lock YAMAHA TDR 125 2000 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2000, Model line: TDR 125, Model: YAMAHA TDR 125 2000Pages: 104, PDF Size: 4.88 MB

Page 68 of 104

6-23

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

98Refill with the same type of brake

fluid. Mixing fluids may result in a

harmful chemical reaction and

lead to poor brake performance.

8Be careful that water does not

enter the master cylinder when

refilling. Water will significantly

lower the boiling point of the fluid

and may result in vapor lock.

8Brake fluid may deteriorate paint-

ed surfaces or plastic parts.

Always clean up spilled fluid

immediately.

8Have a Yamaha dealer check

the cause if the brake fluid level

goes down.

EAU00742Brake fluid replacement

The brake fluid should be replaced

only by trained Yamaha service per-

sonnel. Have the Yamaha dealer

replace the following components

during periodic maintenance or when

they are damaged or leaking:

8oil seals (every two years)

8brake hoses (every four years)

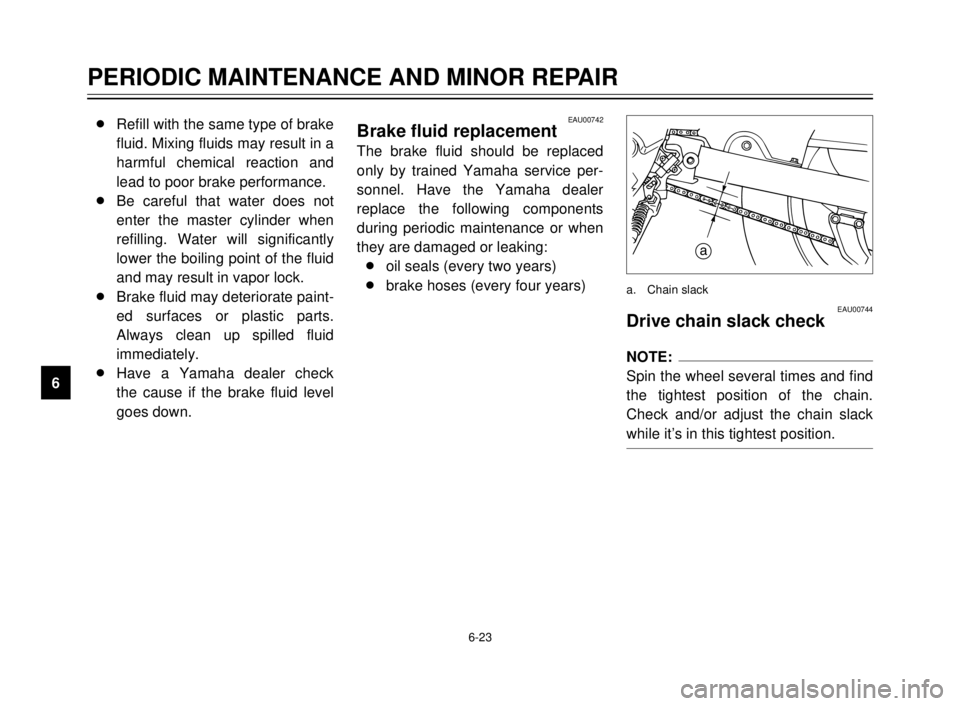

EAU00744Drive chain slack check

NOTE:

Spin the wheel several times and find

the tightest position of the chain.

Check and/or adjust the chain slack

while it’s in this tightest position.

