bolt A

2. Gasket

3. Oil strainer

4. Compression spring

5. O-ring

6. Engine oil drain bolt B

Tightenin g torque:

Engine oil drain bolt A: 20 N·m (2.0 kgf·m, 14 lb·ft)

Engine oil drain bolt B:

32 N·m (3.2 kgf·m, 23 lb·ft)

1

3

4

5

6

2

UBV3E0E0.book Page 11 Monday, September 26, 2016 3:42 PM

Page 52 of 94

Periodic maintenance an d a djustment

6-12

6

TIP

Be sure to wipe off spilled oil on any

parts after the engine and exhaust sys-

tem have cooled down.

NOTICE

ECA11621

In or der to prevent clutch slip-

pa ge (since the en gine oil also

lu bricates the clutch), do not

mix any chemical additives. Do

not use oils with a diesel speci-

fication of “CD” or oils of a hi gh-

er quality than specifie d. In

a ddition, do not use oils la bele d

“ENERGY CONSERVING II” or

hi gher.

Make sure that no forei gn mate-

rial enters the crankcase.

8. Start the engine, and then let it idle for several minutes while checking

it for oil leakage. If oil is leaking,

immediately turn the engine off

and check for the cause.

9. Turn the engine off, and then check the oil level and correct it if

necessary.

10. Reset the oil change tripmeter and oil change indicator “OIL”. (See

page 3-6 for reset procedures.)

EAU20067

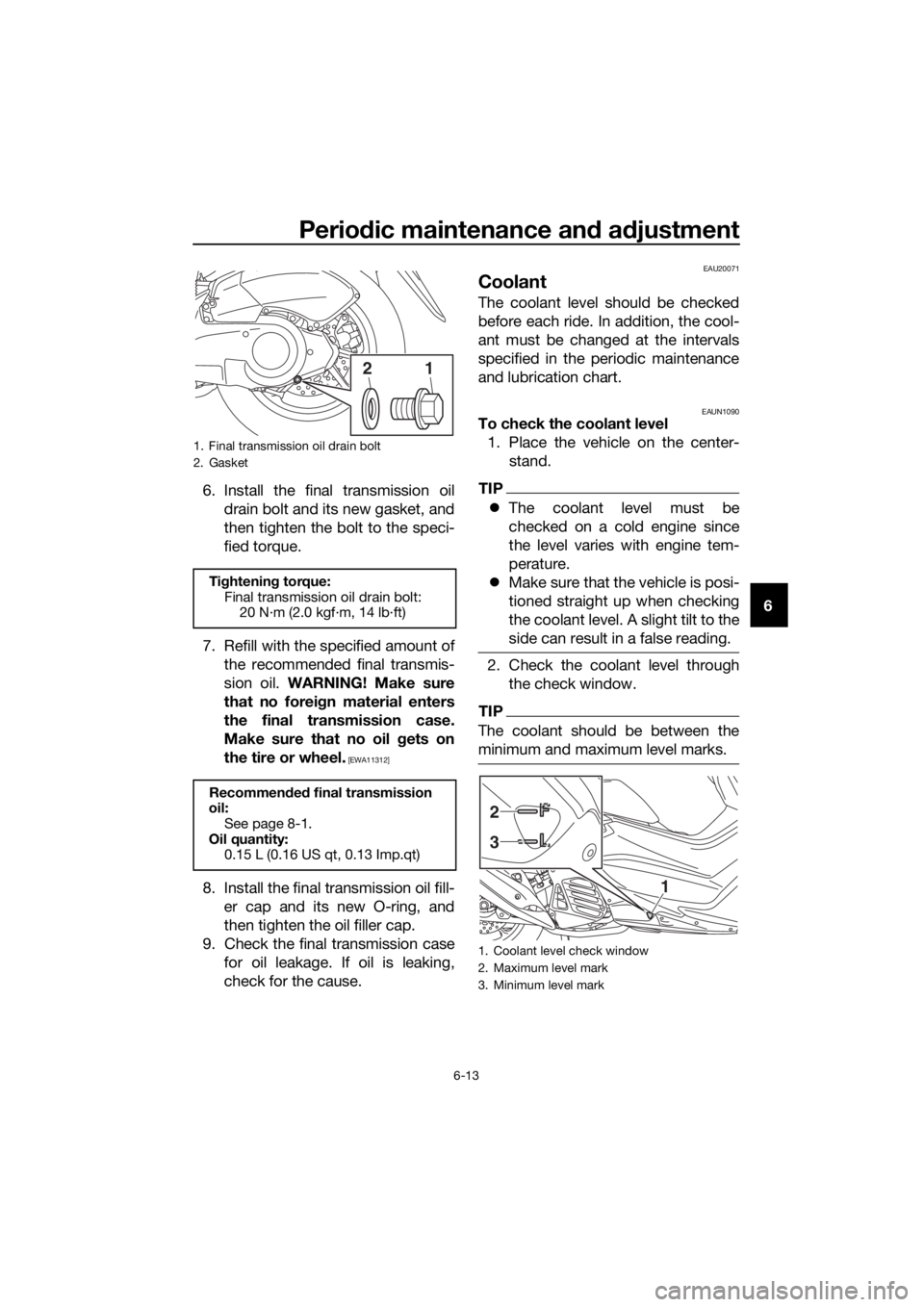

Final transmission oil

The final transmission case must be

checked for oil leakage before each

ride. If any leakage is found, have a

Yamaha dealer check and repair the scooter. In addition, the final transmis-

sion oil must be changed as follows at

the intervals specified in the periodic

maintenance and lubrication chart. 1. Start the engine, warm up the final transmission oil by riding the

scooter for several minutes, and

then stop the engine.

