steering YAMAHA SUPERJET 2001 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: SUPERJET, Model: YAMAHA SUPERJET 2001Pages: 107, PDF Size: 6.2 MB

Page 62 of 107

3-27

E

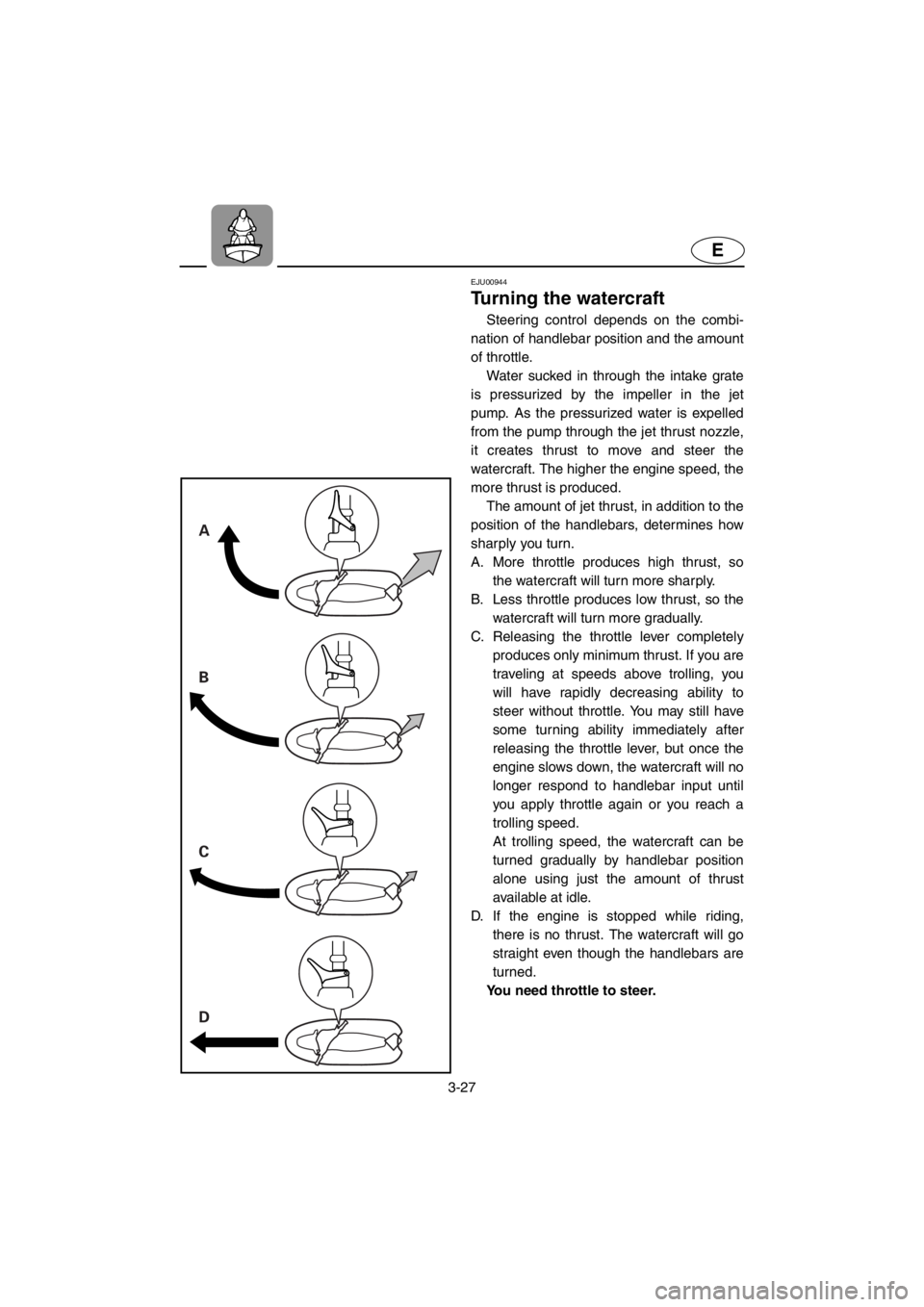

A

B

C

D

EJU00944

Turning the watercraft

Steering control depends on the combi-

nation of handlebar position and the amount

of throttle.