a

a. Chain slack

5AE-9-E3 (ENG) 4/11/0 11:06 AM Page 66

Page 69 of 104

6-24

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

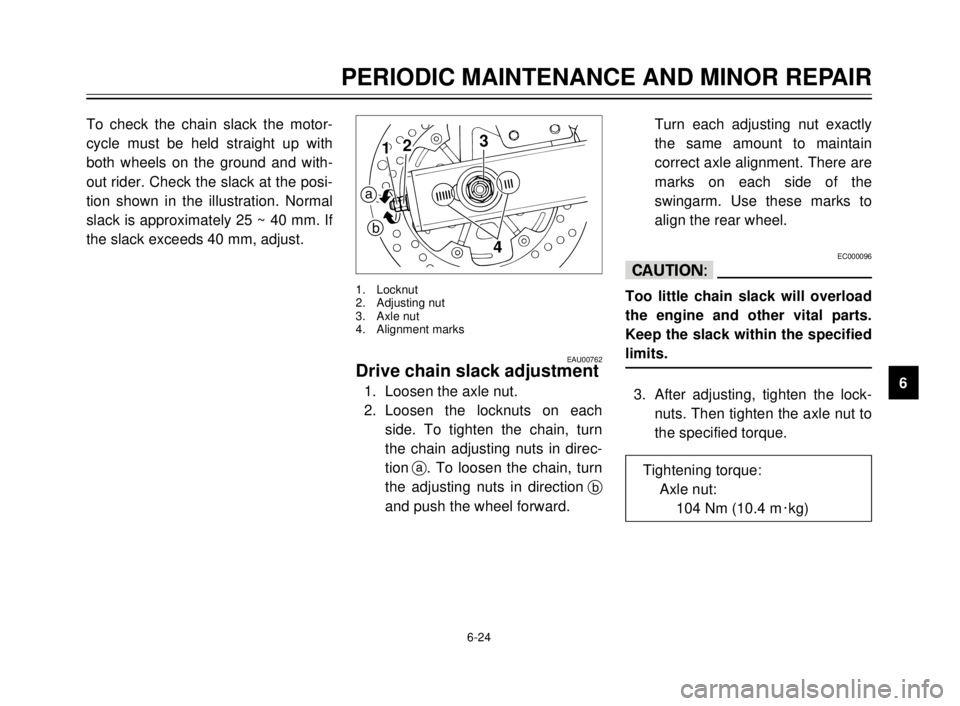

9 To check the chain slack the motor-

cycle must be held straight up with

both wheels on the ground and with-

out rider. Check the slack at the posi-

tion shown in the illustration. Normal

slack is approximately 25 ~ 40 mm. If

the slack exceeds 40 mm, adjust.

EAU00762Drive chain slack adjustment

1. Loosen the axle nut.

2. Loosen the locknuts on each

side. To tighten the chain, turn

the chain adjusting nuts in direc-

tiona. To loosen the chain, turn

the adjusting nuts in directionb

and push the wheel forward.

3

412

a

b

1. Locknut

2. Adjusting nut

3. Axle nut

4. Alignment marks

Turn each adjusting nut exactly

the same amount to maintain

correct axle alignment. There are

marks on each side of the

swingarm. Use these marks to

align the rear wheel.

EC000096

cC

Too little chain slack will overload

the engine and other vital parts.

Keep the slack within the specified

limits.

3. After adjusting, tighten the lock-

nuts. Then tighten the axle nut to

the specified torque.

Tightening torque:

Axle nut:

104 Nm (10.4 m0kg)

5AE-9-E3 (ENG) 4/11/0 11:06 AM Page 67

Page 77 of 104

6-32

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

9

12

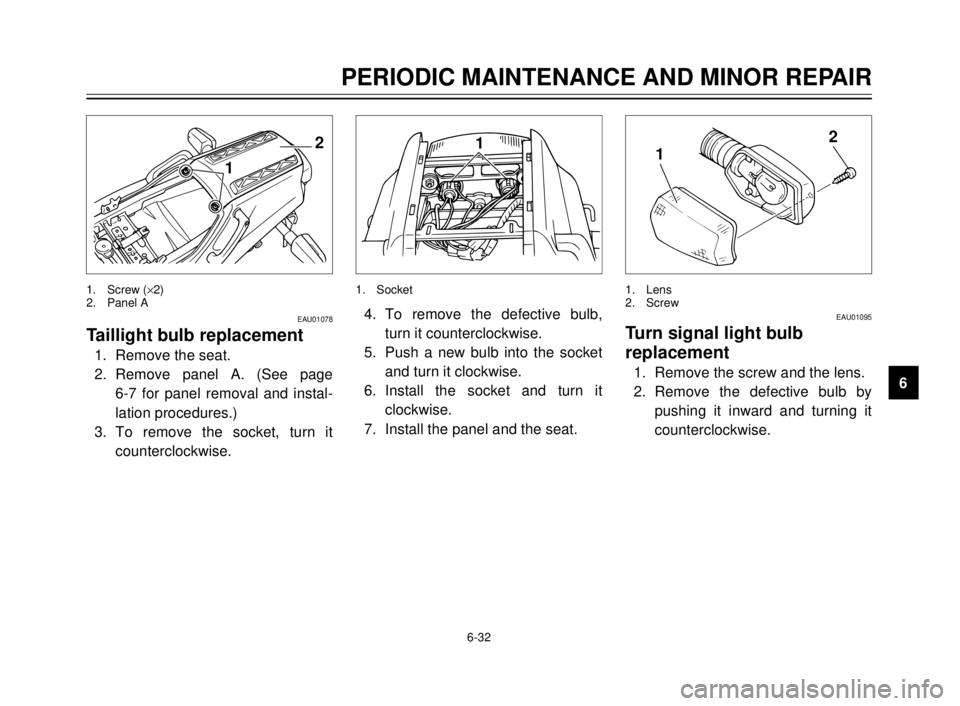

EAU01078

Taillight bulb replacement

1. Remove the seat.

2. Remove panel A. (See page

6-7 for panel removal and instal-

lation procedures.)