2. Place the scooter on the center- stand.

3. Place an oil pan under the final transmission case to collect the

used oil.

4. Remove the final transmission oil filler cap and its O-ring from the fi-

nal transmission case.

5. Remove the final transmission oil drain bolt and its gasket to drain

the oil from the final transmission

case.

Recommen ded en gine oil:

See page 8-1.

Oil quantity: 0.90 L (0.95 US qt, 0.79 Imp.qt)

1. Final transmission oil filler cap

2. O-ring

1

2

UBV3E0E0.book Page 12 Monday, September 26, 2016 3:42 PM

Page 53 of 94

Periodic maintenance an d a djustment

6-13

6

6. Install the final transmission oil

drain bolt and its new gasket, and

then tighten the bolt to the speci-

fied torque.

7. Refill with the specified amount of the recommended final transmis-

sion oil. WARNING! Make sure

that no forei gn material enters

the final transmission case.

Make sure that no oil gets on

the tire or wheel.

[EWA11312]

8. Install the final transmission oil fill- er cap and its new O-ring, and

then tighten the oil filler cap.

9. Check the final transmission case for oil leakage. If oil is leaking,

check for the cause.

EAU20071

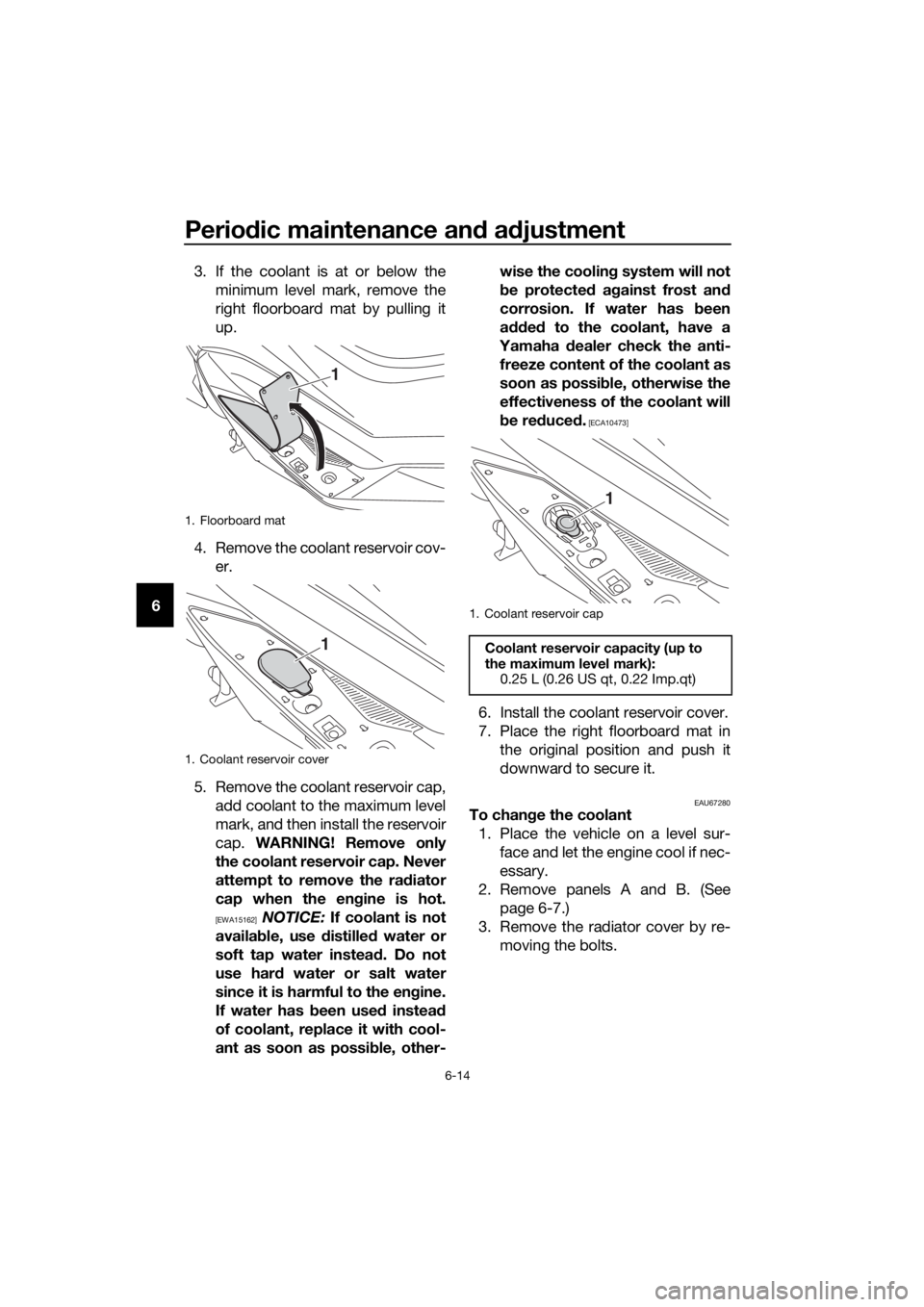

Coolant

The coolant level should be checked

before each ride. In addition, the cool-

ant must be changed at the intervals

specified in the periodic maintenance

and lubrication chart.

EAUN1090To check the coolant level1. Place the vehicle on the center- stand.

TIP

The coolant level must be

checked on a cold engine since

the level varies with engine tem-

perature.

Make sure that the vehicle is posi-

tioned straight up when checking

the coolant level. A slight tilt to the

side can result in a false reading.

