engine YAMAHA SLIDER 50 2006 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: SLIDER 50, Model: YAMAHA SLIDER 50 2006Pages: 80, PDF Size: 2.06 MB

Page 51 of 80

PERIODIC MAINTENANCE AND MINOR REPAIR

6

EAUM0008

Changing the brake fluidHave a Yamaha dealer change the

brake fluid at the intervals specified in

the periodic maintenance and

lubrication chart. In addition, have the

brake hose replaced every four years

or whenever it is damaged or leaking.

EAU02962

Checking and lubricating the

cablesThe operation of all control cables and

the condition of the cables should be

checked before each ride, and the

cables and cable ends should be

lubricated if necessary. If a cable is

damaged or does not move smoothly,

have a Yamaha dealer check or replace

it.

Recommended lubricant:

Engine oil

EW000112

Damage to the outer sheath may

interfere with proper cable operation

and will cause the inner cable to

rust. Replace a damaged cable as

soon as possible to prevent unsafeconditions.

6-14

•

Brake fluid may deteriorate painted

surfaces or plastic parts. Always

clean up spilled fluid immediately.

•

As the brake pads wear, it is nor-

mal for the brake fluid level to

gradually go down. However, if the

brake fluid level goes down

suddenly, have a Yamaha dealer

check the cause.

Page 53 of 80

PERIODIC MAINTENANCE AND MINOR REPAIR

6

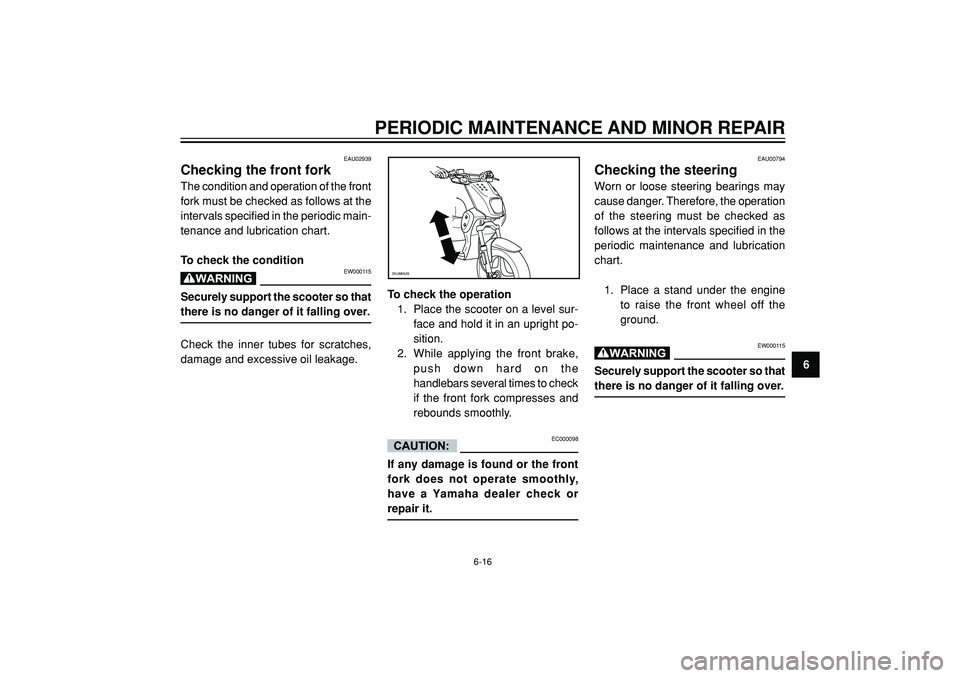

EAU02939

Checking the front forkThe condition and operation of the front

fork must be checked as follows at the

intervals specified in the periodic main-

tenance and lubrication chart.

To check the condition

EW000115

Securely support the scooter so thatthere is no danger of it falling over.

Check the inner tubes for scratches,

damage and excessive oil leakage.To check the operation

1. Place the scooter on a level sur-

face and hold it in an upright po-

sition.

2. While applying the front brake,

push down hard on the

handlebars several times to check

if the front fork compresses and

rebounds smoothly.

EC000098

If any damage is found or the front

fork does not operate smoothly,

have a Yamaha dealer check orrepair it.ZAUM0528

EAU00794

Checking the steeringWorn or loose steering bearings may

cause danger. Therefore, the operation

of the steering must be checked as

follows at the intervals specified in the

periodic maintenance and lubrication

chart.

1. Place a stand under the engine

to raise the front wheel off the

ground.

EW000115

Securely support the scooter so thatthere is no danger of it falling over.

6-16

Page 59 of 80

PERIODIC MAINTENANCE AND MINOR REPAIR

6

6-22

EAU03473

Troubleshooting chart

EW000125

Keep away open flames and do not smoke while checking or working on the fuel system.

Check the fuel level in

the fuel tank.1. Fuel

There is enough fuel.

There is no fuel.

Check the compression.

