fuel YAMAHA SLIDER 50 2007 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2007, Model line: SLIDER 50, Model: YAMAHA SLIDER 50 2007Pages: 80, PDF Size: 2.06 MB

Page 39 of 80

PERIODIC MAINTENANCE AND MINOR REPAIR

6

EAU03686

Periodic maintenance and lubrication chartNOTE :•

The annual checks must be performed every year, except if a kilometer-based maintenance is performed instead.

•

From 30,000 km, repeat the maintenance intervals starting from 6,000 km.

•

Items marked with an asterisk should be performed by a Yamaha dealer as they require special tools, data and technical skills.

1 * Fuel line•Check fuel hoses and vacuum hose for cracks or damage.√√√√ √2 Spark plug•Replace.√√√√ √3 Air filter element•Clean.√√

•Replace.√√

4 * Battery•Check electrolyte level and specific gravity.

√√√√ √•Make sure that the breather hose is properly routed.

•Check operation, fluid level and vehicle for fluid leakage.

√√√√√ √

5 * Front brake(See NOTE on page 6-4.)

•Replace brake pads.Whenever worn to the limit

6 * Rear brake•Check operation and adjust brake lever freeplay.√√√√√ √

•Replace brake shoes.Whenever worn to the limit

7 * Brake hose•Check for cracks or damage.√√√√ √

•Replace. (See NOTE on page 6-4.)Every 4 years

8 * Wheels•Check runout and for damage.√√√√

ODOMETER READING (x 1,000 km)

NO. ItemCheck or maintenance job1

ANNUAL

CHECK

6121824

6-2

Page 58 of 80

PERIODIC MAINTENANCE AND MINOR REPAIR

6

2 1

ZAUM0531

1

2

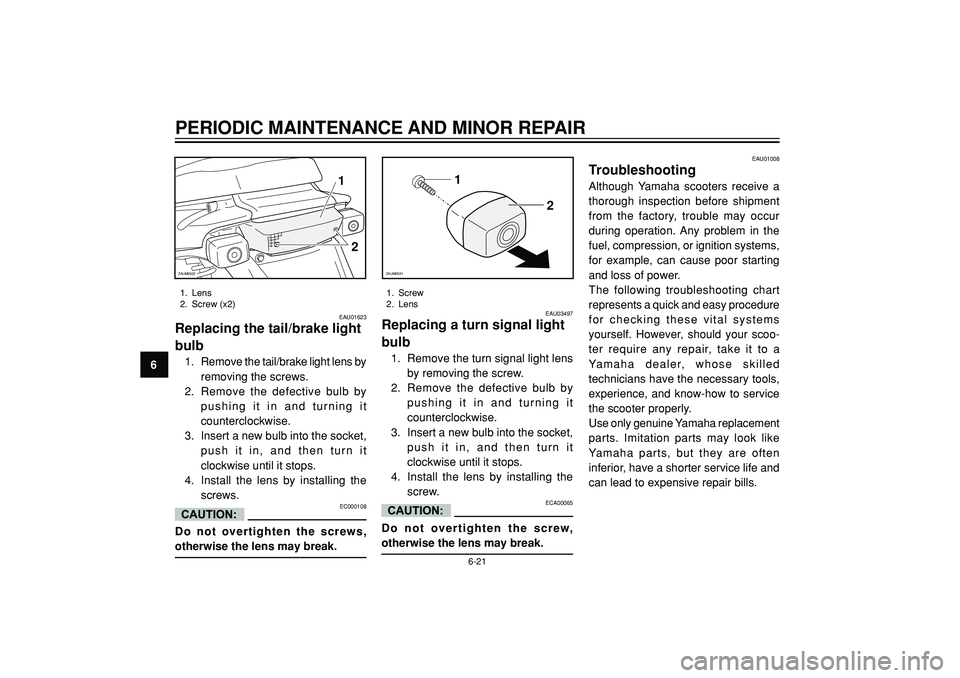

ZAUM05321. Lens

2. Screw (x2)

6-21

EAU01623

Replacing the tail/brake light

bulb1. Remove the tail/brake light lens by

removing the screws.

2. Remove the defective bulb by

pushing it in and turning it

counterclockwise.