2. Check the coolant level through

the check window.

TIP

The coolant should be between the

minimum and maximum level marks.

1. Final transmission oil drain bolt

2. Gasket

Tightening torque:

Final transmission oil drain bolt: 20 N·m (2.0 kgf·m, 14 lb·ft)

Recommen ded final transmission

oil: See page 8-1.

Oil quantity: 0.15 L (0.16 US qt, 0.13 Imp.qt)

12

1. Coolant level check window

2. Maximum level mark

3. Minimum level mark

1

2

3

UBV3E0E0.book Page 13 Monday, September 26, 2016 3:42 PM

Page 54 of 94

Periodic maintenance an d a djustment

6-14

6 3. If the coolant is at or below the

minimum level mark, remove the

right floorboard mat by pulling it

up.

4. Remove the coolant reservoir cov- er.

5. Remove the coolant reservoir cap, add coolant to the maximum level

mark, and then install the reservoir

cap. WARNING! Remove only

the coolant reservoir cap. Never

attempt to remove the ra diator

cap when the en gine is hot.

[EWA15162] NOTICE: If coolant is not

availa ble, use d istilled water or

soft tap water instea d. Do not

use har d water or salt water

since it is harmful to the en gine.

If water has been used instead

of coolant, replace it with cool-

ant as soon as possi ble, other- wise the coolin

g system will not

b e protecte d a gainst frost an d

corrosion. If water has b een

a dde d to the coolant, have a

Yamaha dealer check the anti-

freeze content of the coolant as

soon as possi ble, otherwise the

effectiveness of the coolant will

b e red uced.

[ECA10473]

6. Install the coolant reservoir cover.

7. Place the right floorboard mat in

the original position and push it

downward to secure it.

EAU67280To chan ge the coolant

1. Place the vehicle on a level sur- face and let the engine cool if nec-

essary.

2. Remove panels A and B. (See page 6-7.)

3. Remove the radiator cover by re- moving the bolts.

1. Floorboard mat

1. Coolant reservoir cover

1

1

1. Coolant reservoir cap

Coolant reservoir capacity (up to

the maximum level mark):0.25 L (0.26 US qt, 0.22 Imp.qt)

1

UBV3E0E0.book Page 14 Monday, September 26, 2016 3:42 PM

Page 55 of 94

Periodic maintenance an d a djustment

6-15

6

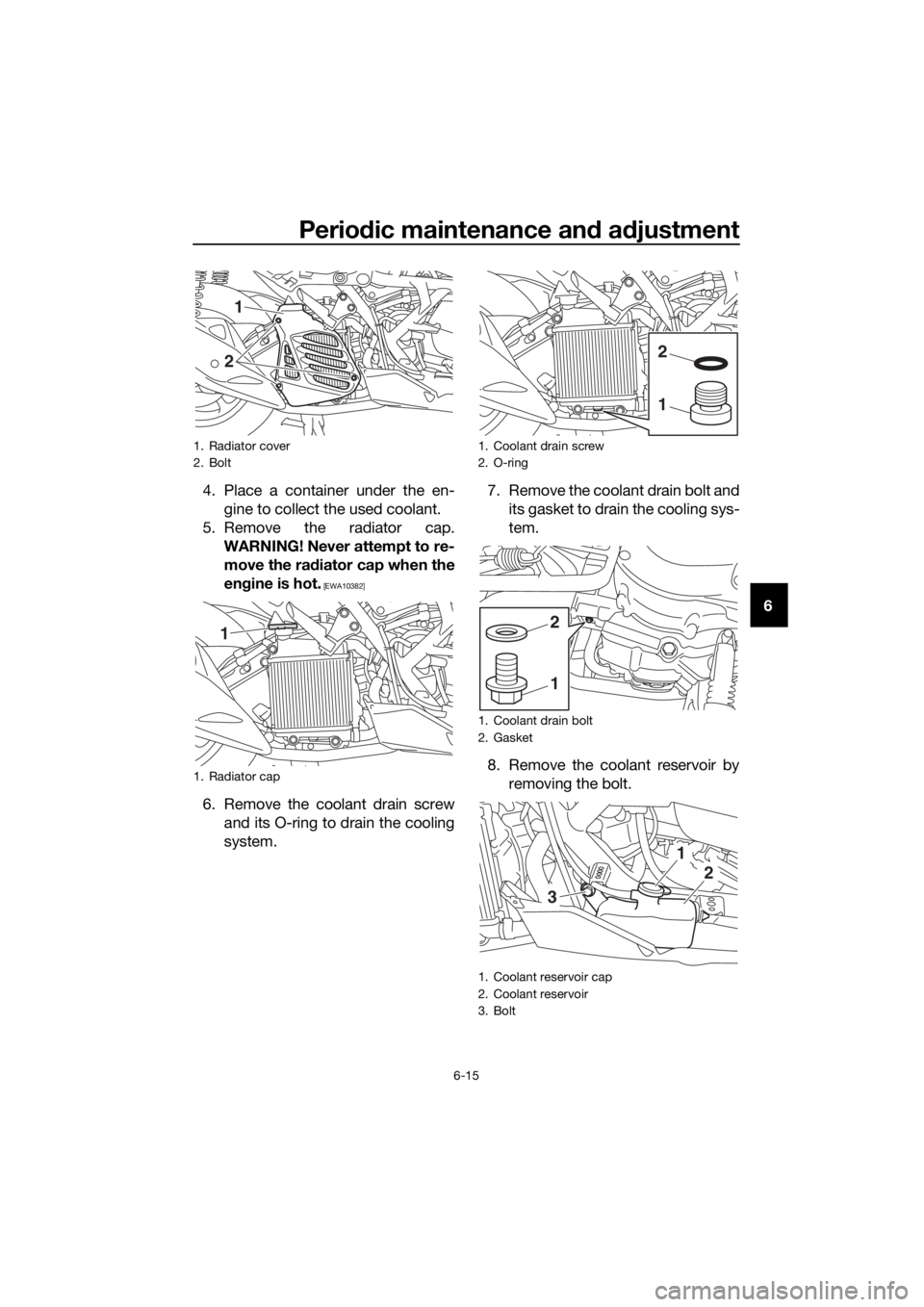

4. Place a container under the en-

gine to collect the used coolant.

