Torque YAMAHA RHINO 700 2013 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2013, Model line: RHINO 700, Model: YAMAHA RHINO 700 2013Pages: 188, PDF Size: 4.9 MB

Page 132 of 188

8-19

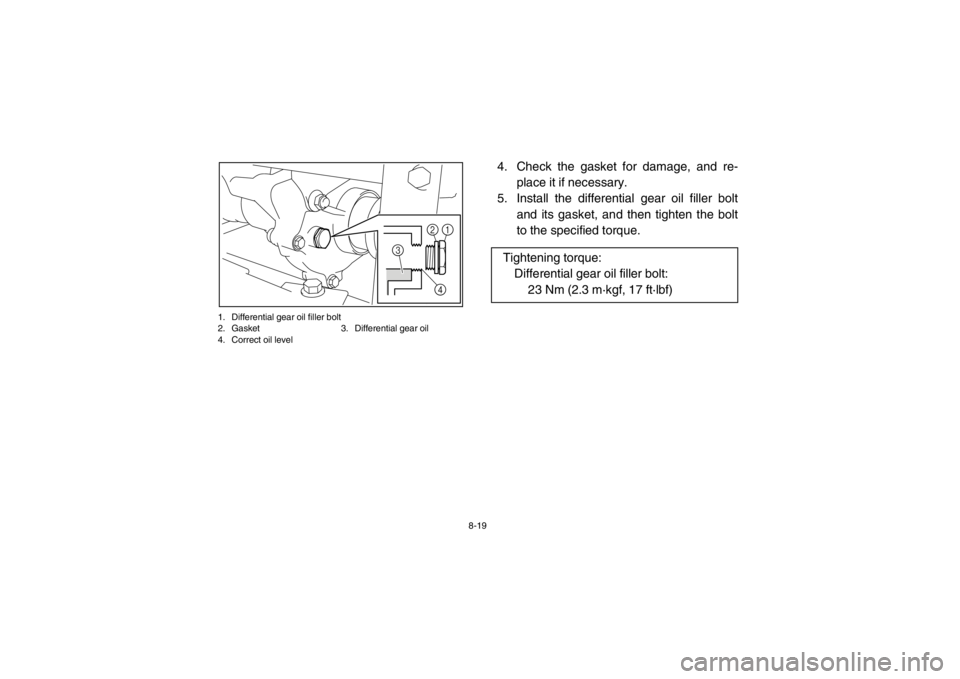

1. Differential gear oil filler bolt

2. Gasket 3. Differential gear oil

4. Correct oil level

4. Check the gasket for damage, and re-

place it if necessary.

5. Install the differential gear oil filler bolt

and its gasket, and then tighten the bolt

to the specified torque.

1

2

3

4

Tightening torque:Differential gear oil filler bolt:

