check oil YAMAHA SR400 2014 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: SR400, Model: YAMAHA SR400 2014Pages: 88, PDF Size: 2.51 MB

Page 6 of 88

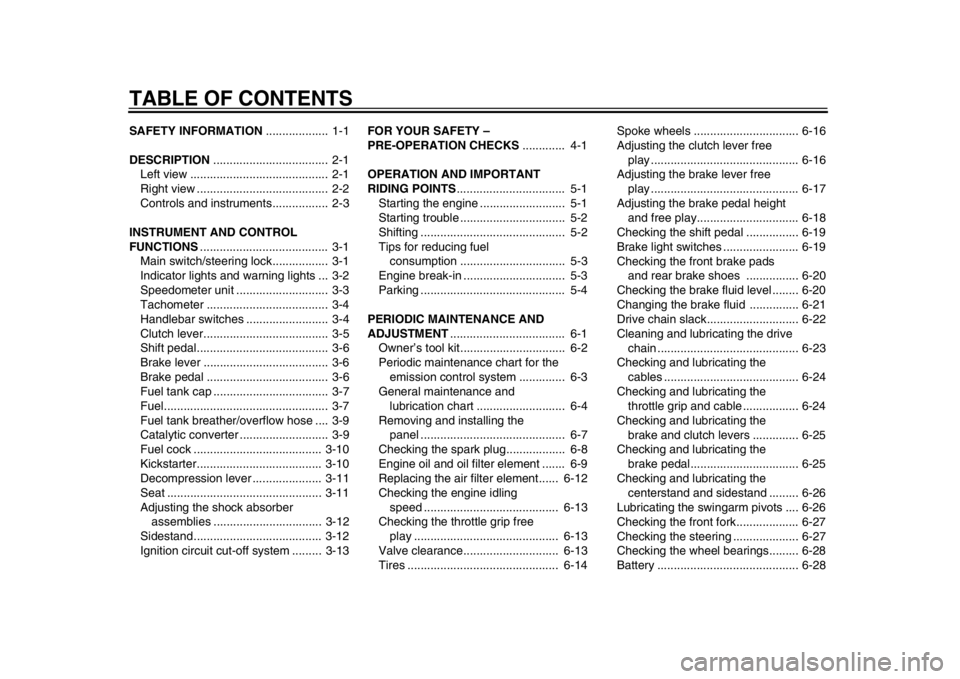

TABLE OF CONTENTSSAFETY INFORMATION................... 1-1

DESCRIPTION ................................... 2-1

Left view .......................................... 2-1

Right view ........................................ 2-2

Controls and instrument s................. 2-3

INSTRUMENT AND CONTROL

FUNCTIONS ....................................... 3-1

Main switch/steering lock................. 3-1

Indicator lights and warning lights ... 3-2

Speedometer unit ............................ 3-3

Tachometer ..................................... 3-4

Handlebar switches ......................... 3-4

Clutch lever...................................... 3-5

Shift pedal....... ............................. .... 3-6

Brake lever ...................................... 3-6

Brake pedal ..................................... 3-6

Fuel tank cap ................................... 3-7

Fuel.................................................. 3-7

Fuel tank breather/o verflow hose .... 3-9

Catalytic converter ........................... 3-9

Fuel cock ....................................... 3-10

Kickstarter....... ............................. .. 3-10

Decompression lever ... .................. 3-11

Seat ............................................... 3-11

Adjusting the shock absorber assemblies ................................. 3-12

Sidestand....................................... 3-12

Ignition circuit cut-of f system ......... 3-13 FOR YOUR SAFETY –

PRE-OPERATION CHECKS

............. 4-1

OPERATION AND IMPORTANT

RIDING POINTS ................................. 5-1

Starting the engine .......................... 5-1

Starting trouble ................................ 5-2

Shifting ............................................ 5-2

Tips for reducing fuel consumption ................................ 5-3

Engine break-in ............................... 5-3

Parking ............................................ 5-4

PERIODIC MAINTENANCE AND

ADJUSTMENT ................................... 6-1

Owner’s tool kit................................ 6-2

Periodic maintenance chart for the

emission control system .............. 6-3

General maintenance and lubrication chart ........................... 6-4

Removing and installing the panel ............................................ 6-7

