lock YAMAHA TDM 850 2000 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2000, Model line: TDM 850, Model: YAMAHA TDM 850 2000Pages: 99, PDF Size: 10.69 MB

Page 29 of 99

INSTRUMENT AND CONTROL FUNCTIONS

3-15

3

EAU01768*

Rear shock absorber

adjustmentThis shock absorber is equipped with

two spring preload adjusters and one

damping force adjuster.

Spring preload

Coarse adjustment (top)Use the special tool in the owner’s tool

kit to turn the lever to “S” when riding

solo and to “H” when riding with a pas-

senger.Fine adjustment (bottom)

Proceed as follows to suit road condi-

tions and the rider’s preference.

1. Loosen the locknut.

2. Turn the adjusting nut in direction

a

to increase spring preload and in di-

rection

b to decrease spring pre-

load.

1. Adjusting lever

1. Locknut

2. Adjusting nut

a. Distance “A”

Spring preload:

Minimum (soft):

Distance “A” = 59 mm

Standard:

Distance “A” = 61 mm

Maximum (hard):

Distance “A” = 63 mm

E_4tx_Functions.fm Page 15 Saturday, October 16, 1999 9:36 AM

Page 30 of 99

INSTRUMENT AND CONTROL FUNCTIONS

3-16

3 3. Tighten the locknut to the speci-

fied torque.

EC000018

CAUTION:@ Always tighten the locknut against

the spring adjusting nut and tighten

the locknut to the specified torque. @

Damping force adjustment

Turn the adjusting knob in direction

a

to increase damping force and in direc-

tion

b to decrease damping force.CI-29E

EC000015CAUTION:@ Never attempt to turn an adjuster

beyond the maximum or minimum

setting. @

EAU00315

WARNING

@ This shock absorber contains high-

ly pressurized nitrogen gas. Read

and understand the following infor-

mation before handling the shock

absorber. The manufacturer cannot

be held responsible for property

damage or personal injury that may

result from improper handling.l

Do not tamper with or attempt to

open the cylinder assembly.

l

Do not subject the shock ab-

sorber to an open flame or other

high heat source. This may

cause the unit to explode due to

excessive gas pressure.

l

Do not deform or damage the

cylinder in any way. Cylinder

damage will result in poor

damping performance.

l

Take your shock absorber to a

Yamaha dealer for any service.

@

Tightening torque:

Locknut:

70 Nm (7.0 m·kg)

1. Adjusting knobMinimum (soft) 20 clicks out*

Standard 10 clicks out*

Maximum (hard) 0 click out*

* From the fully turned-in position

E_4tx_Functions.fm Page 16 Saturday, October 16, 1999 9:36 AM

Page 31 of 99

INSTRUMENT AND CONTROL FUNCTIONS

3-17

3

EAU00324

Luggage strap holdersThere are four luggage strap holders

below the passenger seat, two of which

can be turned outward for easier ac-

cess.

EAU00330

SidestandThis model is equipped with an ignition

circuit cut-off system. The motorcycle

must not be ridden when the sidestand

is down. The sidestand is located on

the left side of the frame. (Refer to

page 5-1 for an explanation of this sys-

tem.)

EW000044

WARNING

@ This motorcycle must not be operat-

ed with the sidestand in the down

position. If the stand is not properly

retracted, it could contact the

ground and distract the operator, re-

sulting in a possible loss of control.

Yamaha has designed into this

motorcycle a lockout system to as-

sist the operator in fulfilling the re-

sponsibility of retracting the

sidestand. Please check carefully

the operating instructions listed be-

low and if there is any indication of a

malfunction, return the motorcycle

to a Yamaha dealer immediately for

repair. @

EAU00331

Sidestand/clutch switch

operation checkCheck the operation of the sidestand

switch and clutch switch against the in-

formation below.CD-11E

1. Luggage strap holder (´ 4)

TURN THE MAIN SWITCH TO “ON”

AND THE ENGINE STOP SWITCH TO

“”.TRANSMISSION IS IN GEAR AND

SIDESTAND IS UP.PULL IN CLUTCH LEVER AND

PUSH THE START SWITCH.ENGINE WILL START.CLUTCH SWITCH IS OK.