5. Remove the radiator cap. WARNING! Never attempt to re-

move the ra diator cap when the

en gine is hot.

[EWA10382]

6. Remove the coolant drain screw

and its O-ring to drain the cooling

system. 7. Remove the coolant drain bolt and

its gasket to drain the cooling sys-

tem.

8. Remove the coolant reservoir by removing the bolt.

1. Radiator cover

2. Bolt

1. Radiator cap

1

2

1

1. Coolant drain screw

2. O-ring

1. Coolant drain bolt

2. Gasket

1. Coolant reservoir cap

2. Coolant reservoir

3. Bolt

1

2

1

2

1

2

3

UBV3E0E0.book Page 15 Monday, September 26, 2016 3:42 PM

Page 56 of 94

Periodic maintenance an d a djustment

6-16

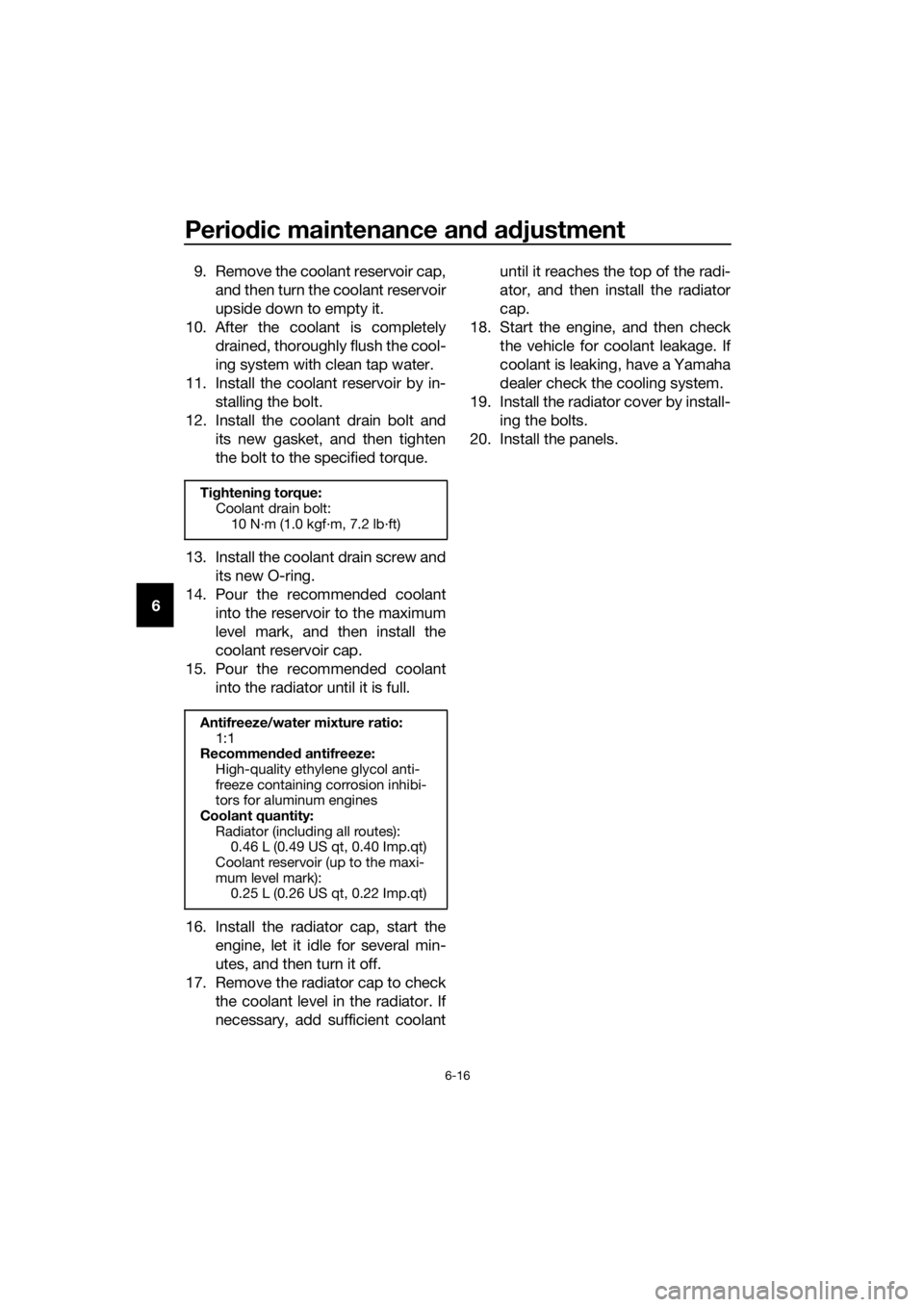

6 9. Remove the coolant reservoir cap,

and then turn the coolant reservoir

upside down to empty it.

10. After the coolant is completely drained, thoroughly flush the cool-

ing system with clean tap water.