3. To remove the socket, turn it

counterclockwise.

1. Screw (´2)

2. Panel A

1

4. To remove the defective bulb,

turn it counterclockwise.

5. Push a new bulb into the socket

and turn it clockwise.

6. Install the socket and turn it

clockwise.

7. Install the panel and the seat.

1. Socket

12

EAU01095

Turn signal light bulb

replacement

1. Remove the screw and the lens.

2. Remove the defective bulb by

pushing it inward and turning it

counterclockwise.

1. Lens

2. Screw

5AE-9-E3 (ENG) 4/11/0 11:06 AM Page 75

Page 78 of 104

6-33

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

9

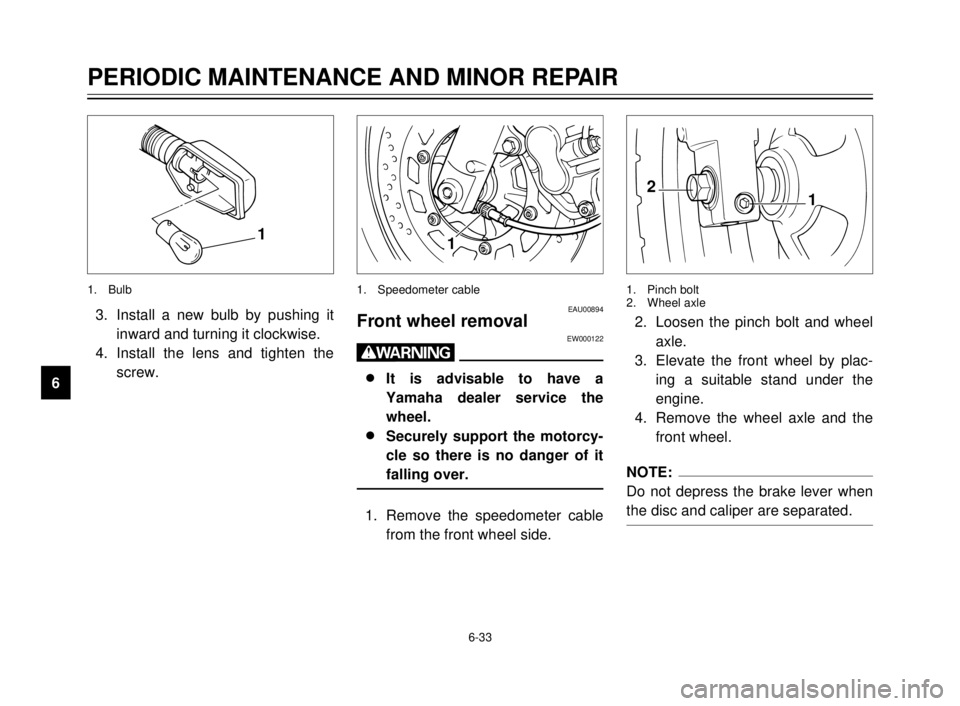

1

1. Speedometer cable

EAU00894Front wheel removalEW000122

w

8 8

It is advisable to have a

Yamaha dealer service the

wheel.

8 8

Securely support the motorcy-

cle so there is no danger of it

falling over.

1. Remove the speedometer cable

from the front wheel side.

2

1

1. Pinch bolt

2. Wheel axle

2. Loosen the pinch bolt and wheel

axle.

3. Elevate the front wheel by plac-

ing a suitable stand under the

engine.

4. Remove the wheel axle and the

front wheel.

NOTE:

Do not depress the brake lever when

the disc and caliper are separated.

1

1. Bulb

3. Install a new bulb by pushing it

inward and turning it clockwise.

4. Install the lens and tighten the

screw.