Checking the spark plug.................. 6-8

Engine oil and oil filter element ....... 6-9

Replacing the air filter element...... 6-12

Checking the engine idling speed ......................................... 6-13

Checking the throttle grip free

play ............................................ 6-13

Valve clearance............................. 6-13

Tires .............................................. 6-14 Spoke wheels ................................ 6-16

Adjusting the clutch lever free

play ............................................. 6-16

Adjusting the brake lever free play ............................................. 6-17

Adjusting the brake pedal height and free play............................... 6-18

Checking the shift pedal ................ 6-19

Brake light switches ....................... 6-19

Checking the front brake pads and rear brake shoes ................ 6-20

Checking the brake fluid level ........ 6-20

Changing the brake fluid ............... 6-21

Drive chain slack............................ 6-22

Cleaning and lubricating the drive chain ........................................... 6-23

Checking and lubricating the

cables ......................................... 6-24

Checking and lubricating the throttle grip and cable ................. 6-24

Checking and lubricating the brake and clutch levers .............. 6-25

Checking and lubricating the

brake pedal................................. 6-25

Checking and lubricating the

centerstand and sidestand ......... 6-26

Lubricating the swingarm pivots .... 6-26

Checking the front fork................... 6-27

Checking the steering .................... 6-27

Checking the wheel bearings......... 6-28

Battery ........................................... 6-282RD-9-E0.book 1 ページ 2013年11月28日 木曜日 午後4時18分

Page 30 of 88

4-1

1

2

34

5

6

7

8

9

10

11

12

FOR YOUR SAFETY – PRE-OPERATION CHECKS

EAU15598

Inspect your vehicle each time you use it to make sure the vehi cle is in safe operating condition. Always follow the inspection

and maintenance procedures and schedules described in the Owner’s Manual.

WARNING

EWA11152

Failure to inspect or maintain the vehicle properly increases the possibility of an accident or equipment damage.

Do not operate the vehicle if you find any problem. If a problem cannot be corrected by the procedures provided inthis manual, have the vehicle inspected by a Yamaha dealer.

Before using this vehicle, check the following points:

ITEM CHECKS PAGE

Fuel Check fuel level in fuel tank.

Refuel if necessary.

Check fuel line for leakage.

Check fuel tank breather hose for

obstructions, cracks or damage, and check

hose connection. 3-7, 3-9

Engine oil Check oil level in oil tank.

If necessary, add recommended oil to specified level.

Check vehicle for oil leakage. 6-9

Front brake Check operation.

If soft or spongy, have Yamaha dealer bleed hydraulic system.

Check lever free play.

Adjust if necessary.

Check brake pads for wear.

Replace if necessary.

Check fluid level in reservoir.

If necessary, add specified brake fluid to specified level.

Check hydraulic system for leakage. 6-17, 6-20

Rear brake Check operation.

Check pedal free play.

