lock YAMAHA TDM 850 2001 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: TDM 850, Model: YAMAHA TDM 850 2001Pages: 110, PDF Size: 12.15 MB

Page 27 of 110

INSTRUMENT AND CONTROL FUNCTIONS

3-12

3

EW000030

WARNING

@ Never ride with a helmet attached to

the helmet holder, since the helmet

may hit objects, causing loss of

control and possibly an accident. @To release the helmet from the hel-

met holder

Remove the seat, remove the helmet

from the helmet holder, and then install

the seat.

EAU01688

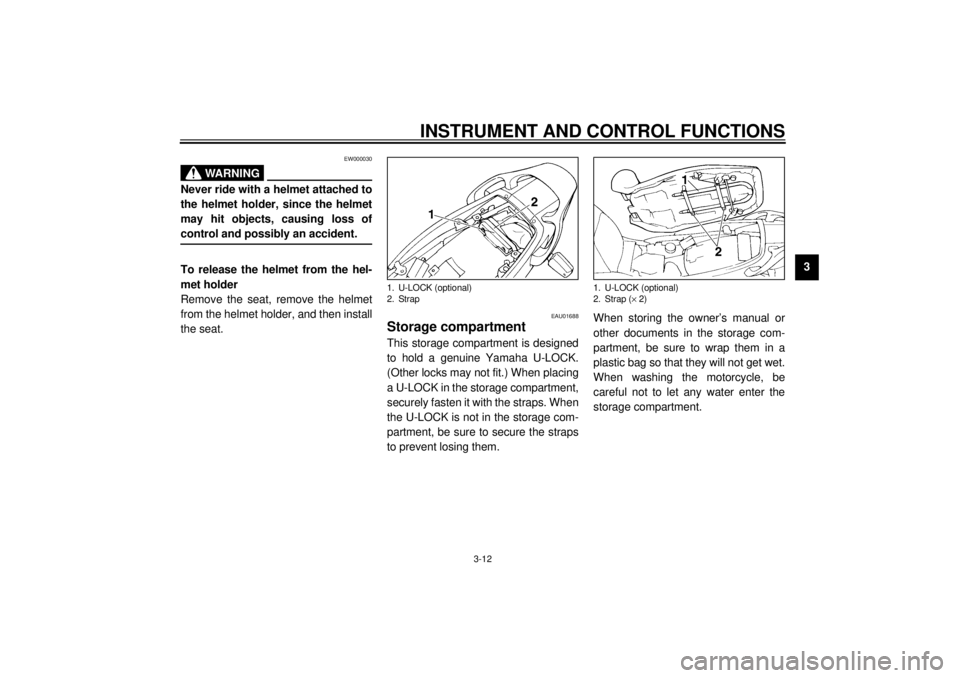

Storage compartment This storage compartment is designed

to hold a genuine Yamaha U-LOCK.

(Other locks may not fit.) When placing

a U-LOCK in the storage compartment,

securely fasten it with the straps. When

the U-LOCK is not in the storage com-

partment, be sure to secure the straps

to prevent losing them.When storing the owner’s manual or

other documents in the storage com-

partment, be sure to wrap them in a

plastic bag so that they will not get wet.

When washing the motorcycle, be

careful not to let any water enter the

storage compartment. 1. U-LOCK (optional)

