brake YAMAHA TDM 850 2000 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2000, Model line: TDM 850, Model: YAMAHA TDM 850 2000Pages: 99, PDF Size: 10.69 MB

Page 67 of 99

PERIODIC MAINTENANCE AND MINOR REPAIR

6-21

6

EAU00713

Brake light switch adjustmentThe rear brake light switch is activated

by the brake pedal and is properly ad-

justed when the brake light comes on

just before braking takes effect. To ad-

just the rear brake light switch, hold the

switch body so it does not rotate while

turning the adjusting nut.

Turn the adjusting nut in direction

a to

make the brake light come on earlier.

Turn the adjusting nut in direction

b to

make the brake light come on later.

EAU00715

Checking the front and rear

brake padsA wear indicator is provided on each

brake. This indicator allows checking

of brake pad wear without disassem-

bling the brake. Apply the brake and

inspect the wear indicator. If the indica-

tor is ALMOST in contact with the disc

plate, ask a Yamaha dealer to replace

the pads.

1. Brake light switch

2. Adjusting nut

1. Wear indicator (´ 2)Front

1. Wear indicator (´ 2)Rear

E_4tx_Periodic.fm Page 21 Saturday, October 16, 1999 9:37 AM

Page 68 of 99

PERIODIC MAINTENANCE AND MINOR REPAIR

6-22

6

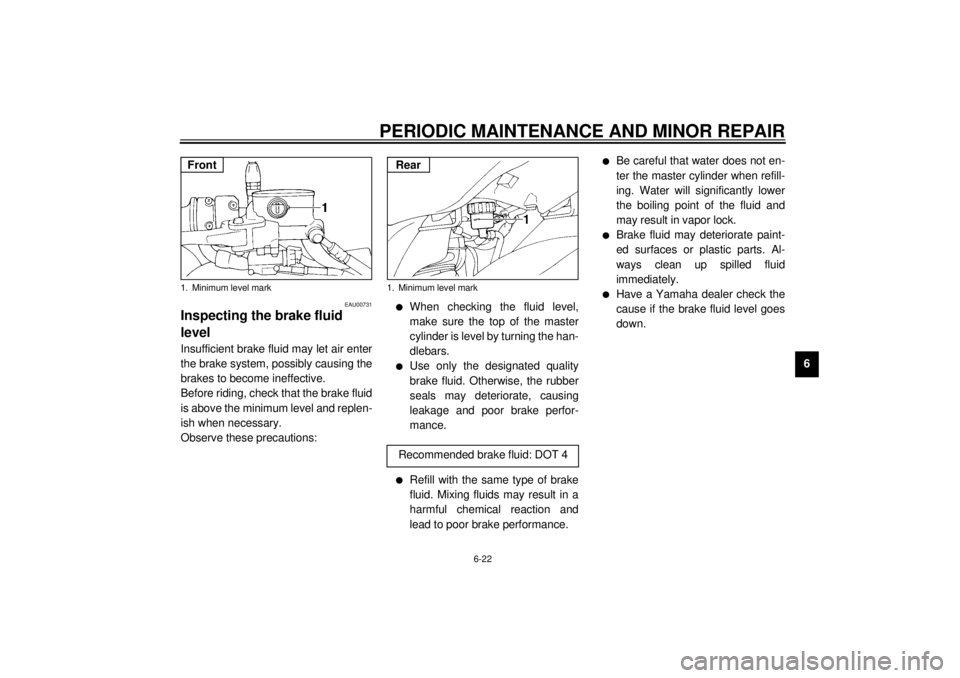

EAU00731

Inspecting the brake fluid

levelInsufficient brake fluid may let air enter

the brake system, possibly causing the

brakes to become ineffective.

Before riding, check that the brake fluid

is above the minimum level and replen-

ish when necessary.

Observe these precautions:

l

When checking the fluid level,

make sure the top of the master

cylinder is level by turning the han-

dlebars.

l

Use only the designated quality

brake fluid. Otherwise, the rubber

seals may deteriorate, causing

leakage and poor brake perfor-

mance.

l

Refill with the same type of brake

fluid. Mixing fluids may result in a

harmful chemical reaction and

lead to poor brake performance.

l

Be careful that water does not en-

ter the master cylinder when refill-

ing. Water will significantly lower

the boiling point of the fluid and

may result in vapor lock.

l

Brake fluid may deteriorate paint-

ed surfaces or plastic parts. Al-

ways clean up spilled fluid

immediately.

l

Have a Yamaha dealer check the

cause if the brake fluid level goes

down.