11. Install the coolant reservoir by in- stalling the bolt.

12. Install the coolant drain bolt and its new gasket, and then tighten

the bolt to the specified torque.

13. Install the coolant drain screw and its new O-ring.

14. Pour the recommended coolant into the reservoir to the maximum

level mark, and then install the

coolant reservoir cap.

15. Pour the recommended coolant into the radiator until it is full.

16. Install the radiator cap, start the engine, let it idle for several min-

utes, and then turn it off.

17. Remove the radiator cap to check the coolant level in the radiator. If

necessary, add sufficient coolant until it reaches the top of the radi-

ator, and then install the radiator

cap.

18. Start the engine, and then check the vehicle for coolant leakage. If

coolant is leaking, have a Yamaha

dealer check the cooling system.

19. Install the radiator cover by install- ing the bolts.

20. Install the panels.

Ti ghtenin g torque:

Coolant drain bolt: 10 N·m (1.0 kgf·m, 7.2 lb·ft)

Antifreeze/water mixture ratio: 1:1

Recommen ded antifreeze:

High-quality ethylene glycol anti-

freeze containing corrosion inhibi-

tors for aluminum engines

Coolant quantity: Radiator (including all routes):0.46 L (0.49 US qt, 0.40 Imp.qt)

Coolant reservoir (up to the maxi-

mum level mark): 0.25 L (0.26 US qt, 0.22 Imp.qt)

UBV3E0E0.book Page 16 Monday, September 26, 2016 3:42 PM

Page 57 of 94

Periodic maintenance an d a djustment

6-17

6

EAU67174

Air filter an d V- belt case air fil-

ter elements

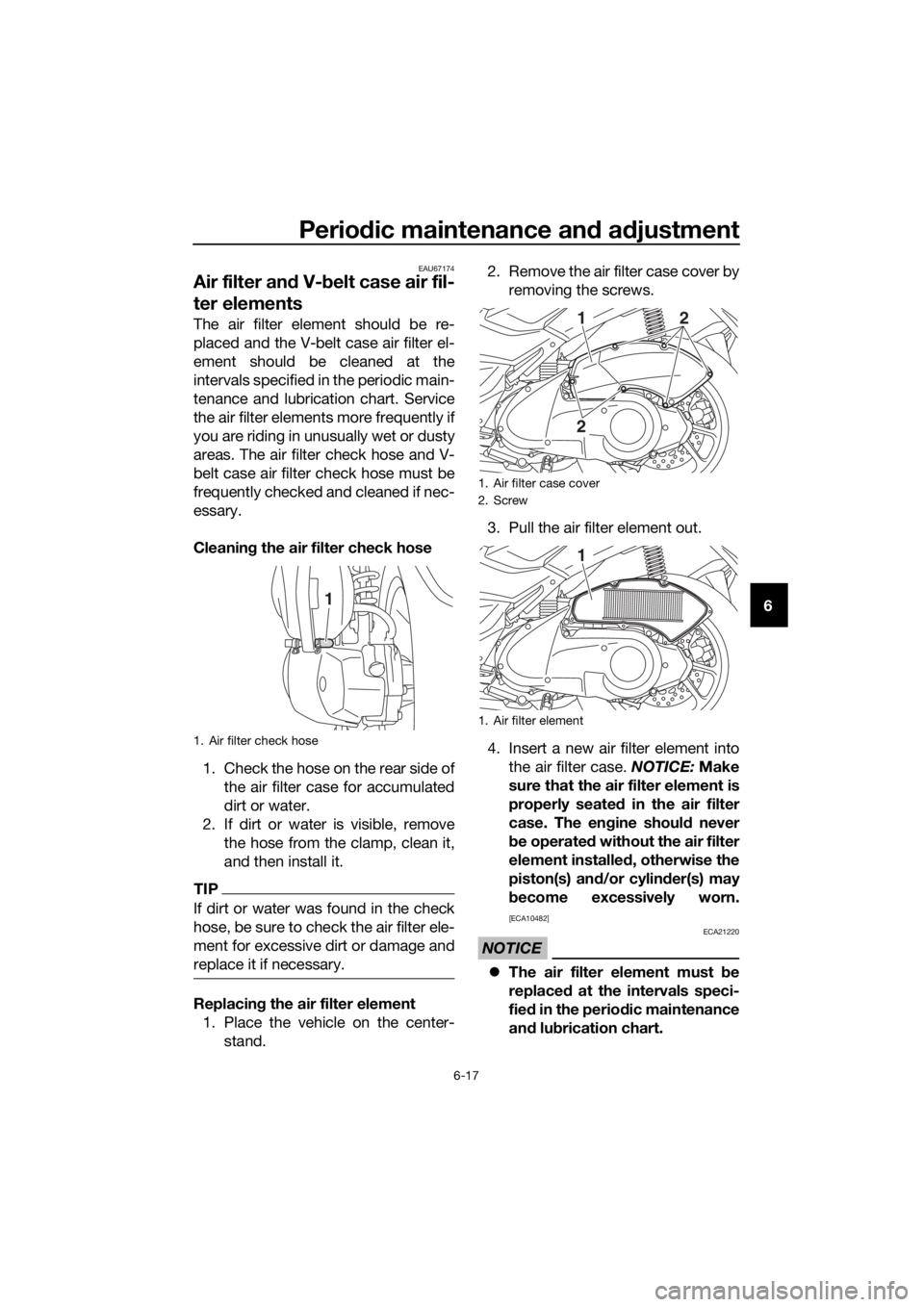

The air filter element should be re-

placed and the V-belt case air filter el-

ement should be cleaned at the

intervals specified in the periodic main-

tenance and lubrication chart. Service

the air filter elements more frequently if

you are riding in unusually wet or dusty

areas. The air filter check hose and V-

belt case air filter check hose must be

frequently checked and cleaned if nec-

essary.