E_4tx_Functions.fm Page 17 Saturday, October 16, 1999 9:36 AM

Page 65 of 99

PERIODIC MAINTENANCE AND MINOR REPAIR

6-19

6

CE-10E

CE-12EEAU00684

WARNING

@ This motorcycle is fitted with super

high-speed running tires. The fol-

lowing points must be observed in

order for you to make fully effective

use of these tires.l

Never fail to use the specified

tires in tire replacement. Other

tires may have a danger of

bursting at super high-speeds.

l

New tires have a relatively low

grip on the road surface until

they have been slightly worn.

Therefore, approximately 100 km

should be traveled at normal

speed before any high-speed

riding is done.

l

Before any high-speed runs, the

tires should be warmed-up suf-

ficiently.

l

Always inflate to the correct tire

pressure according to the oper-

ating conditions.

@

EAU00692

Clutch lever free play

adjustmentThe clutch lever free play should be ad-

justed to 10 ~ 15 mm. If the free play is

incorrect, adjust as follows.

1. Loosen the locknut.

2. Turn the adjusting bolt at the

clutch lever in direction

a to in-

crease free play or in direction

b

to decrease free play.

3. Tighten the locknut.

1. Tire valve

2. Valve core

3. Valve cap with sealFRONT

Manufacturer Size Type

Bridgestone 110/80 ZR18 (58W) BT-54F

Pirelli 110/80 ZR18 (58W) MTR03

Michelin 110/80 ZR18 (58W) MACADAM 90X

REAR

Manufacturer Size Type

Bridgestone 150/70 ZR17 (69W) BT-54R

Pirelli 150/70 ZR17 (69W) MTR04

Michelin 150/70 ZR17 (69W) MACADAM 90X

Type

Tire valve TR412

Valve core #9000A (original)

1. Locknut

2. Adjusting bolt

c. Free play

E_4tx_Periodic.fm Page 19 Saturday, October 16, 1999 9:37 AM

Page 68 of 99

PERIODIC MAINTENANCE AND MINOR REPAIR

6-22

6

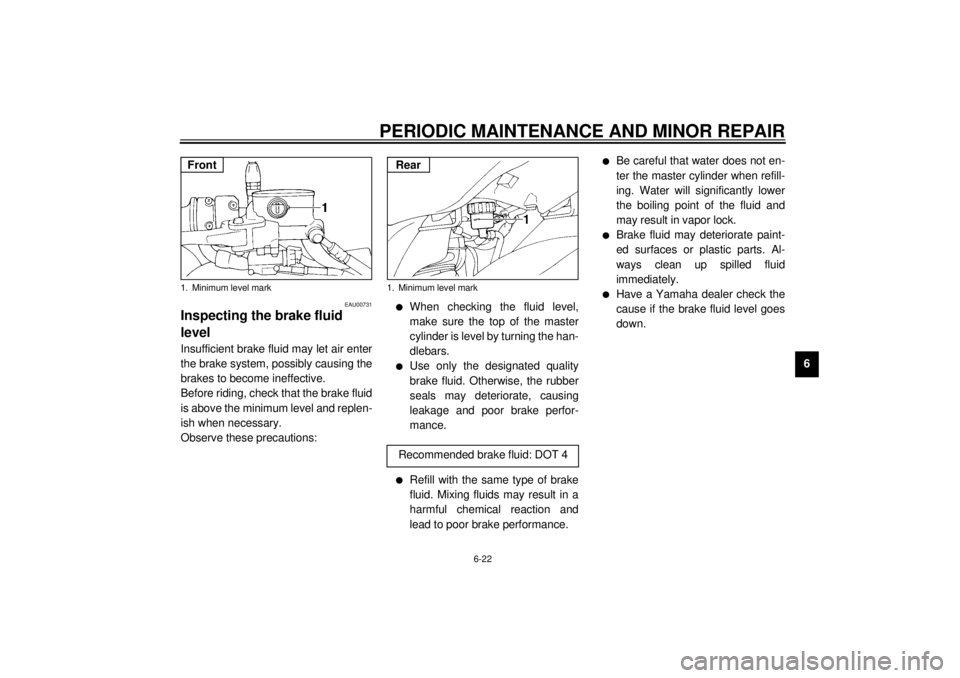

EAU00731

Inspecting the brake fluid

levelInsufficient brake fluid may let air enter

the brake system, possibly causing the

brakes to become ineffective.

