wheel YAMAHA T110C 2013 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2013, Model line: T110C, Model: YAMAHA T110C 2013Pages: 82, PDF Size: 2.06 MB

Page 53 of 82

PERIODIC MAINTENANCE AND ADJUSTMENT

6-22

6 5. Tighten both locknuts, and then

tighten the axle nut and brake

torque rod nut to their specified

torques.

TIPWhen tightening the axle nut, hold the

wheel axle with a wrench to keep it from

turning.6. Adjust the brake pedal free play.

(See page 6-17.) WARNING! Af-

ter adjusting the brake pedal

free play, check the operation of

the brake light.

[EWA16080]

7. Make sure that the drive chain pull-

ers are in the same position, the

drive chain slack is correct, and

the drive chain moves smoothly.

EAU23016

Cleaning and lubricating the

drive chain The drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly wear

out, especially when riding in dusty or

wet areas. Service the drive chain as

follows.NOTICE

ECA10583

The drive chain must be lubricated

after washing the motorcycle, riding

in the rain or riding in wet areas.1. Remove all dirt and mud from the

drive chain with a brush or cloth.TIPFor a thorough cleaning, have a

Yamaha dealer remove the drive chain

and soak it in solvent.2. Spray Yamaha Chain and Cable

Lube or a high-quality spray-type

drive chain lubricant on the entire

chain, making sure that all side

plates and rollers have been suffi-

ciently oiled.

1. Alignment marks

2. Drive chain slack adjusting nut

3. Drive chain pullerTightening torques:

Locknut:

7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Axle nut:

60 Nm (6.0 m·kgf, 43 ft·lbf)

Brake torque rod nut:

19 Nm (1.9 m·kgf, 14 ft·lbf)13

2

(a)

(b)

U40BE2E0.book Page 22 Wednesday, October 10, 2012 8:01 AM

Page 57 of 82

PERIODIC MAINTENANCE AND ADJUSTMENT

6-26

6

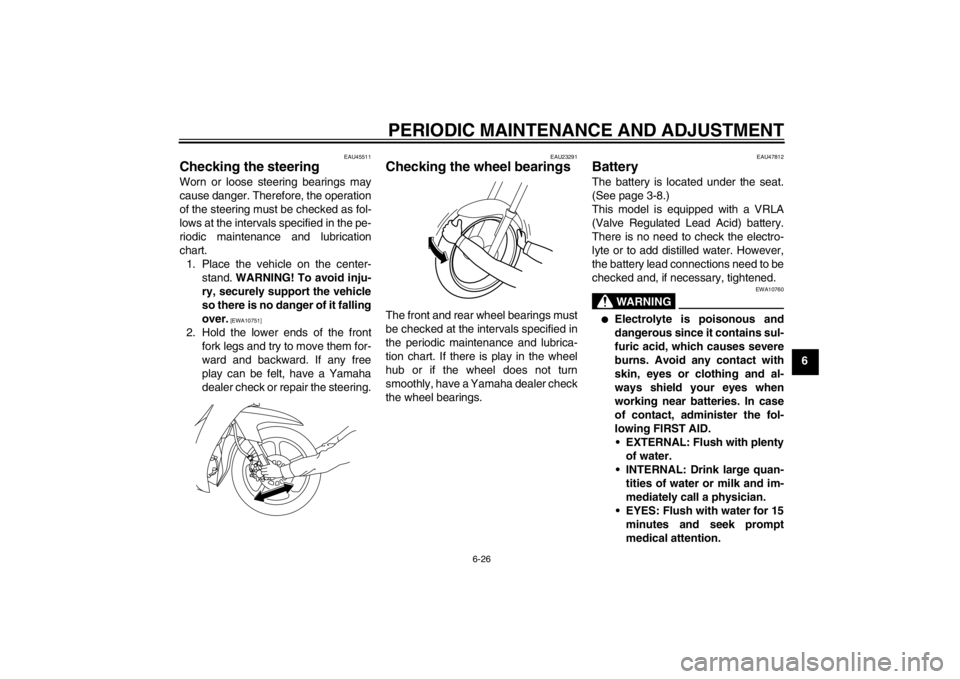

EAU45511

Checking the steering Worn or loose steering bearings may

cause danger. Therefore, the operation

of the steering must be checked as fol-

lows at the intervals specified in the pe-

riodic maintenance and lubrication

chart.

1. Place the vehicle on the center-

stand. WARNING! To avoid inju-

ry, securely support the vehicle

so there is no danger of it falling

over.