Water sucked in through the intake grate

is pressurized by the impeller in the jet

pump. As the pressurized water is expelled

from the pump through the jet thrust nozzle,

it creates thrust to move and steer the

watercraft. The higher the engine speed, the

more thrust is produced.

The amount of jet thrust, in addition to the

position of the handlebars, determines how

sharply you turn.

A. More throttle produces high thrust, so

the watercraft will turn more sharply.

B. Less throttle produces low thrust, so the

watercraft will turn more gradually.

C. Releasing the throttle lever completely

produces only minimum thrust. If you are

traveling at speeds above trolling, you

will have rapidly decreasing ability to

steer without throttle. You may still have

some turning ability immediately after

releasing the throttle lever, but once the

engine slows down, the watercraft will no

longer respond to handlebar input until

you apply throttle again or you reach a

trolling speed.

At trolling speed, the watercraft can be

turned gradually by handlebar position

alone using just the amount of thrust

available at idle.

D. If the engine is stopped while riding,

there is no thrust. The watercraft will go

straight even though the handlebars are

turned.

You need throttle to steer.

E_GM6-3.fm Page 27 Tuesday, July 11, 2000 10:52 AM

Page 66 of 107

3-31

E

EJU00932

Post-operation checks

Always perform the following post-opera-

tion checks after operating the watercraft.

1. Remove the watercraft from the water.

2. Wash down the hull, steering pole, han-

dlebars, and jet unit with fresh water.

3. Remove the hood and check the engine

compartment for water. To drain excess

water, turn the watercraft on its port (left)

side. If necessary, turn the watercraft

upside down to drain water completely.

CAUTION:@●Place a suitable clean cloth or carpet-

ing underneath the watercraft to pro-

tect it from abrasions and scratches.

●Always turn the watercraft over onto

its port (left) side.

●When turning the watercraft onto its

side or inverting it, support the bow

and secure the steering pole, other-

wise the steering pole and handlebars

could be bent or damaged.

@

NOTE:@This watercraft is equipped with an auto-

matic bilge-draining system that removes

water from the engine compartment while

you are underway. However, some residual

water will remain.

@

4. Put the watercraft in a horizontal posi-

tion.

5. Flush the cooling system to prevent it

from clogging with salt, sand, or dirt.

(See pages 4-1 to 4-2 for flushing the

cooling system procedures.)

6. Drain residual water from the exhaust

system by alternately squeezing and

releasing the throttle lever for 10 to

15 seconds while the engine is running.

E_GM6-3.fm Page 31 Tuesday, July 11, 2000 10:52 AM

Page 67 of 107

3-32

E

CAUTION:@Do not run the engine at full throttle or

for more than 15 seconds on land, other-

wise the engine may overheat and seize.

@

7. If the watercraft will be stored for a week

or more, lubricate internal engine com-

ponents to help prevent corrosion. (See

page 4-3 for lubrication procedures.)

8. Rinse the engine and engine compart-

ment with a small amount of water.

CAUTION:@Do not use high pressure when rinsing

the engine or engine compartment as

severe damage could result.

@

9. Wipe the engine and engine compart-

ment dry with a clean cloth (repeat

step 3, if necessary).

10. Wipe the hull, steering pole, handlebars,

and jet unit dry with a clean cloth.

11. Spray a rust inhibitor on metallic parts to

minimize corrosion.

12. Allow the engine compartment to air dry

completely before reinstalling the hood.