1. Minimum level markFront

1. Minimum level markRecommended brake fluid: DOT 4Rear

E_4tx_Periodic.fm Page 22 Saturday, October 16, 1999 9:37 AM

Page 69 of 99

PERIODIC MAINTENANCE AND MINOR REPAIR

6-23

6

EAU00742

Brake fluid replacementThe brake fluid should be replaced only

by trained Yamaha service personnel.

Have the Yamaha dealer replace the

following components during periodic

maintenance or when they are dam-

aged or leaking:l

oil seals (every two years)

l

brake hoses (every four years)

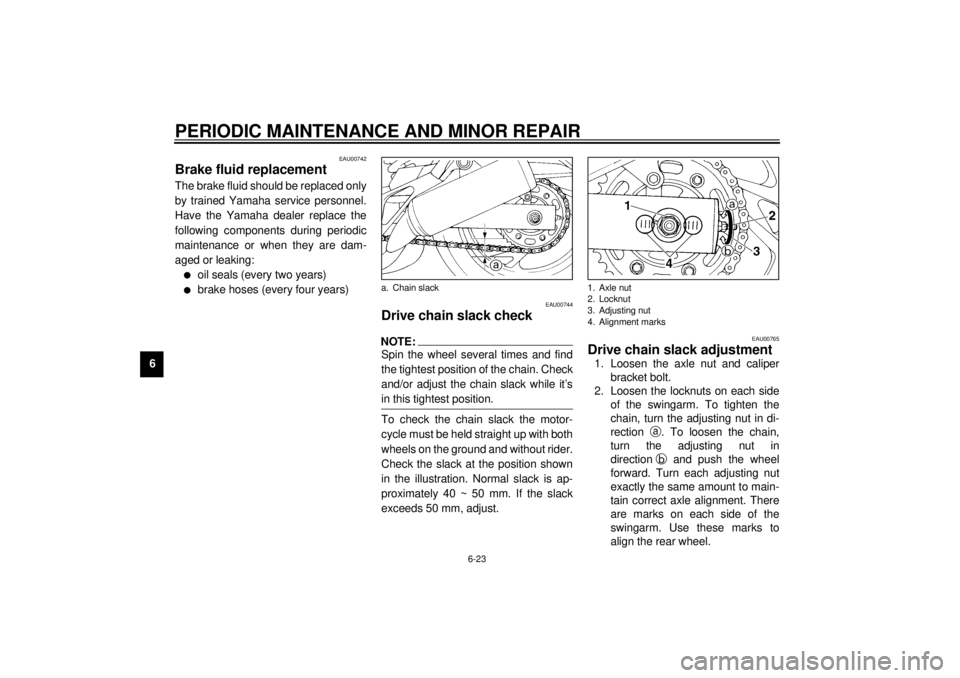

EAU00744

Drive chain slack checkNOTE:@ Spin the wheel several times and find

the tightest position of the chain. Check

and/or adjust the chain slack while it’s

in this tightest position. @To check the chain slack the motor-

cycle must be held straight up with both

wheels on the ground and without rider.

Check the slack at the position shown

in the illustration. Normal slack is ap-

proximately 40 ~ 50 mm. If the slack

exceeds 50 mm, adjust.

EAU00765

Drive chain slack adjustment1. Loosen the axle nut and caliper

bracket bolt.

2. Loosen the locknuts on each side

of the swingarm. To tighten the

chain, turn the adjusting nut in di-

rection

a. To loosen the chain,

turn the adjusting nut in

direction

b and push the wheel

forward. Turn each adjusting nut

exactly the same amount to main-

tain correct axle alignment. There

are marks on each side of the

swingarm. Use these marks to

align the rear wheel.

a. Chain slack

1. Axle nut

2. Locknut

3. Adjusting nut

4. Alignment marks

E_4tx_Periodic.fm Page 23 Saturday, October 16, 1999 9:37 AM

Page 71 of 99

PERIODIC MAINTENANCE AND MINOR REPAIR

6-25

6

EAU00773

Throttle cable and grip

lubricationThe throttle twist grip assembly should

be greased at the time that the cable is

lubricated, since the grip must be re-

moved to get at the end of the throttle

cable. After removing the screws, hold

the end of the cable up in the air and

put in several drops of lubricant. With

the throttle grip disassembled, coat the

metal surface of the grip assembly with

a suitable all-purpose grease.