Adjust if necessary. 6-18, 6-20

2RD-9-E0.book 1 ページ 2013年11月28日 木曜日 午後4時18分

Page 40 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

6-5

1

2

3

4

56

7

8

9

10

11

12

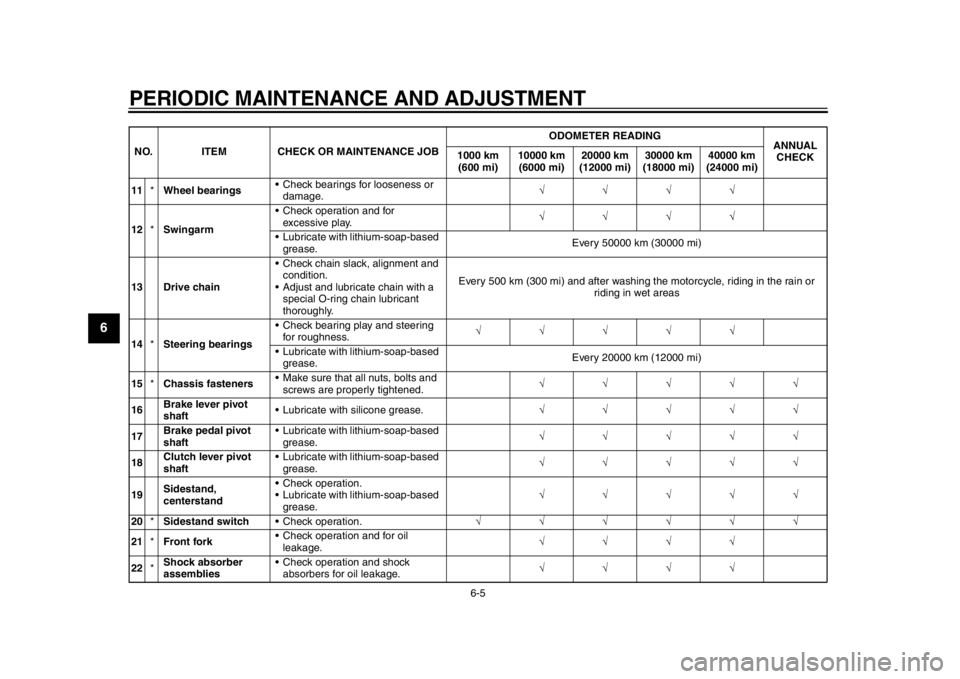

11 *Wheel bearings Check bearings for looseness or

damage.

12 *Swingarm Check operation and for

excessive play.

Lubricate with lithium-soap-based grease. Every 50000 km (30000 mi)

13 Drive chain Check chain slack, alignment and

condition.

Adjust and lubricate chain with a special O-ring chain lubricant

thoroughly. Every 500 km (300 mi) and after washing the motorcycle, riding in the rain or

riding in wet areas

14 *Steering bearings Check bearing play and steering

for roughness.

Lubricate with lithium-soap-based grease. Every 20000 km (12000 mi)

15 *Chassis fasteners Make sure that all nuts, bolts and

screws are properly tightened.

16 Brake lever pivot

shaft Lubricate with silicone grease.

17 Brake pedal pivot

shaft Lubricate with lithium-soap-based

grease.

18 Clutch lever pivot

shaft Lubricate with lithium-soap-based

grease.

19 Sidestand,

centerstand Check operation.

Lubricate with lithium-soap-based

grease.

20 *Sidestand switch Check operation.

21 *Front fork Check operation and for oil

leakage.

22 *Shock absorber

assemblies Check operation and shock

absorbers for oil leakage.

