brake YAMAHA PW50 2018 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2018, Model line: PW50, Model: YAMAHA PW50 2018Pages: 80, PDF Size: 1.9 MB

Page 45 of 80

Periodic maintenance an d a djustment

7-5

7TIP

The air filter needs more frequent service if you are riding in unusually wet or dusty

areas.

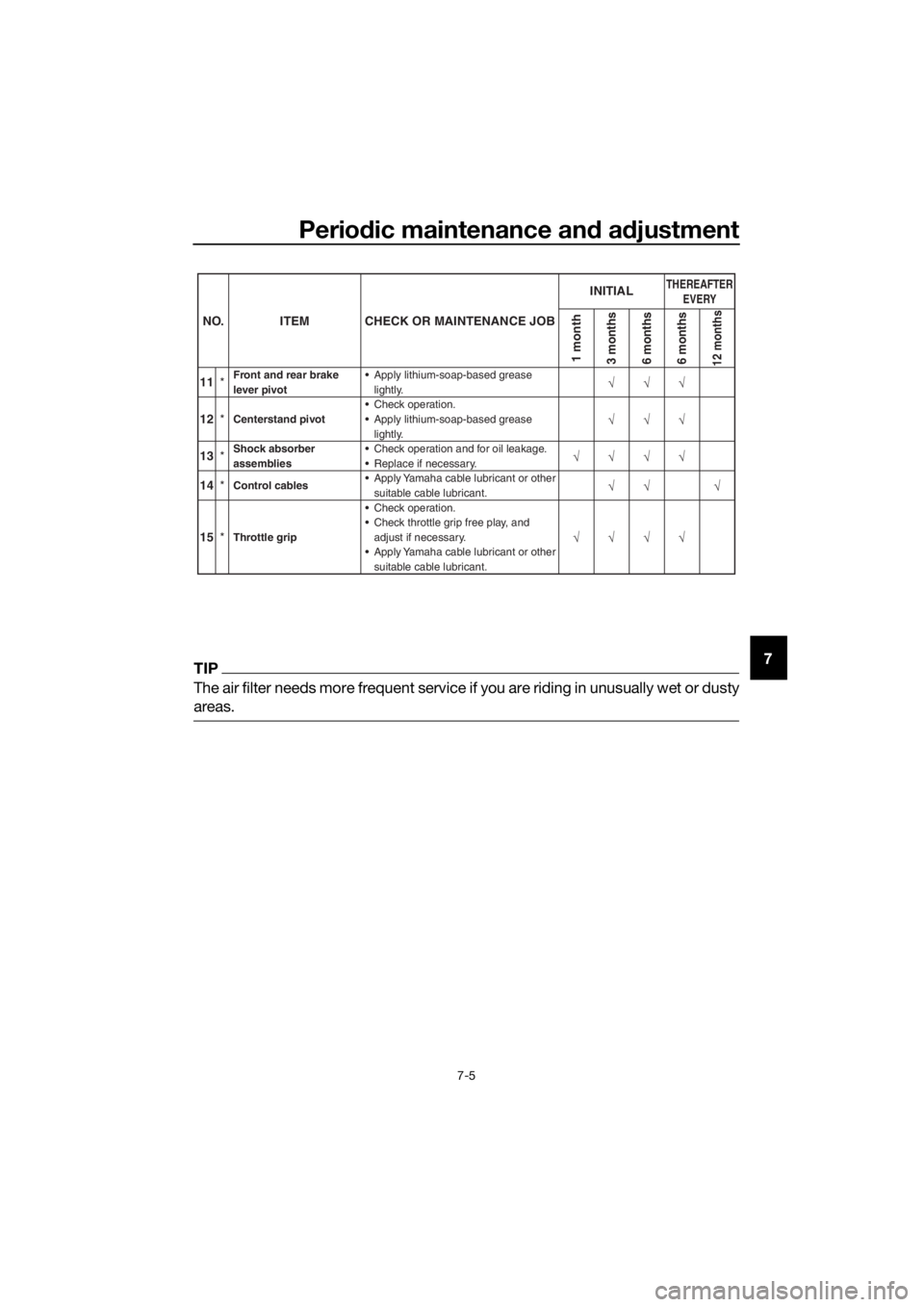

11 *Front and rear brake

lever pivot Apply lithium-soap-based grease

lightly.

12 *Centerstand pivot Check operation.

13

*Shock absorber

assemblies Check operation and for oil leakage.

14

*Control cables Apply Yamaha cab

le lubricant or other

suitab le cable lubricant.

15*Throttle grip Check operation.

Check throttle grip free play, and

adjust if necessary.

Apply Yamaha cab le lubricant or other

suitab le cable lubricant.

Replace if necessary. Apply lithium-soap-based grease

lightly.

