ECU YAMAHA SUPERJET 2001 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: SUPERJET, Model: YAMAHA SUPERJET 2001Pages: 107, PDF Size: 6.2 MB

Page 72 of 107

4-3

E

EJU00945

Lubrication

WARNING@To reduce the risk of fire or explosion:

Never pour or spray gasoline, or any sub-

stance other than a rust inhibitor through

the hole in the carburetor silencer cover.

@

CAUTION:@●Make sure to replace the cap securely

after fogging the engine, otherwise

water could enter the engine and

cause damage.

●Do not attempt to run the engine at full

throttle or for more than 15 seconds

while the watercraft is out of the water,

otherwise the engine may overheat

and/or seize.

@

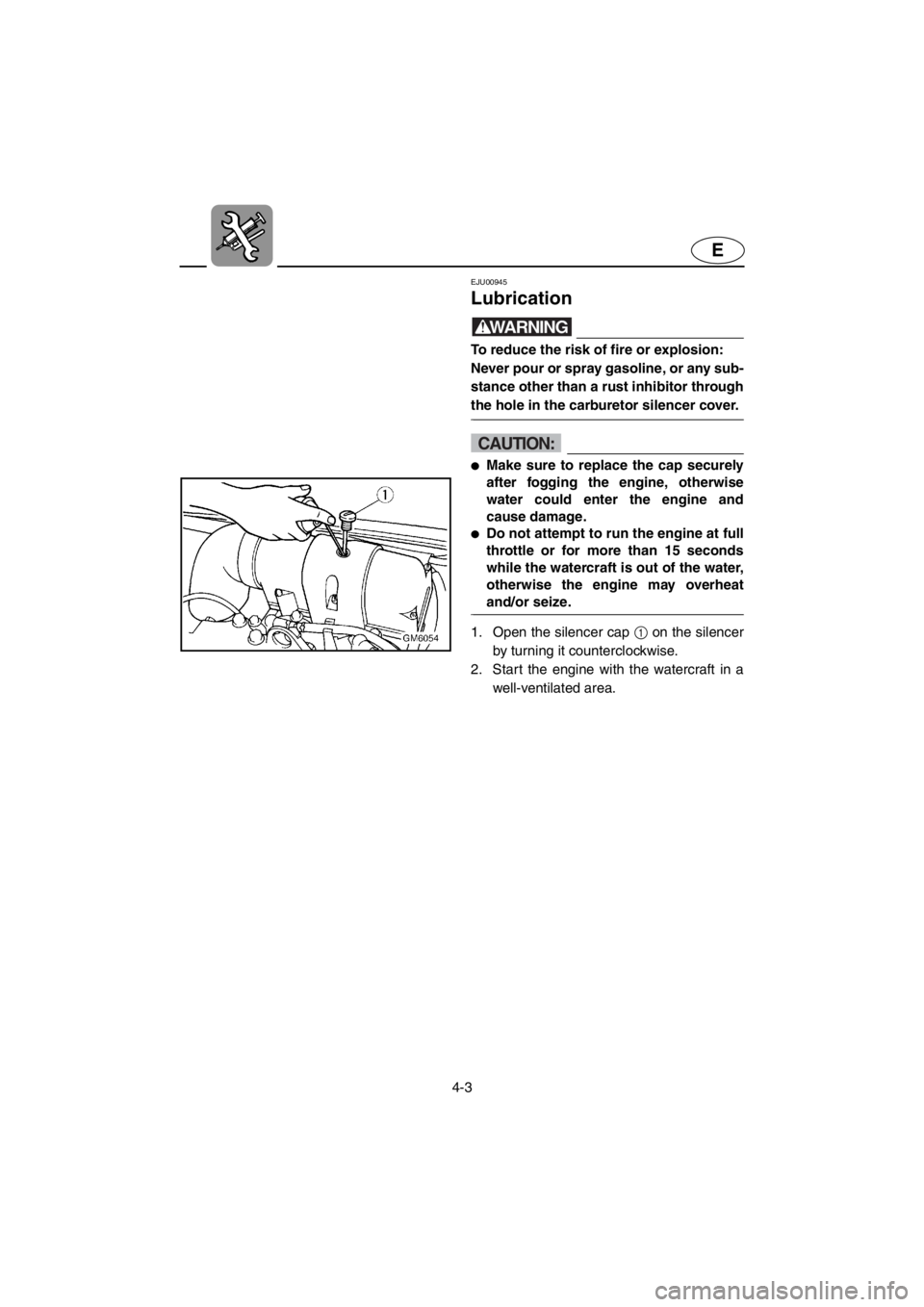

1. Open the silencer cap 1 on the silencer

by turning it counterclockwise.

2. Start the engine with the watercraft in a

well-ventilated area.

E_GM6-4.fm Page 3 Tuesday, July 11, 2000 11:28 AM

Page 73 of 107

4-4

E

3. With the engine running at a fast idle,

quickly spray as much rust inhibitor as

possible through the hole in the silencer

cover. Keep spraying until the engine

stalls (or a maximum of 15 seconds).

4. Install the cap securely.

5. Remove the spark plugs and pour

approximately one tablespoon of engine

oil into each cylinder. Grease the spark

plug threads and install the spark plugs.

6. Lubricate all cables such as the throttle,

choke, and steering cables.

NOTE:@Use a suitable marine grease applicator to

pressure lubricate the cables and purge out

any moisture between the inner and outer

cables.

@

7. Lubricate the areas of the watercraft

specified under Lubrication points on

page 4-14.

E_GM6-4.fm Page 4 Tuesday, July 11, 2000 11:28 AM

Page 83 of 107

4-14

E

NOTE:@●Wipe off any water on the spark plug or

inside the cap before installing the spark

plug cap. Push the spark plug cap down

until it clicks.

●If a torque wrench is not available when

you are fitting a new spark plug, a good

estimate of the correct torque with a new

gasket is a quarter turn to a half turn past

finger tight. Have the spark plug adjusted

to the correct torque with a torque wrench

as soon as possible.

@

WARNING@Be careful not to damage the insulator

when removing or installing a spark plug.

A damaged insulator could allow sparks

to escape, which could lead to explosion

or fire.