E_GM6-3.fm Page 32 Tuesday, July 11, 2000 10:52 AM

Page 68 of 107

3-33

E

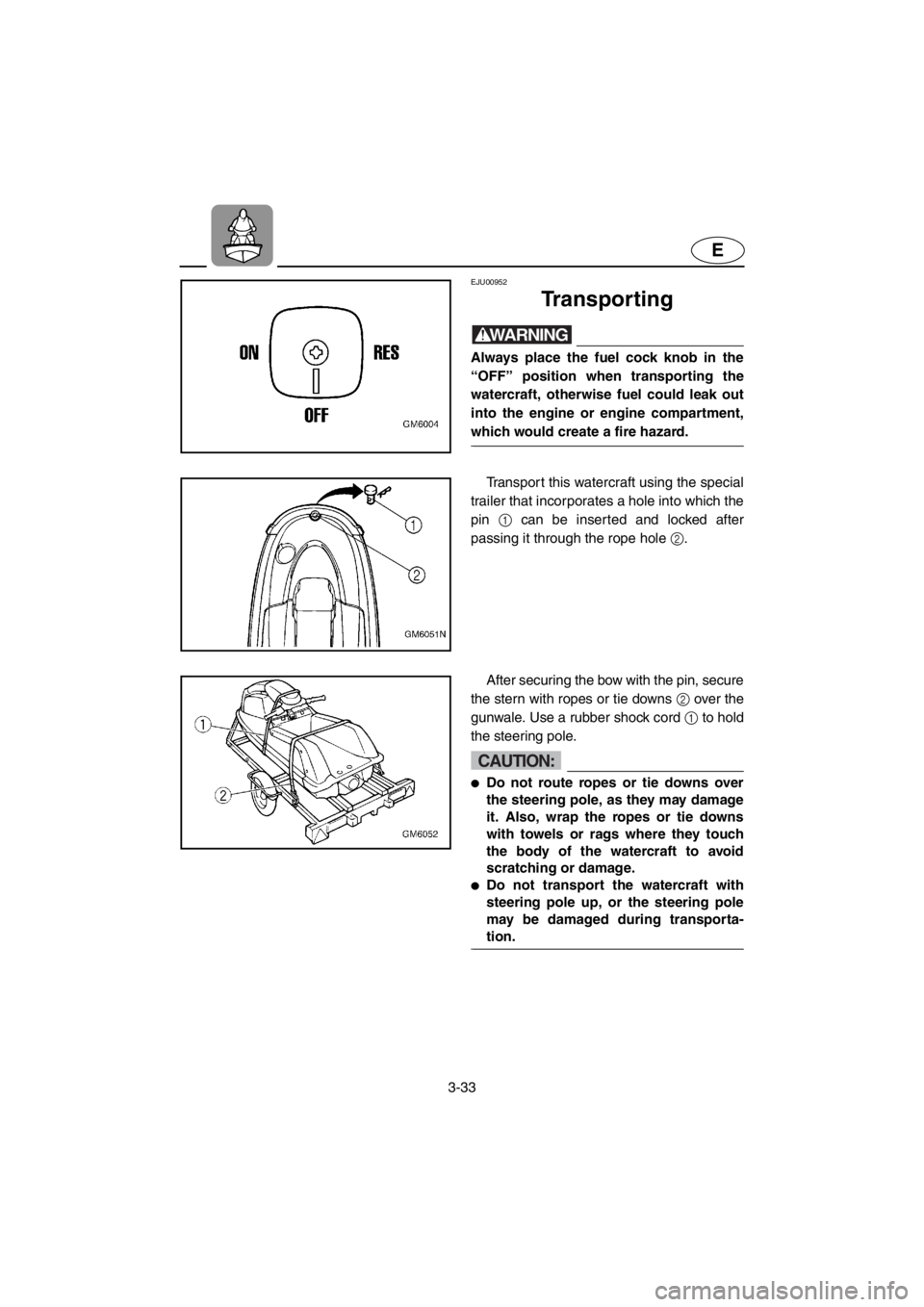

EJU00952

Transporting

WARNING@Always place the fuel cock knob in the

“OFF” position when transporting the

watercraft, otherwise fuel could leak out

into the engine or engine compartment,

which would create a fire hazard.

@

Transport this watercraft using the special

trailer that incorporates a hole into which the

pin 1 can be inserted and locked after

passing it through the rope hole 2.

After securing the bow with the pin, secure

the stern with ropes or tie downs 2 over the

gunwale. Use a rubber shock cord 1 to hold

the steering pole.

CAUTION:@●Do not route ropes or tie downs over

the steering pole, as they may damage

it. Also, wrap the ropes or tie downs

with towels or rags where they touch

the body of the watercraft to avoid

scratching or damage.

●Do not transport the watercraft with

steering pole up, or the steering pole

may be damaged during transporta-

tion.