EAU02984

Brake and shift pedal

lubricationLubricate the pivoting parts.

EAU02985

Brake and clutch lever

lubricationLubricate the pivoting parts.

Recommended lubricant:

Engine oil

Recommended lubricant:

Engine oil

E_4tx_Periodic.fm Page 25 Saturday, October 16, 1999 9:37 AM

Page 73 of 99

PERIODIC MAINTENANCE AND MINOR REPAIR

6-27

6

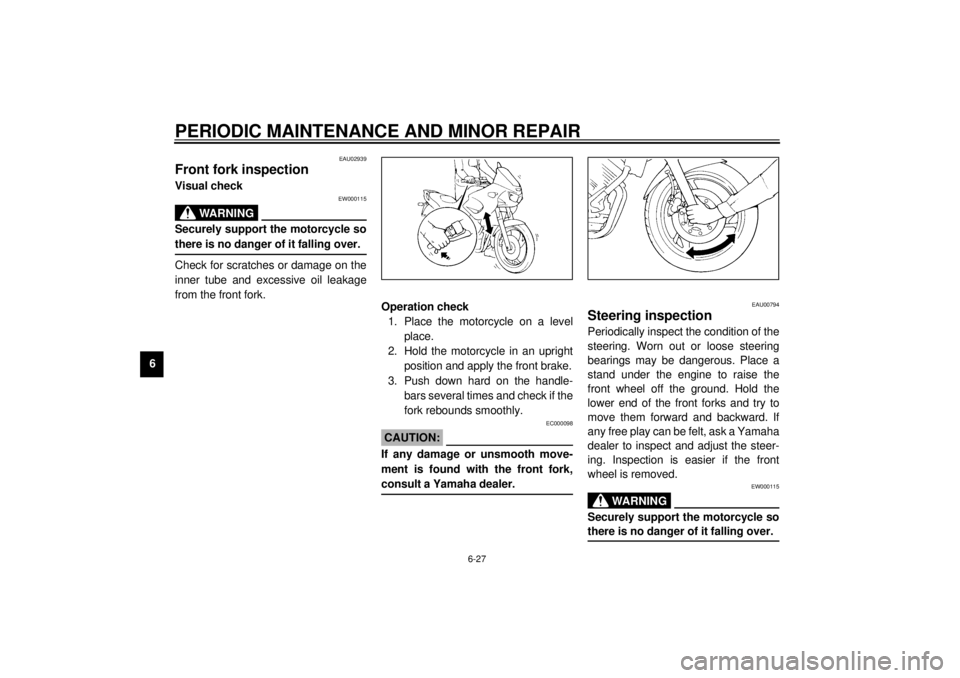

EAU02939

Front fork inspectionVisual check

EW000115

WARNING

@ Securely support the motorcycle so

there is no danger of it falling over. @Check for scratches or damage on the

inner tube and excessive oil leakage

from the front fork.

Operation check

1. Place the motorcycle on a level

place.

2. Hold the motorcycle in an upright

position and apply the front brake.

3. Push down hard on the handle-

bars several times and check if the

fork rebounds smoothly.

EC000098

CAUTION:@ If any damage or unsmooth move-

ment is found with the front fork,

consult a Yamaha dealer. @

EAU00794

Steering inspectionPeriodically inspect the condition of the

steering. Worn out or loose steering

bearings may be dangerous. Place a

stand under the engine to raise the

front wheel off the ground. Hold the

lower end of the front forks and try to

move them forward and backward. If

any free play can be felt, ask a Yamaha

dealer to inspect and adjust the steer-

ing. Inspection is easier if the front

wheel is removed.

EW000115

WARNING

@ Securely support the motorcycle so

there is no danger of it falling over. @

E_4tx_Periodic.fm Page 27 Saturday, October 16, 1999 9:37 AM

Page 77 of 99

PERIODIC MAINTENANCE AND MINOR REPAIR

6-31

64. Install the bulb holder cover and

reconnect the headlight connec-

tors. If the headlight beam adjust-

ment is necessary, ask a Yamaha

dealer to make that adjustment.

EAU01623*

Tail/brake light bulb

replacement1. Remove the screws and the lens.

2. Remove the defective bulb by

pushing it inward and turning it

counterclockwise.