Before riding, check that the brake fluid

is above the minimum level and replen-

ish when necessary.

Observe these precautions:

l

When checking the fluid level,

make sure the top of the master

cylinder is level by turning the han-

dlebars.

l

Use only the designated quality

brake fluid. Otherwise, the rubber

seals may deteriorate, causing

leakage and poor brake perfor-

mance.

l

Refill with the same type of brake

fluid. Mixing fluids may result in a

harmful chemical reaction and

lead to poor brake performance.

l

Be careful that water does not en-

ter the master cylinder when refill-

ing. Water will significantly lower

the boiling point of the fluid and

may result in vapor lock.

l

Brake fluid may deteriorate paint-

ed surfaces or plastic parts. Al-

ways clean up spilled fluid

immediately.

l

Have a Yamaha dealer check the

cause if the brake fluid level goes

down.

1. Minimum level markFront

1. Minimum level markRecommended brake fluid: DOT 4Rear

E_4tx_Periodic.fm Page 22 Saturday, October 16, 1999 9:37 AM

Page 69 of 99

PERIODIC MAINTENANCE AND MINOR REPAIR

6-23

6

EAU00742

Brake fluid replacementThe brake fluid should be replaced only

by trained Yamaha service personnel.

Have the Yamaha dealer replace the

following components during periodic

maintenance or when they are dam-

aged or leaking:l

oil seals (every two years)

l

brake hoses (every four years)

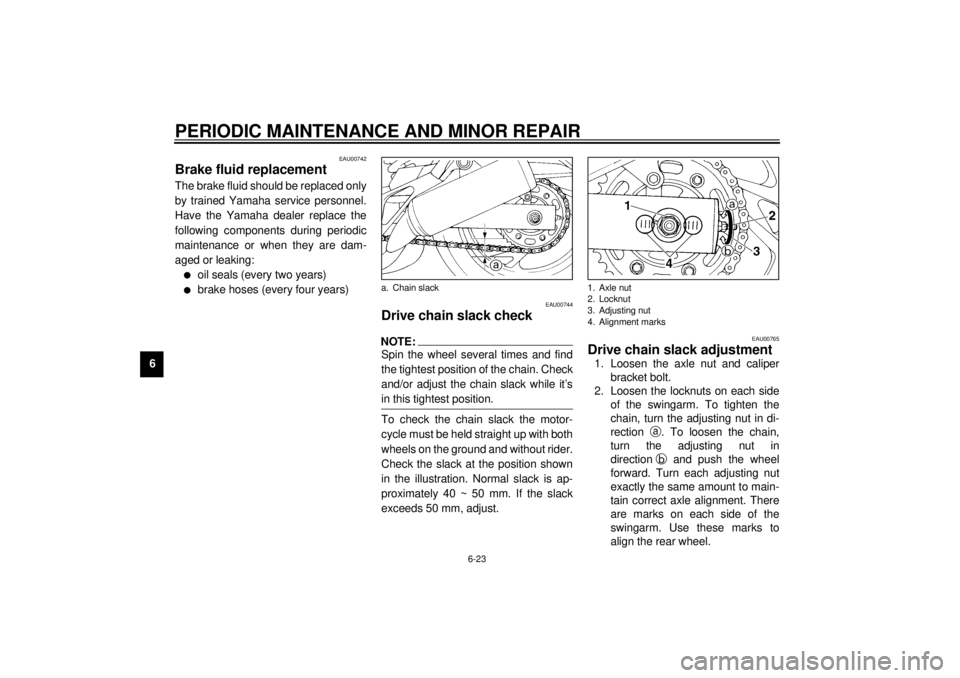

EAU00744

Drive chain slack checkNOTE:@ Spin the wheel several times and find

the tightest position of the chain. Check

and/or adjust the chain slack while it’s

in this tightest position. @To check the chain slack the motor-

cycle must be held straight up with both

wheels on the ground and without rider.