Supply fuel.

The engine does not start.

Check the compression.

Operate the electric starter.2. Compression

There is compression.

There is no compression.

Check the ignition.

Have a Yamaha dealer

check the vehicle.

Remove the spark plug

and check the electrodes.3. Ignition

Wipe off with a dry cloth and correct the

spark plug gap, or replace the spark plug.

Have a Yamaha dealer check the vehicle.

The engine does not start.

Have a Yamaha dealer

check the vehicle.

The engine does not start.

Check the battery.

Operate the electric starter.4. Battery

The engine turns over

quickly.

The engine turns over

slowly.

The battery is good.Check fluid, recharge,

check connections..

DryWet

Open the throttle halfway and operate

the electric starter.

Page 62 of 80

SCOOTER CARE AND STORAGE

7

CareWhile the open design of a scooter

reveals the attractiveness of the

technology, it also makes it more

vulnerable. Rust and corrosion can

develop even if high-quality

components are used. A rusty exhaust

pipe may go unnoticed on a car,

however, it detracts from the overall

appearance of a scooter. Frequent and

proper care does not only comply with

the terms of the warranty, but it will also

keep your scooter looking good, extend

its life and optimize its performance.Before cleaning

1. Cover the muffler outlet with a

plastic bag after the engine has

cooled down.

2. Make sure that all caps and

covers as well as all electrical

couplers and connectors,

including the spark plug cap, are

tightly installed.

3. Remove extremely stubborn dirt,

like oil burnt onto the crankcase,

with a degreasing agent and a

brush, but never apply such

products onto seals, gaskets and

wheel axles. Always rinse the dirt

and degreaser off with water.Cleaning

ECA00011

•

Avoid using strong acidic wheel

cleaners, especially on spoked

wheels. If such products are used

on hard-to-remove dirt, do not

leave the cleaner on the affected

area any longer than instructed.

Also, thoroughly rinse the area off

with water, immediately dry it, and

then apply a corrosion protection

spray.

•

Improper cleaning can damage

windshields, cowlings, panels

and other plastic parts. Use only

a soft, clean cloth or sponge with

mild detergent and water to clean

plastic.

•

Do not use any harsh chemical

products on plastic parts. Be sure

to avoid using cloths or sponges

which have been in contact with

strong or abrasive cleaning

products, solvent or thinner, fuel

(gasoline), rust removers or

inhibitors, brake fluid, antifreeze

or electrolyte.

7-1

Page 63 of 80

SCOOTER CARE AND STORAGE

7

•

Do not use high-pressure

washers or steam-jet cleaners

since they cause water

seepage and deterioration in

the following areas: seals (of

wheel and swingarm bearings,

fork and brakes), electric

components (couplers,

connectors, instruments,

switches and lights), breather

hoses and vents.

•

For scooters equipped with a

windshield: Do not use strong

cleaners or hard sponges as

they will cause dulling or

scratching. Some cleaning

compounds for plastic may

leave scratches on the

windshield. Test the product on

a small hidden part of the

windshield to make sure that it

does not leave any marks. If the

windshield is scratched, use a

quality plastic polishingcompound after washing.

After normal use

Remove dirt with warm water, a mild

detergent, and a soft, clean sponge,

and then rinse thoroughly with clean

water. Use a toothbrush or bottlebrush

for hard-to-reach areas. Stubborn dirt

and insects will come off more easily if

the area is covered with a wet cloth for

a few minutes before cleaning.After riding in the rain, near the seaor on salt-sprayed roads

Since sea salt or salt sprayed on the

roads during winter are extremely cor-

rosive in combination with water, carry

out the following steps after each ride

in the rain, near the sea or on salt-

sprayed roads.NOTE :

Salt sprayed on roads in the winter mayremain well into spring.1. Clean the scooter with cold water

and a mild detergent after the

engine has cooled down.

ECA00012

Do not use warm water since it

increases the corrosive action of thesalt.

2. Apply a corrosion protection spray

on all metal, including chrome-

and nickel-plated, surfaces to

prevent corrosion.

7-2

Page 65 of 80

SCOOTER CARE AND STORAGE

7

StorageShort-term

Always store your scooter in a cool, dry

place and, if necessary, protect it

against dust with a porous cover.

ECA00015

•

Storing the scooter in a poorly

ventilated room or covering it

with a tarp, while it is still wet,

will allow water and humidity to

seep in and cause rust.

•

To prevent corrosion, avoid

damp cellars, stables (because

of the presence of ammonia)

and areas where strongchemicals are stored.Long-term

Before storing your scooter for several

months:

1. Follow all the instructions in the

"Care" section of this chapter.

2. Drain the carburetor float

chamber by loosening the drain

bolt; this will prevent fuel deposits

from building up. Pour the drained

fuel into the fuel tank.

3. Fill up the fuel tank and add fuel

stabilizer (if available) to prevent

the fuel tank from rusting and the

fuel from deteriorating.