[EWA10751]

2. Hold the lower ends of the front

fork legs and try to move them for-

ward and backward. If any free

play can be felt, have a Yamaha

dealer check or repair the steering.

EAU23291

Checking the wheel bearings The front and rear wheel bearings must

be checked at the intervals specified in

the periodic maintenance and lubrica-

tion chart. If there is play in the wheel

hub or if the wheel does not turn

smoothly, have a Yamaha dealer check

the wheel bearings.

EAU47812

Battery The battery is located under the seat.

(See page 3-8.)

This model is equipped with a VRLA

(Valve Regulated Lead Acid) battery.

There is no need to check the electro-

lyte or to add distilled water. However,

the battery lead connections need to be

checked and, if necessary, tightened.

WARNING

EWA10760

●

Electrolyte is poisonous and

dangerous since it contains sul-

furic acid, which causes severe

burns. Avoid any contact with

skin, eyes or clothing and al-

ways shield your eyes when

working near batteries. In case

of contact, administer the fol-

lowing FIRST AID.

EXTERNAL: Flush with plenty

of water.

INTERNAL: Drink large quan-

tities of water or milk and im-

mediately call a physician.

EYES: Flush with water for 15

minutes and seek prompt

medical attention.

U40BE2E0.book Page 26 Wednesday, October 10, 2012 8:01 AM

Page 64 of 82

PERIODIC MAINTENANCE AND ADJUSTMENT

6-33

6

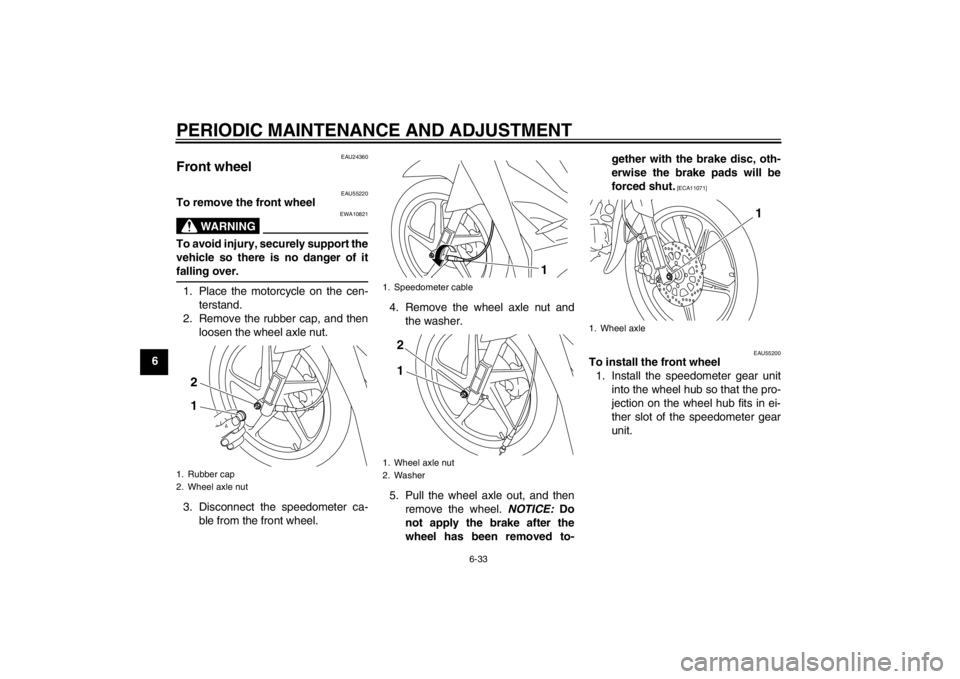

EAU24360

Front wheel

EAU55220

To remove the front wheel

WARNING

EWA10821

To avoid injury, securely support the

vehicle so there is no danger of it

falling over.1. Place the motorcycle on the cen-

terstand.

2. Remove the rubber cap, and then

loosen the wheel axle nut.

3. Disconnect the speedometer ca-

ble from the front wheel.4. Remove the wheel axle nut and

the washer.

5. Pull the wheel axle out, and then

remove the wheel. NOTICE: Do

not apply the brake after the

wheel has been removed to-gether with the brake disc, oth-

erwise the brake pads will be

forced shut.

[ECA11071]

EAU55200

To install the front wheel

1. Install the speedometer gear unit

into the wheel hub so that the pro-

jection on the wheel hub fits in ei-

ther slot of the speedometer gear

unit.

