wheel bolts YAMAHA TDM 850 2001 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: TDM 850, Model: YAMAHA TDM 850 2001Pages: 110, PDF Size: 12.15 MB

Page 37 of 110

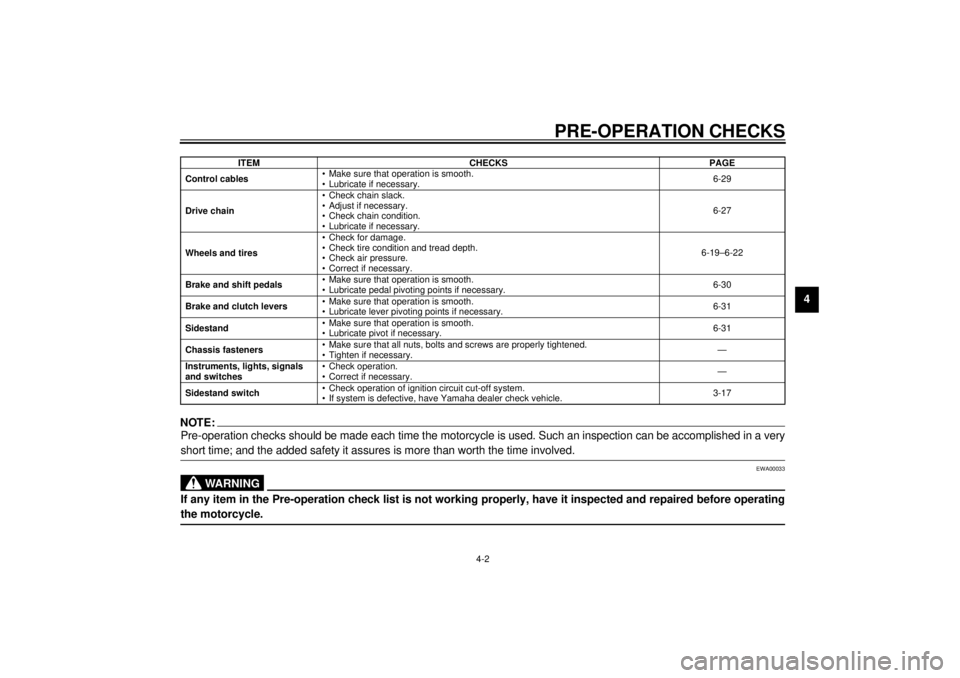

PRE-OPERATION CHECKS

4-2

4

NOTE:_ Pre-operation checks should be made each time the motorcycle is used. Such an inspection can be accomplished in a very

short time; and the added safety it assures is more than worth the time involved. _

EWA00033

WARNING

_ If any item in the Pre-operation check list is not working properly, have it inspected and repaired before operating

the motorcycle. _Control cables• Make sure that operation is smooth.

• Lubricate if necessary.6-29

Drive chain• Check chain slack.

• Adjust if necessary.

• Check chain condition.

• Lubricate if necessary.6-27

Wheels and tires• Check for damage.

• Check tire condition and tread depth.

• Check air pressure.

• Correct if necessary.6-19–6-22

Brake and shift pedals• Make sure that operation is smooth.

• Lubricate pedal pivoting points if necessary.6-30

Brake and clutch levers• Make sure that operation is smooth.

• Lubricate lever pivoting points if necessary.6-31

Sidestand• Make sure that operation is smooth.

• Lubricate pivot if necessary.6-31

Chassis fasteners• Make sure that all nuts, bolts and screws are properly tightened.

• Tighten if necessary.—

Instruments, lights, signals

and switches• Check operation.

• Correct if necessary.—

Sidestand switch• Check operation of ignition circuit cut-off system.