NO. ITEM CHECK OR MAINTENANCE JOB

ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 10000 km

(6000 mi) 20000 km

(12000 mi) 30000 km

(18000 mi) 40000 km

(24000 mi)2RD-9-E0.book 5 ページ 2013年11月28日 木曜日 午後4時18分

Page 41 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

6-6

1

2

3

4

567

8

9

10

11

12

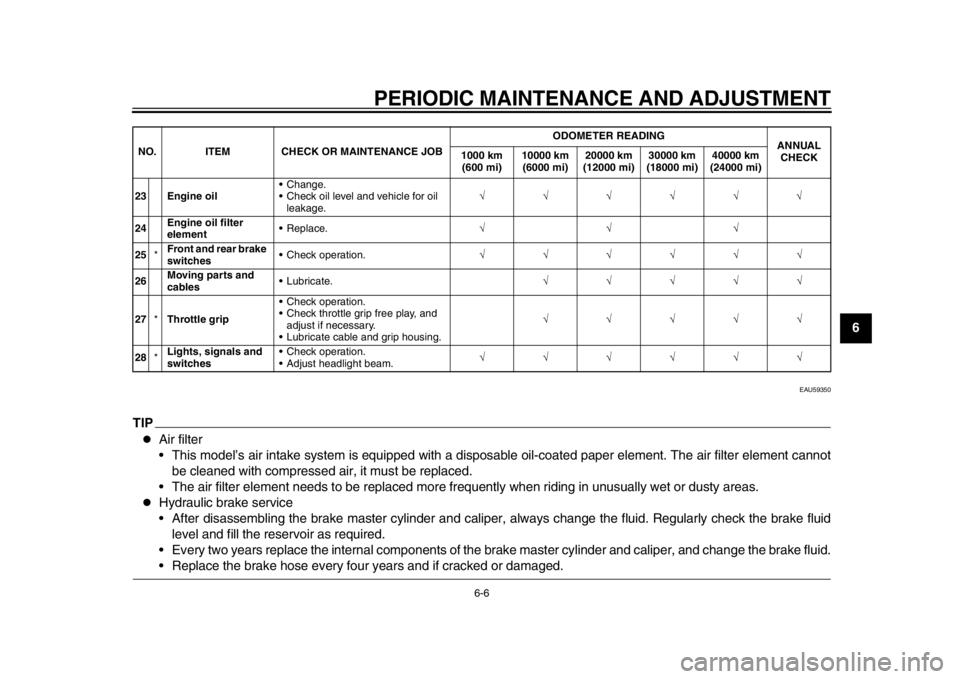

EAU59350

TIP

Air filter

This model’s air intake system is equipped with a disposable oil-coated paper element. The air filter element cannot

be cleaned with compressed air, it must be replaced.

The air filter element needs to be replaced more fr equently when riding in unusually wet or dusty areas.

Hydraulic brake service

After disassembling the brake master cylinder and caliper, always change the fluid. Regularly check the brake fluid

level and fill the reservoir as required.

Every two years replace the internal components of the brake master cylinder and caliper, and change the brake fluid. Replace the brake hose every four years and if cracked or damaged.

23 Engine oil Change.

Check oil level and vehicle for oil

leakage.

24 Engine oil filter

element Replace.

25 *Front and rear brake

switches Check operation.

26 Moving parts and

cables Lubricate.

27 *Throttle grip Check operation.

Check throttle grip free play, and

adjust if necessary.

Lubricate cable and grip housing.

28 *Lights, signals and

switches Check operation.

Adjust headlight beam.

NO. ITEM CHECK OR MAINTENANCE JOB

ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 10000 km

(6000 mi) 20000 km

(12000 mi) 30000 km

(18000 mi) 40000 km

(24000 mi)

2RD-9-E0.book 6 ページ 2013年11月28日 木曜日 午後4時18分

Page 44 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

6-9

1

2

3

4

56

7

8

9

10

11

12 spark plug wrench, and then tight-

en it to the specified torque.

TIPIf a torque wrench is not available when

installing a spark plug, a good estimate

of the correct torque is 1/4–1/2 turn

past finger tight. However, the spark

plug should be tightened to the speci-fied torque as soon as possible.

3. Install the spark plug cap.

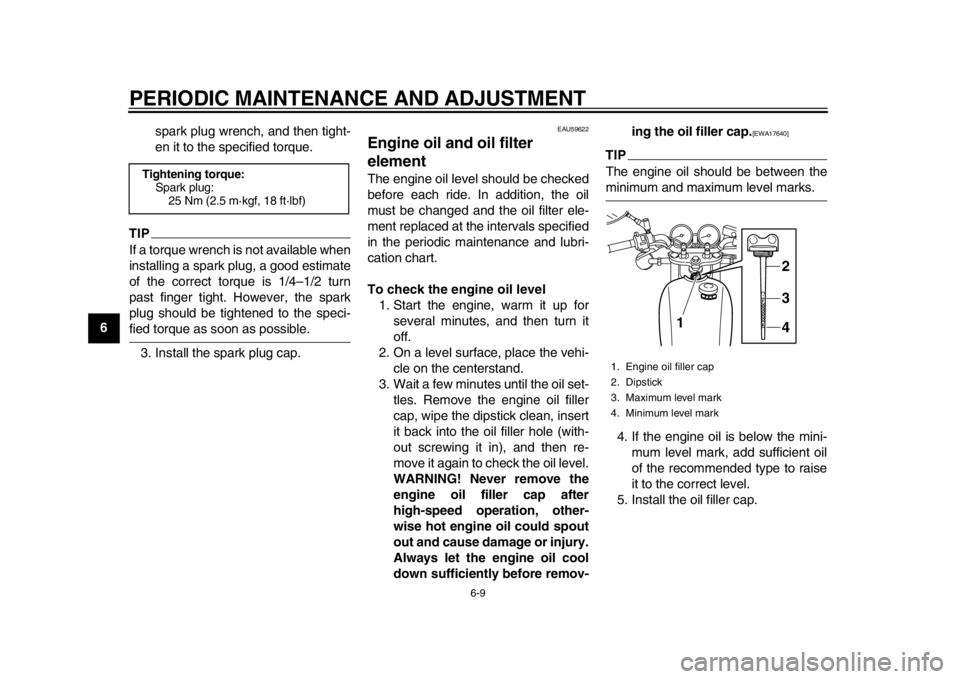

EAU59622

Engine oil and oil filter

elementThe engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil filter ele-

ment replaced at the intervals specified

in the periodic maintenance and lubri-

cation chart.