1. Rubber cap

2. Wheel axle nut

12

1. Speedometer cable

1. Wheel axle nut

2. Washer

1

12

1. Wheel axle

1

U40BE2E0.book Page 33 Wednesday, October 10, 2012 8:01 AM

Page 65 of 82

PERIODIC MAINTENANCE AND ADJUSTMENT

6-34

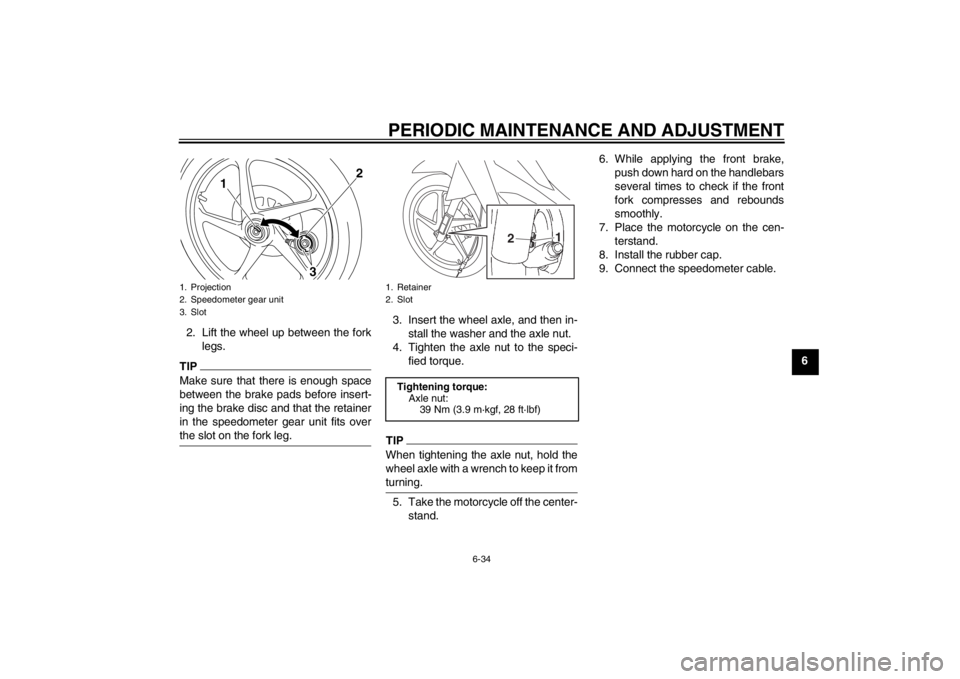

6 2. Lift the wheel up between the fork

legs.

TIPMake sure that there is enough space

between the brake pads before insert-

ing the brake disc and that the retainer

in the speedometer gear unit fits over

the slot on the fork leg.

3. Insert the wheel axle, and then in-

stall the washer and the axle nut.

4. Tighten the axle nut to the speci-

fied torque.TIPWhen tightening the axle nut, hold the

wheel axle with a wrench to keep it from

turning.5. Take the motorcycle off the center-

stand.6. While applying the front brake,

push down hard on the handlebars

several times to check if the front

fork compresses and rebounds

smoothly.

7. Place the motorcycle on the cen-

terstand.

8. Install the rubber cap.

9. Connect the speedometer cable.

1. Projection

2. Speedometer gear unit

3. Slot

2

3

1

1. Retainer

2. Slot

Tightening torque:

Axle nut:

39 Nm (3.9 m·kgf, 28 ft·lbf)

2

1

U40BE2E0.book Page 34 Wednesday, October 10, 2012 8:01 AM

Page 66 of 82

PERIODIC MAINTENANCE AND ADJUSTMENT

6-35

6

EAU25080

Rear wheel

EAU55240

To remove the rear wheel

WARNING

EWA10821

To avoid injury, securely support the

vehicle so there is no danger of it

falling over.1. Place the motorcycle on the cen-

terstand.

2. Loosen the wheel axle nut.

3. Remove the drive chain case by

removing the bolts.4. Loosen the locknut and the drive

chain slack adjusting nut on both

ends of the swingarm.5. Disconnect the brake torque rod

from the brake shoe plate by re-

moving the cotter pin, the nut, the

washer and the bolt.

