torque YAMAHA TDM 850 2001 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: TDM 850, Model: YAMAHA TDM 850 2001Pages: 110, PDF Size: 12.15 MB

Page 31 of 110

INSTRUMENT AND CONTROL FUNCTIONS

3-16

3

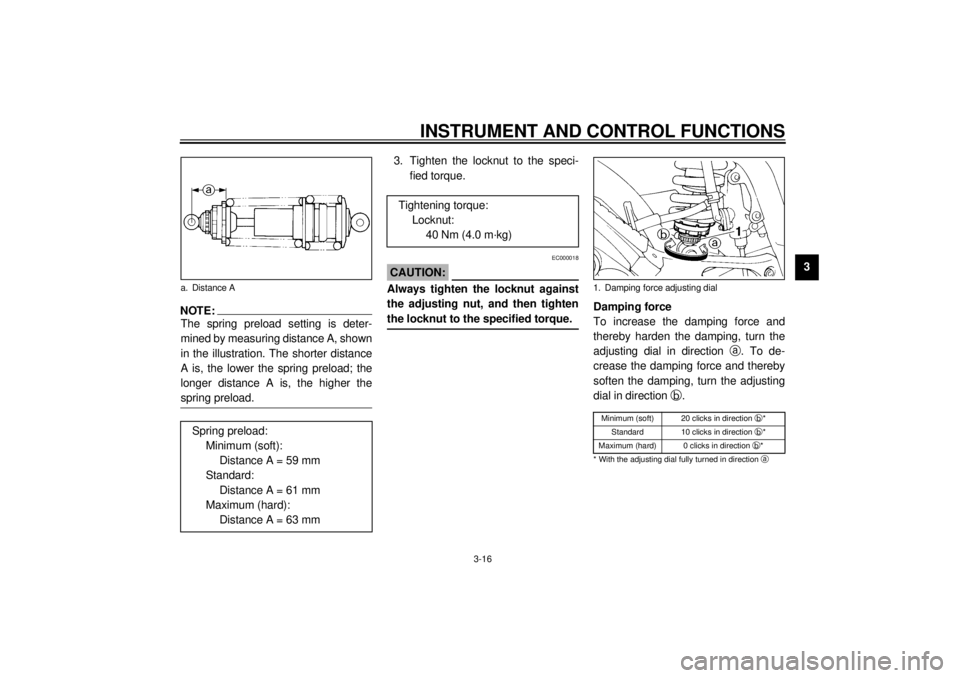

NOTE:_ The spring preload setting is deter-

mined by measuring distance A, shown

in the illustration. The shorter distance

A is, the lower the spring preload; the

longer distance A is, the higher the

spring preload. _

3. Tighten the locknut to the speci-

fied torque.

EC000018

CAUTION:_ Always tighten the locknut against

the adjusting nut, and then tighten

the locknut to the specified torque. _

Damping force

To increase the damping force and

thereby harden the damping, turn the

adjusting dial in direction

a. To de-

crease the damping force and thereby

soften the damping, turn the adjusting

dial in direction

b.CI-04E

a. Distance A

Spring preload:

Minimum (soft):

Distance A = 59 mm

Standard:

Distance A = 61 mm

Maximum (hard):

Distance A = 63 mm

Tightening torque:

Locknut:

40 Nm (4.0 m·kg)

1. Damping force adjusting dialMinimum (soft) 20 clicks in direction

b*

Standard 10 clicks in direction

b*

Maximum (hard) 0 clicks in direction

b*

* With the adjusting dial fully turned in direction

a

E_4tx.book Page 16 Wednesday, October 4, 2000 4:28 PM

Page 46 of 110

6-1

6

EAU00462

6-PERIODIC MAINTENANCE AND MINOR REPAIR

EAU00464

Safety is an obligation of the owner.

Periodic inspection, adjustment and lu-

brication will keep your vehicle in the

safest and most efficient condition pos-

sible. The most important points of in-

spection, adjustment, and lubrication

are explained on the following pages.

The intervals given in the periodic

maintenance and lubrication chart

should be simply considered as a gen-

eral guide under normal riding condi-

tions. However, DEPENDING ON THE

WEATHER, TERRAIN, GEOGRAPHI-

CAL LOCATION, AND INDIVIDUAL

USE, THE MAINTENANCE INTER-

VALS MAY NEED TO BE SHORT-

ENED.

