ECU YAMAHA SUPERJET 2021 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2021, Model line: SUPERJET, Model: YAMAHA SUPERJET 2021Pages: 84, PDF Size: 3.76 MB

Page 29 of 84

Control function operation

22

EJU31273Steering pole

The steering pole can be moved up or down

to change the height of the handlebars.

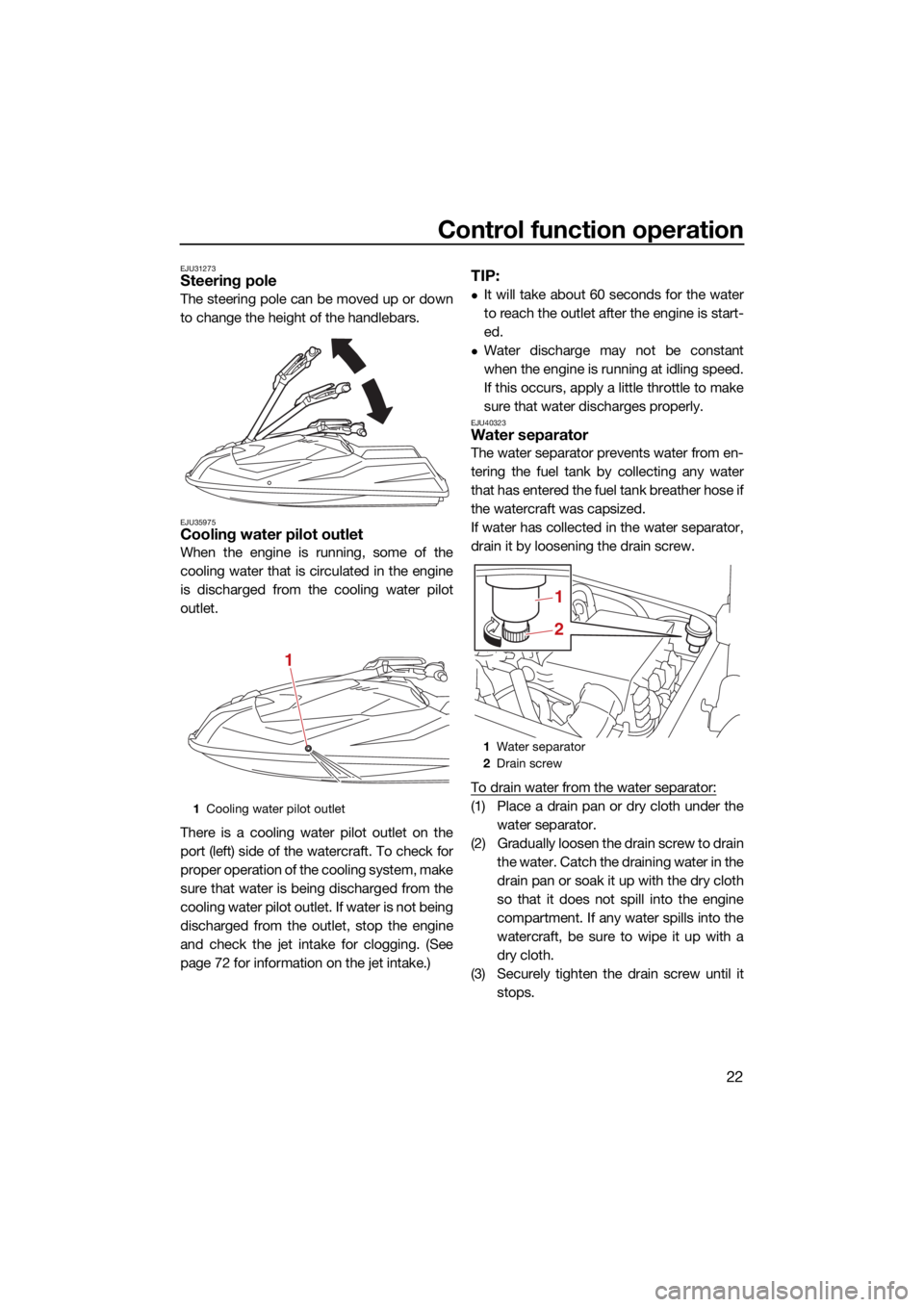

EJU35975Cooling water pilot outlet

When the engine is running, some of the

cooling water that is circulated in the engine

is discharged from the cooling water pilot

outlet.

There is a cooling water pilot outlet on the

port (left) side of the watercraft. To check for

proper operation of the cooling system, make

sure that water is being discharged from the

cooling water pilot outlet. If water is not being

discharged from the outlet, stop the engine

and check the jet intake for clogging. (See

page 72 for information on the jet intake.)

TIP:

It will take about 60 seconds for the water

to reach the outlet after the engine is start-

ed.

Water discharge may not be constant

when the engine is running at idling speed.

If this occurs, apply a little throttle to make

sure that water discharges properly.

EJU40323Water separator

The water separator prevents water from en-

tering the fuel tank by collecting any water

that has entered the fuel tank breather hose if

the watercraft was capsized.

If water has collected in the water separator,

drain it by loosening the drain screw.

To drain water from the water separator:

(1) Place a drain pan or dry cloth under thewater separator.

(2) Gradually loosen the drain screw to drain the water. Catch the draining water in the

drain pan or soak it up with the dry cloth

so that it does not spill into the engine

compartment. If any water spills into the

watercraft, be sure to wipe it up with a

dry cloth.