Cleanin g the air filter check hose

1. Check the hose on the rear side of the air filter case for accumulated

dirt or water.

2. If dirt or water is visible, remove the hose from the clamp, clean it,

and then install it.

TIP

If dirt or water was found in the check

hose, be sure to check the air filter ele-

ment for excessive dirt or damage and

replace it if necessary.

Replacin g the air filter element

1. Place the vehicle on the center- stand. 2. Remove the air filter case cover by

removing the screws.

3. Pull the air filter element out.

4. Insert a new air filter element into the air filter case. NOTICE: Make

sure that the air filter element is

properly seated in the air filter

case. The en gine shoul d never

b e operated without the air filter

element installed , otherwise the

piston(s) an d/or cylin der(s) may

b ecome excessively worn.

[ECA10482]

NOTICE

ECA21220

The air filter element must be

replaced at the intervals speci-

fie d in the perio dic maintenance

an d lu brication chart.

1. Air filter check hose

1

1. Air filter case cover

2. Screw

1. Air filter element

2

21

1

UBV3E0E0.book Page 17 Monday, September 26, 2016 3:42 PM

Page 58 of 94

Periodic maintenance an d a djustment

6-18

6

The air filter element nee ds

more frequent replacement if

you are ri din g in unusually wet

or dusty areas.

Do not clean the air filter ele-

ment by blowin g it with com-

pressed air.

5. Install the air filter case cover by

installing the screws.

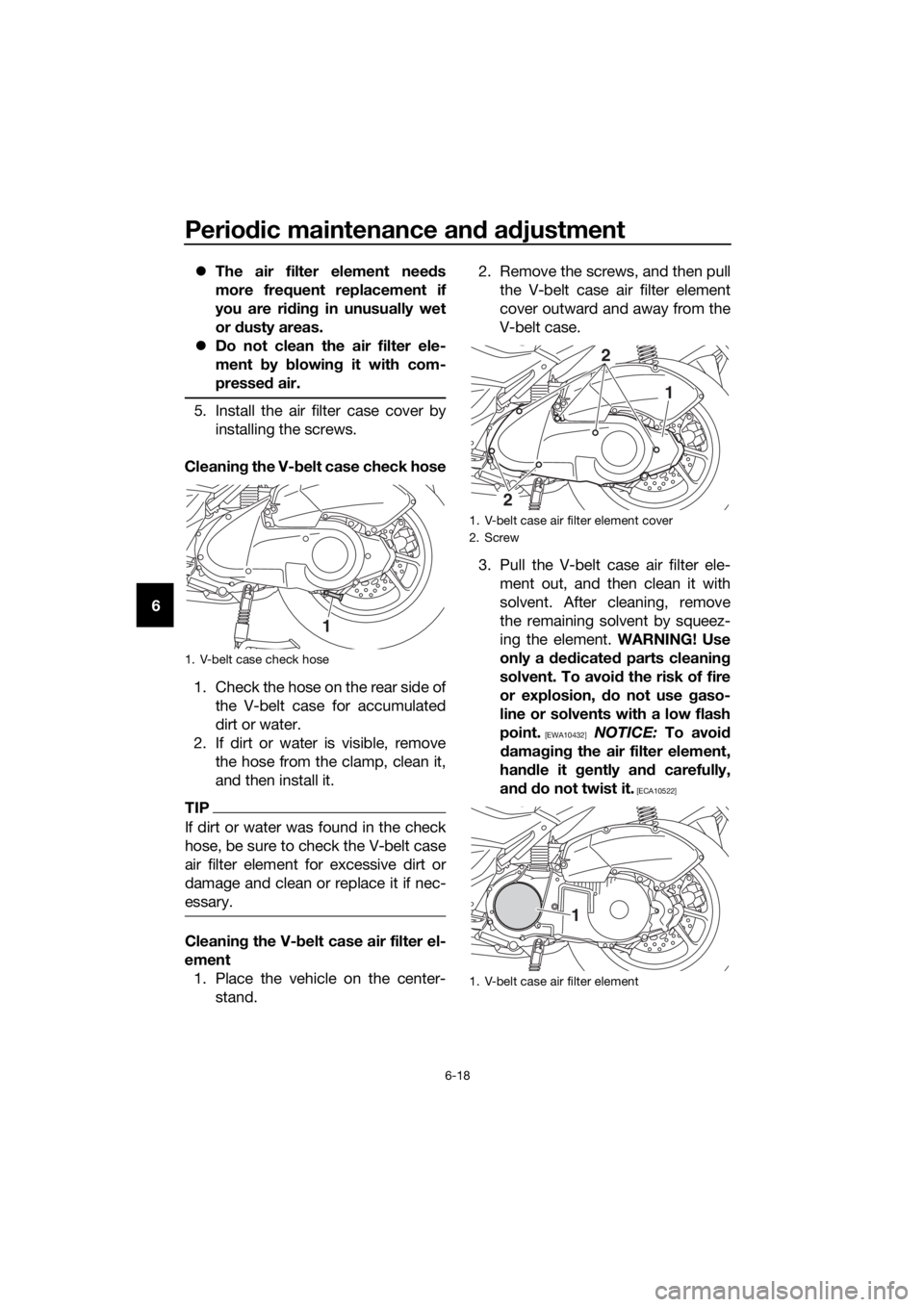

Cleanin g the V- belt case check hose

1. Check the hose on the rear side of the V-belt case for accumulated

dirt or water.