• If system is defective, have Yamaha dealer check vehicle.3-17 ITEM CHECKS PAGE

E_4tx.book Page 2 Wednesday, October 4, 2000 4:28 PM

Page 48 of 110

PERIODIC MAINTENANCE AND MINOR REPAIR

6-3

6

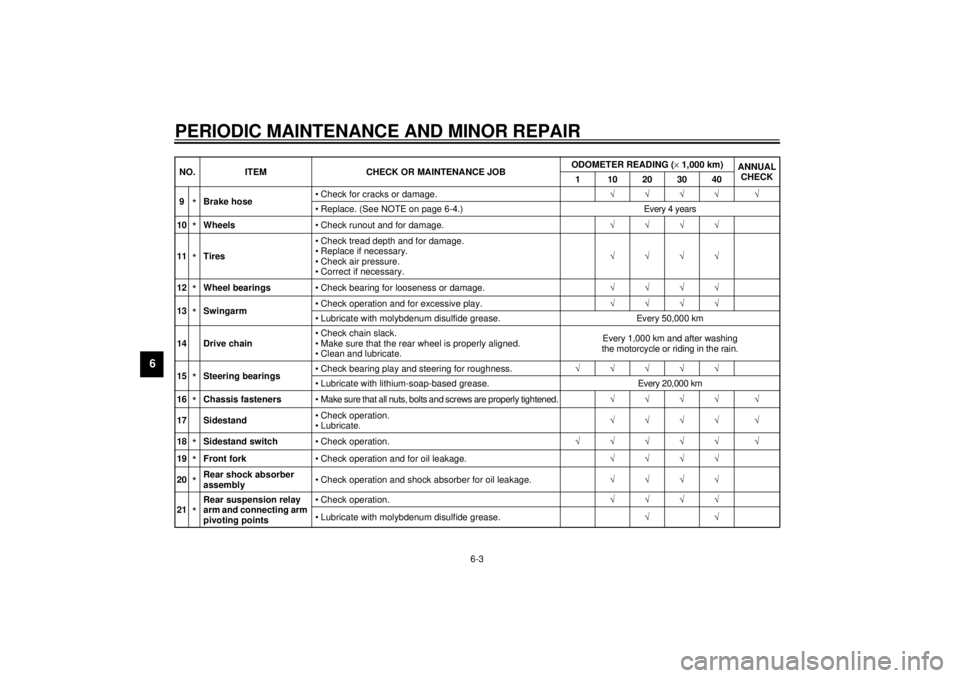

9

*Brake hose• Check for cracks or damage.ÖÖÖÖ Ö

• Replace. (See NOTE on page 6-4.) Every 4 years

10*Wheels• Check runout and for damage.ÖÖÖÖ

11*Tires• Check tread depth and for damage.

• Replace if necessary.

• Check air pressure.

• Correct if necessary.ÖÖÖÖ

12*Wheel bearings• Check bearing for looseness or damage.ÖÖÖÖ

13*Swingarm• Check operation and for excessive play.ÖÖÖÖ

• Lubricate with molybdenum disulfide grease. Every 50,000 km

14 Drive chain• Check chain slack.

• Make sure that the rear wheel is properly aligned.

• Clean and lubricate.Every 1,000 km and after washing

the motorcycle or riding in the rain.

15*Steering bearings• Check bearing play and steering for roughness.ÖÖÖÖÖ

• Lubricate with lithium-soap-based grease. Every 20,000 km

16*Chassis fasteners• Make sure that all nuts, bolts and screws are properly tightened.ÖÖÖÖ Ö

17 Sidestand• Check operation.

• Lubricate.ÖÖÖÖ Ö

18*Sidestand switch• Check operation.ÖÖÖÖÖ Ö

19*Front fork• Check operation and for oil leakage.ÖÖÖÖ

20*Rear shock absorber

assembly• Check operation and shock absorber for oil leakage.ÖÖÖÖ

21*Rear suspension relay

arm and connecting arm

pivoting points• Check operation.ÖÖÖÖ

• Lubricate with molybdenum disulfide grease.ÖÖ NO. ITEM CHECK OR MAINTENANCE JOBODOMETER READING (´1,000 km)

ANNUAL

CHECK

1 10203040

E_4tx.book Page 3 Wednesday, October 4, 2000 4:28 PM

Page 84 of 110

PERIODIC MAINTENANCE AND MINOR REPAIR

6-39

6

EAU01579

Supporting the motorcycle Since this model is not equipped with a

centerstand, follow these precautions

when removing the front and rear

wheel or performing other mainte-

nance requiring the motorcycle to

stand upright. Check that the motor-

cycle is in a stable and level position

before starting any maintenance. A

strong wooden box can be placed un-

der the engine for added stability.