(3) Securely tighten the drain screw until it stops.1Cooling water pilot outlet

1

1Water separator

2 Drain screw

2

1

UF4R71E0.book Page 22 Monday, May 10, 2021 1:14 PM

Page 34 of 84

Equipment operation

27

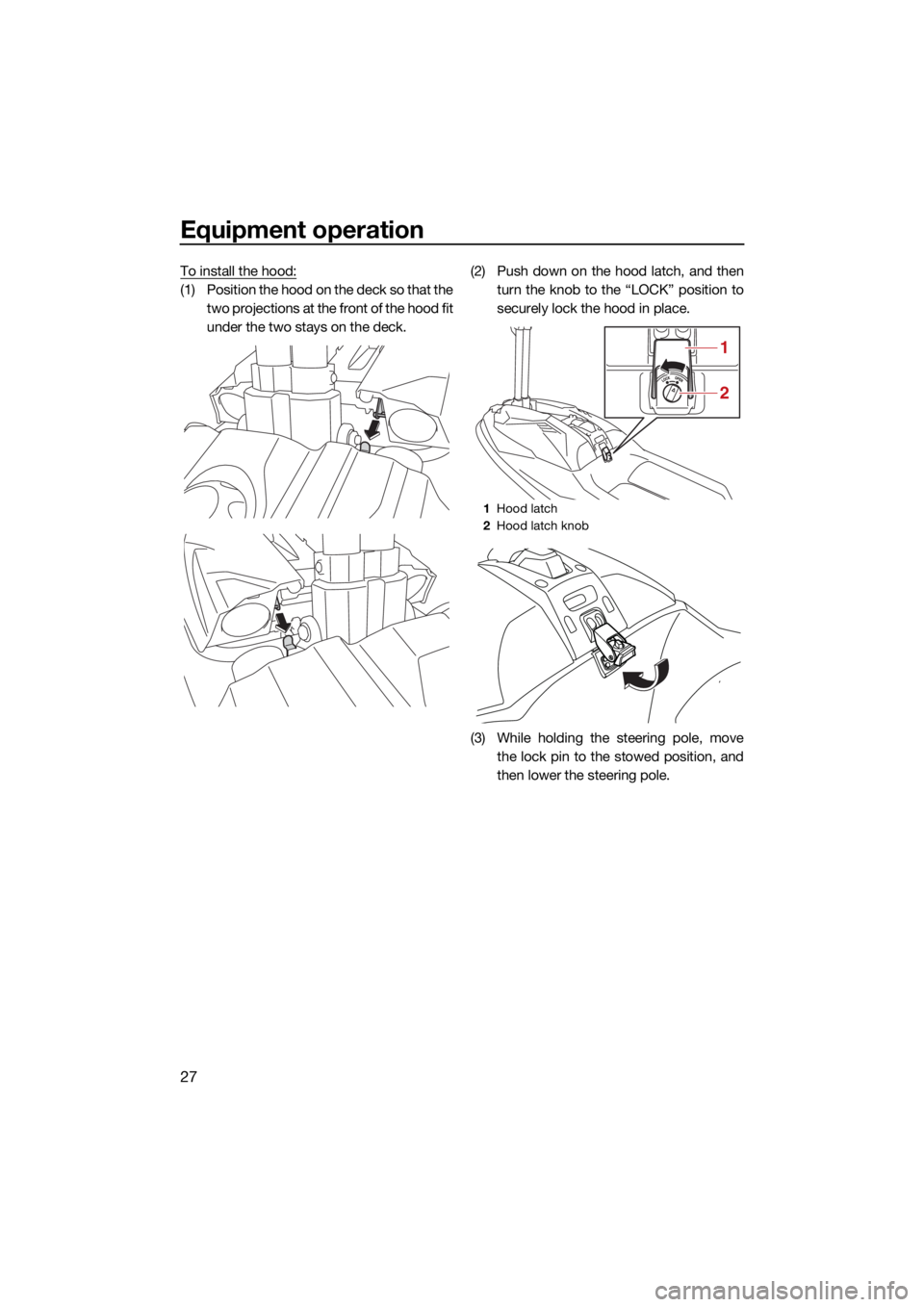

To install the hood:

(1) Position the hood on the deck so that thetwo projections at the front of the hood fit

under the two stays on the deck. (2) Push down on the hood latch, and then

turn the knob to the “LOCK” position to

securely lock the hood in place.

(3) While holding the steering pole, move the lock pin to the stowed position, and

then lower the steering pole.

1Hood latch

2 Hood latch knob

1

2

UF4R71E0.book Page 27 Monday, May 10, 2021 1:14 PM

Page 36 of 84

Equipment operation

29

To install the storage pouch:

(1) Bend the owner’s/operator’s manualslightly to insert it into the storage pouch,

and then add any other small items. Fold

the pouch, and then close the zipper.

(2) Install the storage pouch on the hood and secure it with the bands.

(3) Securely install the hood in its original position.