3. Insert a new bulb into the socket,

push it in, and then turn it

clockwise until it stops.

4. Install the lens by installing the

screws.

EC000108

Do not overtighten the screws,otherwise the lens may break.

EAU03497

Replacing a turn signal light

bulb1. Remove the turn signal light lens

by removing the screw.

2. Remove the defective bulb by

pushing it in and turning it

counterclockwise.

3. Insert a new bulb into the socket,

push it in, and then turn it

clockwise until it stops.

4. Install the lens by installing the

screw.

ECA00065

Do not overtighten the screw,otherwise the lens may break.

EAU01008

TroubleshootingAlthough Yamaha scooters receive a

thorough inspection before shipment

from the factory, trouble may occur

during operation. Any problem in the

fuel, compression, or ignition systems,

for example, can cause poor starting

and loss of power.

The following troubleshooting chart

represents a quick and easy procedure

for checking these vital systems

yourself. However, should your scoo-

ter require any repair, take it to a

Yamaha dealer, whose skilled

technicians have the necessary tools,

experience, and know-how to service

the scooter properly.

Use only genuine Yamaha replacement

parts. Imitation parts may look like

Yamaha parts, but they are often

inferior, have a shorter service life and

can lead to expensive repair bills.

1. Screw

2. Lens

Page 59 of 80

PERIODIC MAINTENANCE AND MINOR REPAIR

6

6-22

EAU03473

Troubleshooting chart

EW000125

Keep away open flames and do not smoke while checking or working on the fuel system.

Check the fuel level in

the fuel tank.1. Fuel

There is enough fuel.

There is no fuel.

Check the compression.

Supply fuel.

The engine does not start.

Check the compression.

Operate the electric starter.2. Compression

There is compression.

There is no compression.

Check the ignition.

Have a Yamaha dealer

check the vehicle.

Remove the spark plug

and check the electrodes.3. Ignition

Wipe off with a dry cloth and correct the

spark plug gap, or replace the spark plug.

Have a Yamaha dealer check the vehicle.

The engine does not start.

Have a Yamaha dealer

check the vehicle.

The engine does not start.

Check the battery.

Operate the electric starter.4. Battery

The engine turns over

quickly.

The engine turns over

slowly.

The battery is good.Check fluid, recharge,

check connections..

DryWet

Open the throttle halfway and operate

the electric starter.

Page 62 of 80

SCOOTER CARE AND STORAGE

7

CareWhile the open design of a scooter

reveals the attractiveness of the

technology, it also makes it more

vulnerable. Rust and corrosion can

develop even if high-quality

components are used. A rusty exhaust

pipe may go unnoticed on a car,

however, it detracts from the overall

appearance of a scooter. Frequent and

proper care does not only comply with

the terms of the warranty, but it will also

keep your scooter looking good, extend

its life and optimize its performance.Before cleaning

1. Cover the muffler outlet with a

plastic bag after the engine has

cooled down.

2. Make sure that all caps and

covers as well as all electrical

couplers and connectors,

including the spark plug cap, are

tightly installed.

3. Remove extremely stubborn dirt,

like oil burnt onto the crankcase,

with a degreasing agent and a

brush, but never apply such

products onto seals, gaskets and

wheel axles. Always rinse the dirt

and degreaser off with water.Cleaning

ECA00011

•

Avoid using strong acidic wheel

cleaners, especially on spoked

wheels. If such products are used

on hard-to-remove dirt, do not

leave the cleaner on the affected

area any longer than instructed.

Also, thoroughly rinse the area off

with water, immediately dry it, and

then apply a corrosion protection

spray.

•

Improper cleaning can damage

windshields, cowlings, panels

and other plastic parts. Use only

a soft, clean cloth or sponge with

mild detergent and water to clean

plastic.

•

Do not use any harsh chemical

products on plastic parts. Be sure

to avoid using cloths or sponges

which have been in contact with

strong or abrasive cleaning

products, solvent or thinner, fuel

(gasoline), rust removers or

inhibitors, brake fluid, antifreeze

or electrolyte.

7-1

Page 65 of 80

SCOOTER CARE AND STORAGE

7

StorageShort-term

Always store your scooter in a cool, dry

place and, if necessary, protect it

against dust with a porous cover.