5AE-9-E3 (ENG) 4/11/0 11:06 AM Page 76

Page 79 of 104

6-34

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

9

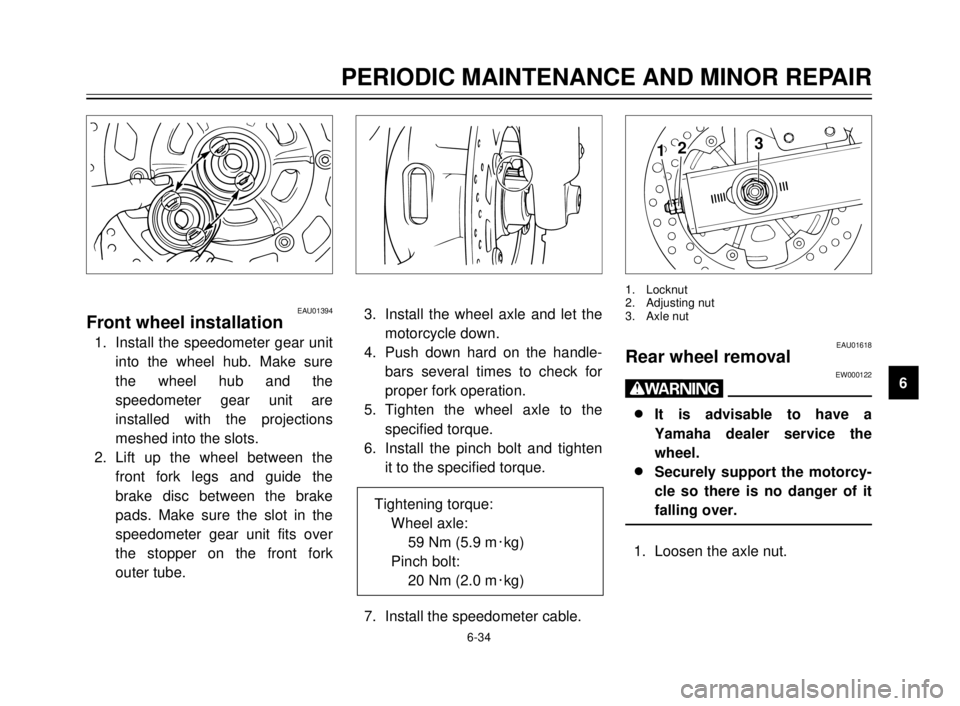

3. Install the wheel axle and let the

motorcycle down.

4. Push down hard on the handle-

bars several times to check for

proper fork operation.

5. Tighten the wheel axle to the

specified torque.

6. Install the pinch bolt and tighten

it to the specified torque.

7. Install the speedometer cable.Tightening torque:

Wheel axle:

59 Nm (5.9 m0kg)

Pinch bolt:

20 Nm (2.0 m0kg)

312

EAU01618Rear wheel removalEW000122

w

8 8

It is advisable to have a

Yamaha dealer service the

wheel.

8 8

Securely support the motorcy-

cle so there is no danger of it

falling over.

1. Loosen the axle nut.

1. Locknut

2. Adjusting nut

3. Axle nut

EAU01394Front wheel installation

1. Install the speedometer gear unit

into the wheel hub. Make sure

the wheel hub and the

speedometer gear unit are

installed with the projections

meshed into the slots.

2. Lift up the wheel between the

front fork legs and guide the

brake disc between the brake

pads. Make sure the slot in the

speedometer gear unit fits over

the stopper on the front fork

outer tube.