@

EJU00553

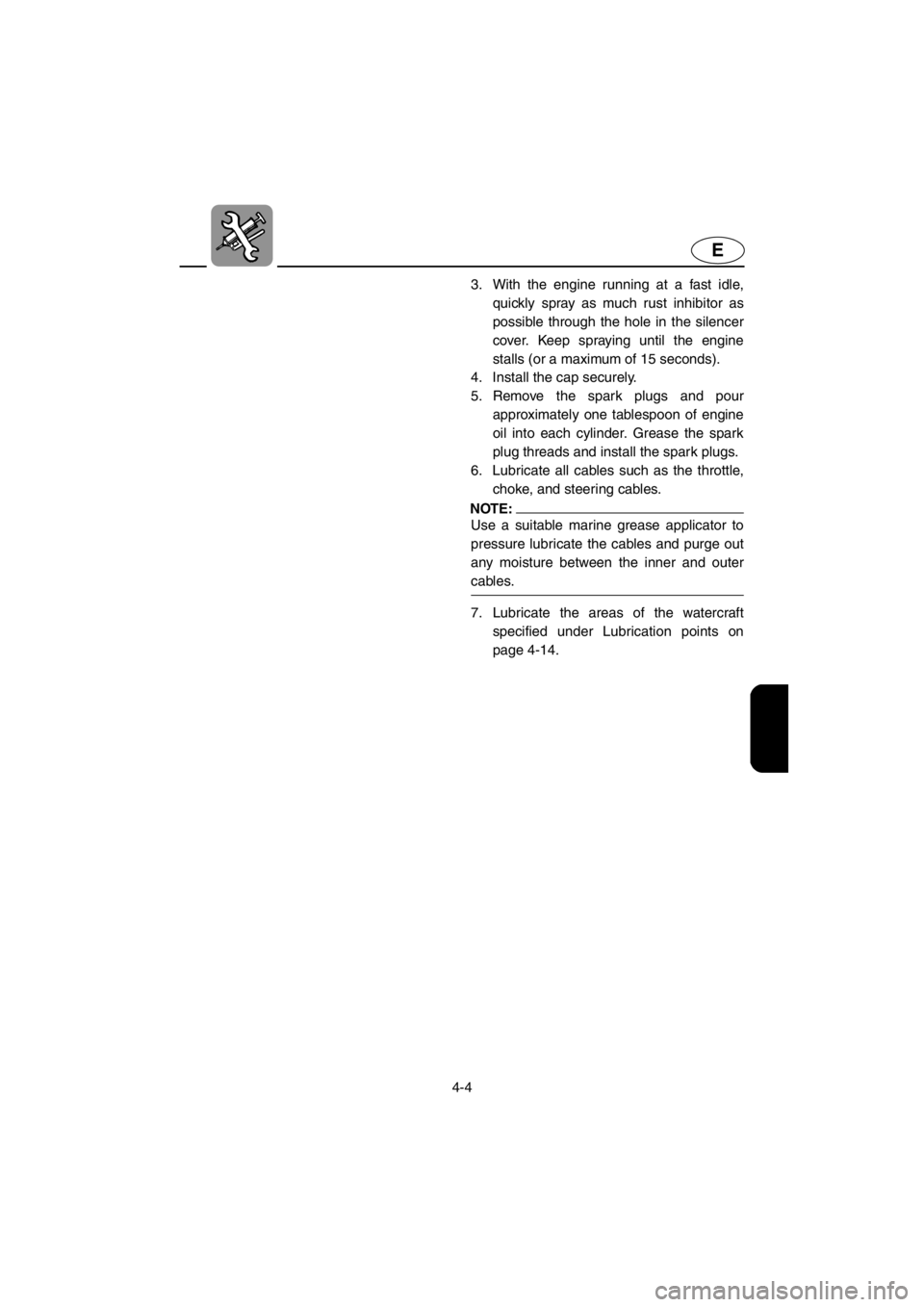

Lubrication points

To keep moving parts sliding or rotating

smoothly, coat them with water-resistant

grease.

●Throttle cable (carburetor end)

●Choke cable (carburetor end)

●Throttle cable (handlebar end)

Pull the throttle lever and remove the seal 1.

Spray a rust inhibitor into the outer cable. Refit

the seal securely.

Recommended water resistant grease:

Yamaha Marine Grease/

Yamaha Grease A

E_GM6-4.fm Page 14 Tuesday, July 11, 2000 11:28 AM

Page 86 of 107

4-17

E

EJU00572

Inspecting the battery

Check the level of the battery electrolyte

and make sure the leads are secure.

WARNING@Battery electrolyte is poisonous and dan-

gerous, causing severe burns, etc. Elec-

trolyte contains sulfuric acid. Avoid

contact with skin, eyes or clothing.

Antidotes

External: Flush with water.

Internal: Drink large quantities of water

or milk. Follow with milk of magnesia,

beaten egg or vegetable oil. Call physi-

cian immediately.

Eyes: Flush with water for 15 minutes

and get prompt medical attention.

Batteries produce explosive gases. Keep

sparks, flame, cigarettes, etc., well away.

If using or charging the battery in an

enclosed space, make sure that it is well

ventilated. Always shield your eyes when

working near batteries.

KEEP OUT OF THE REACH OF CHIL-

DREN.

@

CAUTION:

Be careful not to place the battery on its

side.

Make sure to remove the battery from the

battery compartment when adding the

battery electrolyte or charging the bat-

tery.

When checking the battery, make sure

the breather hose is connected to the

battery and not obstructed.