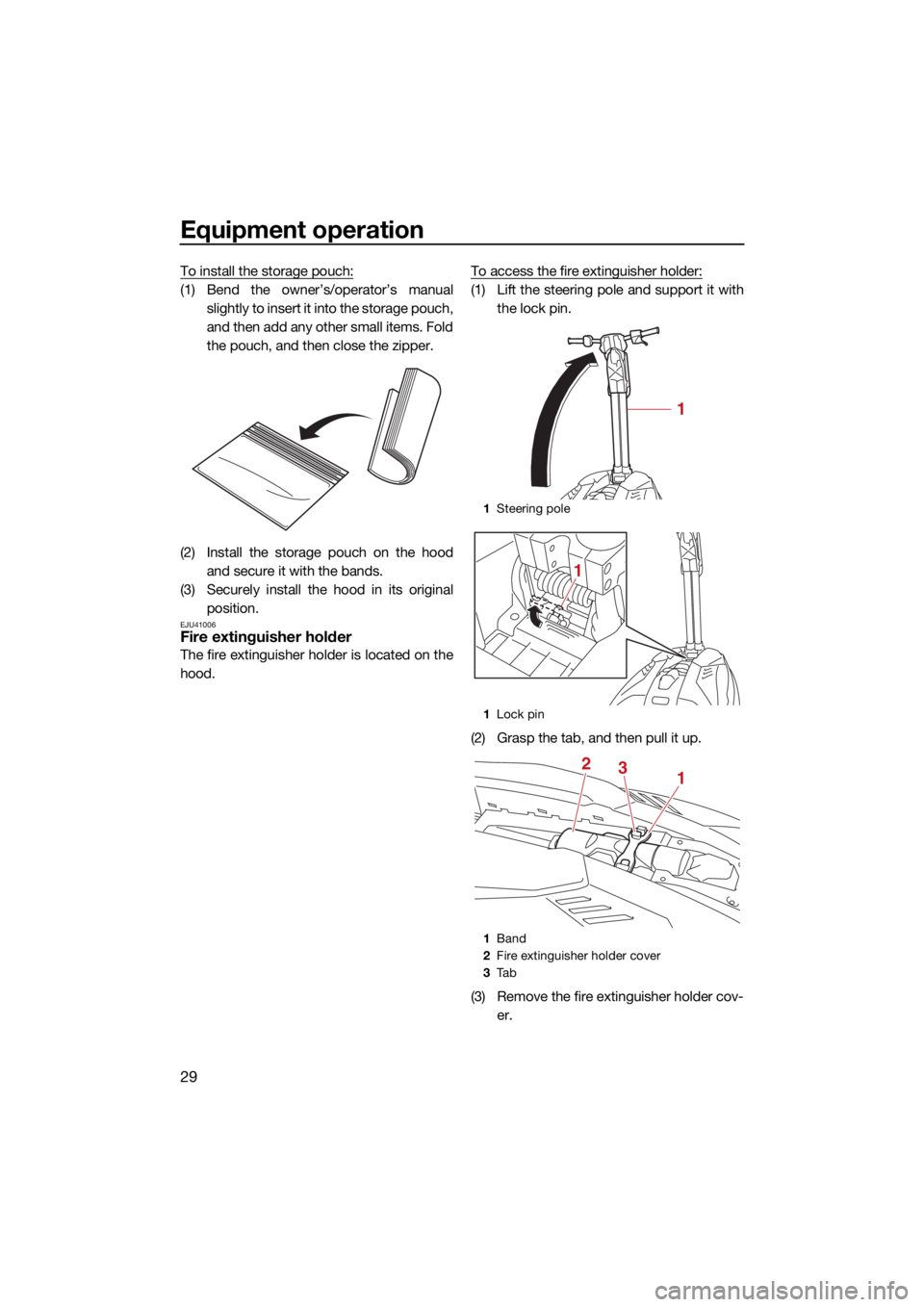

EJU41006Fire extinguisher holder

The fire extinguisher holder is located on the

hood. To access the fire extinguisher holder:

(1) Lift the steering pole and support it with

the lock pin.

(2) Grasp the tab, and then pull it up.

(3) Remove the fire extinguisher holder cov- er.