6. Remove the brake pedal free play

adjusting nut, and then disconnect

the brake rod from the brake cam-

shaft lever.1. Wheel axle nut

1

1. Drive chain case

2. Bolt

1. Locknut

2. Drive chain slack adjusting nut

1

2

2

1

2

1. Brake torque rod

2. Cotter pin

3. Brake torque rod nut and bolt

4. Washer

1

2

4

3

U40BE2E0.book Page 35 Wednesday, October 10, 2012 8:01 AM

Page 67 of 82

PERIODIC MAINTENANCE AND ADJUSTMENT

6-36

6 7. Remove the axle nut and the

washer, and then pull the wheel

axle out.8. Push the wheel forward, and then

remove the drive chain from the

rear sprocket.

TIPThe drive chain does not need to be

disassembled in order to remove and

install the wheel.9. Remove the wheel.

EAU47702

To install the rear wheel

1. Install the wheel by inserting the

wheel axle from the left-hand side.

2. Install the drive chain onto the rear

sprocket.

3. Install the washer and the axle nut.

4. Install the brake rod onto the brake

camshaft lever, and then install the

brake pedal free play adjusting nut

onto the brake rod.

5. Connect the brake torque rod to

the brake shoe plate by installing

the bolt, the washer and the nut.

6. Adjust the drive chain slack. (See

page 6-20.)

7. Tighten the brake torque rod nut

and axle nut to the specified

torques.

TIPWhen tightening the axle nut, hold the

wheel axle with a wrench to keep it from

turning.8. Insert a new cotter pin.

9. Adjust the brake pedal free play.

(See page 6-17.) WARNING! Af-

ter adjusting the brake pedal

free play, check the operation of

the brake light.

[EWA16080]

10. Install the drive chain case by in-

stalling the bolts.

1. Washer

2. Axle nut

3. Brake rod

4. Brake pedal free play adjusting nut

5. Brake camshaft lever

1. Wheel axle4

5

1

2

3

1

Tightening torques:

Brake torque rod nut:

19 Nm (1.9 m·kgf, 14 ft·lbf)

Axle nut:

60 Nm (6.0 m·kgf, 43 ft·lbf)

U40BE2E0.book Page 36 Wednesday, October 10, 2012 8:01 AM

Page 70 of 82

MOTORCYCLE CARE AND STORAGE

7-1

7

EAU37833

Matte color caution NOTICE

ECA15192

Some models are equipped with

matte colored finished parts. Be

sure to consult a Yamaha dealer for

advice on what products to use be-

fore cleaning the vehicle. Using a

brush, harsh chemical products or

cleaning compounds when cleaning

these parts will scratch or damage

their surface. Wax also should not

be applied to any matte colored fin-

ished parts.

EAU26004

Care While the open design of a motorcycle

reveals the attractiveness of the tech-

nology, it also makes it more vulnera-

ble. Rust and corrosion can develop

even if high-quality components are

used. A rusty exhaust pipe may go un-

noticed on a car, however, it detracts

from the overall appearance of a motor-

cycle. Frequent and proper care does

not only comply with the terms of the

warranty, but it will also keep your mo-

torcycle looking good, extend its life

and optimize its performance.

Before cleaning

1. Cover the muffler outlet with a

plastic bag after the engine has

cooled down.

2. Make sure that all caps and covers

as well as all electrical couplers

and connectors, including the

spark plug cap, are tightly in-

stalled.

3. Remove extremely stubborn dirt,

like oil burnt onto the crankcase,

with a degreasing agent and a

brush, but never apply such prod-ucts onto seals, gaskets, sprock-

ets, the drive chain and wheel

axles. Always rinse the dirt and de-

greaser off with water.

Cleaning

NOTICE

ECA10772

●

Avoid using strong acidic wheel

cleaners, especially on spoked

wheels. If such products are

used on hard-to-remove dirt, do

not leave the cleaner on the af-

fected area any longer than in-

structed. Also, thoroughly rinse

the area off with water, immedi-

ately dry it, and then apply a cor-

rosion protection spray.

●

Improper cleaning can damage

plastic parts (such as cowlings,

panels, windshields, headlight

lenses, meter lenses, etc.) and

the mufflers. Use only a soft,

clean cloth or sponge with wa-

ter to clean plastic. However, if

the plastic parts cannot be thor-

oughly cleaned with water, di-

luted mild detergent with water

may be used. Be sure to rinse

U40BE2E0.book Page 1 Wednesday, October 10, 2012 8:01 AM

Page 71 of 82

MOTORCYCLE CARE AND STORAGE

7-2

7 off any detergent residue using

plenty of water, as it is harmful

to plastic parts.