EW000060

WARNING

@ If you are not familiar with motor-

cycle maintenance work, have a

Yamaha dealer do it for you. @

EAU01299

Owner’s tool kit The owner’s tool kit is located inside

the storage compartment under the

seat. (See page 3-11 for seat removal

procedures.)

The service information included in this

manual and the tools provided in the

owner’s tool kit are intended to assist

you in the performance of preventive

maintenance and minor repairs. How-

ever, additional tools such as a torque

wrench may be necessary to perform

certain maintenance work correctly.

NOTE:@ If you do not have the tools or experi-

ence required for a particular job, have

a Yamaha dealer perform it for you. @

EW000063

WARNING

@ Modifications not approved by

Yamaha may cause loss of perfor-

mance and render the vehicle un-

safe for use. Consult a Yamaha

dealer before attempting any chang-

es. @

1. Owner’s tool kit

E_4tx.book Page 1 Wednesday, October 4, 2000 4:28 PM

Page 53 of 110

PERIODIC MAINTENANCE AND MINOR REPAIR

6-8

6 To install a spark plug

1. Measure the spark plug gap with a

wire thickness gauge and, if nec-

essary, adjust the gap to specifica-

tion.

2. Clean the surface of the spark

plug gasket and its mating sur-

face, and then wipe off any grime

from the spark plug threads.

3. Install the spark plug with the

spark plug wrench, and then tight-

en it to the specified torque.

NOTE:@ If a torque wrench is not available when

installing a spark plug, a good estimate

of the correct torque is 1/4–1/2 turn

past finger tight. However, the spark

plug should be tightened to the speci-

fied torque as soon as possible. @4. Install the spark plug cap.

5. Install the cowling.

a. Spark plug gap

Spark plug gap:

0.8–0.9 mm

Tightening torque:

Spark plug:

18 Nm (1.8 m·kg)

E_4tx.book Page 8 Wednesday, October 4, 2000 4:28 PM

Page 55 of 110

PERIODIC MAINTENANCE AND MINOR REPAIR

6-10

6 3. Remove the engine oil tank cap

and drain bolts to drain the oil from

the crankcase.

NOTE:@ Skip steps 4–6 if the oil filter element is

not being replaced. @

4. Remove the oil filter element cover

by removing the bolts.5. Remove and replace the oil filter

element and O-rings.

6. Install the oil filter element cover

by installing the bolts, then tighten-

ing them to the specified torque.

NOTE:@ Make sure that the O-rings are properly

seated.@7. Install the engine oil drain bolts,

and then tighten them to the spec-

ified torques.

1. Engine oil drain bolt A

1. Engine oil drain bolt B

2. Oil filter element cover

3. Bolt (´ 5)

1. Oil filter element

2. O-ring (´ 2)Tightening torque:

Oil filter element cover bolt:

10 Nm (1.0 m·kg)

E_4tx.book Page 10 Wednesday, October 4, 2000 4:28 PM

Page 56 of 110

PERIODIC MAINTENANCE AND MINOR REPAIR

6-11

68. Add the specified amount of the

recommended engine oil, and

then install and tighten the oil tank

cap.

EC000072

CAUTION:@ l

In order to prevent clutch slip-

page (since the engine oil also

lubricates the clutch), do not

mix any chemical additives with

the oil or use oils of a higher

grade than “CD”. In addition, do

not use oils labeled “ENERGY

CONSERVING II” or higher.

l

Make sure that no foreign mate-

rial enters the crankcase.

@9. Start the engine, and then let it idle

for several minutes while checking

it for oil leakage. If oil is leaking,

immediately turn the engine off

and check for the cause.

10. Turn the engine off, and then

check the oil level and correct it if

necessary.

EAU03495

Coolant The coolant level should be checked

before each ride. In addition, the cool-

ant must be changed at the intervals

specified in the periodic maintenance

and lubrication chart.

If the engine overheats, see page 6-45

for further instructions.

To check the coolant level

1. Place the motorcycle on a level

surface and hold it in an upright

position.NOTE:@ l

The coolant level must be checked

on a cold engine since the level

varies with engine temperature.

l

Make sure that the motorcycle is

positioned straight up when

checking the coolant level. A slight

tilt to the side can result in a false

reading.

@

Tightening torques:

Engine oil drain bolt A:

35 Nm (3.5 m·kg)

Engine oil drain bolt B:

30 Nm (3.0 m·kg)

Recommended engine oil:

See page 8-1.