1Steering pole

1 Lock pin

1 Band

2 Fire extinguisher holder cover

3 Ta b

1

1

132

UF4R71E0.book Page 29 Monday, May 10, 2021 1:14 PM

Page 37 of 84

Equipment operation

30

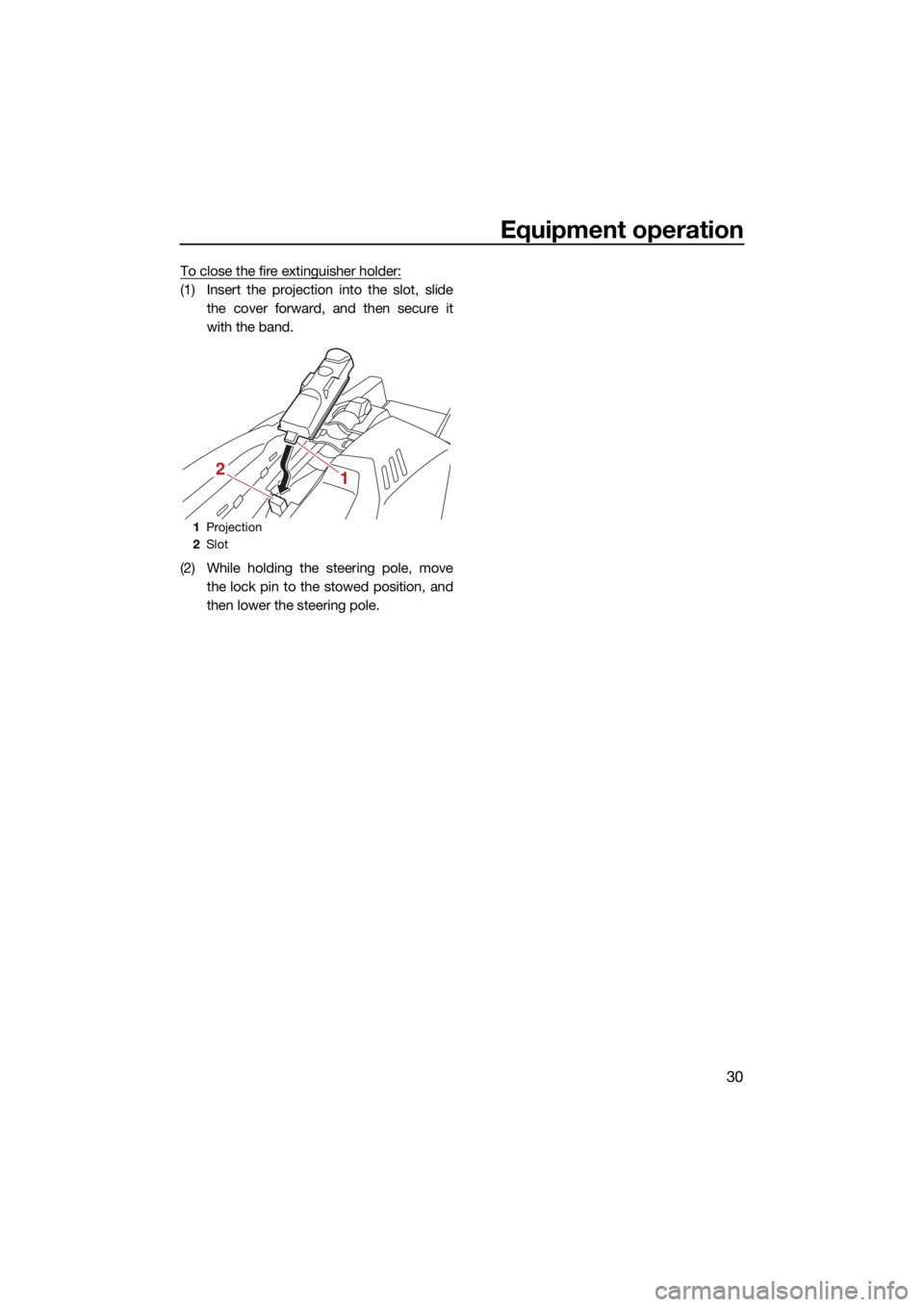

To close the fire extinguisher holder:

(1) Insert the projection into the slot, slidethe cover forward, and then secure it

with the band.

(2) While holding the steering pole, move the lock pin to the stowed position, and

then lower the steering pole.

1Projection

2 Slot

12

UF4R71E0.book Page 30 Monday, May 10, 2021 1:14 PM

Page 39 of 84

Operation and handling requirements

32

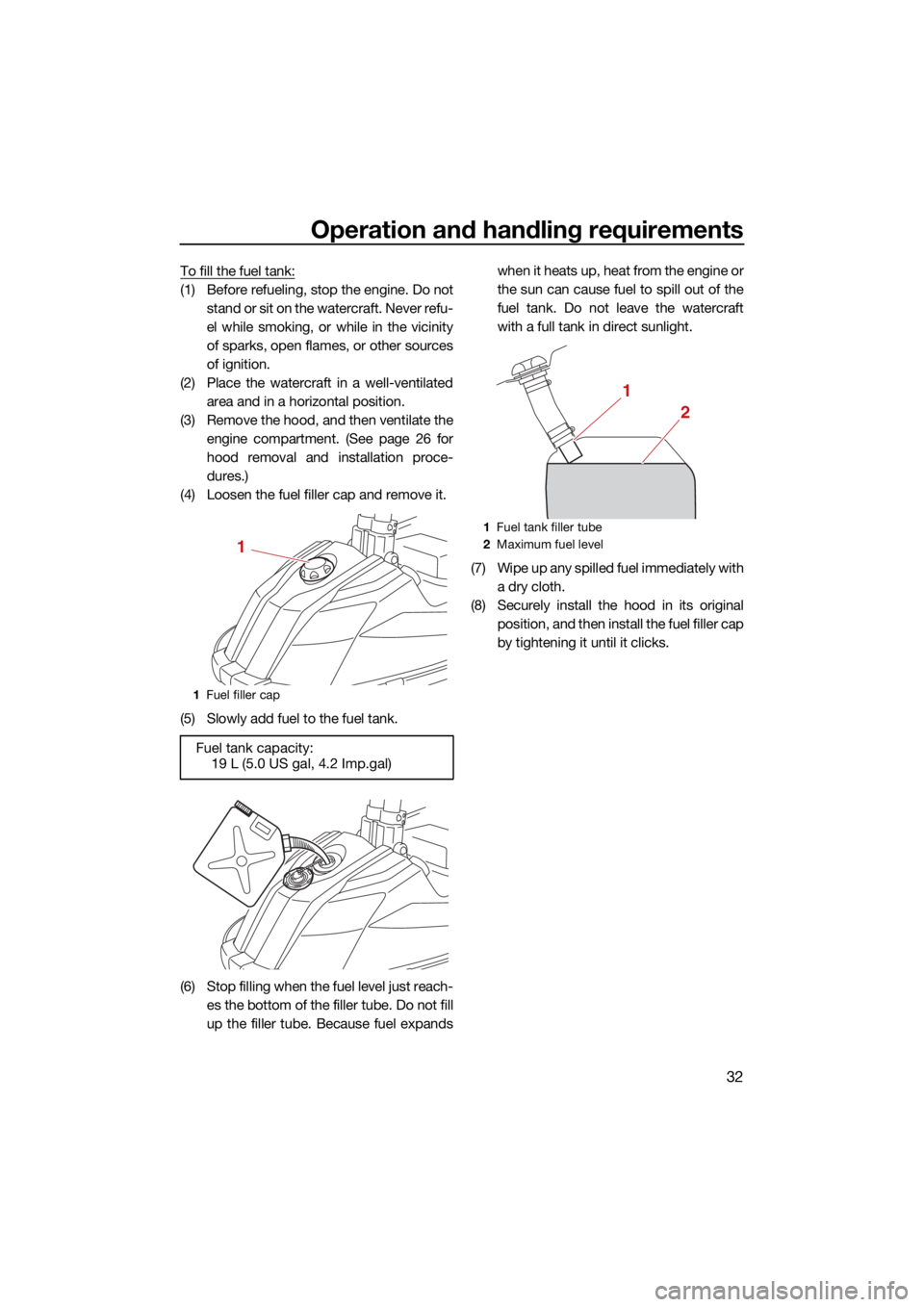

To fill the fuel tank:

(1) Before refueling, stop the engine. Do notstand or sit on the watercraft. Never refu-

el while smoking, or while in the vicinity

of sparks, open flames, or other sources

of ignition.

(2) Place the watercraft in a well-ventilated area and in a horizontal position.

(3) Remove the hood, and then ventilate the engine compartment. (See page 26 for

hood removal and installation proce-

dures.)

(4) Loosen the fuel filler cap and remove it.

(5) Slowly add fuel to the fuel tank.

(6) Stop filling when the fuel level just reach- es the bottom of the filler tube. Do not fill

up the filler tube. Because fuel expands when it heats up, heat from the engine or

the sun can cause fuel to spill out of the

fuel tank. Do not leave the watercraft

with a full tank in direct sunlight.