NO. ITEM CHECK OR MAINTENANCE JOB

1 month3 months

6 months

6 months12 months

√√√ √

√√√ √√√

√

√√

√

√

√√

THEREAFTER

EVERYINITIAL

U2SA84E0.book Page 5 Wednesday, May 10, 2017 9:37 AM

Page 57 of 80

Periodic maintenance an d a djustment

7-17

7

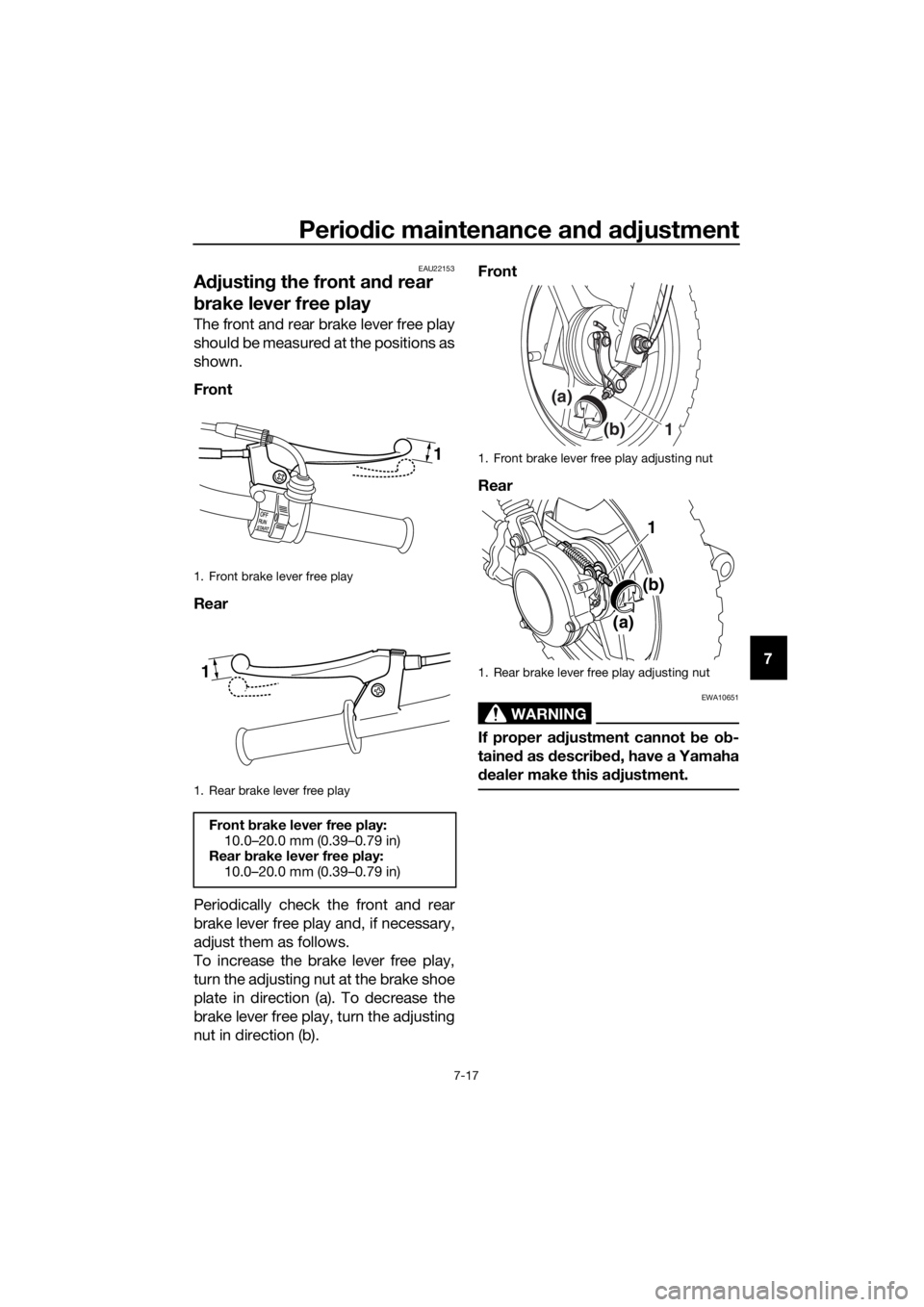

EAU22153

A djustin g the front an d rear

b rake lever free play

The front and rear brake lever free play

should be measured at the positions as

shown.

Front

Rear

Periodically check the front and rear

brake lever free play and, if necessary,

adjust them as follows.

To increase the brake lever free play,

turn the adjusting nut at the brake shoe

plate in direction (a). To decrease the

brake lever free play, turn the adjusting

nut in direction (b). Front

Rear

WARNING

EWA10651

If proper a

djustment cannot b e ob-

taine d as d escri bed , have a Yamaha

d ealer make this a djustment.

1. Front brake lever free play

1. Rear brake lever free play

Front brake lever free play:

10.0–20.0 mm (0.39–0.79 in)

Rear brake lever free play:

10.0–20.0 mm (0.39–0.79 in)

1

1

1. Front brake lever free play adjusting nut

1. Rear brake lever free play adjusting nut

1

(a)

(b)

1

(a)(b)