2. Strap

1. U-LOCK (optional)

2. Strap (´ 2)

E_4tx.book Page 12 Wednesday, October 4, 2000 4:28 PM

Page 30 of 110

INSTRUMENT AND CONTROL FUNCTIONS

3-15

3

EAU03834

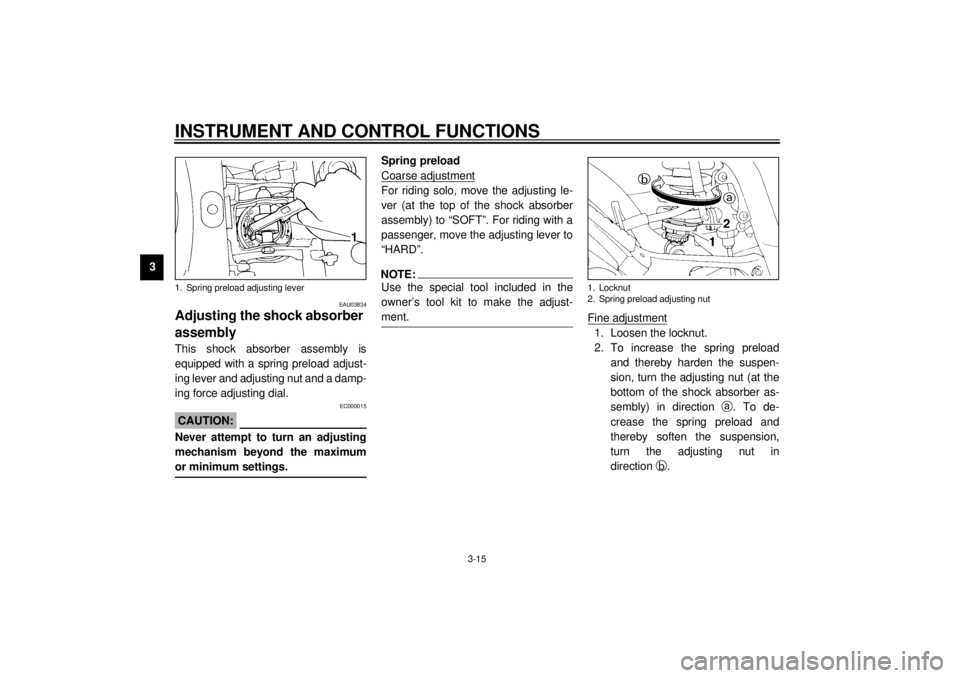

Adjusting the shock absorber

assembly This shock absorber assembly is

equipped with a spring preload adjust-

ing lever and adjusting nut and a damp-

ing force adjusting dial.

EC000015

CAUTION:_ Never attempt to turn an adjusting

mechanism beyond the maximum

or minimum settings. _

Spring preload

Coarse adjustmentFor riding solo, move the adjusting le-

ver (at the top of the shock absorber

assembly) to “SOFT”. For riding with a

passenger, move the adjusting lever to

“HARD”. NOTE:_ Use the special tool included in the

owner’s tool kit to make the adjust-

ment. _

Fine adjustment1. Loosen the locknut.

2. To increase the spring preload

and thereby harden the suspen-

sion, turn the adjusting nut (at the

bottom of the shock absorber as-

sembly) in direction

a. To de-

crease the spring preload and

thereby soften the suspension,

turn the adjusting nut in

direction

b.