3. Install a new bulb by pushing it in-

ward and turning it clockwise.

4. Install the lens and tighten the

screws.

EC000108

CAUTION:@ Do not over-tighten the screws as

the lens may break. @1. Screw (´ 2)

2. Lens

1. Bulb (´ 2)

E_4tx_Periodic.fm Page 31 Saturday, October 16, 1999 9:37 AM

Page 84 of 99

MOTORCYCLE CARE AND STORAGE

7-2

7

ECA00010

CAUTION:@ l

Avoid using strong acidic wheel

cleaners, especially on spoked

wheels. If you do use such

products for hard-to-remove

dirt, do not leave it on any long-

er than instructed, then thor-

oughly rinse it off with water,

immediately dry the area and

apply a corrosion protection

spray.

l

Improper cleaning can damage

windshields, cowlings, panels

and other plastic parts. Use

only a soft, clean cloth or

sponge with mild detergent and

water to clean plastic.

l

Do not use any harsh chemical

products on plastic parts. Be

sure to avoid using cloths or

sponges which have been in

contact with strong or abrasive

cleaning products, solvent or

thinner, fuel (gasoline), rust re-

movers or inhibitors, brake flu-

id, antifreeze or electrolyte.

l

Do not use high-pressure wash-

ers or steam-jet cleaners since

they cause water seepage and

deterioration in the following ar-

eas: seals (of wheel bearings,

swingarm bearings, forks and

brakes), electric components

(couplers, connectors, instru-

ments, switches and lights),

breather hoses and vents.

l

For motorcycles equipped with

a windshield: Do not use strong

cleaners or hard sponges as

they will cause dulling or

scratching. Some cleaning

compounds for plastic may

leave scratches on the wind-

shield. Test the product on a

small hidden part of the wind-

shield to make sure they do not

leave any marks. If the wind-

shield is scratched, use a quali-

ty plastic polishing compound

after washing.

@After riding in the rain, near the sea oron salt-sprayed roadsSince sea salt or salt sprayed on the

roads in the winter are extremely corro-

sive in combination with water, carry

out the following steps after each ride

in the rain, near the sea or on salt-

sprayed roads. (Salt sprayed in the

winter may remain on the roads well

into spring.)

E_4tx_Cleaning.fm Page 2 Saturday, October 16, 1999 9:38 AM

Page 85 of 99

MOTORCYCLE CARE AND STORAGE

7-3

71. Clean your motorcycle with cold

water and soap after the engine

has cooled down.

ECA00012

CAUTION:@ Do not use warm water since it in-

creases the corrosive action of the

salt. @2. Be sure to apply a corrosion pro-

tection spray on all (even chrome-

and nickel-plated) metal surfaces

to prevent corrosion.After cleaning

1. Dry the motorcycle with a chamois

or an absorbing cloth.

2. Immediately dry the drive chain

and lubricate it to prevent it from

rusting.

3. Use a chrome polish to shine

chrome, aluminum and stainless-

steel parts, including the exhaust

system. (Even the thermally in-

duced discoloring of stainless-

steel exhaust systems can be re-

moved through polishing.)

4. To prevent corrosion, it is recom-

mended to apply a corrosion pro-

tection spray on all (even chrome-

and nickel-plated) metal surfaces.

5. Use spray oil as a universal clean-

er to remove any remaining dirt.

6. Touch up minor paint damage

caused by stones, etc.

7. Wax all painted surfaces.

8. Let the motorcycle dry completely

before storing it or covering it.

EWA00001

WARNING

@ Make sure that there is no oil or wax

on the brakes and tires. If neces-

sary, clean the brake discs and lin-

ings with a regular brake disc

cleaner or acetone, and wash the

tires with warm water and mild soap.