U2SA84E0.book Page 17 Wednesday, May 10, 2017 9:37 AM

Page 58 of 80

Periodic maintenance an d a djustment

7-18

7

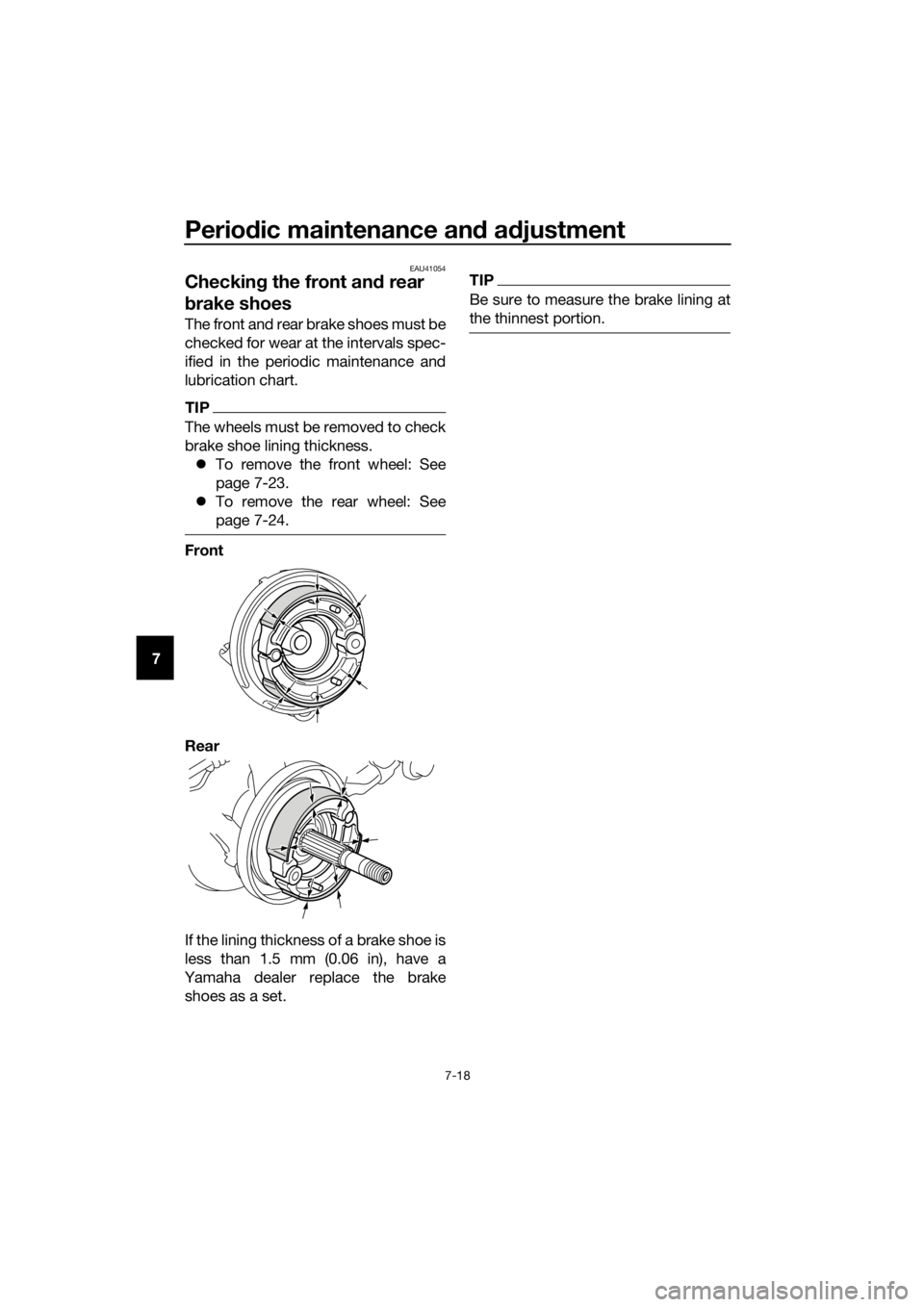

EAU41054

Checkin g the front an d rear

b rake shoes

The front and rear brake shoes must be

checked for wear at the intervals spec-

ified in the periodic maintenance and

lubrication chart.

TIP

The wheels must be removed to check

brake shoe lining thickness.

To remove the front wheel: See

page 7-23.

To remove the rear wheel: See

page 7-24.

Front

Rear

If the lining thickness of a brake shoe is

less than 1.5 mm (0.06 in), have a

Yamaha dealer replace the brake shoes as a set.

TIP

Be sure to measure the brake lining at

the thinnest portion.

U2SA84E0.book Page 18 Wednesday, May 10, 2017 9:37 AM

Page 60 of 80

Periodic maintenance an d a djustment

7-20

7

EAU23121

A djustin g the Autolu be pump

The Autolube pump is a vital and so-

phisticated component of the engine,

which must be adjusted by a Yamaha

dealer at the intervals specified in the

periodic maintenance and lubrication

chart.

EAU43634

Lub ricatin g the front an d rear

b rake levers

The pivoting points of the front and rear

brake levers must be lubricated at the

intervals specified in the periodic main-

tenance and lubrication chart.

Recommen ded lu bricant:

Lithium-soap-based grease

U2SA84E0.book Page 20 Wednesday, May 10, 2017 9:37 AM

Page 61 of 80

Periodic maintenance an d a djustment

7-21

7

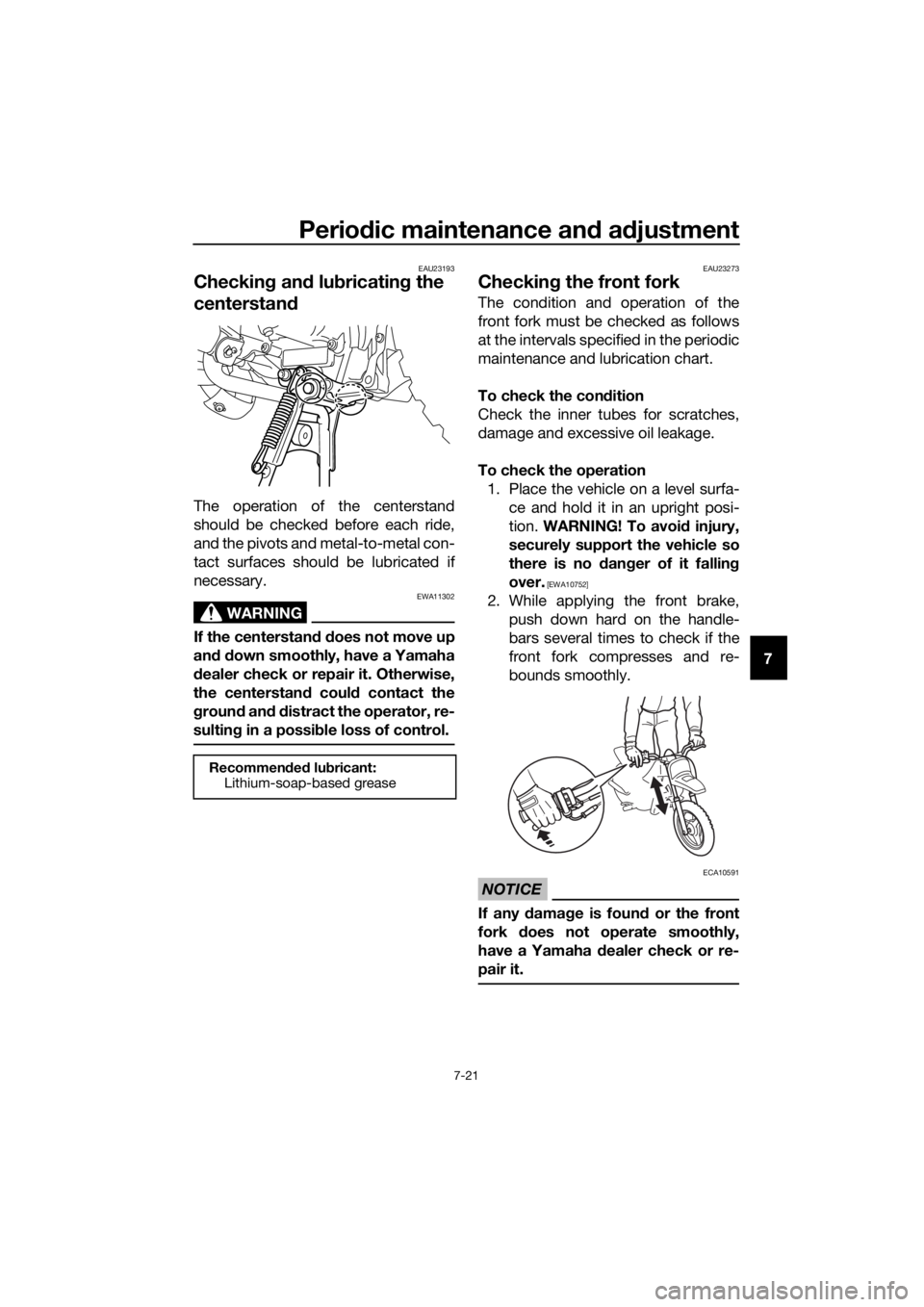

EAU23193

Checkin g an d lu bricatin g the

centerstan d

The operation of the centerstand

should be checked before each ride,

and the pivots and metal-to-metal con-

tact surfaces should be lubricated if

necessary.

WARNING

EWA11302

If the centerstan d d oes not move up

an d d own smoothly, have a Yamaha

d ealer check or repair it. Otherwise,

the centerstan d coul d contact the

g roun d an d d istract the operator, re-

sultin g in a possi ble loss of control.

EAU23273

Checkin g the front fork

The condition and operation of the

front fork must be checked as follows

at the intervals specified in the periodic

maintenance and lubrication chart.

To check the con dition

Check the inner tubes for scratches,

damage and excessive oil leakage.

To check the operation 1. Place the vehicle on a level surfa- ce and hold it in an upright posi-

tion. WARNING! To avoi d injury,

securely support the vehicle so

there is no dan ger of it fallin g

over.

[EWA10752]

2. While applying the front brake, push down hard on the handle-

bars several times to check if the

front fork compresses and re-

bounds smoothly.

NOTICE

ECA10591

If any damag e is foun d or the front

fork does not operate smoothly,

have a Yamaha d ealer check or re-

pair it.

Recommen ded lu bricant:

Lithium-soap-based grease

U2SA84E0.book Page 21 Wednesday, May 10, 2017 9:37 AM

Page 63 of 80

Periodic maintenance an d a djustment

7-23

7

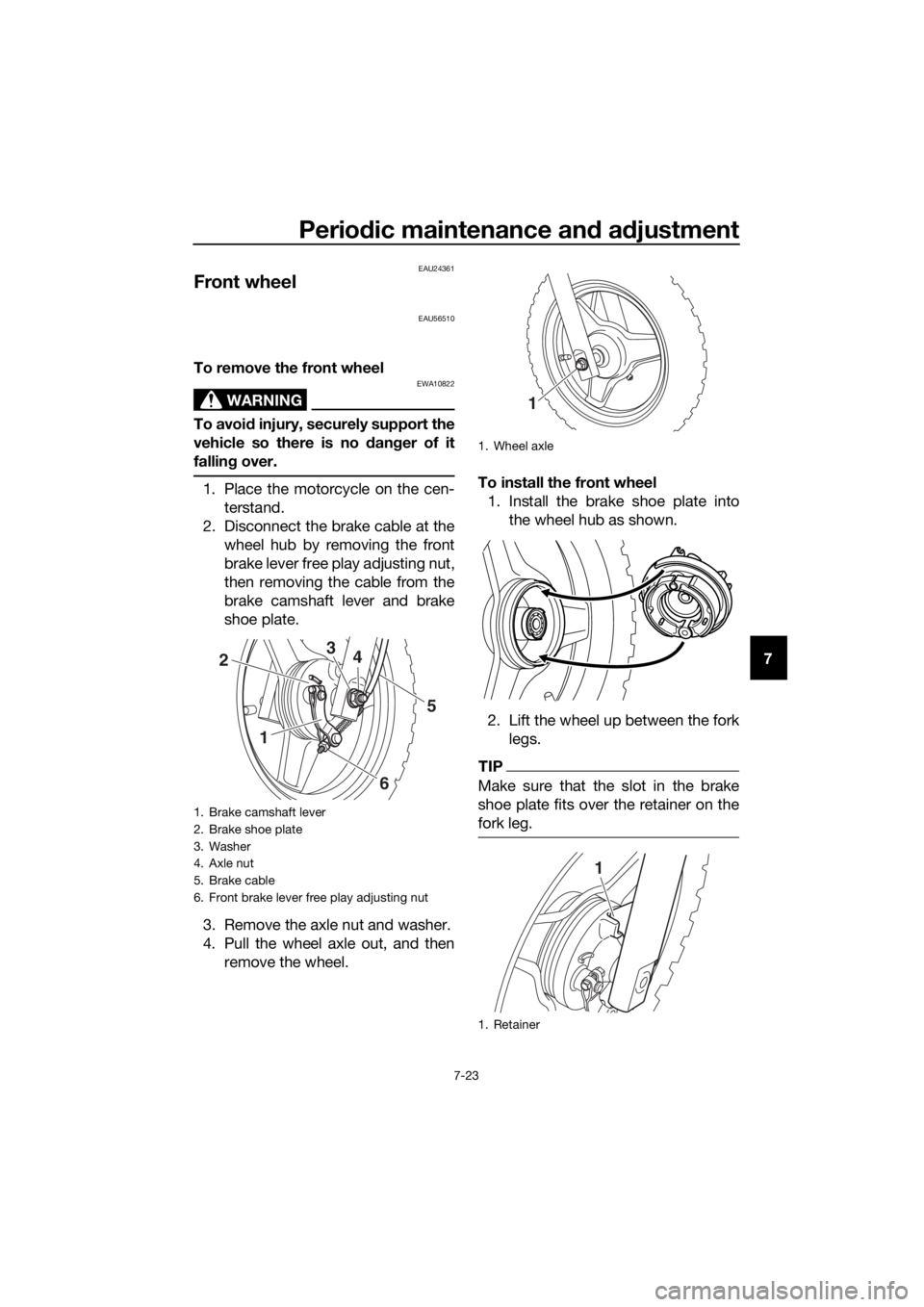

EAU24361

Front wheel

EAU56510

To remove the front wheel

WARNING

EWA10822

To avoi d injury, securely support the

vehicle so there is no d anger of it

fallin g over.