(7) Wipe up any spilled fuel immediately with a dry cloth.

(8) Securely install the hood in its original position, and then install the fuel filler cap

by tightening it until it clicks.

1Fuel filler cap

Fuel tank capacity:

19 L (5.0 US gal, 4.2 Imp.gal)

1

1Fuel tank filler tube

2 Maximum fuel level

2

1

UF4R71E0.book Page 32 Monday, May 10, 2021 1:14 PM

Page 41 of 84

Operation and handling requirements

34

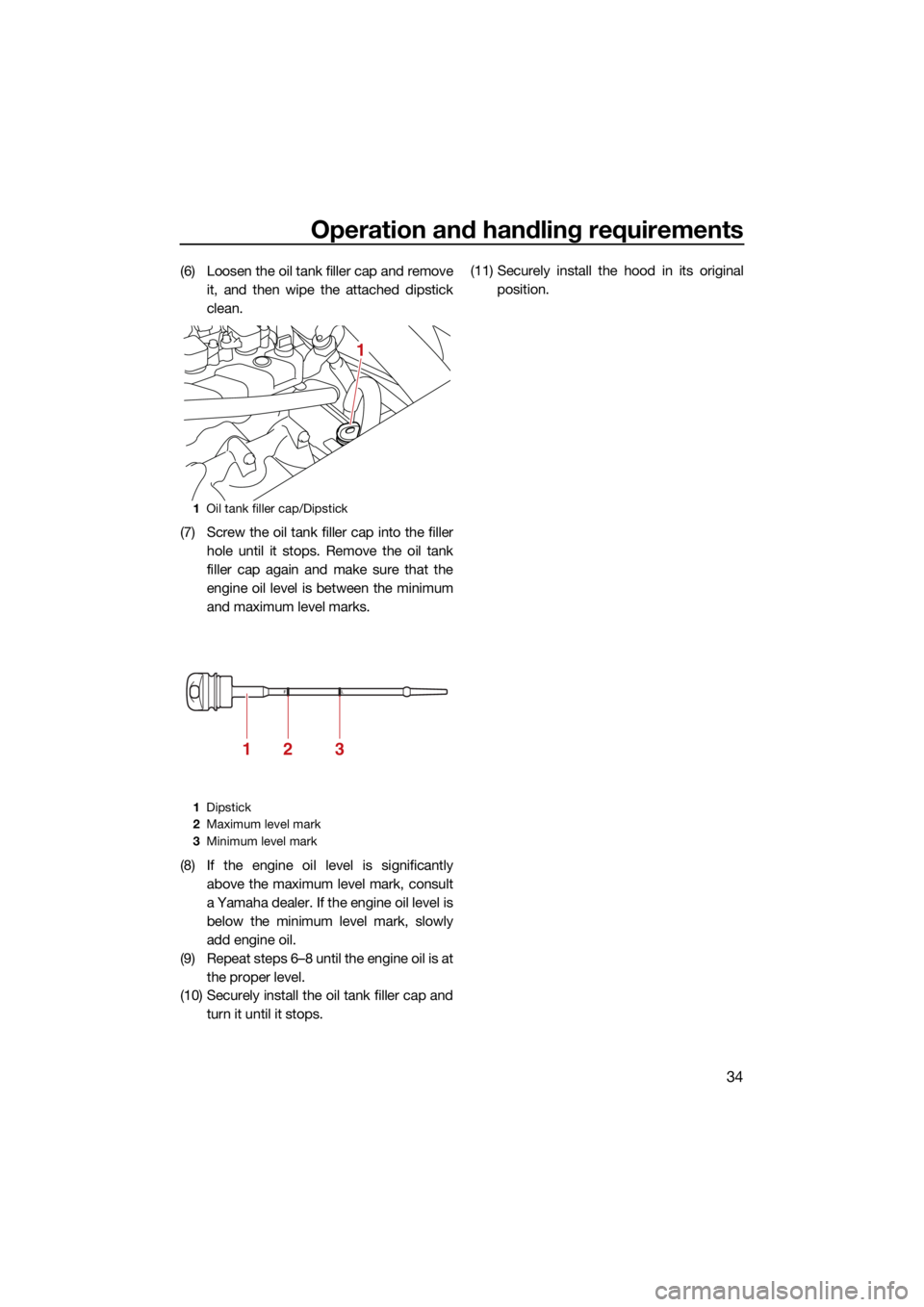

(6) Loosen the oil tank filler cap and removeit, and then wipe the attached dipstick

clean.

(7) Screw the oil tank filler cap into the filler hole until it stops. Remove the oil tank

filler cap again and make sure that the

engine oil level is between the minimum

and maximum level marks.

(8) If the engine oil level is significantly above the maximum level mark, consult

a Yamaha dealer. If the engine oil level is

below the minimum level mark, slowly

add engine oil.

(9) Repeat steps 6–8 until the engine oil is at the proper level.

(10) Securely install the oil tank filler cap and turn it until it stops. (11) Securely install the hood in its original

position.

1Oil tank filler cap/Dipstick

1 Dipstick

2 Maximum level mark

3 Minimum level mark

1

213

UF4R71E0.book Page 34 Monday, May 10, 2021 1:14 PM

Page 42 of 84

Operation and handling requirements

35

EJU40022

Draining the bilge waterECJ01302

Do not run the engine at full throttle when

bilge water remains in the engine com-

partment. The bilge water can splash into

the engine, which can result in severe

damage.