To check the engine oil level1. Start the engine, warm it up for several minutes, and then turn it

off.

2. On a level surface, place the vehi- cle on the centerstand.

3. Wait a few minutes until the oil set- tles. Remove the engine oil filler

cap, wipe the dipstick clean, insert

it back into the oil filler hole (with-

out screwing it in), and then re-

move it again to check the oil level.

WARNING! Never remove the

engine oil filler cap after

high-speed operation, other-

wise hot engine oil could spout

out and cause damage or injury.

Always let the engine oil cool

down sufficiently before remov- ing the oil filler cap.

[EWA17640]

TIPThe engine oil should be between theminimum and maximum level marks.

4. If the engine oil is below the mini- mum level mark, add sufficient oil

of the recommended type to raise

it to the correct level.

5. Install the oil filler cap.

Tightening torque: Spark plug:25 Nm (2.5 m·kgf, 18 ft·lbf)

1. Engine oil filler cap

2. Dipstick

3. Maximum level mark

4. Minimum level mark

3

4

12

2RD-9-E0.book 9 ページ 2013年11月28日 木曜日 午後4時18分

Page 46 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

6-11

1

2

3

4

56

7

8

9

10

11

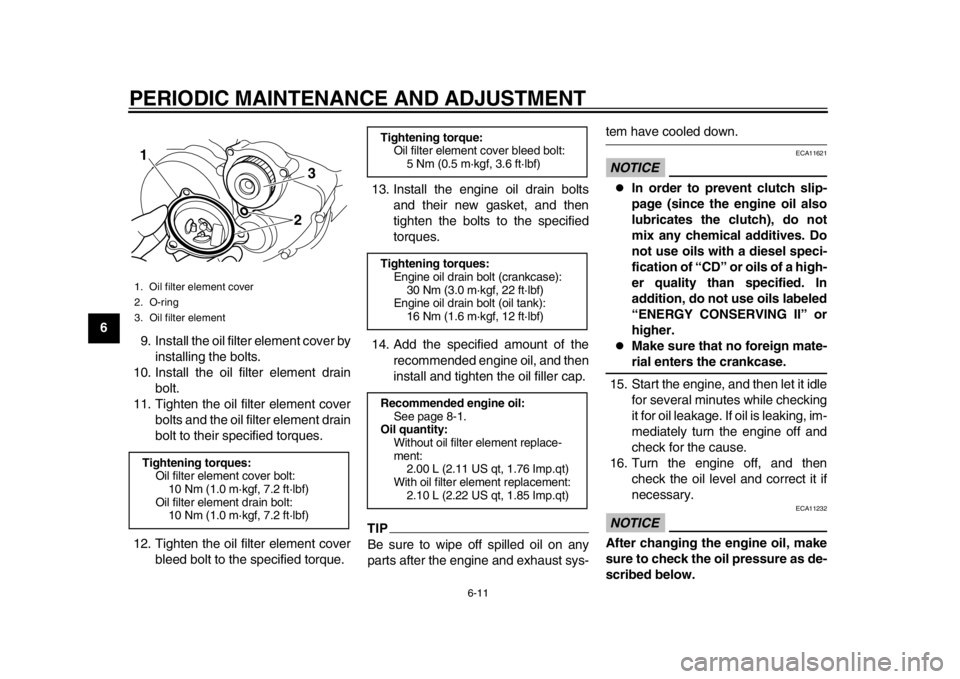

12 9. Install the oil filter element cover by

installing the bolts.

10. Install the oil filter element drain bolt.

11. Tighten the oil filter element cover bolts and the oil filter element drain

bolt to their specified torques.

12. Tighten the oil filter element cover bleed bolt to the specified torque. 13. Install the engine oil drain bolts

and their new gasket, and then

tighten the bolts to the specified

torques.