@

E_GM6-4.fm Page 17 Tuesday, July 11, 2000 11:28 AM

Page 87 of 107

4-18

E

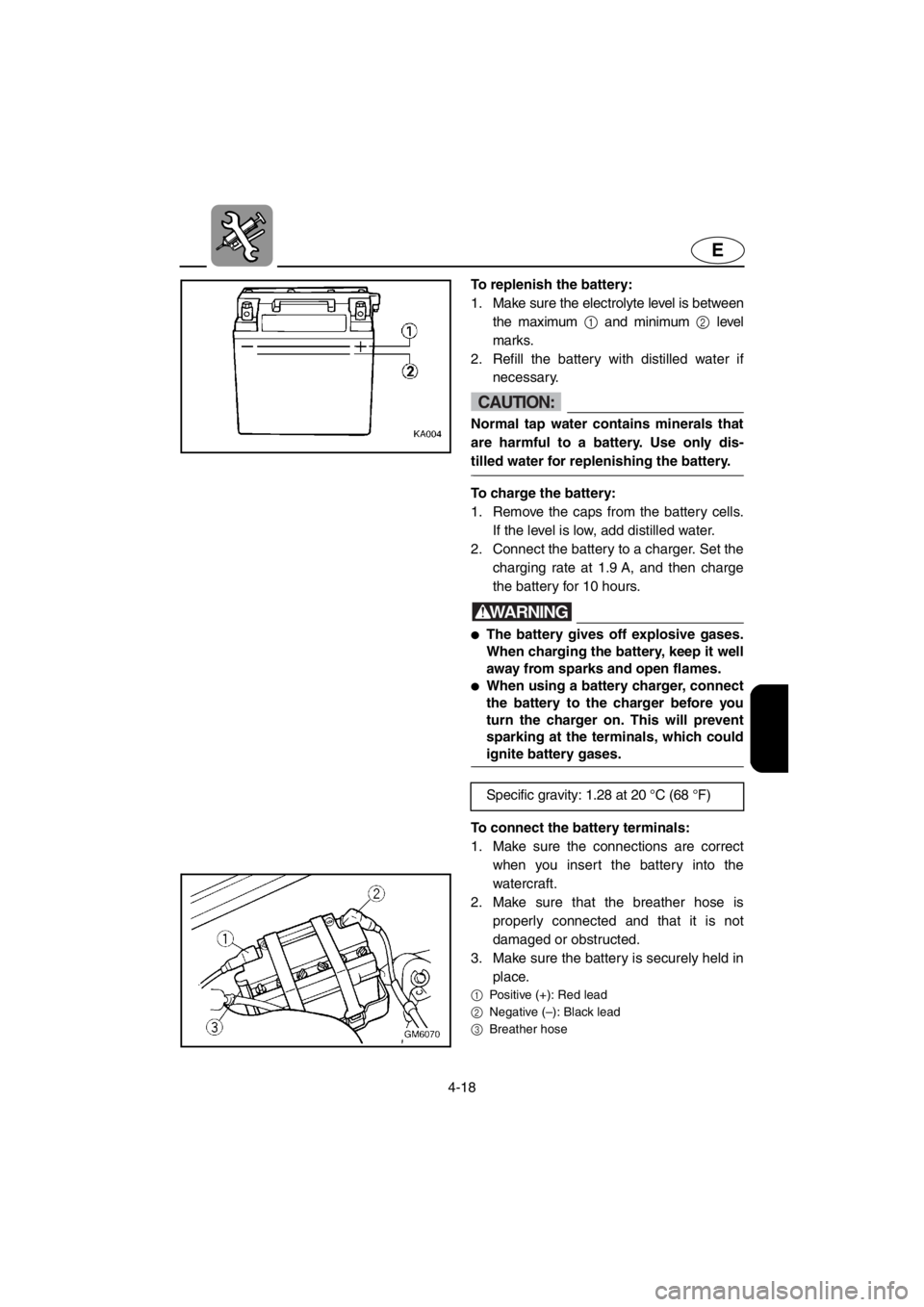

To replenish the battery:

1. Make sure the electrolyte level is between

the maximum 1 and minimum 2 level

marks.

2. Refill the battery with distilled water if

necessary.

CAUTION:@Normal tap water contains minerals that

are harmful to a battery. Use only dis-

tilled water for replenishing the battery.

@

To charge the battery:

1. Remove the caps from the battery cells.

If the level is low, add distilled water.

2. Connect the battery to a charger. Set the

charging rate at 1.9 A, and then charge

the battery for 10 hours.