1. Place the motorcycle on the cen-

terstand.

2. Disconnect the brake cable at the wheel hub by removing the front

brake lever free play adjusting nut,

then removing the cable from the

brake camshaft lever and brake

shoe plate.

3. Remove the axle nut and washer.

4. Pull the wheel axle out, and then remove the wheel. To install the front wheel

1. Install the brake shoe plate into the wheel hub as shown.

2. Lift the wheel up between the fork legs.

TIP

Make sure that the slot in the brake

shoe plate fits over the retainer on the

fork leg.

1. Brake camshaft lever

2. Brake shoe plate

3. Washer

4. Axle nut

5. Brake cable

6. Front brake lever free play adjusting nut

5

6

1 3

4

2

1. Wheel axle

1. Retainer

1

1

U2SA84E0.book Page 23 Wednesday, May 10, 2017 9:37 AM

Page 64 of 80

Periodic maintenance an d a djustment

7-24

7 3. Insert the wheel axle from the right

side.

4. Install the washer and axle nut, and then tighten the axle nut to the

specified torque.

5. Connect the brake cable at the wheel hub, and then install the

brake lever free play adjusting nut.

6. Adjust the brake lever free play. (See page 7-17.)

7. Take the motorcycle off the cen- terstand so that the front wheel is

on the ground.

8. Push down hard on the handlebar several times to check for proper

fork operation.

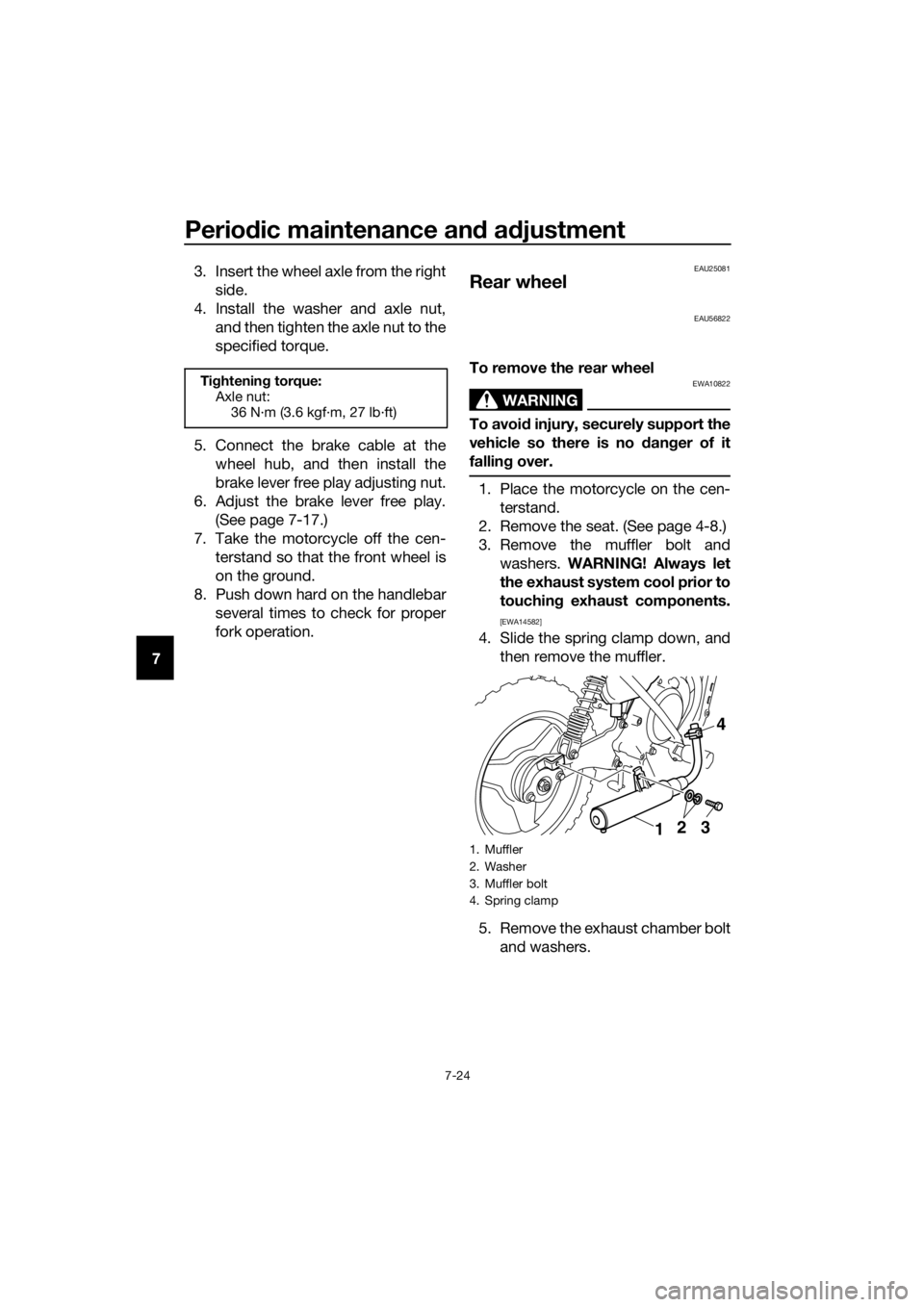

EAU25081

Rear wheel

EAU56822

To remove the rear wheel

WARNING

EWA10822

To avoi d injury, securely support the

vehicle so there is no dan ger of it

fallin g over.