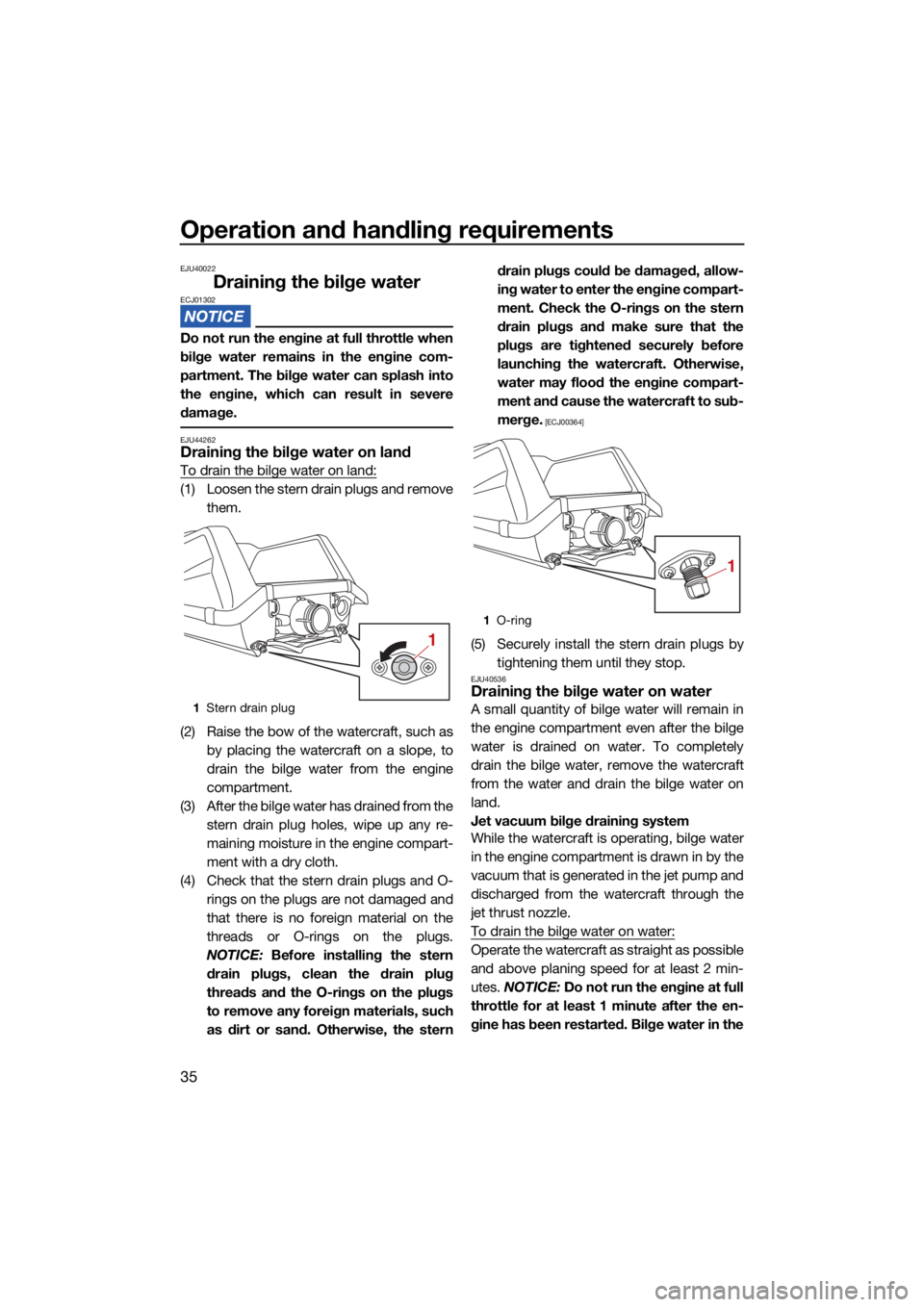

EJU44262Draining the bilge water on land

To drain the bilge water on land:

(1) Loosen the stern drain plugs and removethem.

(2) Raise the bow of the watercraft, such as by placing the watercraft on a slope, to

drain the bilge water from the engine

compartment.

(3) After the bilge water has drained from the stern drain plug holes, wipe up any re-

maining moisture in the engine compart-

ment with a dry cloth.

(4) Check that the stern drain plugs and O- rings on the plugs are not damaged and

that there is no foreign material on the

threads or O-rings on the plugs.

NOTICE: Before installing the stern

drain plugs, clean the drain plug

threads and the O-rings on the plugs

to remove any foreign materials, such

as dirt or sand. Otherwise, the stern drain plugs could be damaged, allow-

ing water to enter the engine compart-

ment. Check the O-rings on the stern

drain plugs and make sure that the

plugs are tightened securely before

launching the watercraft. Otherwise,

water may flood the engine compart-

ment and cause the watercraft to sub-

merge.

[ECJ00364]

(5) Securely install the stern drain plugs by

tightening them until they stop.

EJU40536Draining the bilge water on water

A small quantity of bilge water will remain in

the engine compartment even after the bilge

water is drained on water. To completely

drain the bilge water, remove the watercraft

from the water and drain the bilge water on

land.

Jet vacuum bilge draining system

While the watercraft is operating, bilge water

in the engine compartment is drawn in by the

vacuum that is generated in the jet pump and

discharged from the watercraft through the

jet thrust nozzle.

To drain the bilge water on water:

Operate the watercraft as straight as possible

and above planing speed for at least 2 min-

utes. NOTICE: Do not run the engine at full

throttle for at least 1 minute after the en-

gine has been restarted. Bilge water in the

1 Stern drain plug

1

1O-ring

1

UF4R71E0.book Page 35 Monday, May 10, 2021 1:14 PM

Page 43 of 84

![YAMAHA SUPERJET 2021 Owners Manual Operation and handling requirements

36

engine compartment can splash into the

engine, which can result in severe dam-

age.

[ECJ00554]EJU45602

Transporting on a trailer

When transporting the watercraf YAMAHA SUPERJET 2021 Owners Manual Operation and handling requirements

36

engine compartment can splash into the

engine, which can result in severe dam-

age.

[ECJ00554]EJU45602

Transporting on a trailer

When transporting the watercraf](/img/51/51248/w960_51248-42.png)

Operation and handling requirements

36

engine compartment can splash into the

engine, which can result in severe dam-

age.