@

E_GM6-3.fm Page 33 Tuesday, July 11, 2000 10:52 AM

Page 69 of 107

E

4

EJU00515

MAINTENANCE AND

CARE

Storage....................................................... 4-1

Flushing the cooling system ................... 4-1

Lubrication............................................... 4-3

Fuel system............................................. 4-5

Battery ..................................................... 4-5

Cleaning the watercraft........................... 4-6

Maintenance and adjustments............... 4-7

Owner’s/Operator’s Manual and

tool kit ...................................................... 4-8

Periodic maintenance chart .................... 4-9

Inspecting the fuel system .................... 4-10

Inspecting the steering cable................ 4-12

Inspecting and adjusting the throttle

cable ...................................................... 4-12

Cleaning and adjusting the spark

plugs ...................................................... 4-13

Lubrication points .................................. 4-14

Adjusting the choke cable..................... 4-16

Inspecting the battery ........................... 4-17

Adjusting the carburetor ....................... 4-19

Replacing the fuse ................................ 4-20

Adjusting the steering friction ............... 4-20

Adjusting the jet thrust nozzle angle .... 4-21

Specifications ........................................ 4-23

E_GM6-4TOC.fm Page 1 Tuesday, July 11, 2000 11:27 AM

Page 73 of 107

4-4

E

3. With the engine running at a fast idle,

quickly spray as much rust inhibitor as

possible through the hole in the silencer

cover. Keep spraying until the engine

stalls (or a maximum of 15 seconds).

4. Install the cap securely.

5. Remove the spark plugs and pour

approximately one tablespoon of engine

oil into each cylinder. Grease the spark

plug threads and install the spark plugs.

6. Lubricate all cables such as the throttle,

choke, and steering cables.

NOTE:@Use a suitable marine grease applicator to

pressure lubricate the cables and purge out

any moisture between the inner and outer

cables.

@

7. Lubricate the areas of the watercraft

specified under Lubrication points on

page 4-14.