To service the front wheel

1. Stabilize the rear of the motorcycle

by using a motorcycle stand or, if

an additional motorcycle stand is

not available, by placing a jack un-

der the frame in front of the rear

wheel.

2. Raise the front wheel off the

ground by using a motorcycle

stand.To service the rear wheel

Raise the rear wheel off the ground by

using a motorcycle stand or, if a motor-

cycle stand is not available, by placing

a jack either under each side of the

frame in front of the rear wheel or under

each side of the swingarm.

EAU03498*

Front wheel To remove the front wheel

EW000122

WARNING

@ l

It is advisable to have a Yamaha

dealer service the wheel.

l

Securely support the motor-

cycle so that there is no danger

of it falling over.

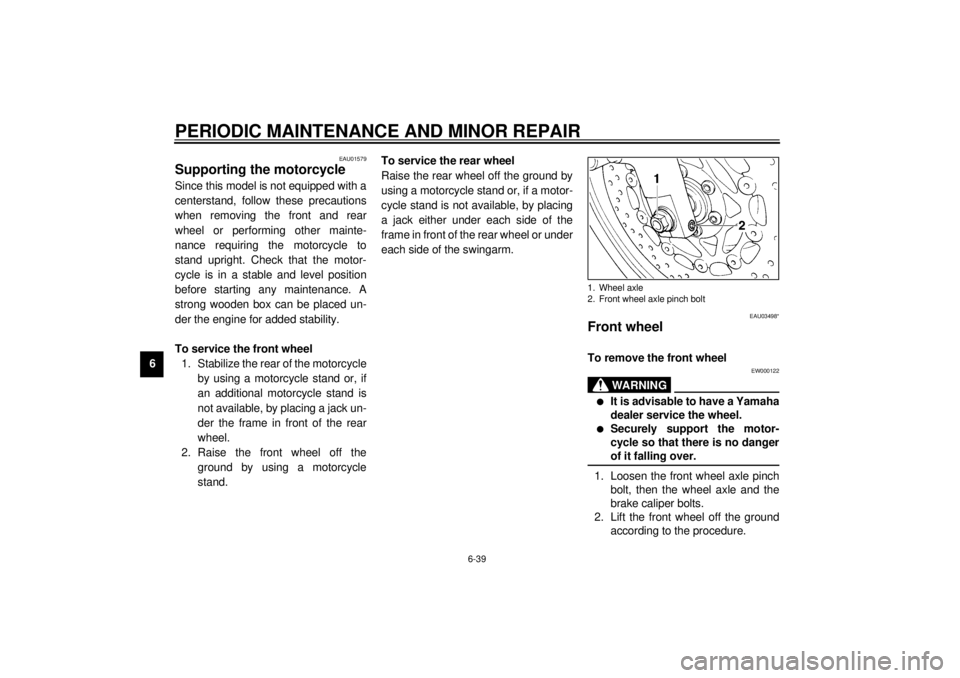

@1. Loosen the front wheel axle pinch

bolt, then the wheel axle and the

brake caliper bolts.