[ECJ00554]EJU45602

Transporting on a trailer

When transporting the watercraft on a trailer,

secure the tie downs to the trailer through the

bow eye and stern eyes. Use a rubber shock

cord to secure the steering pole to the water-

craft.

NOTICE: Do not attach ropes or tie

downs to any part of the watercraft other

than the bow eye and stern eyes to secure

the watercraft to the trailer. Otherwise, the

watercraft may be damaged. Wrap the

ropes or tie downs with towels or rags

where they touch the body of the water-

craft to avoid scratches or damage. Do

not secure the steering pole with ropes or

tie downs and do not secure it to the trail-

er. Also, do not transport the watercraft

UF4R71E0.book Page 36 Monday, May 10, 2021 1:14 PM

Page 46 of 84

Pre-operation checks

39

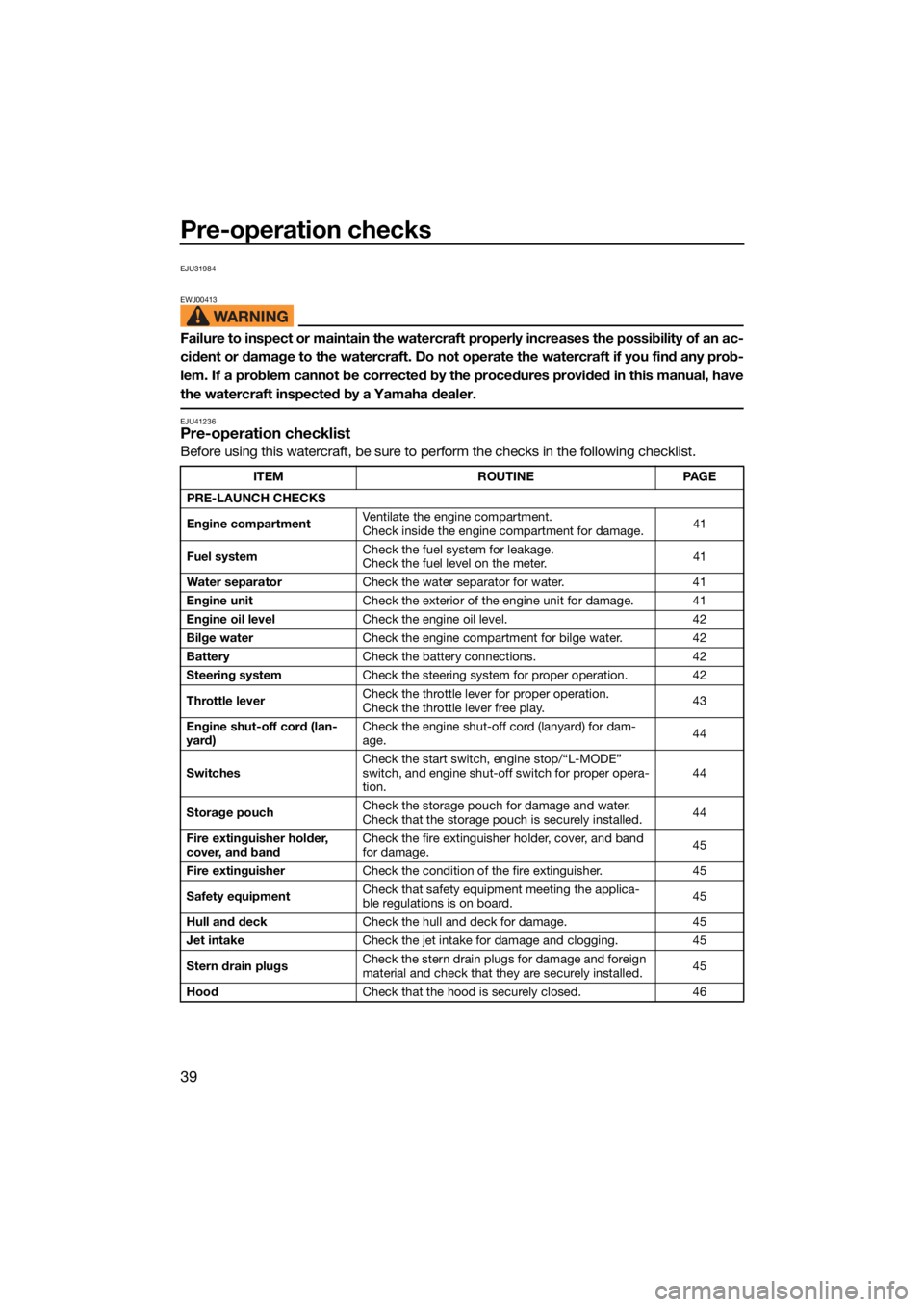

EJU31984

EWJ00413

Failure to inspect or maintain the watercraft properly increases the possibility of an ac-

cident or damage to the watercraft. Do not operate the watercraft if you find any prob-

lem. If a problem cannot be corrected by the procedures provided in this manual, have

the watercraft inspected by a Yamaha dealer.

EJU41236Pre-operation checklist

Before using this watercraft, be sure to perform the checks in the following checklist.

ITEMROUTINEPAGE

PRE-LAUNCH CHECKS

Engine compartment Ventilate the engine compartment.

Check inside the engine compartment for damage.

41

Fuel system Check the fuel system for leakage.

Check the fuel level on the meter.

41

Water separator Check the water separator for water. 41

Engine unit Check the exterior of the engine unit for damage. 41

Engine oil level Check the engine oil level. 42

Bilge water Check the engine compartment for bilge water. 42

Battery Check the battery connections. 42

Steering system Check the steering system for proper operation. 42

Throttle lever Check the throttle lever for proper operation.

Check the throttle lever free play.

43

Engine shut-off cord (lan-

yard) Check the engine shut-off cord (lanyard) for dam-

age.

44

Switches Check the start switch, engine stop/“L-MODE”

switch, and engine shut-off switch for proper opera-

tion. 44

Storage pouch Check the storage pouch for damage and water.

Check that the storage pouch is securely installed.