Then, carefully test the motorcycle

for its braking performance and cor-

nering behavior. @

E_4tx_Cleaning.fm Page 3 Saturday, October 16, 1999 9:38 AM

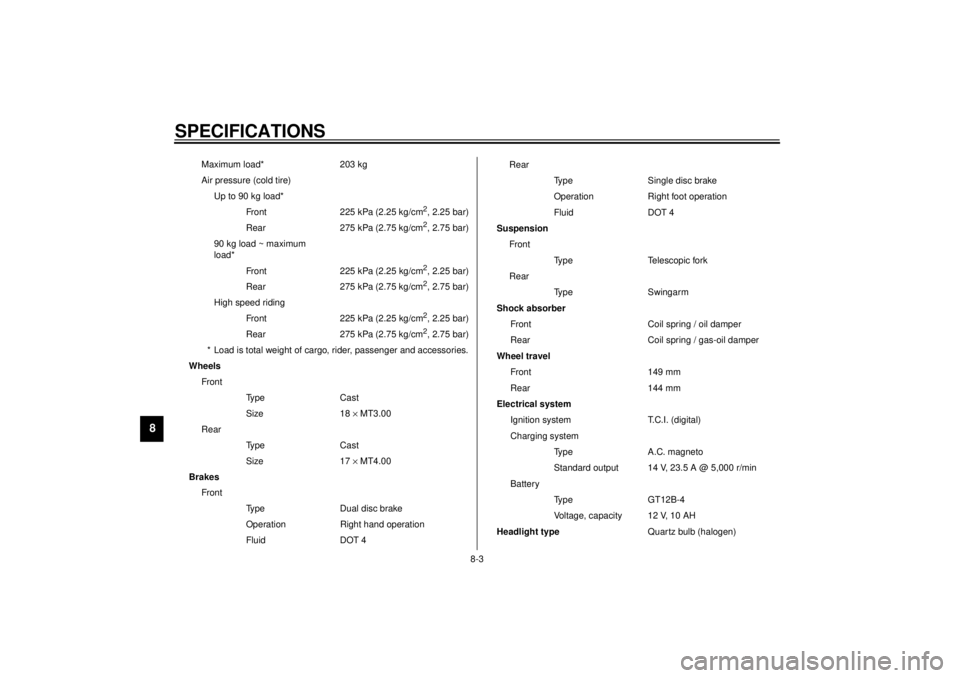

Page 91 of 99

SPECIFICATIONS

8-3

8

Maximum load* 203 kg

Air pressure (cold tire)

Up to 90 kg load*

Front 225 kPa (2.25 kg/cm

2, 2.25 bar)

Rear 275 kPa (2.75 kg/cm2, 2.75 bar)

90 kg load ~ maximum

load*

Front 225 kPa (2.25 kg/cm2, 2.25 bar)

Rear 275 kPa (2.75 kg/cm2, 2.75 bar)

High speed riding

Front 225 kPa (2.25 kg/cm2, 2.25 bar)

Rear 275 kPa (2.75 kg/cm2, 2.75 bar)

* Load is total weight of cargo, rider, passenger and accessories.

Wheels

Front

Ty p e C a s t

Size 18 ´ MT3.00

Rear

Ty p e C a s t

Size 17 ´ MT4.00

Brakes

Front

Type Dual disc brake

Operation Right hand operation

Fluid DOT 4Rear

Type Single disc brake

Operation Right foot operation

Fluid DOT 4

Suspension

Front

Ty p e Te l e s c o p i c f o r k

Rear

Type Swingarm

Shock absorber

Front Coil spring / oil damper

Rear Coil spring / gas-oil damper

Wheel travel

Front 149 mm

Rear 144 mm

Electrical system

Ignition system T.C.I. (digital)

Charging system

Type A.C. magneto

Standard output 14 V, 23.5 A @ 5,000 r/min

Battery

Type GT12B-4

Voltage, capacity 12 V, 10 AH

Headlight typeQuartz bulb (halogen)

E_4tx_Spec.fm Page 3 Saturday, October 16, 1999 9:38 AM

Page 92 of 99

SPECIFICATIONS

8-4

8

Bulb voltage, wattage ´ quantity

Headlight 12 V, 55 W ´ 2

Auxiliary light 12 V, 5 W ´ 1

Tail/brake light 12 V, 5/21 W ´ 2

Turn signal light 12 V, 21 W ´ 4

Meter light 12 V, 2 W ´ 3

Neutral indicator light 14 V, 1.4 W ´ 1

High beam indicator light 14 V, 1.4 W ´ 1

Turn indicator light 14 V, 1.4 W ´ 2

Coolant temperature

indicator light 14 V, 1.4 W ´ 1

Fuel indicator light 12 V, 2 W ´ 1

Fuses

Main fuse 30 A

Headlight fuse 15 A

Signaling system fuse 15 A

Ignition fuse 10 A

Hazard light fuse 10 A

Odometer fuse 5 A

Radiator fan fuse 7.5 A

E_4tx_Spec.fm Page 4 Saturday, October 16, 1999 9:38 AM