1. Place the motorcycle on the cen-

terstand.

2. Remove the seat. (See page 4-8.)

3. Remove the muffler bolt and washers. WARNING! Always let

the exhaust system cool prior to

touching exhaust components.

[EWA14582]

4. Slide the spring clamp down, and

then remove the muffler.

5. Remove the exhaust chamber bolt and washers.

Tightenin g torque:

Axle nut: 36 N·m (3.6 kgf·m, 27 lb·ft)

1. Muffler

2. Washer

3. Muffler bolt

4. Spring clamp

312 4

U2SA84E0.book Page 24 Wednesday, May 10, 2017 9:37 AM

Page 65 of 80

Periodic maintenance an d a djustment

7-25

7

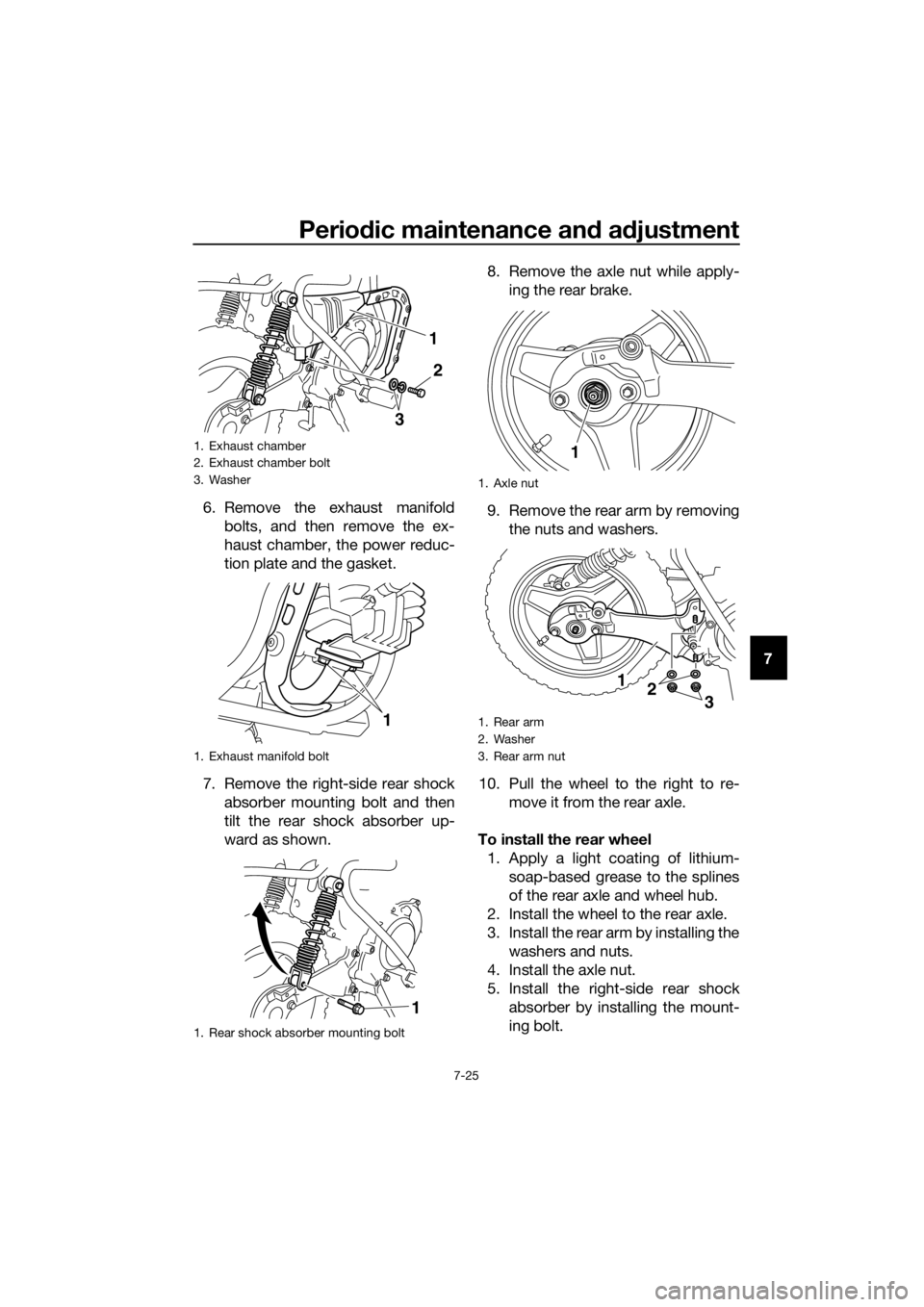

6. Remove the exhaust manifold

bolts, and then remove the ex-

haust chamber, the power reduc-

tion plate and the gasket.

7. Remove the right-side rear shock absorber mounting bolt and then

tilt the rear shock absorber up-

ward as shown. 8. Remove the axle nut while apply-

ing the rear brake.

9. Remove the rear arm by removing the nuts and washers.

10. Pull the wheel to the right to re- move it from the rear axle.

To install the rear wheel 1. Apply a light coating of lithium- soap-based grease to the splines

of the rear axle and wheel hub.

2. Install the wheel to the rear axle.

3. Install the rear arm by installing the washers and nuts.

4. Install the axle nut.

5. Install the right-side rear shock absorber by installing the mount-

ing bolt.

1. Exhaust chamber

2. Exhaust chamber bolt

3. Washer

1. Exhaust manifold bolt

1. Rear shock absorber mounting bolt

2

1

3

1

1

1. Axle nut

1. Rear arm

2. Washer

3. Rear arm nut

1

1

2

3

U2SA84E0.book Page 25 Wednesday, May 10, 2017 9:37 AM

Page 66 of 80

Periodic maintenance an d a djustment

7-26

7 6. While applying the rear brake,

tighten the axle nut to the speci-

fied torque.

7. Tighten the rear arm nuts and rear shock absorber mounting bolt to

the specified torques.