Oil quantity:

Without oil filter element

replacement:

3.5 L

With oil filter element

replacement:

3.6 L

Total amount (dry engine):

4.2 L

E_4tx.book Page 11 Wednesday, October 4, 2000 4:28 PM

Page 59 of 110

PERIODIC MAINTENANCE AND MINOR REPAIR

6-14

6 6. Remove the coolant drain bolts to

drain the cooling system.

7. Remove the coolant reservoir

bolts.

8. Slightly move the coolant reservoir

back, and then disconnect the

hose at the bottom of the coolant

reservoir.

9. Drain the coolant from the coolant

reservoir by opening the cap, then

turning the reservoir upside down.

10. Connect the hose to the coolant

reservoir.

11. Install the coolant reservoir by

placing it in the original position,

then installing the bolts.12. After the coolant is completely

drained, thoroughly flush the cool-

ing system with clean tap water.

13. Install the coolant drain bolts, and

then tighten them to the specified

torque.

NOTE:@ Check the washers for damage and re-

place them if necessary. @14. Pour the recommended coolant

into the radiator until it is full.

1. Coolant drain bolt (´ 2)

1. Coolant reservoir

2. Bolt (´ 2)

3. Clamp

4. Hose

Tightening torque:

Coolant drain bolt:

7 Nm (0.7 m·kg)

E_4tx.book Page 14 Wednesday, October 4, 2000 4:28 PM

Page 73 of 110

PERIODIC MAINTENANCE AND MINOR REPAIR

6-28

6

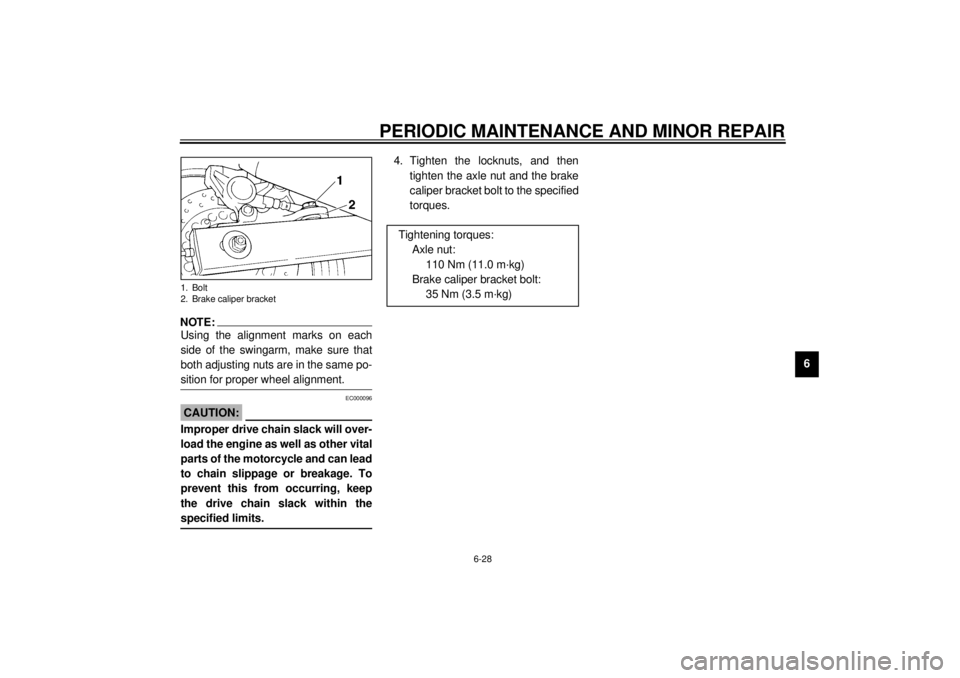

NOTE:@ Using the alignment marks on each

side of the swingarm, make sure that

both adjusting nuts are in the same po-

sition for proper wheel alignment. @

EC000096

CAUTION:@ Improper drive chain slack will over-

load the engine as well as other vital

parts of the motorcycle and can lead

to chain slippage or breakage. To

prevent this from occurring, keep

the drive chain slack within the

specified limits. @

4. Tighten the locknuts, and then

tighten the axle nut and the brake

caliper bracket bolt to the specified

torques.