5AE-9-E3 (ENG) 4/11/0 11:06 AM Page 77

Page 80 of 104

6-35

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

9

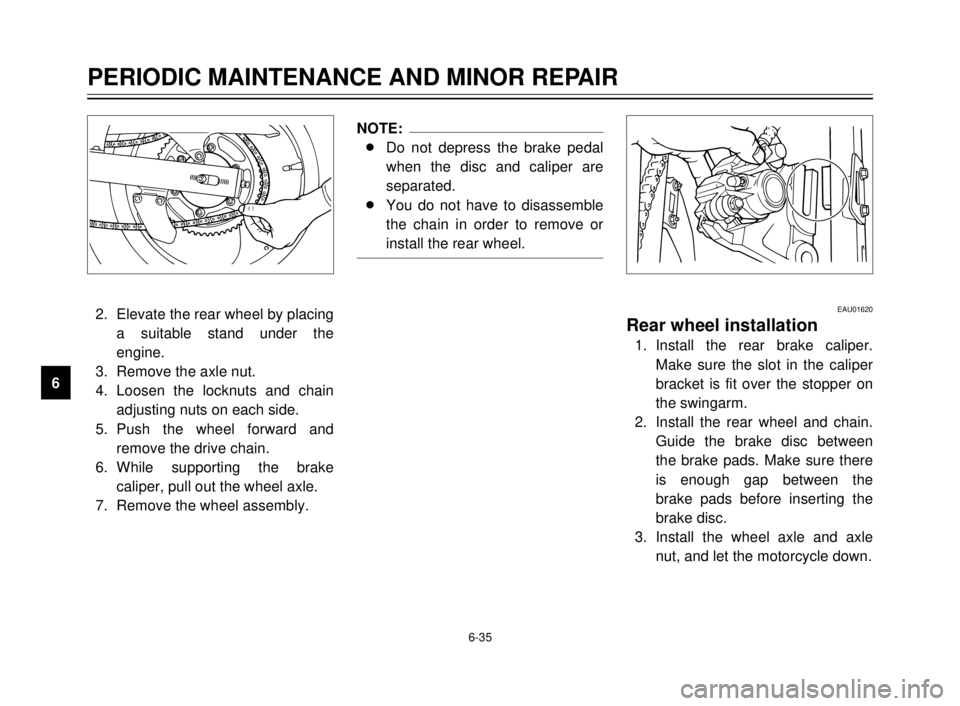

2. Elevate the rear wheel by placing

a suitable stand under the

engine.

3. Remove the axle nut.

4. Loosen the locknuts and chain

adjusting nuts on each side.

5. Push the wheel forward and

remove the drive chain.

6. While supporting the brake

caliper, pull out the wheel axle.

7. Remove the wheel assembly.

NOTE:

8Do not depress the brake pedal

when the disc and caliper are

separated.

8You do not have to disassemble

the chain in order to remove or

install the rear wheel.

EAU01620

Rear wheel installation

1. Install the rear brake caliper.

Make sure the slot in the caliper

bracket is fit over the stopper on

the swingarm.

2. Install the rear wheel and chain.

Guide the brake disc between

the brake pads. Make sure there

is enough gap between the

brake pads before inserting the

brake disc.

3. Install the wheel axle and axle

nut, and let the motorcycle down.

5AE-9-E3 (ENG) 4/11/0 11:06 AM Page 78

Page 83 of 104

6-38

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

9

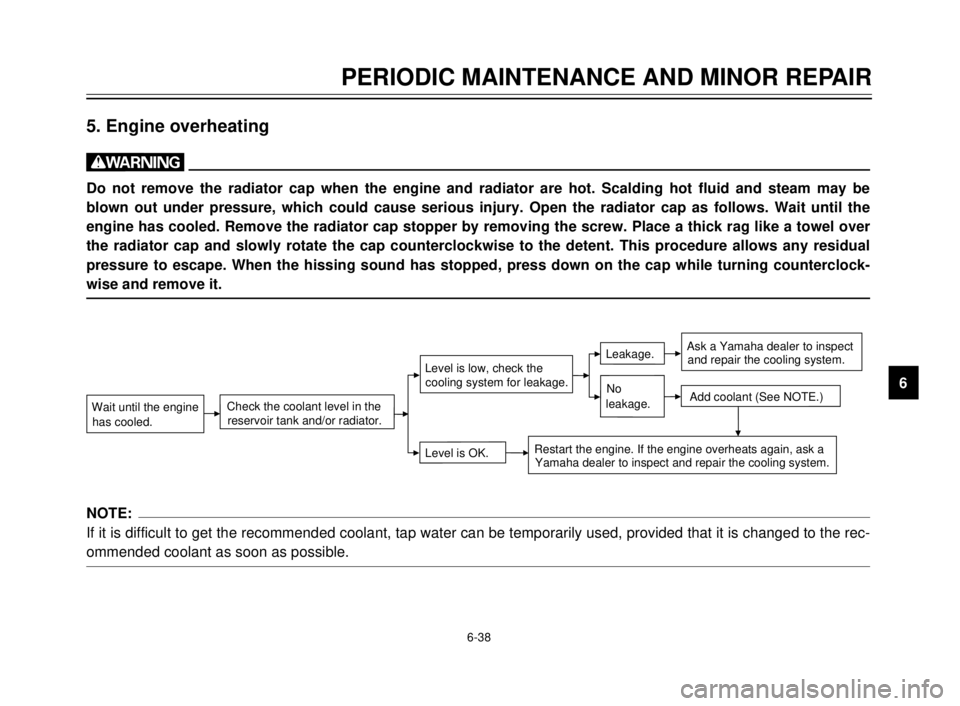

5. Engine overheating

w

Do not remove the radiator cap when the engine and radiator are hot. Scalding hot fluid and steam may be

blown out under pressure, which could cause serious injury. Open the radiator cap as follows. Wait until the

engine has cooled. Remove the radiator cap stopper by removing the screw. Place a thick rag like a towel over

the radiator cap and slowly rotate the cap counterclockwise to the detent. This procedure allows any residual

pressure to escape. When the hissing sound has stopped, press down on the cap while turning counterclock-

wise and remove it.