23 Nm (2.3 m·kgf, 17 ft·lbf)

1RB7A_EE.book Page 19 Tuesday, April 24, 2012 9:07 AM

Page 133 of 188

8-20

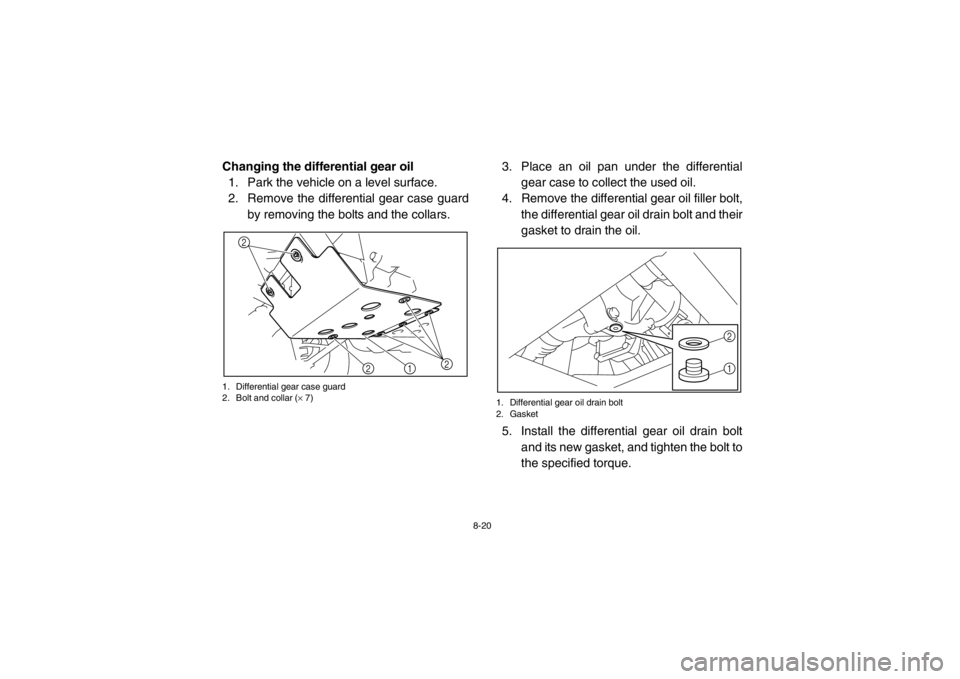

Changing the differential gear oil1. Park the vehicle on a level surface.

2. Remove the differential gear case guard by removing the bolts and the collars.1. Differential gear case guard

2. Bolt and collar ( × 7)

3. Place an oil pan under the differential

gear case to collect the used oil.

4. Remove the differential gear oil filler bolt,

the differential gear oil drain bolt and their

gasket to drain the oil.1. Differential gear oil drain bolt

2. Gasket5. Install the differential gear oil drain boltand its new gasket, and tighten the bolt to

the specified torque.

1

2

2 2

12

1RB7A_EE.book Page 20 Tuesday, April 24, 2012 9:07 AM

Page 134 of 188

8-21

6. Refill the differential gear case with therecommended oil. NOTICE: Be sure no

foreign material enters the differential

gear case.

7. Check the oil filler bolt gasket for dam- age, and replace it if necessary.

8. Install the differential gear oil filler bolt

and its gasket, and then tighten the bolt

to the specified torque. 9. Check for oil leakage. If oil leakage is

found, check for the cause.

10. Install the differential gear case guard by

installing the bolts and the collars, and

then tightening the bolts to the specified

torque.

Tightening torque:

Differential gear oil drain bolt: 9.8 Nm (0.98 m·kgf, 7.1 ft·lbf)

Recommended oil: SAE 80 API GL-4 Hypoid gear oil

Oil quantity: 0.18 L (0.19 US qt, 0.16 Imp.qt)

Tightening torque: Differential gear oil filler bolt:

23 Nm (2.3 m·kgf, 17 ft·lbf)

Tightening torque:Differential gear case guard bolt: 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

1RB7A_EE.book Page 21 Tuesday, April 24, 2012 9:07 AM

Page 139 of 188

8-26

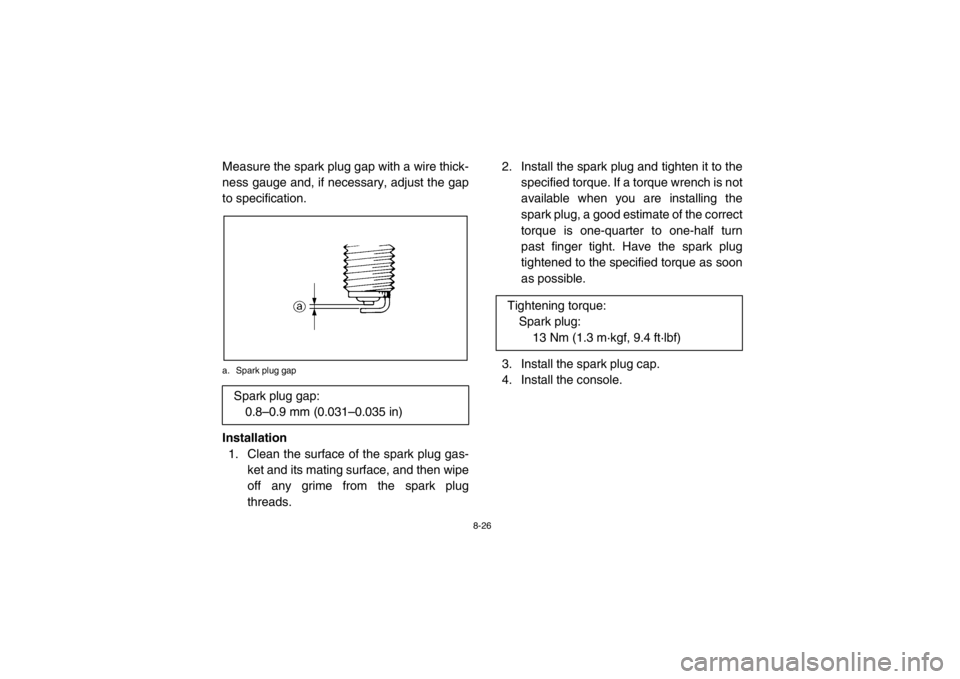

Measure the spark plug gap with a wire thick-

ness gauge and, if necessary, adjust the gap

to specification.a. Spark plug gapInstallation1. Clean the surface of the spark plug gas- ket and its mating surface, and then wipe

off any grime from the spark plug

threads. 2. Install the spark plug and tighten it to the

specified torque. If a torque wrench is not

available when you are installing the

spark plug, a good estimate of the correct

torque is one-quarter to one-half turn

past finger tight. Have the spark plug

tightened to the specified torque as soon

as possible.