ECA00015

•

Storing the scooter in a poorly

ventilated room or covering it

with a tarp, while it is still wet,

will allow water and humidity to

seep in and cause rust.

•

To prevent corrosion, avoid

damp cellars, stables (because

of the presence of ammonia)

and areas where strongchemicals are stored.Long-term

Before storing your scooter for several

months:

1. Follow all the instructions in the

"Care" section of this chapter.

2. Drain the carburetor float

chamber by loosening the drain

bolt; this will prevent fuel deposits

from building up. Pour the drained

fuel into the fuel tank.

3. Fill up the fuel tank and add fuel

stabilizer (if available) to prevent

the fuel tank from rusting and the

fuel from deteriorating.

4. Perform the following steps to

protect the cylinder, piston rings,

etc. from corrosion.

a. Remove the spark plug cap

and spark plug.

b. Pour a teaspoonful of engine

oil into the spark plug bore.

c. Install the spark plug cap onto

the spark plug, and then place

the spark plug on the cylinder

head so that the electrodes are

grounded. (This will limit

sparking during the next step.)

d. Turn the engine over several

times with the starter. (This will

coat the cylinder wall with oil.)

e. Remove the spark plug cap

from the spark plug, and then

install the spark plug and the

spark plug cap.

EWA00003

To prevent damage or injury from

sparking, make sure to ground the

spark plug electrodes while turningthe engine over.

5. Lubricate all control cables and

the pivoting points of all levers and

pedals as well as of the sidestand/

centerstand.

6. Check and, if necessary, correct

the tire air pressure, and then lift

the scooter so that both of its

wheels are off the ground.

Alternatively, turn the wheels a

little every month in order to

prevent the tires from becoming

degraded in one spot.

7-4

Page 68 of 80

SPECIFICATIONS

8

8-1 Model EW50

Dimensions:

Overall length 1,785 mm

Overall width 668 mm

Overall height 1,077 mm

Seat height 787 mm

Wheelbase 1,202 mm

Minimum ground clearance 185 mm

Minimum turning radius 1,800 mm

Weight:

Wet (with oil and a full fuel tank) 81 kg

Engine:

Engine type Air cooled, 2strokes

Cylinder arrangement Single cylinder, vertical

Displacement 49.2 cc

Bore x stroke 40.0 x 39.2 mm

Compression ratio 11.2:1

Starting system type Electric and kick starter

Lubrication system Separate lubrication

(Autolube)

Engine oil:

Type Yamalube 2

or 2 strokes engine oil

Classification Jaso FC or ISO EG-C, EG-D

Capacity 1.3 LFinal transmission oil:

Type SAE 10W30 type SE

Capacity 0.11L

Air filter type:Wet type element

Fuel:

Recommended fuel Regular unleaded gasoline

(RON 91 mini)

Fuel tank capacity 6.5 L

Carburetor:

Type/quantity TK ø12

Manufacturer TEIKEI

Spark plug:

Type / Manufacturer BR8HS / NGK or BR9HS/NGK

Spark plug gap 0.5—0.7 mm

Clutch type:Dry, centrifugal automatic

Transmission:

Primary reduction system Helical gear

Primary reduction ratio 52/13 (4.000)

Secondary reduction system Spur gear

Secondary reduction ratio 42/13 (3.230)

Transmission type V-belt automatic

Operation Centrifugal automatic type

Chassis:

Frame type Steel tube underbone

Caster angle 27°

Trail 90 mm

Specifications

Page 70 of 80

SPECIFICATIONS

8

8-3 Electrical:

Ignition system type C.D.I

Charging system Flywheel magneto

BatteryModel GM4-3B, YB4L-B, FB4-B

Voltage/capacity 12 V / 4 Ah

Headlight type:Bulb

Bulbs (voltage/wattage x quantity):

Headlight 12V, 35W/35Wx1

Tail/brake light 12V, 5W/21Wx1

Turn signal light

Front 12V, 10Wx2

Rear 12V, 10Wx2

Meter lights 12V, 1.2Wx2

High beam indicator light 12V, 2Wx1

Turn signal indicator light 12V, 2Wx1

Oil level warning light 12V, 2Wx1

Fuel level warning light 12V, 2Wx1

Fuses:

Main fuse 7A