1. Bolt

2. Brake caliper bracket

Tightening torques:

Axle nut:

110 Nm (11.0 m·kg)

Brake caliper bracket bolt:

35 Nm (3.5 m·kg)

E_4tx.book Page 28 Wednesday, October 4, 2000 4:28 PM

Page 85 of 110

PERIODIC MAINTENANCE AND MINOR REPAIR

6-40

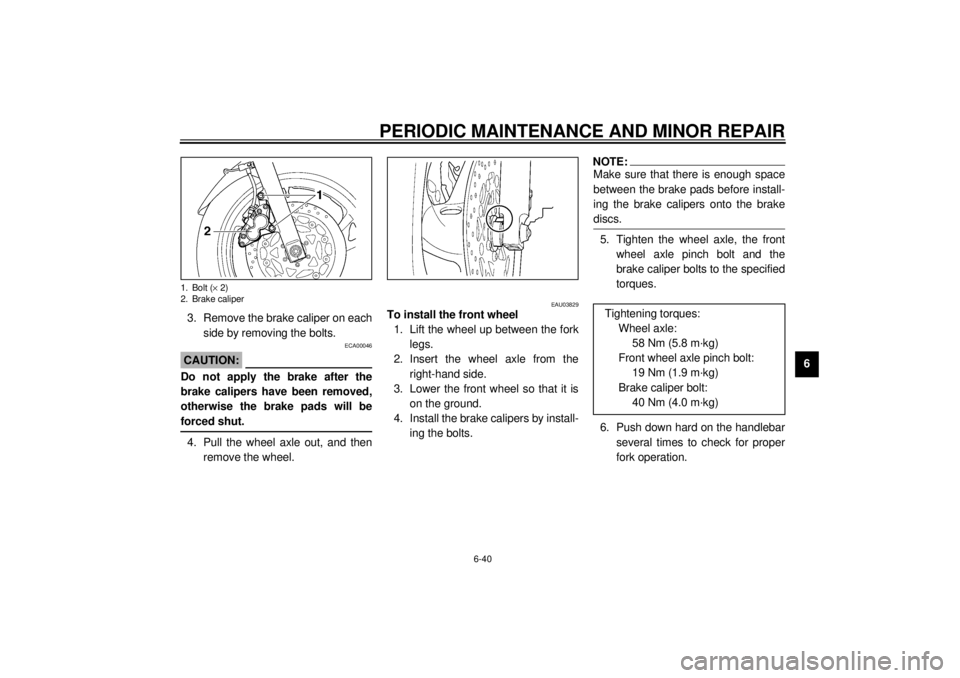

6 3. Remove the brake caliper on each

side by removing the bolts.

ECA00046

CAUTION:@ Do not apply the brake after the

brake calipers have been removed,

otherwise the brake pads will be

forced shut. @4. Pull the wheel axle out, and then

remove the wheel.

EAU03829

To install the front wheel

1. Lift the wheel up between the fork

legs.

2. Insert the wheel axle from the

right-hand side.

3. Lower the front wheel so that it is

on the ground.

4. Install the brake calipers by install-

ing the bolts.

NOTE:_ Make sure that there is enough space

between the brake pads before install-

ing the brake calipers onto the brake

discs. _5. Tighten the wheel axle, the front

wheel axle pinch bolt and the

brake caliper bolts to the specified

torques.

6. Push down hard on the handlebar

several times to check for proper

fork operation.

1. Bolt (´ 2)

2. Brake caliper

Tightening torques:

Wheel axle:

58 Nm (5.8 m·kg)

Front wheel axle pinch bolt:

19 Nm (1.9 m·kg)

Brake caliper bolt:

40 Nm (4.0 m·kg)

E_4tx.book Page 40 Wednesday, October 4, 2000 4:28 PM

Page 87 of 110

PERIODIC MAINTENANCE AND MINOR REPAIR

6-42

6 5. Loosen the locknut on each side of

the swingarm.

6. Turn the drive chain slack adjust-

ing nuts fully in direction

a.7. Push the wheel forward, and then

remove the drive chain from the

rear sprocket.

NOTE:_ The drive chain does not need to be

disassembled in order to remove and

install the rear wheel. _8. Remove the axle nut.

9. Pull the wheel axle out, and then

remove the wheel.

EAU03501

To install the rear wheel

1. Install the wheel by inserting the

wheel axle from the right-hand

side.