1. Spring preload adjusting lever

1. Locknut

2. Spring preload adjusting nut

E_4tx.book Page 15 Wednesday, October 4, 2000 4:28 PM

Page 31 of 110

INSTRUMENT AND CONTROL FUNCTIONS

3-16

3

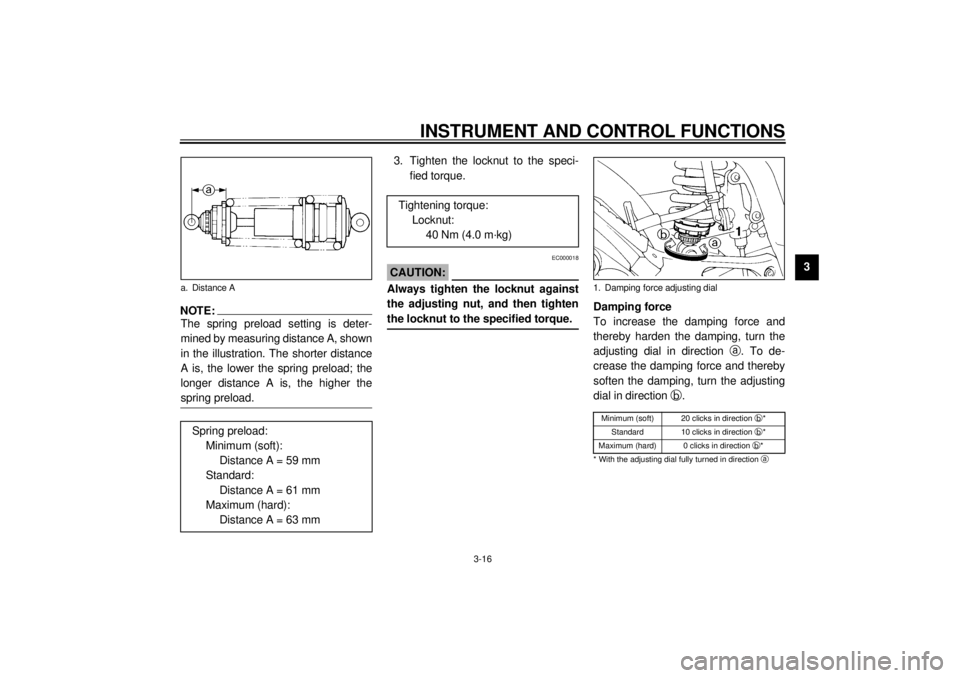

NOTE:_ The spring preload setting is deter-

mined by measuring distance A, shown

in the illustration. The shorter distance

A is, the lower the spring preload; the

longer distance A is, the higher the

spring preload. _

3. Tighten the locknut to the speci-

fied torque.

EC000018

CAUTION:_ Always tighten the locknut against

the adjusting nut, and then tighten

the locknut to the specified torque. _

Damping force

To increase the damping force and

thereby harden the damping, turn the

adjusting dial in direction

a. To de-

crease the damping force and thereby

soften the damping, turn the adjusting

dial in direction

b.CI-04E

a. Distance A

Spring preload:

Minimum (soft):

Distance A = 59 mm

Standard:

Distance A = 61 mm

Maximum (hard):

Distance A = 63 mm

Tightening torque:

Locknut:

40 Nm (4.0 m·kg)

1. Damping force adjusting dialMinimum (soft) 20 clicks in direction

b*

Standard 10 clicks in direction

b*

Maximum (hard) 0 clicks in direction

b*

* With the adjusting dial fully turned in direction

a

E_4tx.book Page 16 Wednesday, October 4, 2000 4:28 PM

Page 68 of 110

PERIODIC MAINTENANCE AND MINOR REPAIR

6-23

6

EAU00692

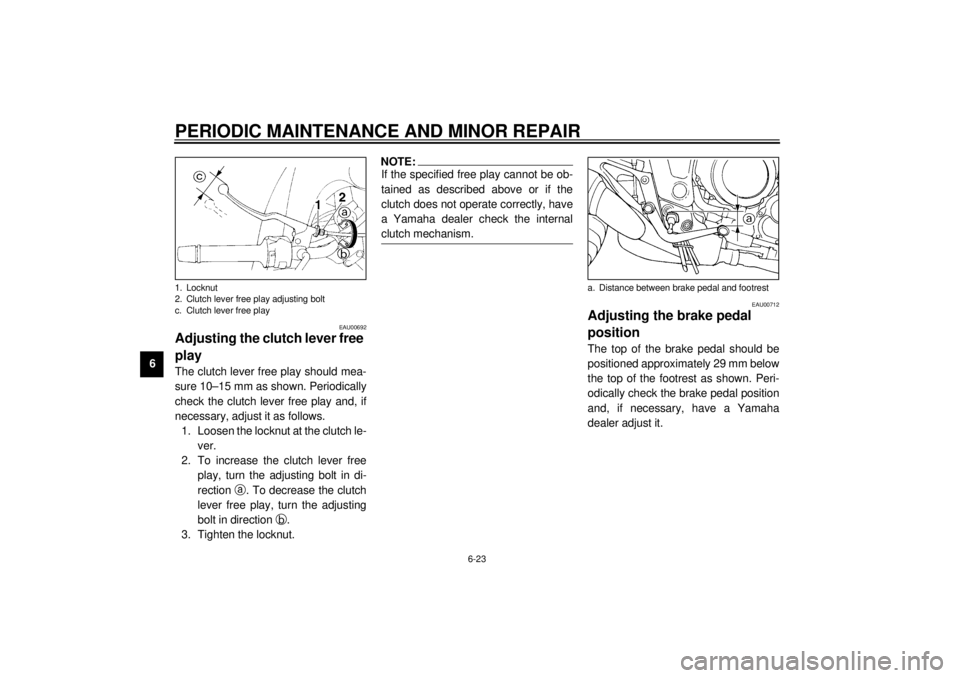

Adjusting the clutch lever free

play The clutch lever free play should mea-

sure 10–15 mm as shown. Periodically

check the clutch lever free play and, if

necessary, adjust it as follows.