3. Install the spark plug cap.

4. Install the console.

Spark plug gap: 0.8–0.9 mm (0.031–0.035 in)

Tightening torque:Spark plug:

13 Nm (1.3 m·kgf, 9.4 ft·lbf)

1RB7A_EE.book Page 26 Tuesday, April 24, 2012 9:07 AM

Page 147 of 188

8-34

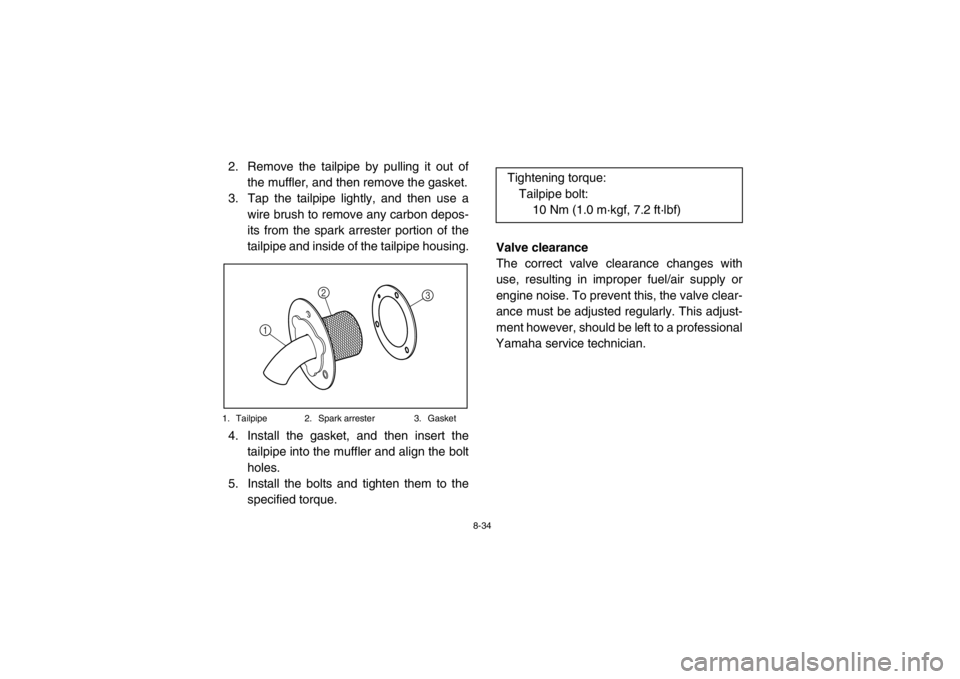

2. Remove the tailpipe by pulling it out ofthe muffler, and then remove the gasket.

3. Tap the tailpipe lightly, and then use a

wire brush to remove any carbon depos-

its from the spark arrester portion of the

tailpipe and inside of the tailpipe housing.1. Tailpipe 2. Spark arrester 3. Gasket4. Install the gasket, and then insert thetailpipe into the muffler and align the bolt

holes.

5. Install the bolts and tighten them to the specified torque. Valve clearance

The correct valve clearance changes with

use, resulting in improper fuel/air supply or

engine noise. To prevent this, the valve clear-

ance must be adjusted regularly. This adjust-

ment however, should be left to a professional

Yamaha service technician.

3

1 2

Tightening torque:

Tailpipe bolt: 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

1RB7A_EE.book Page 34 Tuesday, April 24, 2012 9:07 AM

Page 156 of 188

8-43

3. Install the lower arm protector by install-ing the bolts and tightening them to the

specified torque.