2. Lift the front wheel off the ground

according to the procedure.1. Wheel axle

2. Front wheel axle pinch bolt

E_4tx.book Page 39 Wednesday, October 4, 2000 4:28 PM

Page 85 of 110

PERIODIC MAINTENANCE AND MINOR REPAIR

6-40

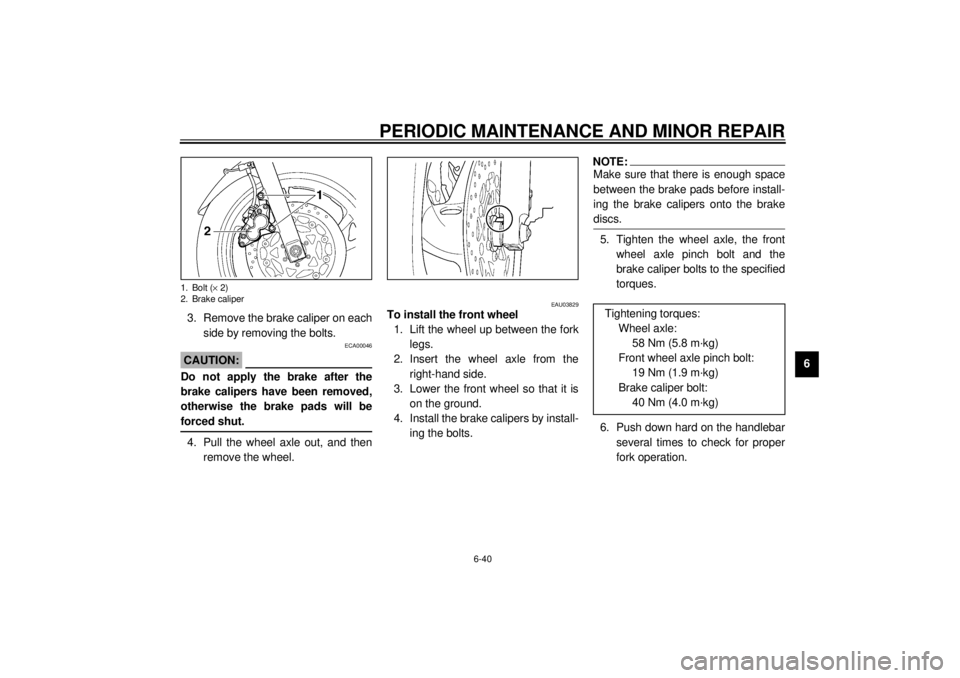

6 3. Remove the brake caliper on each

side by removing the bolts.

ECA00046

CAUTION:@ Do not apply the brake after the

brake calipers have been removed,

otherwise the brake pads will be

forced shut. @4. Pull the wheel axle out, and then

remove the wheel.

EAU03829

To install the front wheel

1. Lift the wheel up between the fork

legs.

2. Insert the wheel axle from the

right-hand side.

3. Lower the front wheel so that it is

on the ground.

4. Install the brake calipers by install-

ing the bolts.

NOTE:_ Make sure that there is enough space

between the brake pads before install-

ing the brake calipers onto the brake

discs. _5. Tighten the wheel axle, the front

wheel axle pinch bolt and the

brake caliper bolts to the specified

torques.

6. Push down hard on the handlebar

several times to check for proper

fork operation.

1. Bolt (´ 2)

2. Brake caliper

Tightening torques:

Wheel axle:

58 Nm (5.8 m·kg)

Front wheel axle pinch bolt:

19 Nm (1.9 m·kg)

Brake caliper bolt:

40 Nm (4.0 m·kg)

E_4tx.book Page 40 Wednesday, October 4, 2000 4:28 PM

Page 86 of 110

PERIODIC MAINTENANCE AND MINOR REPAIR

6-41

6

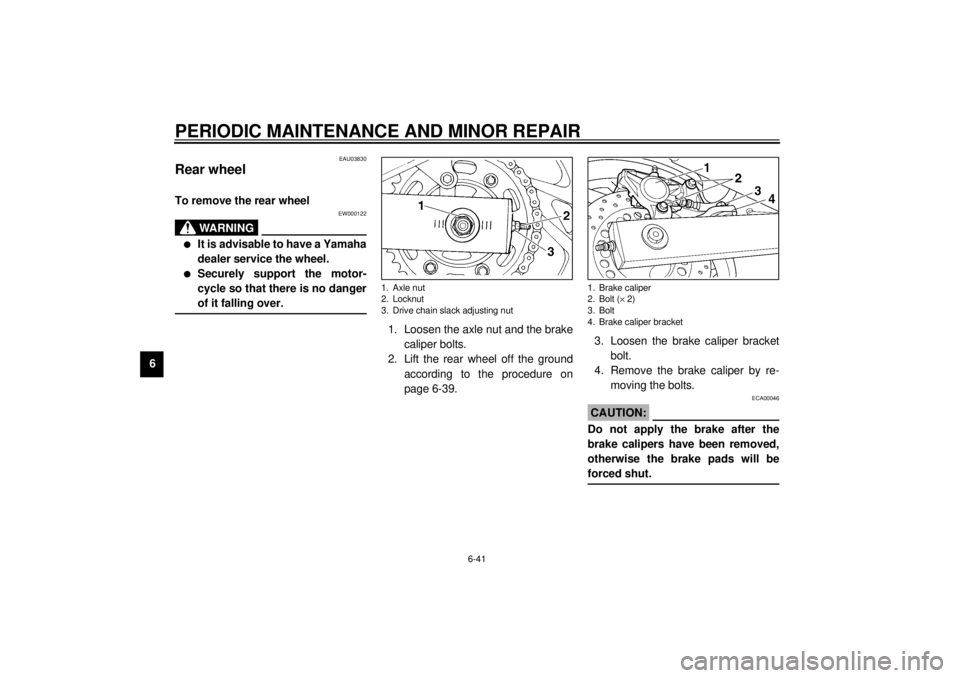

EAU03830

Rear wheel To remove the rear wheel

EW000122

WARNING

_ l

It is advisable to have a Yamaha

dealer service the wheel.

l

Securely support the motor-

cycle so that there is no danger

of it falling over.

_

1. Loosen the axle nut and the brake

caliper bolts.

2. Lift the rear wheel off the ground

according to the procedure on

page 6-39.3. Loosen the brake caliper bracket

bolt.

4. Remove the brake caliper by re-

moving the bolts.

ECA00046

CAUTION:_ Do not apply the brake after the

brake calipers have been removed,

otherwise the brake pads will be

forced shut. _

1. Axle nut

2. Locknut

3. Drive chain slack adjusting nut

1. Brake caliper

2. Bolt (´ 2)

3. Bolt

4. Brake caliper bracket

E_4tx.book Page 41 Wednesday, October 4, 2000 4:28 PM

Page 87 of 110

PERIODIC MAINTENANCE AND MINOR REPAIR

6-42

6 5. Loosen the locknut on each side of

the swingarm.

6. Turn the drive chain slack adjust-

ing nuts fully in direction

a.7. Push the wheel forward, and then

remove the drive chain from the

rear sprocket.

NOTE:_ The drive chain does not need to be

disassembled in order to remove and

install the rear wheel. _8. Remove the axle nut.

9. Pull the wheel axle out, and then

remove the wheel.

EAU03501

To install the rear wheel

1. Install the wheel by inserting the

wheel axle from the right-hand

side.

2. Install the drive chain onto the rear

sprocket, and then adjust the drive

chain slack. (See page 6-27 for

drive chain slack adjustment pro-

cedures.)

3. Install the brake caliper by install-

ing the bolts.

4. Install the axle nut, and then lower

the rear wheel so that it is on the

ground.

5. Tighten the axle nut, the brake cal-

iper bolts and the brake caliper

bracket bolt to the specified

torques.

1. Locknut

2. Drive chain slack adjusting nut

Tightening torques:

Axle nut:

110 Nm (11.0 m·kg)

Brake caliper bolt:

40 Nm (4.0 m·kg)

Brake caliper bracket bolt:

35 Nm (3.5 m·kg)

E_4tx.book Page 42 Wednesday, October 4, 2000 4:28 PM