14. Add the specified amount of the recommended engine oil, and then

install and tighten the oil filler cap.

TIPBe sure to wipe off spilled oil on any

parts after the engine and exhaust sys-

tem have cooled down.NOTICE

ECA11621

In order to prevent clutch slip-

page (since the engine oil also

lubricates the clutch), do not

mix any chemical additives. Do

not use oils with a diesel speci-

fication of “CD” or oils of a high-

er quality than specified. In

addition, do not use oils labeled

“ENERGY CONSERVING II” or

higher.

Make sure that no foreign mate-rial enters the crankcase.

15. Start the engine, and then let it idle for several minutes while checking

it for oil leakage. If oil is leaking, im-

mediately turn the engine off and

check for the cause.

16. Turn the engine off, and then check the oil level and correct it if

necessary.

NOTICE

ECA11232

After changing the engine oil, make

sure to check the oil pressure as de-

scribed below.

1. Oil filter element cover

2. O-ring

3. Oil filter elementTightening torques:Oil filter element cover bolt:10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Oil filter element drain bolt:

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

2

1

3

Tightening torque:Oil filter element cover bleed bolt:5 Nm (0.5 m·kgf, 3.6 ft·lbf)

Tightening torques: Engine oil drain bolt (crankcase):30 Nm (3.0 m·kgf, 22 ft·lbf)

Engine oil drain bolt (oil tank):

16 Nm (1.6 m·kgf, 12 ft·lbf)

Recommended engine oil: See page 8-1.

Oil quantity:

Without oil filter element replace-

ment:2.00 L (2.11 US qt, 1.76 Imp.qt)

With oil filter element replacement: 2.10 L (2.22 US qt, 1.85 Imp.qt)

2RD-9-E0.book 11 ページ 2013年11月28日 木曜日 午後4時18分

Page 47 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

6-12

1

2

3

4

567

8

9

10

11

12

Loosen the bleed bolt.

Start the engine and keep it

idling until oil flows out. If no oil

comes out after one minute,

turn the engine off immediately

so it will not seize. If this occurs,

have a Yamaha dealer repair the

vehicle.

After checking the oil pressure,

tighten the bleed bolt to thespecified torque.

EAU52031

Replacing the air filter elementThe air filter element should be re-

placed at the intervals specified in the

periodic maintenance and lubrication

chart. Replace the air filter element

more frequently if you are riding in un-

usually wet or dusty areas.

To replace the air filter element 1. Remove panel A. (See page 6-7.)

2. Remove the air filter case cover by removing the screws.

3. Pull the air filter element out. 4. Insert a new air filter element into

the air filter case. NOTICE: Make

sure that the air filter element is

properly seated in the air filter

case. The engine should never

be operated without the air filter

element installed, otherwise the

piston(s) and/or cylinder(s) may

become excessively worn.

[ECA10482]

5. Install the air filter case cover by in- stalling the screws.

6. Install the panel.

1. Bleed boltTightening torque: Bleed bolt: 18 Nm (1.8 m·kgf, 13 ft·lbf)

1

1. Screw

2. Air filter case cover

1

2

1

1. Air filter element

1

2RD-9-E0.book 12 ページ 2013年11月28日 木曜日 午後4時18分

Page 56 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

6-21

1

2

3

4

56

7

8

9

10

11

12 performance.

Clean the filler cap before re-

moving. Use only DOT 4 brake

fluid from a sealed container.

Use only the specified brake flu-

id; otherwise, the rubber seals

may deteriorate, causing leak-

age.

Refill with the same type of

brake fluid. Adding a brake fluid

other than DOT 4 may result in a

harmful chemical reaction.

Be careful that water does not

enter the brake fluid reservoir

when refilling. Water will signifi-

cantly lower the boiling point of

the fluid and may result in vaporlock.

NOTICE

ECA17641

Brake fluid may damage painted sur-

faces or plastic parts. Always cleanup spilled fluid immediately.

As the brake pads wear, it is normal for

the brake fluid level to gradually go

down. A low brake fluid level may indi-

cate worn brake pads and/or brake sys-

tem leakage; therefore, be sure to check the brake pads for wear and the

brake system for leakage. If the brake

fluid level goes down suddenly, have a

Yamaha dealer check the cause before

further riding.