8. Install the exhaust chamber by in- stalling the bolt and washers.

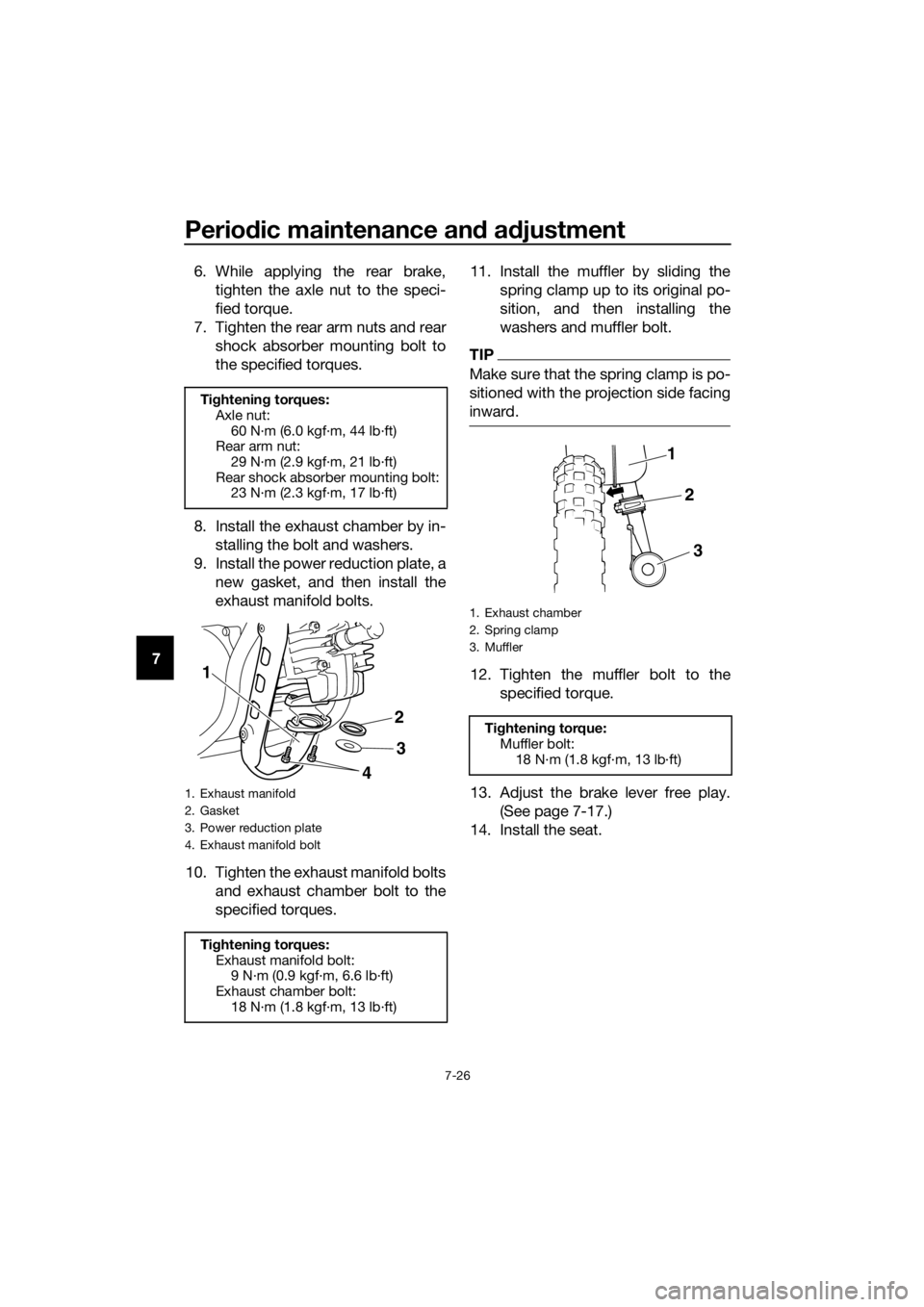

9. Install the power reduction plate, a new gasket, and then install the

exhaust manifold bolts.