1. Loosen the locknut at the clutch le-

ver.

2. To increase the clutch lever free

play, turn the adjusting bolt in di-

rection

a. To decrease the clutch

lever free play, turn the adjusting

bolt in direction

b.

3. Tighten the locknut.

NOTE:@ If the specified free play cannot be ob-

tained as described above or if the

clutch does not operate correctly, have

a Yamaha dealer check the internal

clutch mechanism. @

EAU00712

Adjusting the brake pedal

position The top of the brake pedal should be

positioned approximately 29 mm below

the top of the footrest as shown. Peri-

odically check the brake pedal position

and, if necessary, have a Yamaha

dealer adjust it.

1. Locknut

2. Clutch lever free play adjusting bolt

c. Clutch lever free play

a. Distance between brake pedal and footrest

E_4tx.book Page 23 Wednesday, October 4, 2000 4:28 PM

Page 71 of 110

PERIODIC MAINTENANCE AND MINOR REPAIR

6-26

6 Observe these precautions:

l

When checking the fluid level,

make sure that the top of the brake

fluid reservoir is level.

l

Use only the recommended quali-

ty brake fluid, otherwise the rubber

seals may deteriorate, causing

leakage and poor braking perfor-

mance.

l

Refill with the same type of brake

fluid. Mixing fluids may result in a

harmful chemical reaction and

lead to poor braking performance.

l

Be careful that water does not en-

ter the brake fluid reservoir when

refilling. Water will significantly

lower the boiling point of the fluid

and may result in vapor lock.

l

Brake fluid may deteriorate paint-

ed surfaces or plastic parts. Al-

ways clean up spilled fluid

immediately.

l

As the brake pads wear, it is nor-

mal for the brake fluid level to

gradually go down. However, if the

brake fluid level goes down sud-

denly, have a Yamaha dealer

check the cause.

EAU03238

Changing the brake fluid Have a Yamaha dealer change the

brake fluid at the intervals specified in

the periodic maintenance and lubrica-

tion chart. In addition, have the oil seals

of the brake master cylinder and caliper

as well as the brake hose replaced at

the intervals listed below or whenever

they are damaged or leaking.l

Oil seals: Replace every two

years.

l

Brake hose: Replace every four

years.