E_GM6-4.fm Page 4 Tuesday, July 11, 2000 11:28 AM

Page 78 of 107

4-9

E

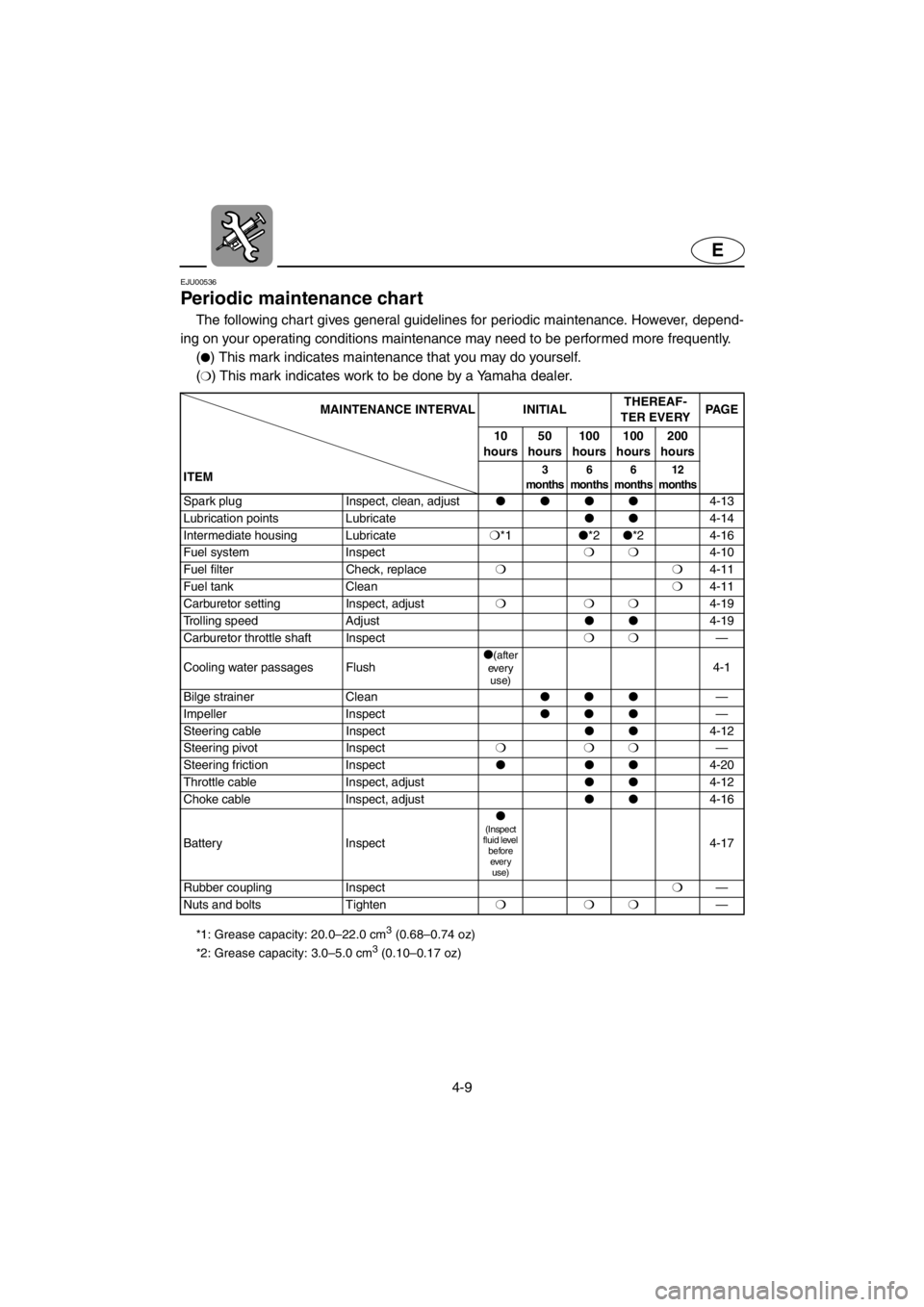

EJU00536

Periodic maintenance chart

The following chart gives general guidelines for periodic maintenance. However, depend-

ing on your operating conditions maintenance may need to be performed more frequently.

(

●) This mark indicates maintenance that you may do yourself.

(

❍) This mark indicates work to be done by a Yamaha dealer.

*1: Grease capacity: 20.0–22.0 cm3 (0.68–0.74 oz)

*2: Grease capacity: 3.0–5.0 cm3 (0.10–0.17 oz) MAINTENANCE INTERVAL INITIALTHEREAF-