EAU22724

Changing the brake fluid Have a Yamaha dealer change the

brake fluid at the intervals specified in

the periodic maintenance and lubrica-

tion chart. In addition, have the oil seals

of the brake master cylinder and caliper

as well as the brake hose replaced at

the intervals listed below or whenever

they are damaged or leaking.

Oil seals: Replace every two

years.

Brake hose: Replace every four

years.

2RD-9-E0.book 21 ページ 2013年11月28日 木曜日 午後4時18分

Page 58 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

6-23

1

2

3

4

56

7

8

9

10

11

12 gine as well as other vital parts

of the motorcycle and can lead

to chain slippage or breakage.

To prevent this from occurring,

keep the drive chain slack with-

in the specified limits.

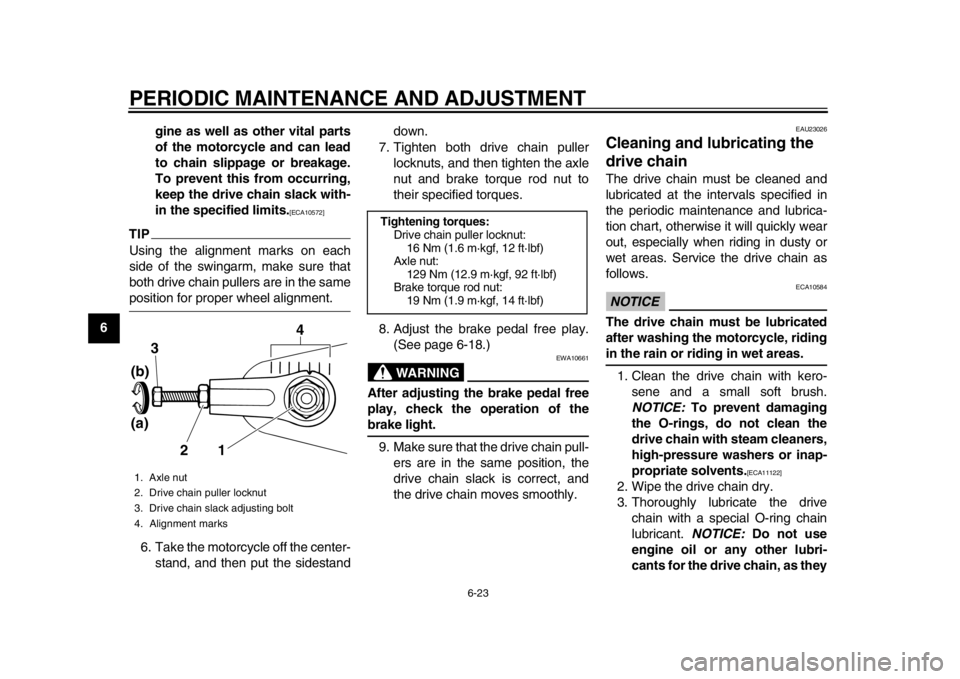

[ECA10572]

TIPUsing the alignment marks on each

side of the swingarm, make sure that

both drive chain pullers are in the sameposition for proper wheel alignment.

6. Take the motorcycle off the center- stand, and then put the sidestand down.

7. Tighten both drive chain puller locknuts, and then tighten the axle

nut and brake torque rod nut to

their specified torques.

8. Adjust the brake pedal free play. (See page 6-18.)

WARNING

EWA10661

After adjusting the brake pedal free

play, check the operation of thebrake light.

9. Make sure that the drive chain pull- ers are in the same position, the

drive chain slack is correct, and

the drive chain moves smoothly.

EAU23026

Cleaning and lubricating the

drive chainThe drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly wear

out, especially when riding in dusty or

wet areas. Service the drive chain as

follows.NOTICE

ECA10584

The drive chain must be lubricated

after washing the motorcycle, ridingin the rain or riding in wet areas.

1. Clean the drive chain with kero- sene and a small soft brush.

NOTICE: To prevent damaging

the O-rings, do not clean the

drive chain with steam cleaners,

high-pressure washers or inap-

propriate solvents.