WARNING@●The battery gives off explosive gases.

When charging the battery, keep it well

away from sparks and open flames.

●When using a battery charger, connect

the battery to the charger before you

turn the charger on. This will prevent

sparking at the terminals, which could

ignite battery gases.

@

To connect the battery terminals:

1. Make sure the connections are correct

when you insert the battery into the

watercraft.

2. Make sure that the breather hose is

properly connected and that it is not

damaged or obstructed.

3. Make sure the battery is securely held in

place.

1Positive (+): Red lead

2Negative (–): Black lead

3Breather hose

Specific gravity: 1.28 at 20 °C (68 °F)

E_GM6-4.fm Page 18 Tuesday, July 11, 2000 11:28 AM

Page 91 of 107

4-22

E

To change the position for the steering

cable pivot bolt:

1. Pull back the outer sleeve, and then dis-

connect the steering cable.

2. Remove the steering cable joint from the

steering cable pivot bolt.

3. Loosen the pivot bolt and install it with

the lock washer in the desired position

(P1 or P2). Make sure to tighten it to the

specified torque.

4. Install the steering cable joint on the

steering cable pivot bolt.

To change the handlebar stopper posi-

tion:

1. Loosen the handle stopper nut 2 on the

operator’s side of the steering pole.

2. Lift and turn the handlebar stopper to the

desired position (S1 or S2), and then

tighten the handlebar stopper nut. Make

sure to tighten it to the specified torque.

3. Install the steering pole cover securely. Tightening torque:

5.4 Nm (0.5 m·kg, 3.9 ft·lb)

Tightening torque:

31 Nm (3.1 m·kg, 22.4 ft·lb)

E_GM6-4.fm Page 22 Tuesday, July 11, 2000 11:28 AM

Page 96 of 107

5-3

E

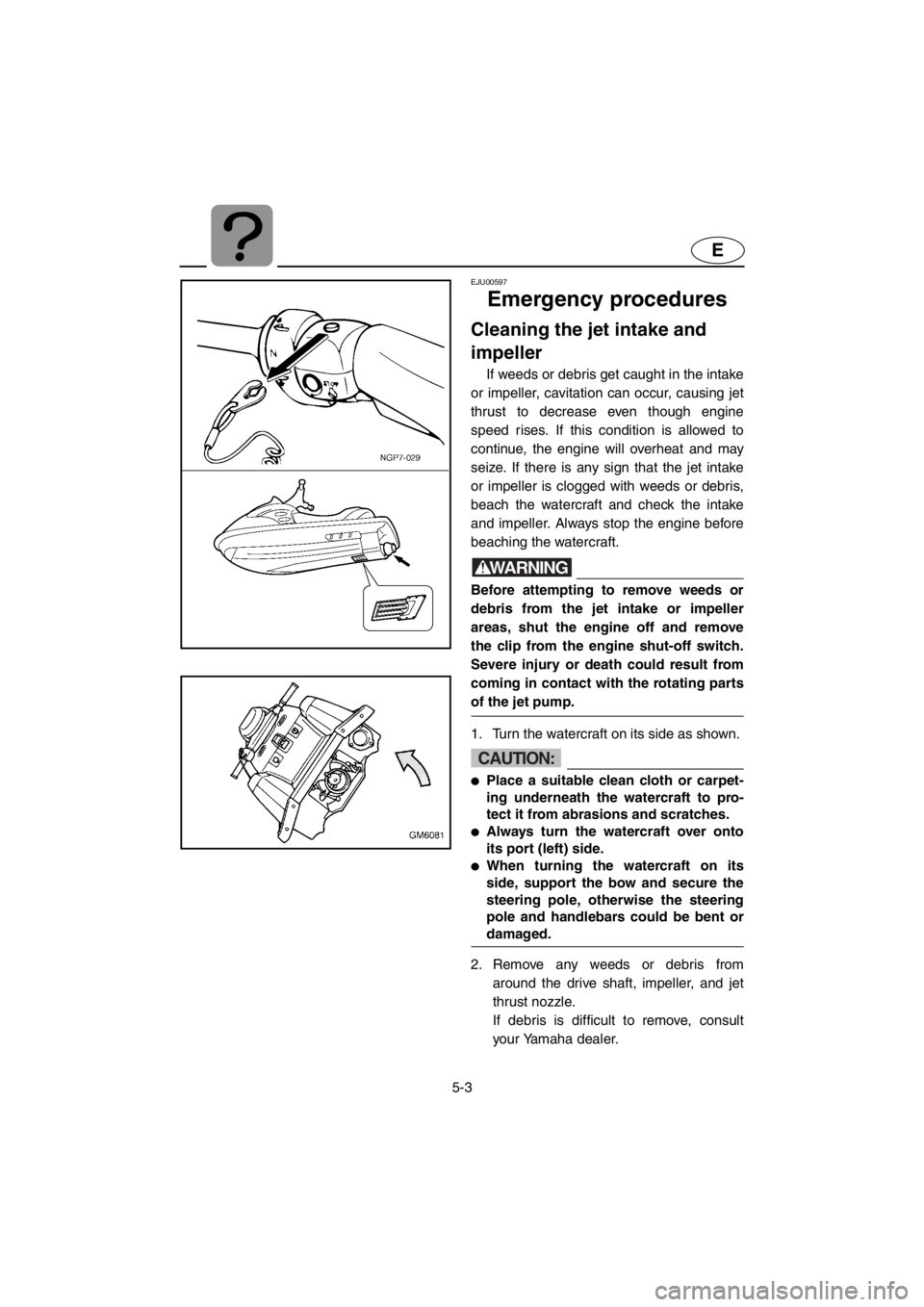

EJU00597

Emergency procedures

Cleaning the jet intake and

impeller

If weeds or debris get caught in the intake

or impeller, cavitation can occur, causing jet

thrust to decrease even though engine

speed rises. If this condition is allowed to

continue, the engine will overheat and may

seize. If there is any sign that the jet intake

or impeller is clogged with weeds or debris,

beach the watercraft and check the intake

and impeller. Always stop the engine before

beaching the watercraft.

WARNING@Before attempting to remove weeds or

debris from the jet intake or impeller

areas, shut the engine off and remove

the clip from the engine shut-off switch.

Severe injury or death could result from

coming in contact with the rotating parts

of the jet pump.

@

1. Turn the watercraft on its side as shown.

CAUTION:@●Place a suitable clean cloth or carpet-

ing underneath the watercraft to pro-

tect it from abrasions and scratches.

●Always turn the watercraft over onto

its port (left) side.

●When turning the watercraft on its

side, support the bow and secure the

steering pole, otherwise the steering

pole and handlebars could be bent or

damaged.

@