Check the slack at the position shown

in the illustration. Normal slack is ap-

proximately 40 ~ 50 mm. If the slack

exceeds 50 mm, adjust.

EAU00765

Drive chain slack adjustment1. Loosen the axle nut and caliper

bracket bolt.

2. Loosen the locknuts on each side

of the swingarm. To tighten the

chain, turn the adjusting nut in di-

rection

a. To loosen the chain,

turn the adjusting nut in

direction

b and push the wheel

forward. Turn each adjusting nut

exactly the same amount to main-

tain correct axle alignment. There

are marks on each side of the

swingarm. Use these marks to

align the rear wheel.

a. Chain slack

1. Axle nut

2. Locknut

3. Adjusting nut

4. Alignment marks

E_4tx_Periodic.fm Page 23 Saturday, October 16, 1999 9:37 AM

Page 77 of 99

PERIODIC MAINTENANCE AND MINOR REPAIR

6-31

64. Install the bulb holder cover and

reconnect the headlight connec-

tors. If the headlight beam adjust-

ment is necessary, ask a Yamaha

dealer to make that adjustment.

EAU01623*

Tail/brake light bulb

replacement1. Remove the screws and the lens.

2. Remove the defective bulb by

pushing it inward and turning it

counterclockwise.

3. Install a new bulb by pushing it in-

ward and turning it clockwise.

4. Install the lens and tighten the

screws.

EC000108

CAUTION:@ Do not over-tighten the screws as

the lens may break. @1. Screw (´ 2)

2. Lens

1. Bulb (´ 2)

E_4tx_Periodic.fm Page 31 Saturday, October 16, 1999 9:37 AM

Page 78 of 99

PERIODIC MAINTENANCE AND MINOR REPAIR

6-32

6

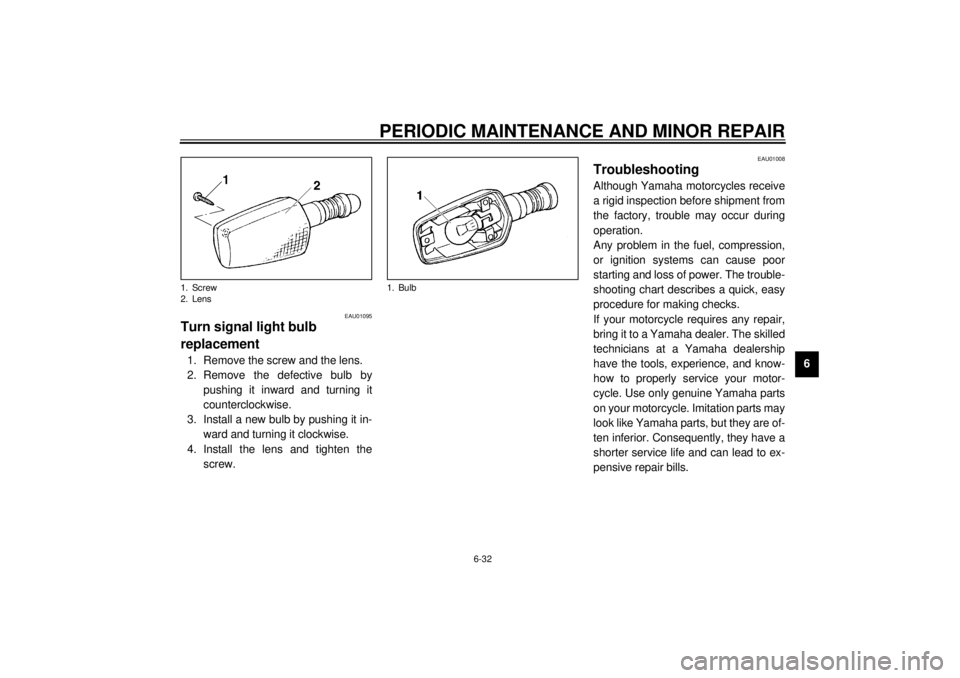

EAU01095

Turn signal light bulb

replacement1. Remove the screw and the lens.