NOTE:

If it is difficult to get the recommended coolant, tap water can be temporarily used, provided that it is changed to the rec-

ommended coolant as soon as possible.

Level is OK.

Wait until the engine

has cooled.

Restart the engine. If the engine overheats again, ask a

Yamaha dealer to inspect and repair the cooling system. Check the coolant level in the

reservoir tank and/or radiator.

Add coolant (See NOTE.)

Level is low, check thecooling system for leakage.Leakage.No

leakage.Ask a Yamaha dealer to inspect

and repair the cooling system.

5AE-9-E3 (ENG) 4/11/0 11:06 AM Page 81

Page 100 of 104

INDEX

Engine stop switch ..................................3-7

Engine temperature gauge ......................3-5

F

Front brake lever .....................................3-8

Front brake lever free play

adjustment ..........................................6-20

Front fork inspection ..............................6-28

Front wheel installation..........................6-34

Front wheel removal ..............................6-33

Fuel .......................................................3-10

Fuel cock ...............................................3-12

Fuel tank cap ...........................................3-9

Fuse replacement..................................6-30

H

Handlebar switches .................................3-5

Dimmer switch ......................................3-5

Engine stop switch ................................3-7

Headlight beam variation ......................3-6

Horn switch ...........................................3-5

Lights switch .........................................3-5

Start switch ...........................................3-7

Turn signal switch .................................3-5

Headlight beam variation.........................3-6

Headlight bulb replacement...................6-31

Helmet holder ........................................3-14

High beam indicator light .........................3-2

Horn switch..............................................3-5

How to use the conversion table .............8-5

I

Identification number records ..................9-1

Idle speed adjustment ...........................6-15

Indicator lights .........................................3-2

High beam indicator light ......................3-2Neutral indicator light ............................3-2

Oil level indicator light ...........................3-2

Turn indicator light ................................3-2

Inspecting the brake fluid level ..............6-22

K

Key identification number ........................9-1

L

Lights switch ............................................3-5

Left view ..................................................2-1

M

Main switch/Steering lock ........................3-1

Model lavel ..............................................9-2

N

Neutral indicator light...............................3-2

Note on handling of the Yamaha

Energy Induction System (Y.E.I.S.) ....3-15

O

Oil level indicator circuit check ................3-3

Oil level indicator light .............................3-2

P

Panel A ....................................................6-7

Parking ....................................................5-6

Periodic maintenance and

lubrication .............................................6-3

Pre-operation check list ...........................4-1

R

Rear brake pedal .....................................3-9

Rear brake pedal height adjustment .....6-20

Rear shock absorber adjustment ..........3-14

Rear suspension lubrication ..................6-27

Rear wheel installation ..........................6-35

Rear wheel removal ..............................6-34A

Air filter ..................................................6-13

Autolube pump adjustment....................6-26

B

Battery ...................................................6-29

Brake and clutch lever lubrication .........6-27

Brake and shift pedal lubrication ...........6-26

Brake fluid replacement.........................6-23

Brake light switch adjustment ................6-21

C

Cable inspection and lubrication ...........6-25

Carburetor adjustment...........................6-15

Care.........................................................7-1

Catalyzer

(for Switzerland and Austria) ..............3-11

Checking the front and rear brake

pads ....................................................6-21

Clutch lever .............................................3-8

Clutch lever free play adjustment ..........6-19

Controls/Instruments ...............................2-3

Cooling system ......................................6-11

Cowling A, B ............................................6-7

Cowling and panel removal and

installation .............................................6-6

D

Description ..............................................2-1

Dimmer switch .........................................3-5

Drive chain lubrication ...........................6-25

Drive chain slack adjustment.................6-24

Drive chain slack check .........................6-23

E

Engine break-in .......................................5-5

5AE-9-E3 (ENG) 4/11/0 11:06 AM Page 98