●

Do not use any harsh chemical

products on plastic parts. Be

sure to avoid using cloths or

sponges which have been in

contact with strong or abrasive

cleaning products, solvent or

thinner, fuel (gasoline), rust re-

movers or inhibitors, brake flu-

id, antifreeze or electrolyte.

●

Do not use high-pressure wash-

ers or steam-jet cleaners since

they cause water seepage and

deterioration in the following ar-

eas: seals (of wheel and swing-

arm bearings, fork and brakes),

electric components (couplers,

connectors, instruments,

switches and lights), breather

hoses and vents.

●

For motorcycles equipped with

a windshield: Do not use strong

cleaners or hard sponges as

they will cause dulling or

scratching. Some cleaning com-

pounds for plastic may leave

scratches on the windshield.Test the product on a small hid-

den part of the windshield to

make sure that it does not leave

any marks. If the windshield is

scratched, use a quality plastic

polishing compound after

washing.

After normal useRemove dirt with warm water, a mild

detergent, and a soft, clean sponge,

and then rinse thoroughly with clean

water. Use a toothbrush or bottlebrush

for hard-to-reach areas. Stubborn dirt

and insects will come off more easily if

the area is covered with a wet cloth for

a few minutes before cleaning.

After riding in the rain, near the sea oron salt-sprayed roadsSince sea salt or salt sprayed on roads

during winter are extremely corrosive in

combination with water, carry out the

following steps after each ride in the

rain, near the sea or on salt-sprayed

roads.

TIPSalt sprayed on roads in the winter may

remain well into spring.1. Clean the motorcycle with cold wa-

ter and a mild detergent, after the

engine has cooled down.

NOTICE: Do not use warm water

since it increases the corrosive

action of the salt.

[ECA10791]

2. Apply a corrosion protection spray

on all metal, including chrome- and

nickel-plated, surfaces to prevent

corrosion.

After cleaning

1. Dry the motorcycle with a chamois

or an absorbing cloth.

2. Immediately dry the drive chain

and lubricate it to prevent it from

rusting.

3. Use a chrome polish to shine

chrome, aluminum and stainless-

steel parts, including the exhaust

system. (Even the thermally in-

duced discoloring of stainless-

steel exhaust systems can be re-

moved through polishing.)

U40BE2E0.book Page 2 Wednesday, October 10, 2012 8:01 AM

Page 73 of 82

MOTORCYCLE CARE AND STORAGE

7-4

7 2. For motorcycles equipped with a

fuel cock that has an “OFF” posi-

tion: Turn the fuel cock lever to

“OFF”.

3. Drain the carburetor float chamber

by loosening the drain bolt; this will

prevent fuel deposits from building

up. Pour the drained fuel into the

fuel tank.

4. Fill up the fuel tank and add fuel

stabilizer (if available) to prevent

the fuel tank from rusting and the

fuel from deteriorating.

5. Perform the following steps to pro-

tect the cylinder, piston rings, etc.

from corrosion.

a. Remove the spark plug cap

and spark plug.

b. Pour a teaspoonful of engine oil

into the spark plug bore.

c. Install the spark plug cap onto

the spark plug, and then place

the spark plug on the cylinder

head so that the electrodes are

grounded. (This will limit spark-

ing during the next step.)

d. Turn the engine over several

times with the starter. (This will

coat the cylinder wall with oil.)WARNING! To prevent dam-

age or injury from sparking,

make sure to ground the

spark plug electrodes while

turning the engine over.

[EWA10951]

e. Remove the spark plug cap

from the spark plug, and then

install the spark plug and the

spark plug cap.

6. Lubricate all control cables and the

pivoting points of all levers and

pedals as well as of the side-

stand/centerstand.

7. Check and, if necessary, correct

the tire air pressure, and then lift

the motorcycle so that both of its

wheels are off the ground. Alterna-

tively, turn the wheels a little every

month in order to prevent the tires

from becoming degraded in one

spot.

8. Cover the muffler outlet with a

plastic bag to prevent moisture

from entering it.

9. Remove the battery and fully

charge it. Store it in a cool, dry

place and charge it once a month.

Do not store the battery in an ex-cessively cold or warm place [less

than 0 °C (30 °F) or more than 30

°C (90 °F)]. For more information

on storing the battery, see page

6-26.

TIPMake any necessary repairs before

storing the motorcycle.