2. Remove the defective bulb by

pushing it inward and turning it

counterclockwise.

3. Install a new bulb by pushing it in-

ward and turning it clockwise.

4. Install the lens and tighten the

screw.

EAU01008

TroubleshootingAlthough Yamaha motorcycles receive

a rigid inspection before shipment from

the factory, trouble may occur during

operation.

Any problem in the fuel, compression,

or ignition systems can cause poor

starting and loss of power. The trouble-

shooting chart describes a quick, easy

procedure for making checks.

If your motorcycle requires any repair,

bring it to a Yamaha dealer. The skilled

technicians at a Yamaha dealership

have the tools, experience, and know-

how to properly service your motor-

cycle. Use only genuine Yamaha parts

on your motorcycle. Imitation parts may

look like Yamaha parts, but they are of-

ten inferior. Consequently, they have a

shorter service life and can lead to ex-

pensive repair bills.

1. Screw

2. Lens

1. Bulb

E_4tx_Periodic.fm Page 32 Saturday, October 16, 1999 9:37 AM

Page 80 of 99

PERIODIC MAINTENANCE AND MINOR REPAIR

6-34

6

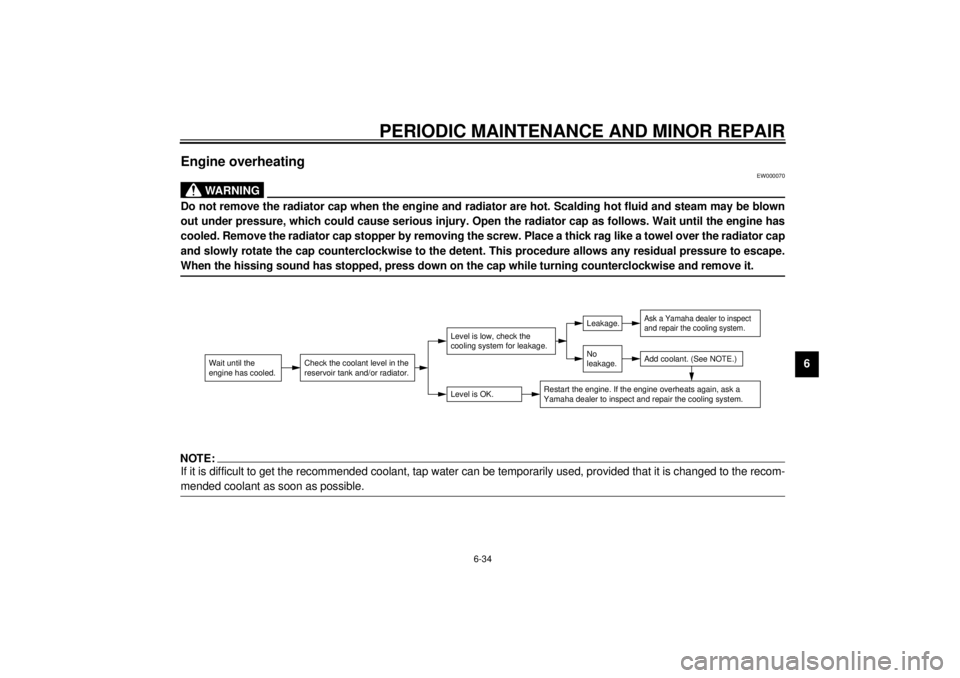

Engine overheating

EW000070

WARNING

@ Do not remove the radiator cap when the engine and radiator are hot. Scalding hot fluid and steam may be blown

out under pressure, which could cause serious injury. Open the radiator cap as follows. Wait until the engine has

cooled. Remove the radiator cap stopper by removing the screw. Place a thick rag like a towel over the radiator cap

and slowly rotate the cap counterclockwise to the detent. This procedure allows any residual pressure to escape.