1. Minimum level mark

Recommended brake fluid: DOT 4Rear brake

E_4tx.book Page 26 Wednesday, October 4, 2000 4:28 PM

Page 72 of 110

PERIODIC MAINTENANCE AND MINOR REPAIR

6-27

6

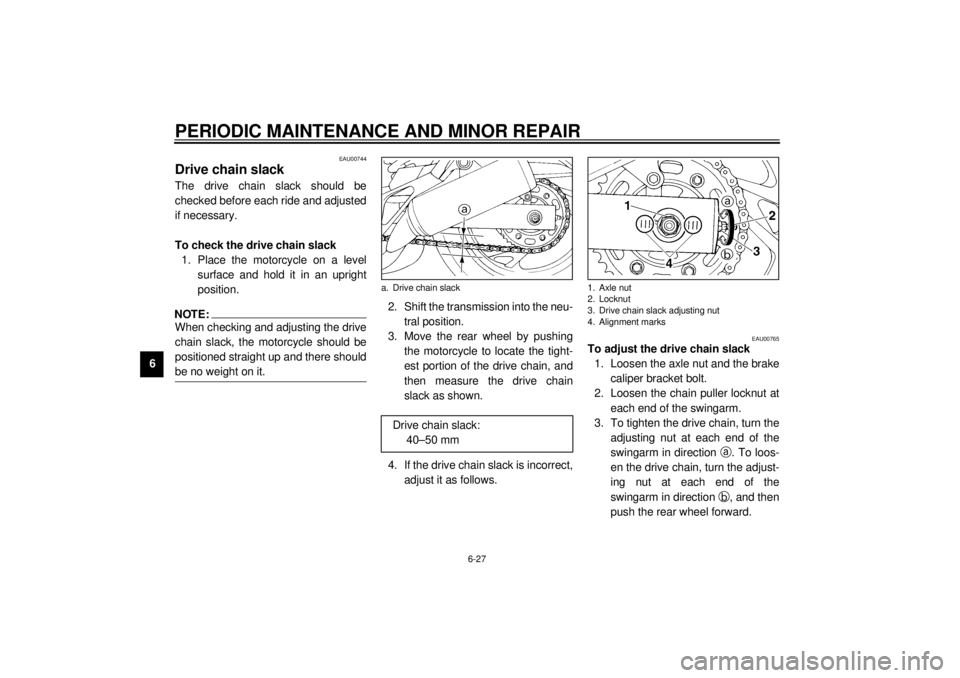

EAU00744

Drive chain slack The drive chain slack should be

checked before each ride and adjusted

if necessary.

To check the drive chain slack

1. Place the motorcycle on a level

surface and hold it in an upright

position.NOTE:@ When checking and adjusting the drive

chain slack, the motorcycle should be

positioned straight up and there should

be no weight on it. @

2. Shift the transmission into the neu-

tral position.

3. Move the rear wheel by pushing

the motorcycle to locate the tight-

est portion of the drive chain, and

then measure the drive chain

slack as shown.

4. If the drive chain slack is incorrect,

adjust it as follows.

EAU00765

To adjust the drive chain slack

1. Loosen the axle nut and the brake

caliper bracket bolt.

2. Loosen the chain puller locknut at

each end of the swingarm.

3. To tighten the drive chain, turn the

adjusting nut at each end of the

swingarm in direction

a. To loos-

en the drive chain, turn the adjust-

ing nut at each end of the

swingarm in direction

b, and then

push the rear wheel forward.

a. Drive chain slack

Drive chain slack:

40–50 mm

1. Axle nut

2. Locknut

3. Drive chain slack adjusting nut

4. Alignment marks

E_4tx.book Page 27 Wednesday, October 4, 2000 4:28 PM

Page 73 of 110

PERIODIC MAINTENANCE AND MINOR REPAIR

6-28

6

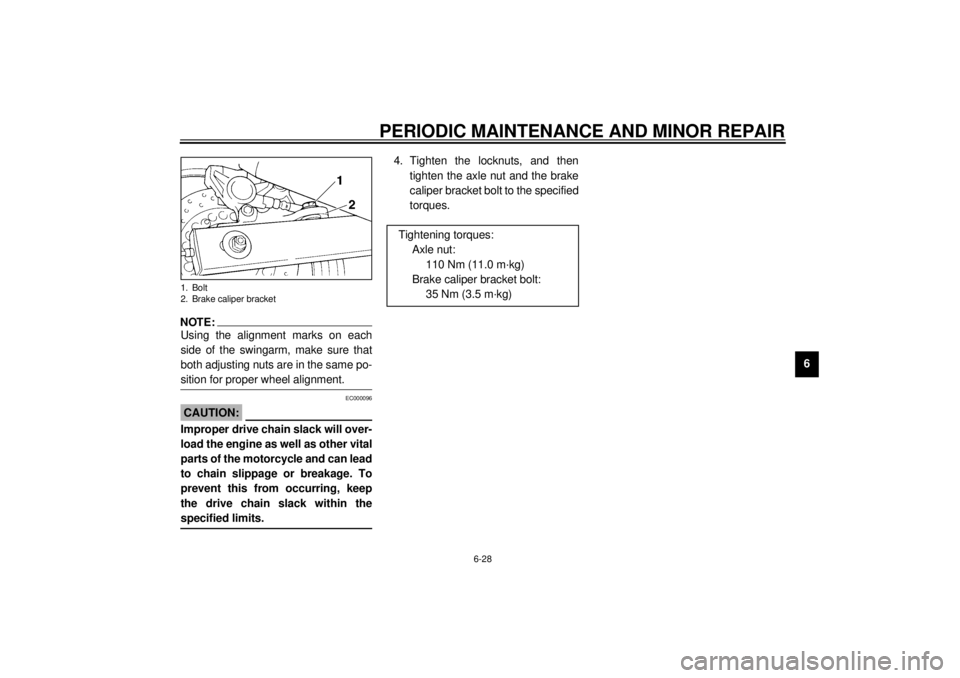

NOTE:@ Using the alignment marks on each

side of the swingarm, make sure that

both adjusting nuts are in the same po-

sition for proper wheel alignment. @

EC000096

CAUTION:@ Improper drive chain slack will over-

load the engine as well as other vital

parts of the motorcycle and can lead

to chain slippage or breakage. To

prevent this from occurring, keep

the drive chain slack within the

specified limits. @

4. Tighten the locknuts, and then

tighten the axle nut and the brake

caliper bracket bolt to the specified

torques.

1. Bolt

2. Brake caliper bracket

Tightening torques:

Axle nut:

110 Nm (11.0 m·kg)

Brake caliper bracket bolt:

35 Nm (3.5 m·kg)

E_4tx.book Page 28 Wednesday, October 4, 2000 4:28 PM

Page 82 of 110

PERIODIC MAINTENANCE AND MINOR REPAIR

6-37

6

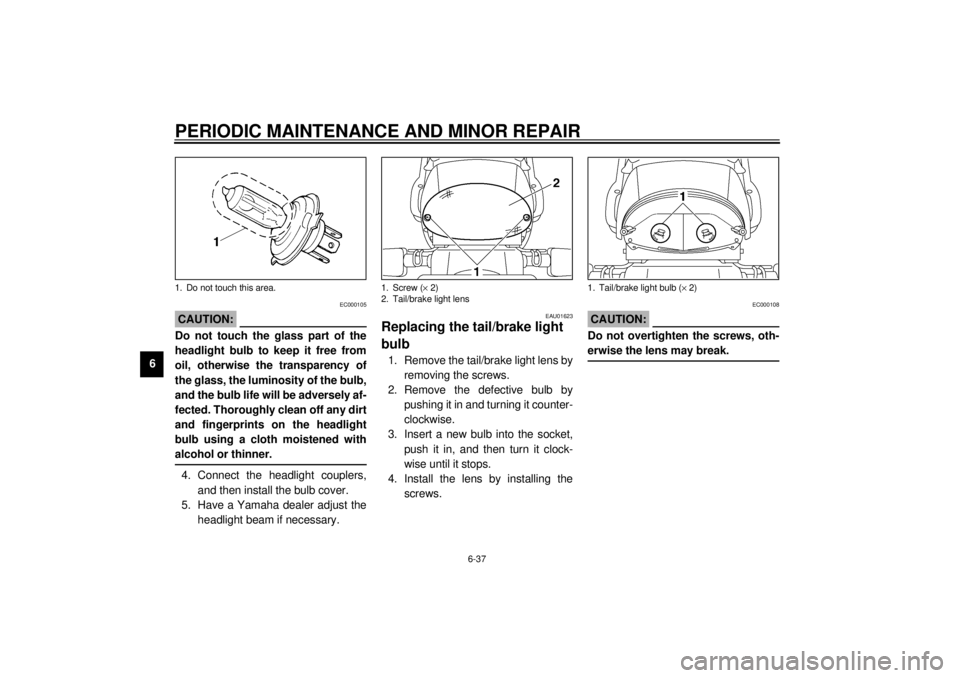

EC000105

CAUTION:_ Do not touch the glass part of the

headlight bulb to keep it free from

oil, otherwise the transparency of

the glass, the luminosity of the bulb,

and the bulb life will be adversely af-

fected. Thoroughly clean off any dirt

and fingerprints on the headlight

bulb using a cloth moistened with

alcohol or thinner. _4. Connect the headlight couplers,

and then install the bulb cover.

5. Have a Yamaha dealer adjust the

headlight beam if necessary.

EAU01623

Replacing the tail/brake light

bulb 1. Remove the tail/brake light lens by

removing the screws.

2. Remove the defective bulb by

pushing it in and turning it counter-

clockwise.

3. Insert a new bulb into the socket,

push it in, and then turn it clock-

wise until it stops.

4. Install the lens by installing the

screws.