TER EVERYPA G E

10

hours50

hours100

hours 100

hours 200

hours

ITEM

3

months6

months6

months12

months

Spark plug Inspect, clean, adjust ●●●●

4-13

Lubrication points Lubricate●●

4-14

Intermediate housing Lubricate❍

*1●

*2●

*2 4-16

Fuel system Inspect❍❍

4-10

Fuel filter Check, replace❍❍

4-11

Fuel tank Clean❍

4-11

Carburetor setting Inspect, adjust❍❍❍

4-19

Trolling speed Adjust●●

4-19

Carburetor throttle shaft Inspect❍❍

—

Cooling water passages Flush●

(after

ever y

use) 4-1

Bilge strainer Clean●●●

—

Impeller Inspect●●●

—

Steering cable Inspect●●

4-12

Steering pivot Inspect❍❍❍

—

Steering friction Inspect●●●

4-20

Throttle cable Inspect, adjust●●

4-12

Choke cable Inspect, adjust ●●

4-16

Battery Inspect●

(Inspect

fluid level

before

ever y

use)4-17

Rubber coupling Inspect❍

—

Nuts and bolts Tighten❍❍❍

—

E_GM6-4.fm Page 9 Tuesday, July 11, 2000 11:28 AM

Page 81 of 107

4-12

E

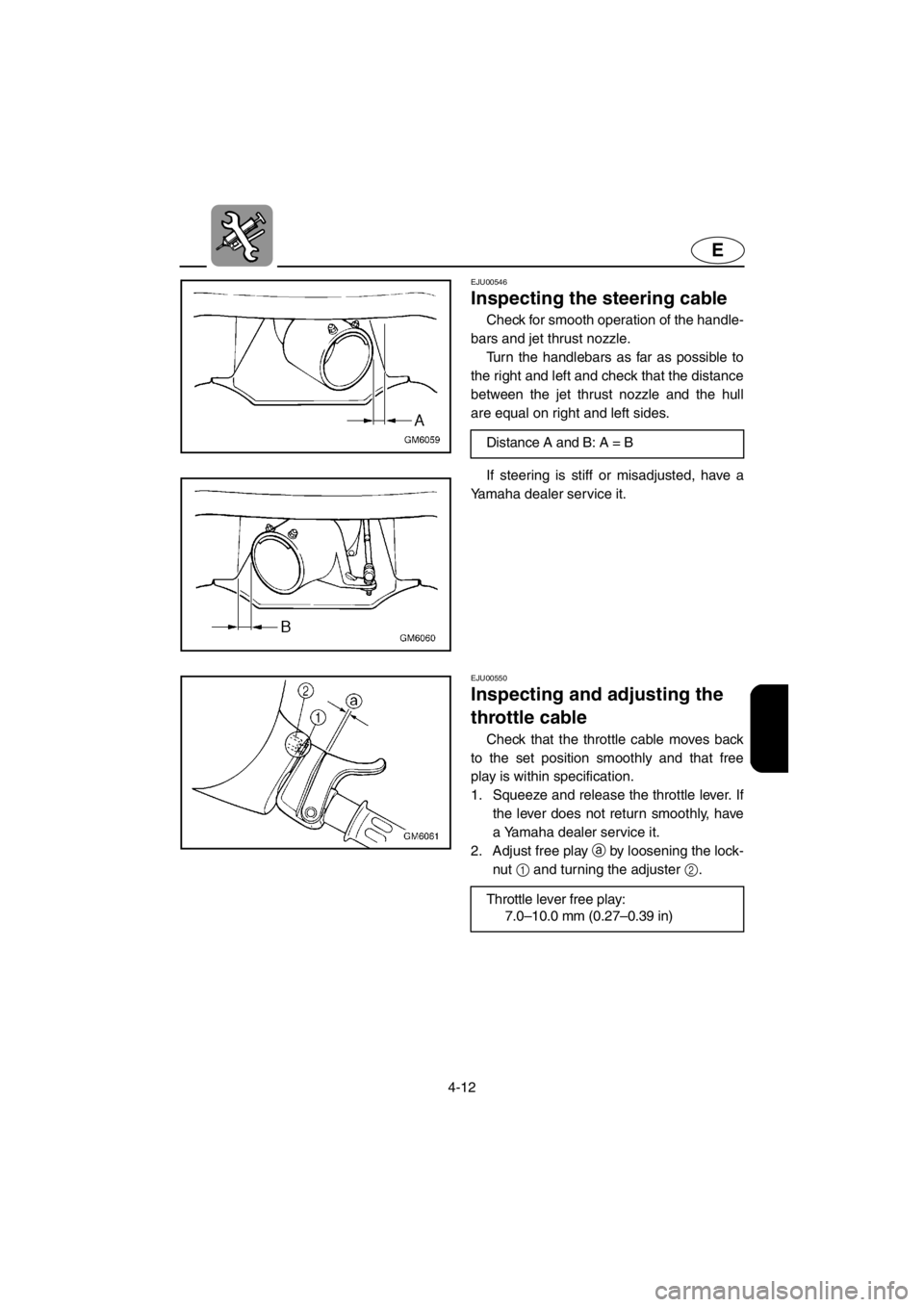

EJU00546

Inspecting the steering cable

Check for smooth operation of the handle-

bars and jet thrust nozzle.

Turn the handlebars as far as possible to

the right and left and check that the distance

between the jet thrust nozzle and the hull

are equal on right and left sides.

If steering is stiff or misadjusted, have a

Yamaha dealer service it.Distance A and B: A = B

EJU00550

Inspecting and adjusting the

throttle cable

Check that the throttle cable moves back

to the set position smoothly and that free

play is within specification.

1. Squeeze and release the throttle lever. If

the lever does not return smoothly, have

a Yamaha dealer service it.

2. Adjust free play a by loosening the lock-

nut 1 and turning the adjuster 2.

Throttle lever free play:

7.0–10.0 mm (0.27–0.39 in)