2. Install the drive chain onto the rear

sprocket, and then adjust the drive

chain slack. (See page 6-27 for

drive chain slack adjustment pro-

cedures.)

3. Install the brake caliper by install-

ing the bolts.

4. Install the axle nut, and then lower

the rear wheel so that it is on the

ground.

5. Tighten the axle nut, the brake cal-

iper bolts and the brake caliper

bracket bolt to the specified

torques.

1. Locknut

2. Drive chain slack adjusting nut

Tightening torques:

Axle nut:

110 Nm (11.0 m·kg)

Brake caliper bolt:

40 Nm (4.0 m·kg)

Brake caliper bracket bolt:

35 Nm (3.5 m·kg)

E_4tx.book Page 42 Wednesday, October 4, 2000 4:28 PM

Page 102 of 110

SPECIFICATIONS

8-5

8

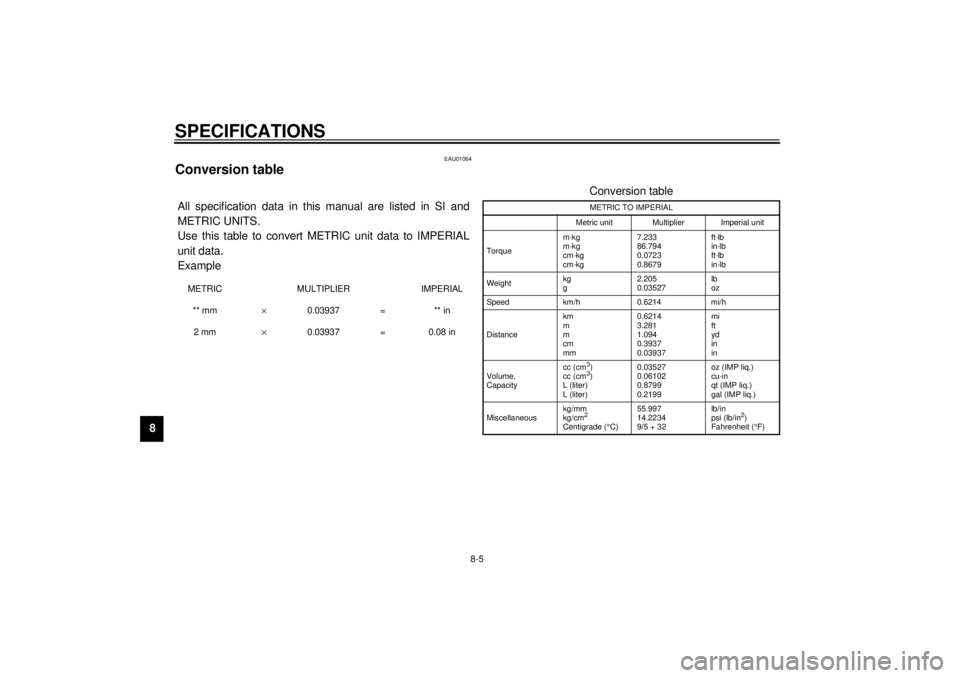

EAU01064

Conversion table CS-02EAll specification data in this manual are listed in SI and

METRIC UNITS.

Use this table to convert METRIC unit data to IMPERIAL

unit data.

ExampleMETRIC MULTIPLIER IMPERIAL

** mm´ 0.03937 = ** in

2 mm´ 0.03937 = 0.08 in

Conversion tableMETRIC TO IMPERIAL

Metric unit Multiplier Imperial unit

Torquem·kg

m·kg

cm·kg

cm·kg7.233

86.794

0.0723

0.8679ft·lb

in·lb

ft·lb

in·lb

Weightkg

g2.205

0.03527lb

oz

Speed km/h 0.6214 mi/h

Distancekm

m

m

cm

mm0.6214

3.281

1.094

0.3937

0.03937mi

ft

yd

in

in

Volume,

Capacitycc (cm3)

cc (cm3)

L (liter)

L (liter)0.03527

0.06102

0.8799

0.2199oz (IMP liq.)

cu·in

qt (IMP liq.)

gal (IMP liq.)

Miscellaneouskg/mm

kg/cm2

Centigrade (°

C)55.997

14.2234

9/5 + 32 lb/in

psi (lb/in

2)

Fahrenheit (°

F)

E_4tx.book Page 5 Wednesday, October 4, 2000 4:28 PM