2. If dirt or water is visible, remove the hose from the clamp, clean it,

and then install it.

TIP

If dirt or water was found in the check

hose, be sure to check the V-belt case

air filter element for excessive dirt or

damage and clean or replace it if nec-

essary.

Cleanin g the V- belt case air filter el-

ement 1. Place the vehicle on the center- stand. 2. Remove the screws, and then pull

the V-belt case air filter element

cover outward and away from the

V-belt case.

3. Pull the V-belt case air filter ele- ment out, and then clean it with

solvent. After cleaning, remove

the remaining solvent by squeez-

ing the element. WARNING! Use

only a ded icated parts cleanin g

solvent. To avoi d the risk of fire

or explosion, do not use gaso-

line or solvents with a low flash

point.

[EWA10432] NOTICE: To avoi d

d amag ing the air filter element,

han dle it gently an d carefully,

an d d o not twist it.

[ECA10522]

1. V-belt case check hose

1

1. V-belt case air filter element cover

2. Screw

1. V-belt case air filter element

2

2

1

1

UBV3E0E0.book Page 18 Monday, September 26, 2016 3:42 PM

Page 59 of 94

Periodic maintenance an d a djustment

6-19

6

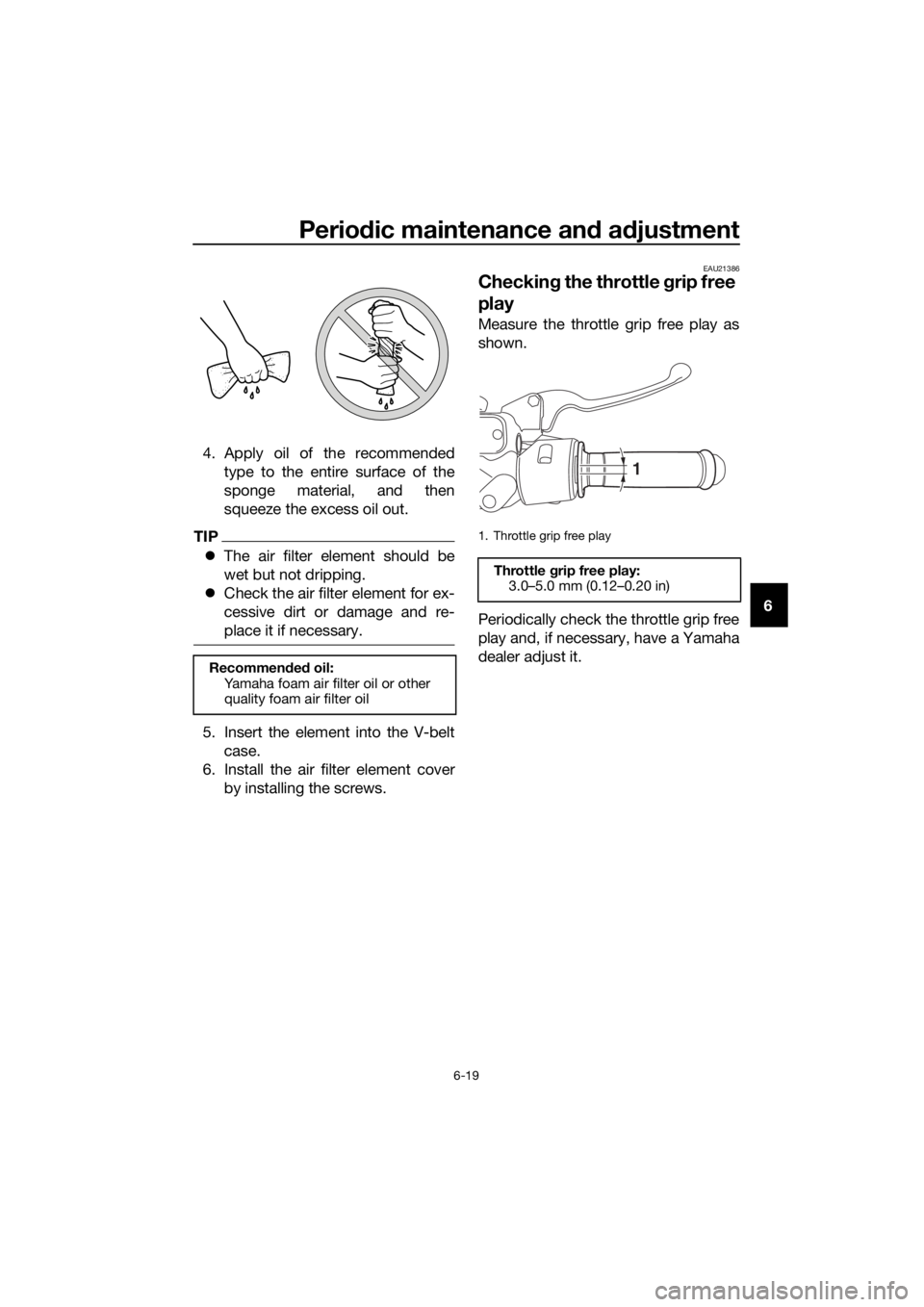

4. Apply oil of the recommended

type to the entire surface of the

sponge material, and then

squeeze the excess oil out.

TIP

The air filter element should be

wet but not dripping.

Check the air filter element for ex-

cessive dirt or damage and re-

place it if necessary.

5. Insert the element into the V-belt

case.