U40BE2E0.book Page 4 Wednesday, October 10, 2012 8:01 AM

Page 74 of 82

SPECIFICATIONS

8-1

8

Dimensions:Overall length:

1870 mm (73.6 in)

Overall width:

675 mm (26.6 in)

Overall height:

1040 mm (40.9 in)

Seat height:

770 mm (30.3 in)

Wheelbase:

1205 mm (47.4 in)

Ground clearance:

130 mm (5.12 in)

Minimum turning radius:

1900 mm (74.8 in)Weight:Curb weight:

102 kg (225 lb)Engine:Engine type:

Air cooled 4-stroke, SOHC

Cylinder arrangement:

Single cylinder

Displacement:

110 cm³

Bore × stroke:

51.0 × 54.0 mm (2.01 × 2.13 in)

Compression ratio:

9.30 : 1

Starting system:

Electric starter and kickstarter

Lubrication system:

Wet sump

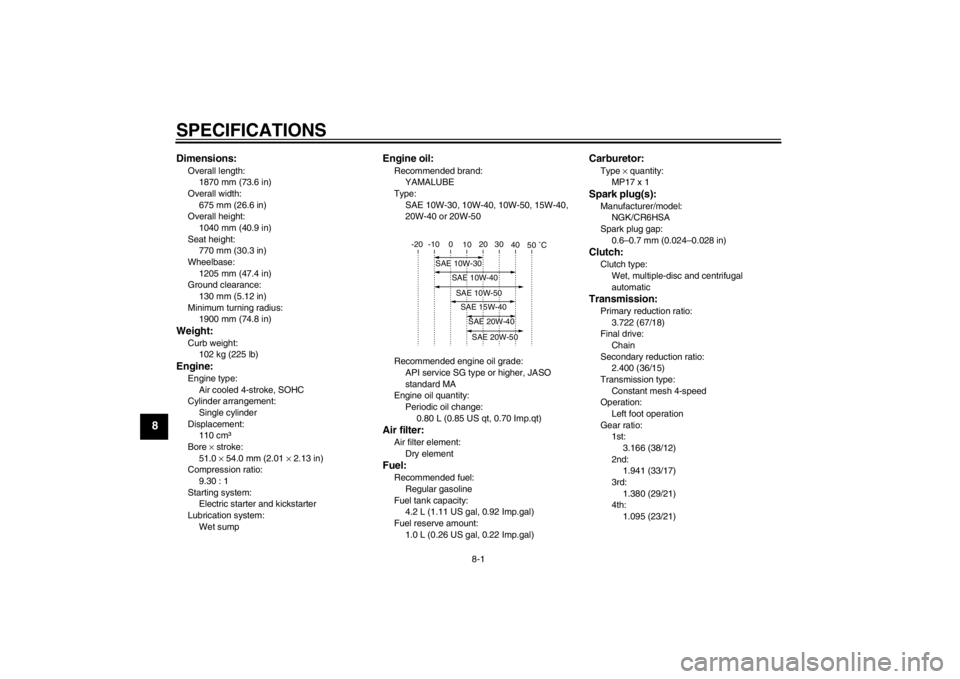

Engine oil:Recommended brand:

YAMALUBE

Type:

SAE 10W-30, 10W-40, 10W-50, 15W-40,

20W-40 or 20W-50

Recommended engine oil grade:

API service SG type or higher, JASO

standard MA

Engine oil quantity:

Periodic oil change:

0.80 L (0.85 US qt, 0.70 Imp.qt)Air filter:Air filter element:

Dry elementFuel:Recommended fuel:

Regular gasoline

Fuel tank capacity:

4.2 L (1.11 US gal, 0.92 Imp.gal)

Fuel reserve amount:

1.0 L (0.26 US gal, 0.22 Imp.gal)

Carburetor:Type × quantity:

MP17 x 1Spark plug(s):Manufacturer/model:

NGK/CR6HSA

Spark plug gap:

0.6–0.7 mm (0.024–0.028 in)Clutch:Clutch type:

Wet, multiple-disc and centrifugal

automaticTransmission:Primary reduction ratio:

3.722 (67/18)

Final drive:

Chain

Secondary reduction ratio:

2.400 (36/15)

Transmission type:

Constant mesh 4-speed

Operation:

Left foot operation

Gear ratio:

1st:

3.166 (38/12)

2nd:

1.941 (33/17)

3rd:

1.380 (29/21)

4th:

1.095 (23/21)

-20 -10 0

10 20 30

40

50 ˚C

SAE 10W-30

SAE 15W-40SAE 20W-40SAE 20W-50

SAE 10W-40SAE 10W-50

U40BE2E0.book Page 1 Wednesday, October 10, 2012 8:01 AM