2. Remove any weeds or debris from

around the drive shaft, impeller, and jet

thrust nozzle.

If debris is difficult to remove, consult

your Yamaha dealer.

E_GM6-5.fm Page 3 Tuesday, July 11, 2000 11:29 AM

Page 98 of 107

5-5

E

EJU00600

Connecting the jumper cables

1. Connect the positive (+) jumper cable 2

to the positive (+) terminals of both bat-

teries.

2. Connect one end of the negative (–)

jumper cable 1 to the negative (–) termi-

nal of the booster battery 3.

3. Connect the other end of the negative (–)

cable to an unpainted bolt on the cylinder

head.

CAUTION:@Do not connect the end of the jumper

cable to the negative (–) terminal on the

watercraft battery! Make sure all connec-

tions are secure and correct before

attempting to start the engine. Any

wrong connection may damage the elec-

trical system.

@

4. Start the engine, and then disconnect

the cables by reversing the steps above.

CAUTION:@●Never push the start switch while the

engine is running.

●Do not operate the start switch for

more than 5 seconds, otherwise the

battery will be discharged and the

engine will not start. Also, the starter

motor may be damaged. If the engine

does not start in 5 seconds, release

the start switch, wait 15 seconds, and

try again.

@

E_GM6-5.fm Page 5 Tuesday, July 11, 2000 11:29 AM