E_GM6-4.fm Page 12 Tuesday, July 11, 2000 11:28 AM

Page 84 of 107

4-15

E

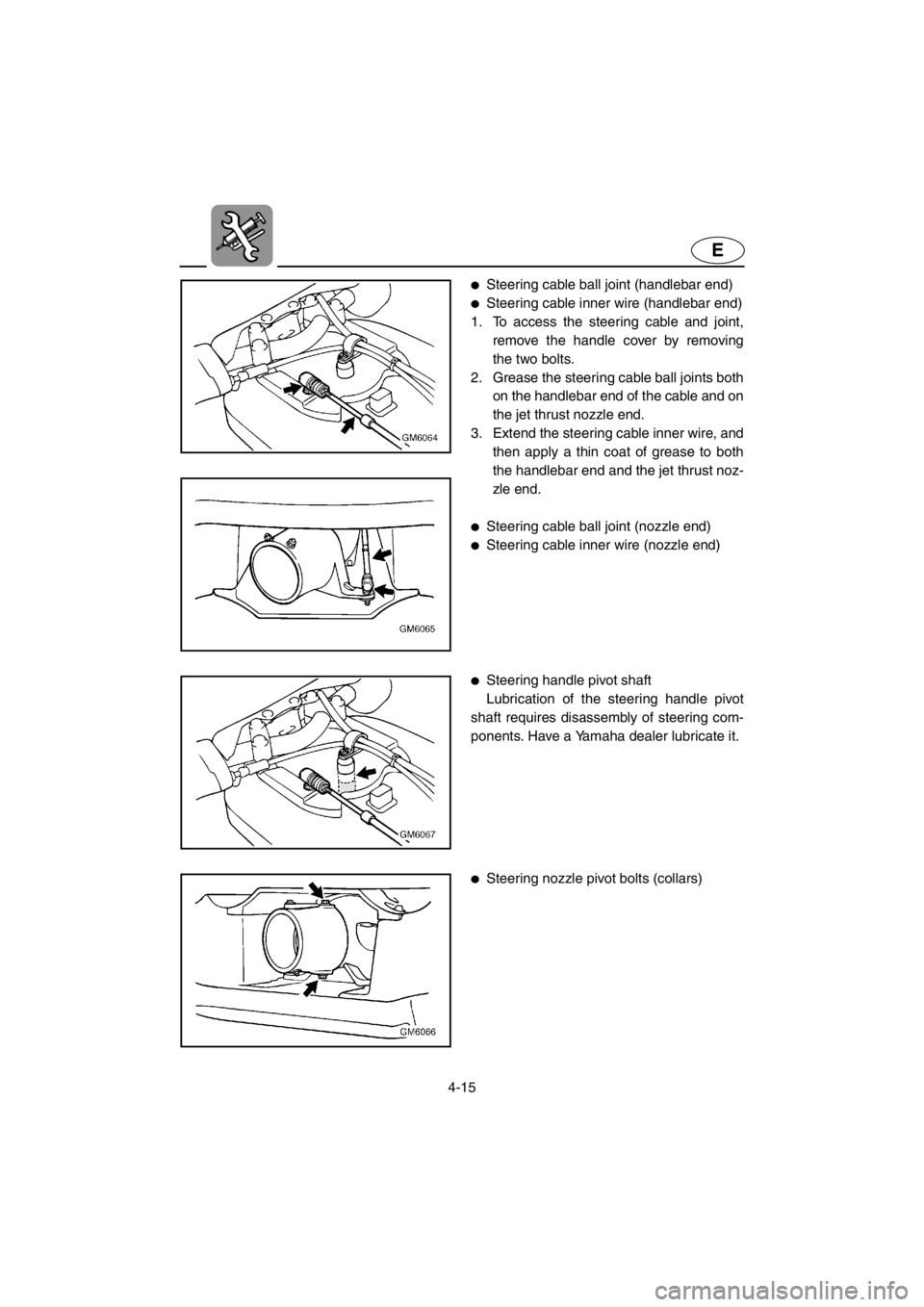

●Steering cable ball joint (handlebar end)

●Steering cable inner wire (handlebar end)

1. To access the steering cable and joint,

remove the handle cover by removing

the two bolts.

2. Grease the steering cable ball joints both

on the handlebar end of the cable and on

the jet thrust nozzle end.

3. Extend the steering cable inner wire, and

then apply a thin coat of grease to both

the handlebar end and the jet thrust noz-

zle end.

●Steering cable ball joint (nozzle end)

●Steering cable inner wire (nozzle end)

●Steering handle pivot shaft

Lubrication of the steering handle pivot

shaft requires disassembly of steering com-

ponents. Have a Yamaha dealer lubricate it.

●Steering nozzle pivot bolts (collars)