When the hissing sound has stopped, press down on the cap while turning counterclockwise and remove it. @NOTE:@ If it is difficult to get the recommended coolant, tap water can be temporarily used, provided that it is changed to the recom-

mended coolant as soon as possible. @

Wait until the

engine has cooled.

Check the coolant level in the

reservoir tank and/or radiator.

Level is OK.Level is low, check the

cooling system for leakage.

No

leakage.Leakage.

Ask a Yamaha dealer to inspect

and repair the cooling system.Add coolant. (See NOTE.)

Restart the engine. If the engine overheats again, ask a

Yamaha dealer to inspect and repair the cooling system.

E_4tx_Periodic.fm Page 34 Saturday, October 16, 1999 9:37 AM

Page 97 of 99

10-INDEXAAir filter .................................................. 6-13

Antitheft alarm (optional) ..........................3-5BBattery ................................................... 6-28

Brake and clutch lever lubrication........... 6-25

Brake and shift pedal lubrication ............ 6-25

Brake fluid replacement ......................... 6-23

Brake light switch adjustment ................. 6-21CCable inspection and lubrication ............ 6-24

Carburetor adjustment ........................... 6-15

Care.........................................................7-1

Changing the coolant ............................. 6-11

Checking the front and

rear brake pads ................................... 6-21

Clutch lever ..............................................3-8

Clutch lever free play adjustment ........... 6-19

Controls/Instruments ................................2-3

Coolant temperature indicator light...........3-2

Cooling system ...................................... 6-10

Cowling and panel removal and

installation .............................................6-5

Cowlings A and B ....................................6-5DDiagnosis device......................................3-5

Dimmer switch .........................................3-6

Drive chain lubrication ............................ 6-24

Drive chain slack adjustment.................. 6-23

Drive chain slack check.......................... 6-23

EEngine break-in ....................................... 5-5

Engine oil ................................................ 6-8

Engine overheating ................................. 6-34

Engine stop switch................................... 3-7FFront brake lever ..................................... 3-9

Front fork adjustment............................. 3-14

Front fork inspection .............................. 6-27

Fuel ....................................................... 3-11

Fuel gauge .............................................. 3-5

Fuel indicator light ................................... 3-3

Fuel tank breather hose

(for Germany only) .............................. 3-12

Fuel tank cap ......................................... 3-10

Fuse replacement.................................. 6-29GGive safety the right of way ..................... 1-1HHandlebar switches ................................. 3-6

Dimmer switch ................................... 3-6

Engine stop switch ............................. 3-7

Hazard switch .................................... 3-6

Horn switch ........................................ 3-6

Lights switch ...................................... 3-7

Pass switch ........................................ 3-6

Start switch ........................................ 3-7

Turn signal switch .............................. 3-6

Hazard switch .......................................... 3-6

Headlight bulb replacement ................... 6-30

Helmet holder ........................................ 3-13

High beam indicator light ..........................3-2

Horn switch ..............................................3-6IIdentification number records ...................9-1

Idle speed adjustment ............................6-15

Indicator lights ..........................................3-2

Coolant temperature indicator light .....3-2

Fuel indicator light...............................3-3

High beam indicator light ....................3-2

Neutral indicator light ..........................3-2

Turn indicator lights ............................3-2

Inspecting the brake fluid level ...............6-22KKey identification number .........................9-1LLeft view...................................................2-1

Lights switch ............................................3-7

Luggage strap holders ...........................3-17MMain switch/steering lock .........................3-1

Model label ..............................................9-2NNeutral indicator light ...............................3-2PPanels A and B ........................................6-6

Parking.....................................................5-6

Pass switch ..............................................3-6

Periodic maintenance and lubrication .......6-2

Pre-operation check list ............................4-1

E_4txIX.fm Page 1 Saturday, October 16, 1999 9:38 AM