10. Tighten the exhaust manifold bolts and exhaust chamber bolt to the

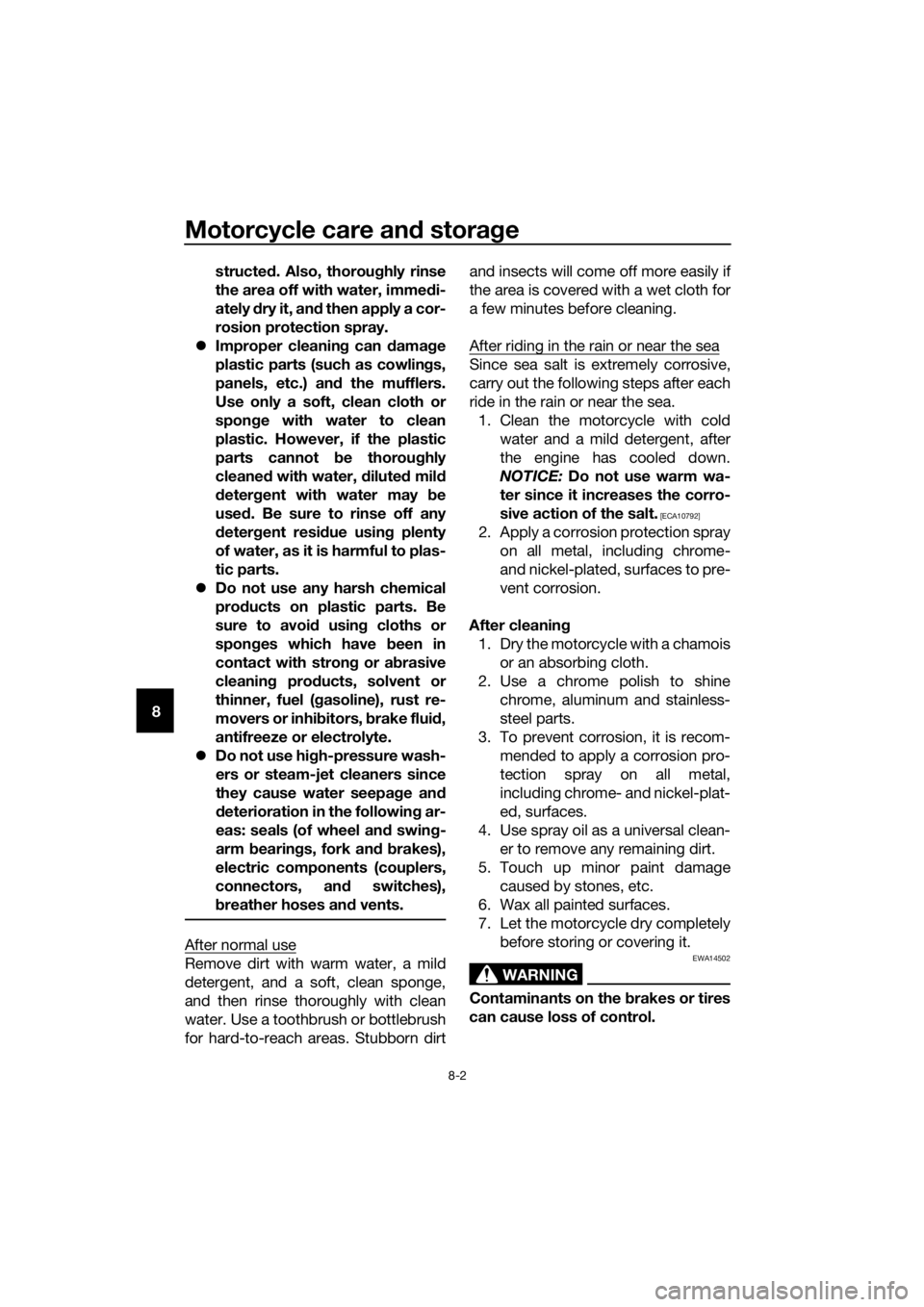

specified torques. 11. Install the muffler by sliding the

spring clamp up to its original po-

sition, and then installing the

washers and muffler bolt.

TIP

Make sure that the spring clamp is po-

sitioned with the projection side facing

inward.

12. Tighten the muffler bolt to thespecified torque.

13. Adjust the brake lever free play. (See page 7-17.)

14. Install the seat.

Ti ghtenin g torques:

Axle nut: 60 N·m (6.0 kgf·m, 44 lb·ft)

Rear arm nut:

29 N·m (2.9 kgf·m, 21 lb·ft)

Rear shock absorber mounting bolt: 23 N·m (2.3 kgf·m, 17 lb·ft)

1. Exhaust manifold

2. Gasket

3. Power reduction plate

4. Exhaust manifold bolt

Tightenin g torques:

Exhaust manifold bolt: 9 N·m (0.9 kgf·m, 6.6 lb·ft)

Exhaust chamber bolt:

18 N·m (1.8 kgf·m, 13 lb·ft)

2

3

4

1

1. Exhaust chamber

2. Spring clamp

3. Muffler

Tightening torque:

Muffler bolt: 18 N·m (1.8 kgf·m, 13 lb·ft)

1

2

3

U2SA84E0.book Page 26 Wednesday, May 10, 2017 9:37 AM

Page 70 of 80

Motorcycle care and stora ge

8-2

8 structe

d. Also, thorou ghly rinse

the area off with water, imme di-

ately dry it, an d then apply a cor-

rosion protection spray.

Improper cleanin g can d amage

plastic parts (such as cowlin gs,

panels, etc.) an d the mufflers.

Use only a soft, clean cloth or

spon ge with water to clean

plastic. However, if the plastic

parts cannot be thorou ghly

cleaned with water, dilute d mil d

d eter gent with water may b e

use d. Be sure to rinse off any

d eter gent resi due using plenty

of water, as it is harmful to plas-

tic parts.

Do not use any harsh chemical

prod ucts on plastic parts. Be

sure to avoi d using cloths or

spon ges which have been in

contact with stron g or a brasive

cleanin g prod ucts, solvent or

thinner, fuel (g asoline), rust re-

movers or inhi bitors, brake flui d,

antifreeze or electrolyte.

Do not use hi

gh-pr

essure wash-

ers or steam-jet cleaners since

they cause water seepa ge an d

d eterioration in the followin g ar-

eas: seals (of wheel an d swin g-

arm bearin gs, fork an d b rakes),

electric components (couplers,

connectors, an d switches),

b reather hoses an d vents.

After normal use

Remove dirt with warm water, a mild

detergent, and a soft, clean sponge,

and then rinse thoroughly with clean

water. Use a toothbrush or bottlebrush

for hard-to-reach areas. Stubborn dirt and insects will come off more easily if

the area is covered with a wet cloth for

a few minutes before cleaning.

After riding in the rain or near the sea

Since sea salt is extremely corrosive,

carry out the following steps after each

ride in the rain or near the sea.

1. Clean the motorcycle with cold water and a mild detergent, after

the engine has cooled down.

NOTICE: Do not use warm wa-

ter since it increases the corro-

sive action of the salt.

[ECA10792]

2. Apply a corrosion protection spray on all metal, including chrome-

and nickel-plated, surfaces to pre-

vent corrosion.

After cleaning 1. Dry the motorcycle with a chamois or an absorbing cloth.

2. Use a chrome polish to shine chrome, aluminum and stainless-

steel parts.

3. To prevent corrosion, it is recom- mended to apply a corrosion pro-

tection spray on all metal,

including chrome- and nickel-plat-

ed, surfaces.

4. Use spray oil as a universal clean- er to remove any remaining dirt.

5. Touch up minor paint damage caused by stones, etc.

6. Wax all painted surfaces.

7. Let the motorcycle dry completely before storing or covering it.

WARNING

EWA14502

Contaminants on the brakes or tires

can cause loss of control.

U2SA84E0.book Page 2 Wednesday, May 10, 2017 9:37 AM