E_GM6-4.fm Page 15 Tuesday, July 11, 2000 11:28 AM

Page 89 of 107

4-20

E

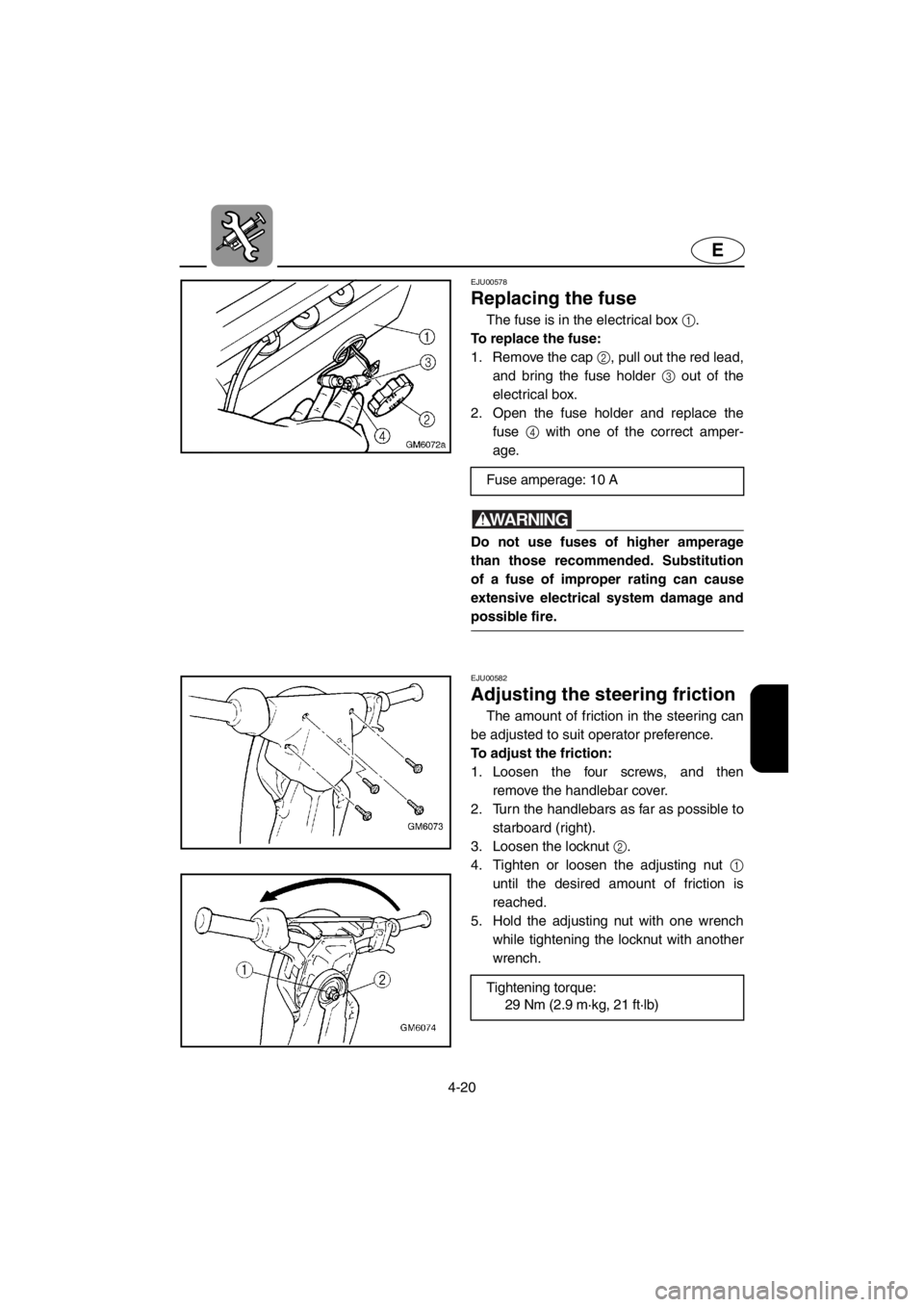

EJU00578

Replacing the fuse

The fuse is in the electrical box 1.

To replace the fuse:

1. Remove the cap 2, pull out the red lead,

and bring the fuse holder 3 out of the

electrical box.

2. Open the fuse holder and replace the

fuse4 with one of the correct amper-

age.

WARNING@Do not use fuses of higher amperage

than those recommended. Substitution

of a fuse of improper rating can cause

extensive electrical system damage and

possible fire.

@

Fuse amperage: 10 A

EJU00582

Adjusting the steering friction

The amount of friction in the steering can

be adjusted to suit operator preference.

To adjust the friction:

1. Loosen the four screws, and then

remove the handlebar cover.

2. Turn the handlebars as far as possible to

starboard (right).

3. Loosen the locknut 2.

4. Tighten or loosen the adjusting nut 1

until the desired amount of friction is

reached.

5. Hold the adjusting nut with one wrench

while tightening the locknut with another

wrench.

Tightening torque:

29 Nm (2.9 m·kg, 21 ft·lb)

E_GM6-4.fm Page 20 Tuesday, July 11, 2000 11:28 AM