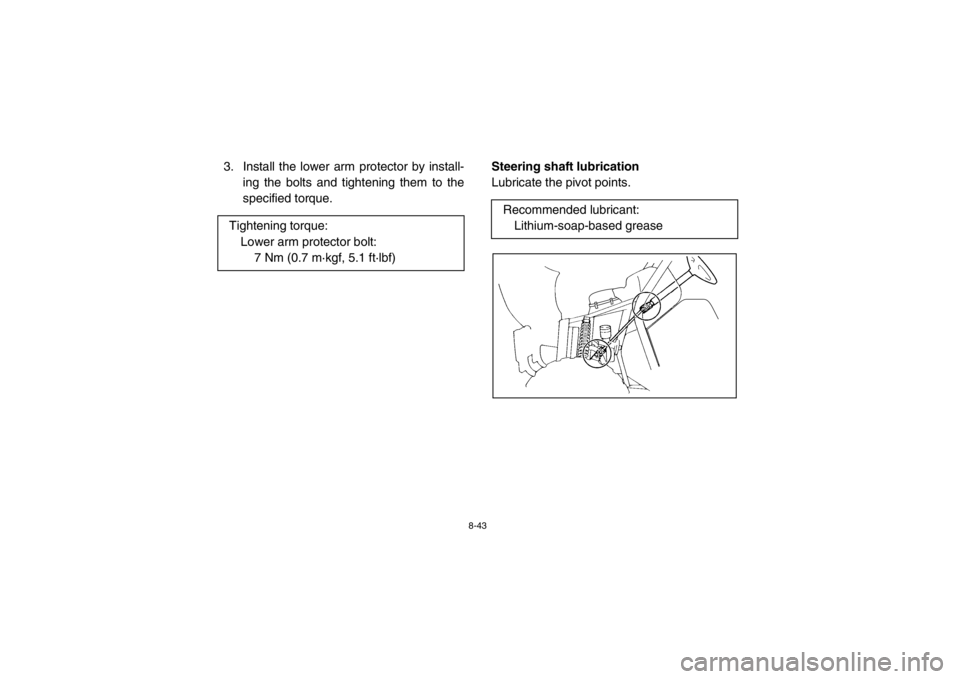

EVU00920Steering shaft lubrication

Lubricate the pivot points.

Tightening torque: Lower arm protector bolt: 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Recommended lubricant:Lithium-soap-based grease

1RB7A_EE.book Page 43 Tuesday, April 24, 2012 9:07 AM

Page 158 of 188

8-45

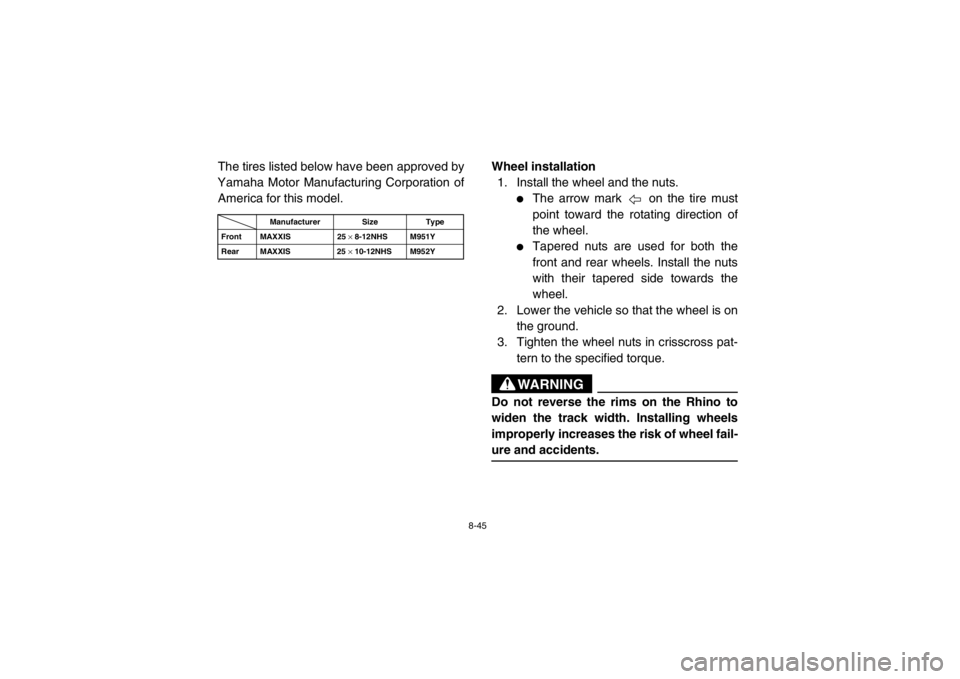

The tires listed below have been approved by

Yamaha Motor Manufacturing Corporation of America for this model.