6. Install the air filter element cover by installing the screws.

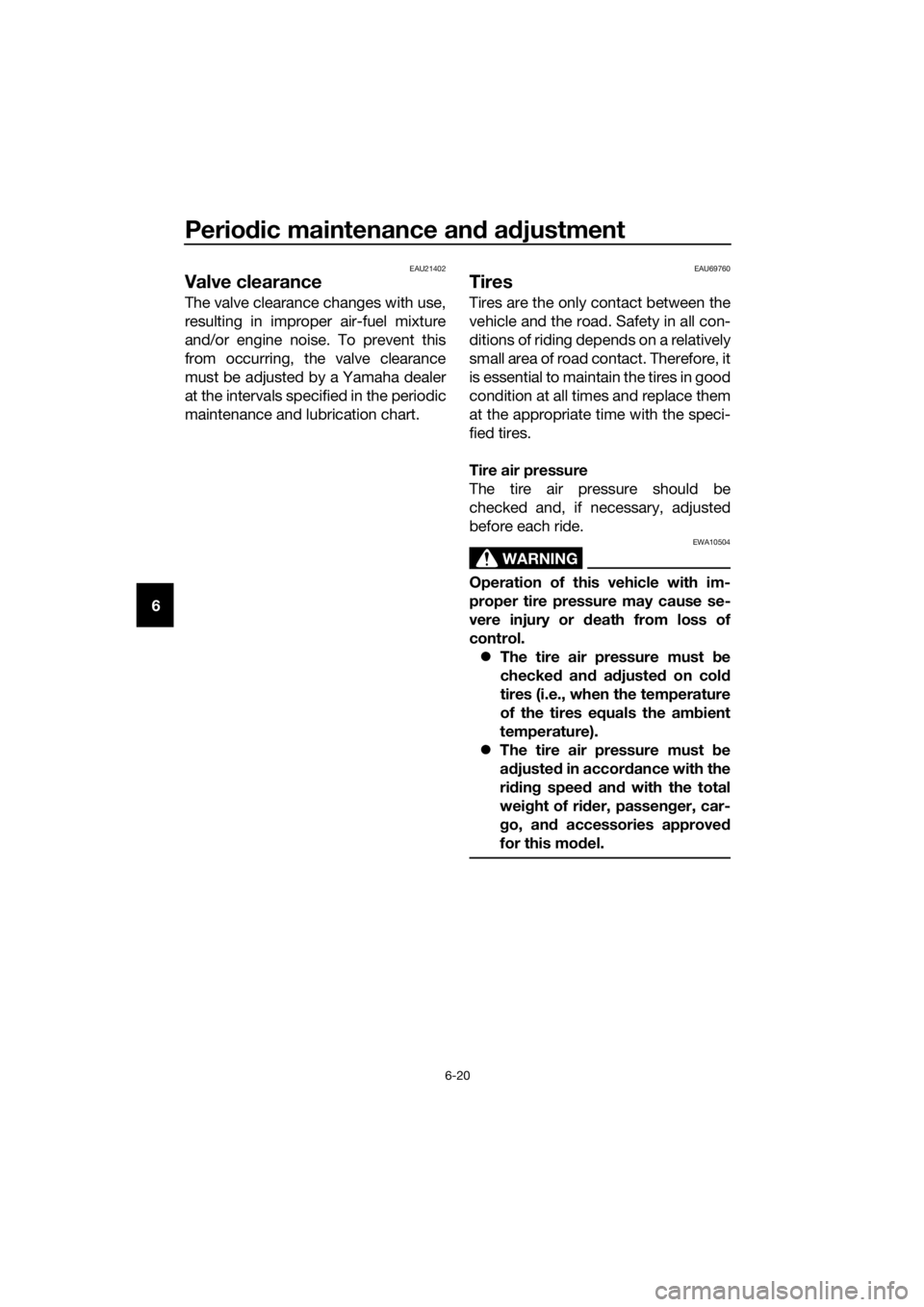

EAU21386

Checkin g the throttle grip free

play

Measure the throttle grip free play as

shown.

Periodically check the throttle grip free

play and, if necessary, have a Yamaha

dealer adjust it.

Recommen ded oil:

Yamaha foam air filter oil or other

quality foam air filter oil

1. Throttle grip free play

Throttle grip free play:

3.0–5.0 mm (0.12–0.20 in)

1

UBV3E0E0.book Page 19 Monday, September 26, 2016 3:42 PM

Page 60 of 94

Periodic maintenance an d a djustment

6-20

6

EAU21402

Valve clearance

The valve clearance changes with use,

resulting in improper air-fuel mixture

and/or engine noise. To prevent this

from occurring, the valve clearance

must be adjusted by a Yamaha dealer

at the intervals specified in the periodic

maintenance and lubrication chart.

EAU69760

Tires

Tires are the only contact between the

vehicle and the road. Safety in all con-

ditions of riding depends on a relatively

small area of road contact. Therefore, it

is essential to maintain the tires in good

condition at all times and replace them

at the appropriate time with the speci-

fied tires.

Tire air pressure

The tire air pressure should be

checked and, if necessary, adjusted

before each ride.

WARNING

EWA10504

Operation of this vehicle with im-

proper tire pressure may cause se-

vere injury or d eath from loss of

control. The tire air pressure must be

checked and a djuste d on col d

tires (i.e., when the temperature

of the tires equals the am bient

temperature).

The tire air pressure must be

a d juste d in accor dance with the

ri din g speed and with the total

wei ght of ri der, passen ger, car-

g o, an d accessories approve d

for this mo del.

UBV3E0E0.book Page 20 Monday, September 26, 2016 3:42 PM