44

Fire extinguisher holder,

cover, and band Check the fire extinguisher holder, cover, and band

for damage.

45

Fire extinguisher Check the condition of the fire extinguisher. 45

Safety equipment Check that safety equipment meeting the applica-

ble regulations is on board.

45

Hull and deck Check the hull and deck for damage. 45

Jet intake Check the jet intake for damage and clogging. 45

Stern drain plugs Check the stern drain plugs for damage and foreign

material and check that they are securely installed.

45

Hood Check that the hood is securely closed. 46

UF4R71E0.book Page 39 Monday, May 10, 2021 1:14 PM

Page 49 of 84

Pre-operation checks

42

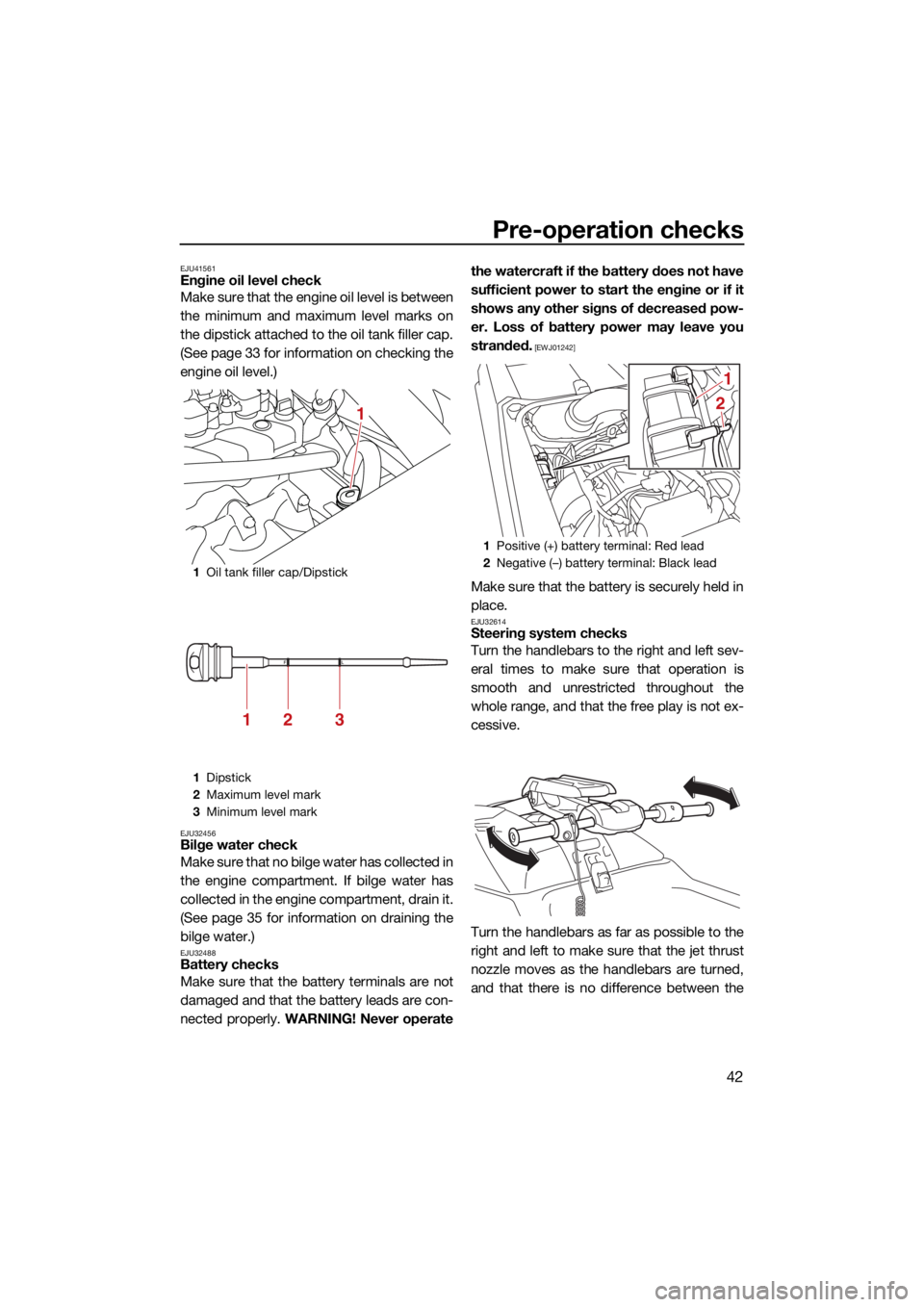

EJU41561Engine oil level check

Make sure that the engine oil level is between

the minimum and maximum level marks on

the dipstick attached to the oil tank filler cap.

(See page 33 for information on checking the

engine oil level.)

EJU32456Bilge water check

Make sure that no bilge water has collected in

the engine compartment. If bilge water has

collected in the engine compartment, drain it.

(See page 35 for information on draining the

bilge water.)

EJU32488Battery checks

Make sure that the battery terminals are not

damaged and that the battery leads are con-

nected properly. WARNING! Never operate the watercraft if the battery does not have

sufficient power to start the engine or if it

shows any other signs of decreased pow-

er. Loss of battery power may leave you

stranded.

[EWJ01242]

Make sure that the battery is securely held in

place.

EJU32614Steering system checks

Turn the handlebars to the right and left sev-

eral times to make sure that operation is

smooth and unrestricted throughout the

whole range, and that the free play is not ex-

cessive.

Turn the handlebars as far as possible to the

right and left to make sure that the jet thrust

nozzle moves as the handlebars are turned,

and that there is no difference between the

1

Oil tank filler cap/Dipstick

1 Dipstick

2 Maximum level mark

3 Minimum level mark

1

213

1Positive (+) battery terminal: Red lead

2 Negative (–) battery terminal: Black lead

1

2

UF4R71E0.book Page 42 Monday, May 10, 2021 1:14 PM