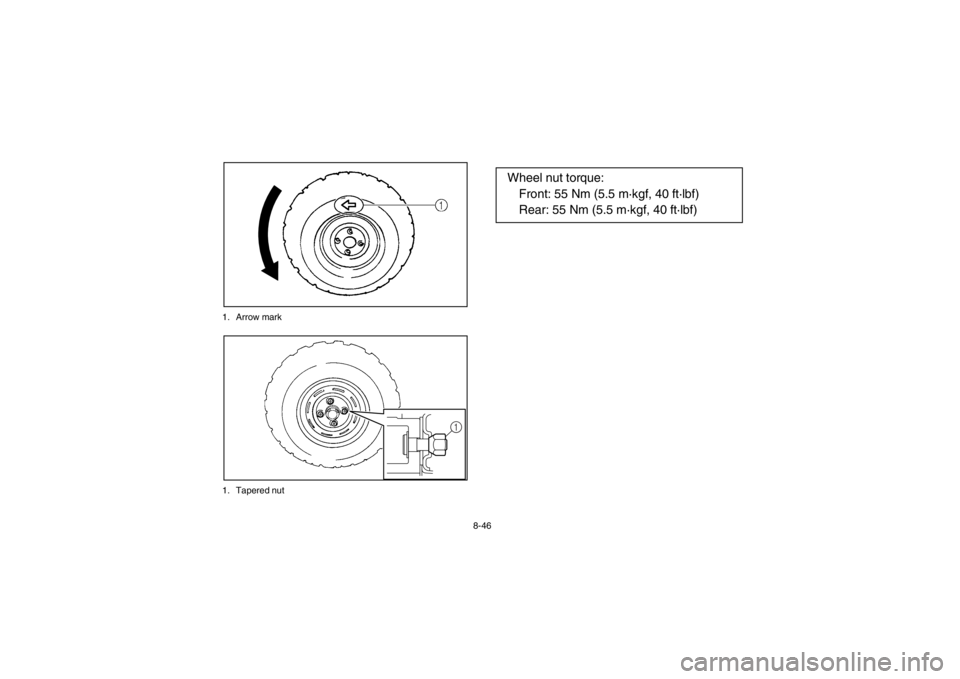

EVU00940Wheel installation

1. Install the wheel and the nuts.

●

The arrow mark on the tire must

point toward the rotating direction of

the wheel.

●

Tapered nuts are used for both the

front and rear wheels. Install the nuts

with their tapered side towards the

wheel.

2. Lower the vehicle so that the wheel is on the ground.

3. Tighten the wheel nuts in crisscross pat-

tern to the specified torque.

WARNING

Do not reverse the rims on the Rhino to

widen the track width. Installing wheels

improperly increases the risk of wheel fail-

ure and accidents.

Manufacturer SizeType

Front MAXXIS 25 × 8-12NHS M951Y

Rear MAXXIS 25 × 10-12NHS M952Y

1RB7A_EE.book Page 45 Tuesday, April 24, 2012 9:07 AM

Page 159 of 188

8-46

1. Arrow mark

1. Tapered nut

1

Wheel nut torque:

Front: 55 Nm (5.5 m·kgf, 40 ft·lbf)

Rear: 55 Nm (5.5 m·kgf, 40 ft·lbf)

1RB7A_EE.book Page 46 Tuesday, April 24, 2012 9:07 AM

Page 173 of 188

8-60

7. Install the bulb holder (together with thebulb) by turning it clockwise.

8. Install the panel.

9. Lower the cargo bed.

10. Install the quick fastener screws, bolts and nuts, and then tighten the nuts to the

specified torque.

EVU01010Troubleshooting

Although Yamaha vehicles receive an inspec-

tion before shipment from the factory, trouble

may occur during operation. Any problem in

the fuel, compression, or ignition systems can

cause poor starting and loss of power. The

troubleshooting chart describes a quick, easy

procedure for making checks. If your vehicle

requires any repair, take it to a Yamaha deal-

er.

The skilled technicians at a Yamaha dealer-

ship have the tools, experience, and know-

how to properly service your vehicle. Use only

genuine Yamaha parts on your vehicle. Imita-

tion parts may look like Yamaha parts, but

they are often inferior. Consequently, they

have a shorter service life and can lead to ex-

pensive repair bills.

Tightening torque:

Panel nut: 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

1RB7A_EE.book Page 60 Tuesday, April 24, 2012 9:07 AM