EC000108

CAUTION:@ Do not overtighten the screws, oth-

erwise the lens may break. @

1. Do not touch this area.

1. Screw (´ 2)

2. Tail/brake light lens

1. Tail/brake light bulb (´ 2)

E_4tx.book Page 37 Wednesday, October 4, 2000 4:28 PM

Page 83 of 110

PERIODIC MAINTENANCE AND MINOR REPAIR

6-38

6

EAU03497

Replacing a turn signal light

bulb 1. Remove the turn signal light lens

by removing the screw.

2. Remove the defective bulb by

pushing it in and turning it counter-

clockwise.3. Insert a new bulb into the socket,

push it in, and then turn it clock-

wise until it stops.

4. Install the lens by installing the

screw.

ECA00065

CAUTION:@ Do not overtighten the screw, other-

wise the lens may break. @

1. Screw

2. Turn signal light lens

1. Turn signal light bulb

E_4tx.book Page 38 Wednesday, October 4, 2000 4:28 PM

Page 86 of 110

PERIODIC MAINTENANCE AND MINOR REPAIR

6-41

6

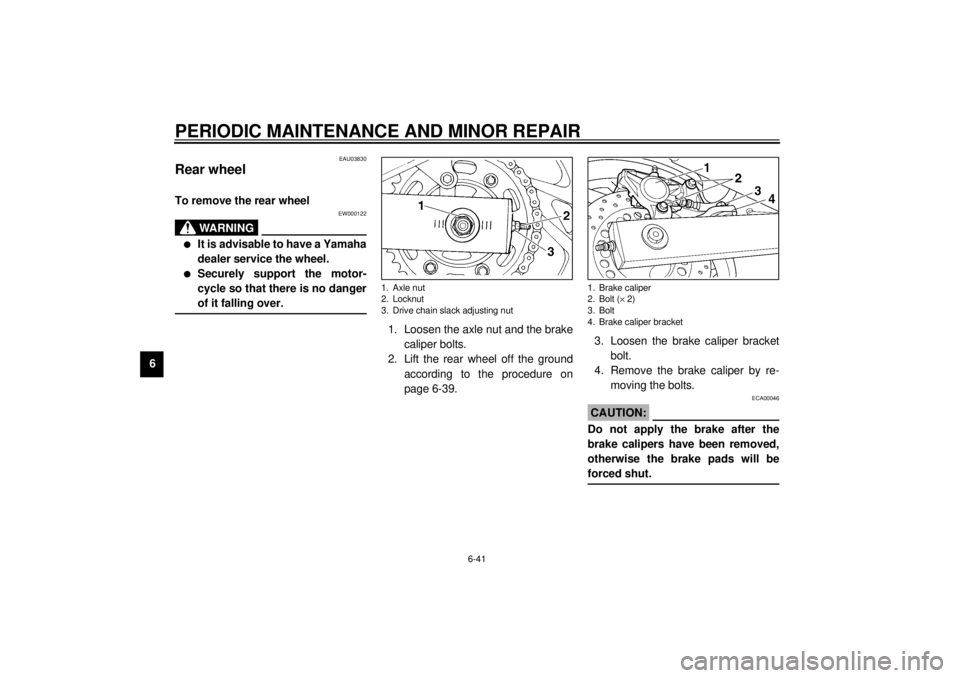

EAU03830

Rear wheel To remove the rear wheel

EW000122

WARNING

_ l

It is advisable to have a Yamaha

dealer service the wheel.

l

Securely support the motor-

cycle so that there is no danger

of it falling over.

_

1. Loosen the axle nut and the brake

caliper bolts.

2. Lift the rear wheel off the ground

according to the procedure on

page 6-39.3. Loosen the brake caliper bracket

bolt.

4. Remove the brake caliper by re-

moving the bolts.

ECA00046

CAUTION:_ Do not apply the brake after the

brake calipers have been removed,

otherwise the brake pads will be

forced shut. _

1. Axle nut

2. Locknut

3. Drive chain slack adjusting nut

1. Brake caliper

2. Bolt (´ 2)

3. Bolt

4. Brake caliper bracket

E_4tx.book Page 41 Wednesday, October 4, 2000 4:28 PM