[ECA11122]

2. Wipe the drive chain dry.

3. Thoroughly lubricate the drive chain with a special O-ring chain

lubricant. NOTICE: Do not use

engine oil or any other lubri-

cants for the drive chain, as they

1. Axle nut

2. Drive chain puller locknut

3. Drive chain slack adjusting bolt

4. Alignment marks

1

2

(a) (b)

3

4

Tightening torques:

Drive chain puller locknut:16 Nm (1.6 m·kgf, 12 ft·lbf)

Axle nut: 129 Nm (12.9 m·kgf, 92 ft·lbf)

Brake torque rod nut:

19 Nm (1.9 m·kgf, 14 ft·lbf)

2RD-9-E0.book 23 ページ 2013年11月28日 木曜日 午後4時18分

Page 62 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

6-27

1

2

3

4

56

7

8

9

10

11

12

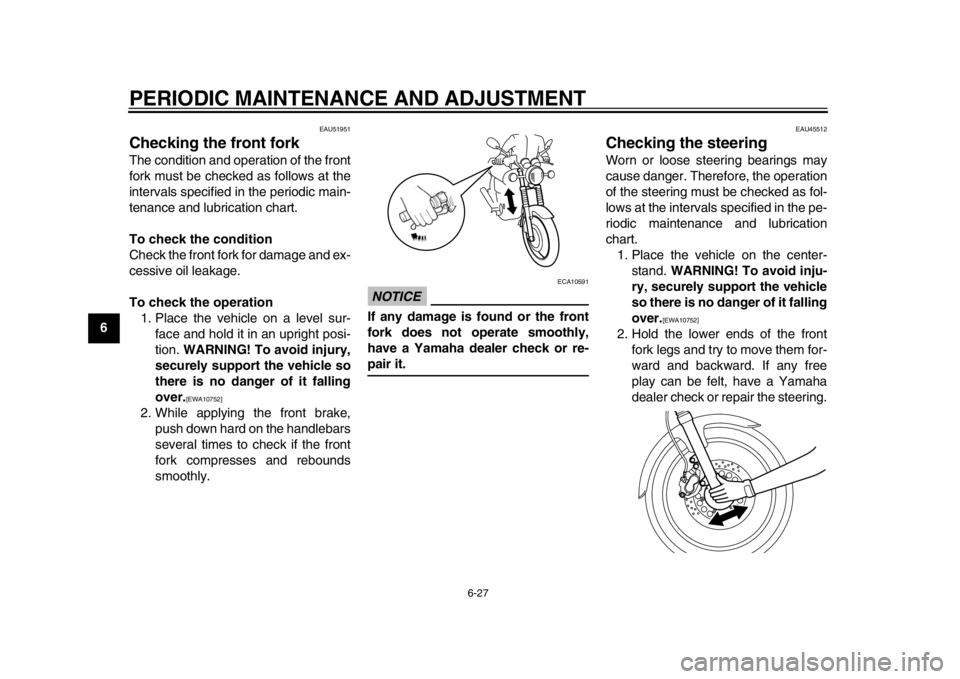

EAU51951

Checking the front forkThe condition and operation of the front

fork must be checked as follows at the

intervals specified in the periodic main-

tenance and lubrication chart.

To check the condition

Check the front fork for damage and ex-

cessive oil leakage.

To check the operation 1. Place the vehicle on a level sur- face and hold it in an upright posi-

tion. WARNING! To avoid injury,

securely support the vehicle so

there is no danger of it falling

over.

[EWA10752]

2. While applying the front brake, push down hard on the handlebars

several times to check if the front

fork compresses and rebounds

smoothly.

NOTICE

ECA10591

If any damage is found or the front

fork does not operate smoothly,

have a Yamaha dealer check or re-pair it.

EAU45512

Checking the steeringWorn or loose steering bearings may

cause danger. Therefore, the operation

of the steering must be checked as fol-

lows at the intervals specified in the pe-

riodic maintenance and lubrication

chart.1. Place the vehicle on the center- stand. WARNING! To avoid inju-

ry, securely support the vehicle

so there is no danger of it falling

over.

[EWA10752]

2. Hold the lower ends of the front fork legs and try to move them for-

ward and backward. If any free

play can be felt, have a Yamaha

dealer check or repair the steering.

2RD-9-E0.book 27 ページ 2013年11月28日 木曜日 午後4時18分