4. Perform the following steps to

protect the cylinder, piston rings,

etc. from corrosion.

a. Remove the spark plug cap

and spark plug.

b. Pour a teaspoonful of engine

oil into the spark plug bore.

c. Install the spark plug cap onto

the spark plug, and then place

the spark plug on the cylinder

head so that the electrodes are

grounded. (This will limit

sparking during the next step.)

d. Turn the engine over several

times with the starter. (This will

coat the cylinder wall with oil.)

e. Remove the spark plug cap

from the spark plug, and then

install the spark plug and the

spark plug cap.

EWA00003

To prevent damage or injury from

sparking, make sure to ground the

spark plug electrodes while turningthe engine over.

5. Lubricate all control cables and

the pivoting points of all levers and

pedals as well as of the sidestand/

centerstand.

6. Check and, if necessary, correct

the tire air pressure, and then lift

the scooter so that both of its

wheels are off the ground.

Alternatively, turn the wheels a

little every month in order to

prevent the tires from becoming

degraded in one spot.

7-4

Page 68 of 80

SPECIFICATIONS

8

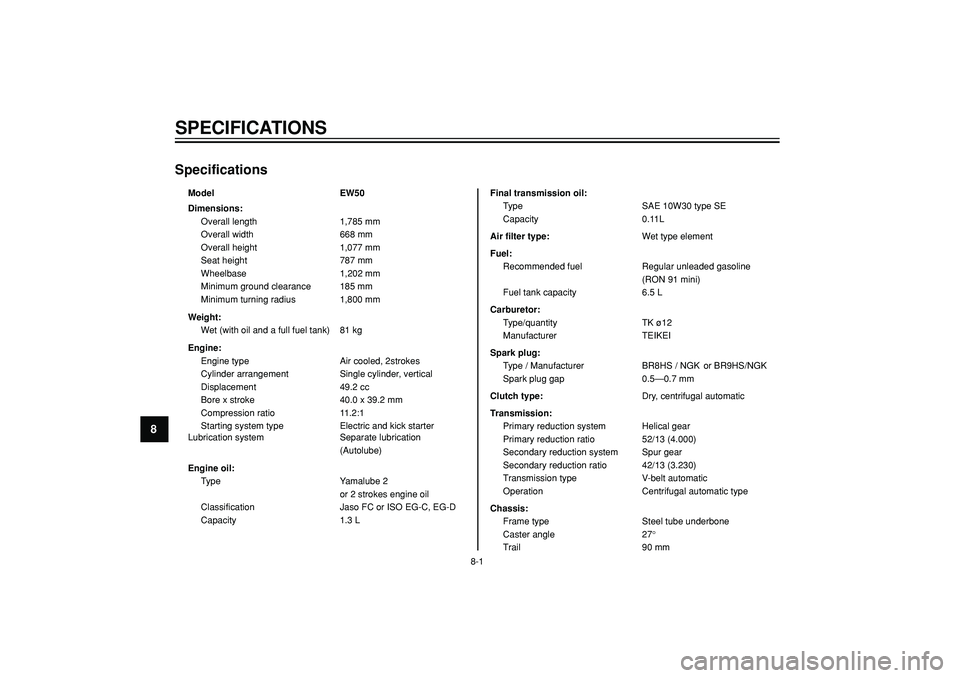

8-1 Model EW50

Dimensions:

Overall length 1,785 mm

Overall width 668 mm

Overall height 1,077 mm

Seat height 787 mm

Wheelbase 1,202 mm

Minimum ground clearance 185 mm

Minimum turning radius 1,800 mm

Weight:

Wet (with oil and a full fuel tank) 81 kg

Engine:

Engine type Air cooled, 2strokes

Cylinder arrangement Single cylinder, vertical

Displacement 49.2 cc

Bore x stroke 40.0 x 39.2 mm

Compression ratio 11.2:1

Starting system type Electric and kick starter

Lubrication system Separate lubrication

(Autolube)

Engine oil:

Type Yamalube 2

or 2 strokes engine oil

Classification Jaso FC or ISO EG-C, EG-D

Capacity 1.3 LFinal transmission oil:

Type SAE 10W30 type SE

Capacity 0.11L

Air filter type:Wet type element

Fuel:

Recommended fuel Regular unleaded gasoline

(RON 91 mini)

Fuel tank capacity 6.5 L

Carburetor:

Type/quantity TK ø12

Manufacturer TEIKEI

Spark plug:

Type / Manufacturer BR8HS / NGK or BR9HS/NGK

Spark plug gap 0.5—0.7 mm

Clutch type:Dry, centrifugal automatic

Transmission:

Primary reduction system Helical gear

Primary reduction ratio 52/13 (4.000)

Secondary reduction system Spur gear

Secondary reduction ratio 42/13 (3.230)

Transmission type V-belt automatic

Operation Centrifugal automatic type

Chassis:

Frame type Steel tube underbone

Caster angle 27°

Trail 90 mm

Specifications